Professional Documents

Culture Documents

Cleaning Tools

Cleaning Tools

Uploaded by

Asim ali0 ratings0% found this document useful (0 votes)

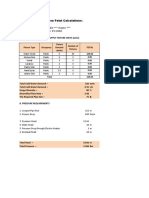

3 views1 page1) 155 tons/hour of exhaust steam is available from the factory and is used to heat various processes including the FFE, DC heater, and evaporator boiling.

2) The first vapor bleeding is used for additional FFE heating, refine pans, remelters, pre-heaters, and washings.

3) The second vapor bleeding heats the largest Robert evaporator surface as well as secondary heaters, conti pans, graining pans, and a molasses conditioner.

Original Description:

yh

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) 155 tons/hour of exhaust steam is available from the factory and is used to heat various processes including the FFE, DC heater, and evaporator boiling.

2) The first vapor bleeding is used for additional FFE heating, refine pans, remelters, pre-heaters, and washings.

3) The second vapor bleeding heats the largest Robert evaporator surface as well as secondary heaters, conti pans, graining pans, and a molasses conditioner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageCleaning Tools

Cleaning Tools

Uploaded by

Asim ali1) 155 tons/hour of exhaust steam is available from the factory and is used to heat various processes including the FFE, DC heater, and evaporator boiling.

2) The first vapor bleeding is used for additional FFE heating, refine pans, remelters, pre-heaters, and washings.

3) The second vapor bleeding heats the largest Robert evaporator surface as well as secondary heaters, conti pans, graining pans, and a molasses conditioner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

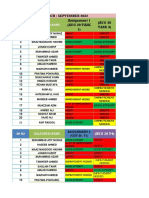

Steam and vapour Bleeding Arrangement.

Exhaust Steam Available 155 T/ Hr ( Mix juice 108 % on cane)

1) Exhaust Steam i) FFE (5000 m2)

ii) DC Heater (clear Juice)

iii) Soda boiling of evaporators

2) 1st Vapour bleeding i) FFE (5000 m2) 2nd effect

ii) 01 Refine Pan

iii) A – Sugar Remelter

iv) Liqour Heater & Pre juice heater

v) Defecated juice DC Heater

vi) Raw pan washing

3) 2nd Vapour bleeding i) Robert evaporator (2500 m2 + 2300 m2) 4800m2 as 3rd effect

ii) 02 Secondary juice Heater

iii) B – Conti Pan

iv) A ,B , C graining Pan

v) 03 Refine Pan

vi) Molasses conditioner

4) 3rd Vapour bleeding i) Robert evaporator 1500m2 / 1100m2 as 4th effect

ii) 01 Primary juice Heater

iii) A – Conti Pan 02 Nos.

iv) C – Conti Pan 01 Nos.

5) Juice Heating ( Primary) i) Last evaporator vapour Line Heater

ii) Condensate Heater

iii) 01 Heater at 3rd vapour

Note:- i) Centrifugal Machine Washing, Refine pan washing, Refine pumps line washing with 4 Bar steam.

ii) Sugar dryer radiator with condensate

You might also like

- Operating Mannua2Document96 pagesOperating Mannua2Ajay Kumar0% (1)

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Boiler Operation Engineers Examination Papers Nov 2016Document10 pagesBoiler Operation Engineers Examination Papers Nov 20169766224189No ratings yet

- Linda Harris: Events ManagerDocument2 pagesLinda Harris: Events ManagerAsim aliNo ratings yet

- Ch3 Steam Turbine System - BoilerDocument49 pagesCh3 Steam Turbine System - BoilerAzraqul Ilmi100% (1)

- Sajjad Usman, 00611764, Cardiff School of Certified Professional, 1297Document19 pagesSajjad Usman, 00611764, Cardiff School of Certified Professional, 1297Asim aliNo ratings yet

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani amineNo ratings yet

- Vapour Line Dia Online Calculation For Juice Heater and EvaporatorDocument17 pagesVapour Line Dia Online Calculation For Juice Heater and EvaporatorRajeshNo ratings yet

- Boiler Trouble ShootingDocument2 pagesBoiler Trouble Shootingkumarmm1234No ratings yet

- Boilers - An OverviewDocument22 pagesBoilers - An OverviewjsnathNo ratings yet

- Power PlantDocument2 pagesPower PlantSoumya SanjibNo ratings yet

- MH Boe-2011 PDFDocument10 pagesMH Boe-2011 PDFcynaiduNo ratings yet

- Question & Answers On PPT BasicsDocument25 pagesQuestion & Answers On PPT BasicsMadhubalan AlagarNo ratings yet

- Ppe PyqDocument4 pagesPpe PyqBISHUNo ratings yet

- 2.8 Heat and Mass TransferDocument6 pages2.8 Heat and Mass Transferglennfaycarausa6No ratings yet

- FME 421 Thermodynamics IV TutorialDocument3 pagesFME 421 Thermodynamics IV TutorialSebastian AnnanakiNo ratings yet

- RAC QB Unit 2 SVCRCDocument3 pagesRAC QB Unit 2 SVCRCddownload 1No ratings yet

- Exercise No. 2 ChE Thermodynamics PDFDocument3 pagesExercise No. 2 ChE Thermodynamics PDFbadeth.pagcaliwagan23No ratings yet

- DC Absoption ChillerDocument18 pagesDC Absoption ChillermohamadNo ratings yet

- UntitledDocument3 pagesUntitledAshutosh RajNo ratings yet

- Steam Turbine Gas Turbine and Dual FuelDocument37 pagesSteam Turbine Gas Turbine and Dual FuelJomeru- SenpaiNo ratings yet

- 8.water CirculationDocument33 pages8.water CirculationSatadru HalderNo ratings yet

- 2 Class Boilers 2RA3 08-GDocument1 page2 Class Boilers 2RA3 08-GChad AndersonNo ratings yet

- 22me32 Etd Unit-Iv Problem SheetDocument2 pages22me32 Etd Unit-Iv Problem SheetU-36 Le0nelNo ratings yet

- Septic & UG Tank CalculationDocument7 pagesSeptic & UG Tank CalculationsivasankarNo ratings yet

- LM-15-NCE-Various Types of Geothermal ResourcesDocument34 pagesLM-15-NCE-Various Types of Geothermal ResourcesSantosh SahuNo ratings yet

- BoilerDocument60 pagesBoilermuhammad aliNo ratings yet

- Electrical MCQsDocument60 pagesElectrical MCQsHamza SaleemNo ratings yet

- Chlorosulphonatlon Main Reaction: "Chemical Reactions For Vinyl S Ulph ON EE Ster of Aniline"Document22 pagesChlorosulphonatlon Main Reaction: "Chemical Reactions For Vinyl S Ulph ON EE Ster of Aniline"Ankit PatelNo ratings yet

- T1406 Mheac 1.7.14Document2 pagesT1406 Mheac 1.7.14STUDENTS OF DOE CUSATNo ratings yet

- Define or Describe The FollowingDocument2 pagesDefine or Describe The FollowingRosalyNo ratings yet

- Energy Engineering Question Bank - NSDocument7 pagesEnergy Engineering Question Bank - NSNilesh Singh100% (1)

- QP1 PDFDocument3 pagesQP1 PDFArasuNo ratings yet

- Refrig 1Document2 pagesRefrig 1Nabeel SalimNo ratings yet

- Manufacturing Process of Fertilizers: (1) Ammonia (Haber-Bosch Process)Document7 pagesManufacturing Process of Fertilizers: (1) Ammonia (Haber-Bosch Process)SalsabilaNo ratings yet

- AAVIN ReportDocument44 pagesAAVIN ReportBubbleNo ratings yet

- Grey Water Connection PointDocument1 pageGrey Water Connection PointSatya N.GNo ratings yet

- Question (1) :: Choose The Correct AnswerDocument3 pagesQuestion (1) :: Choose The Correct Answerphysics a2No ratings yet

- My RecordsDocument16 pagesMy RecordsKolawole KehindeNo ratings yet

- 02 ManajemenLimbahCairDocument32 pages02 ManajemenLimbahCairMochammad YazidNo ratings yet

- Chhattisgarh: Operatlon Engineer EngineerlngDocument3 pagesChhattisgarh: Operatlon Engineer Engineerlngpadmashree sonawaneNo ratings yet

- Cypark Project WTE Firefighting System Design (Spec - Calc.Draw.)Document29 pagesCypark Project WTE Firefighting System Design (Spec - Calc.Draw.)psaayoNo ratings yet

- Siklus Thermal PembangkitDocument15 pagesSiklus Thermal PembangkitIwan RuhiyanaNo ratings yet

- Quadruple Evaporator EvaluationDocument8 pagesQuadruple Evaporator EvaluationRemington SalayaNo ratings yet

- Yield Report 26 03 2024 BDocument1 pageYield Report 26 03 2024 BHatem ZedanNo ratings yet

- CTE CCA ExcelDocument11 pagesCTE CCA ExcelManish PatelNo ratings yet

- Multi V Features A To Z - 20130716Document24 pagesMulti V Features A To Z - 20130716jaime giovanny buitrago arenasNo ratings yet

- Tutorial - Steam BasicsDocument2 pagesTutorial - Steam BasicsShazni AhamedNo ratings yet

- Melt ClarificationDocument5 pagesMelt ClarificationRizvanVavanNo ratings yet

- R&AC Assigment-cum-Turorial Questions - Unit-III - 2017Document3 pagesR&AC Assigment-cum-Turorial Questions - Unit-III - 2017sivakrishnaNo ratings yet

- Coaching Set 4 PinkDocument7 pagesCoaching Set 4 Pinkjoe1256No ratings yet

- Industrial ProcessesDocument5 pagesIndustrial ProcessesKenani WycliffeNo ratings yet

- Inspection Report of Sub Committee II in Respect of Bulk Waste Generators in South Delhi Municipal Corporation AreaDocument78 pagesInspection Report of Sub Committee II in Respect of Bulk Waste Generators in South Delhi Municipal Corporation AreaProjectinsightNo ratings yet

- Water Heater ComparisonDocument3 pagesWater Heater ComparisonPCK Technical EngineeringNo ratings yet

- Materials To Be Supplied by Examination Centres: Maritime & CoastguardDocument6 pagesMaterials To Be Supplied by Examination Centres: Maritime & CoastguardAnonymous 4ylE57C6No ratings yet

- 2000 LPH Auto-35.40 Lakh - Anwesha Mondal - Purulia - S.podder - 18-03-2023Document21 pages2000 LPH Auto-35.40 Lakh - Anwesha Mondal - Purulia - S.podder - 18-03-2023Anwesha MondalNo ratings yet

- Pharma Engineering: Ideal Distillation Setup Based On Required Boil-UpDocument3 pagesPharma Engineering: Ideal Distillation Setup Based On Required Boil-UpRavindra V. LakhapatiNo ratings yet

- 27, Navarathinanagar, BPL Complex Karaikudi - 630 001Document1 page27, Navarathinanagar, BPL Complex Karaikudi - 630 001ganesh15No ratings yet

- GeoThermal EnergyDocument9 pagesGeoThermal EnergyARPIT RASTOGINo ratings yet

- Steam AnalysisDocument2 pagesSteam Analysisprathamesh sawantNo ratings yet

- 3, 4 - Case Study BoilerDocument38 pages3, 4 - Case Study BoilerAzora GeovaniNo ratings yet

- CI Engine CombustionDocument74 pagesCI Engine CombustionNirmalkumar AnbuchelvanNo ratings yet

- Biochemistry: Inside The LabDocument1 pageBiochemistry: Inside The LabAsim aliNo ratings yet

- Links For Hazard Identification and Control MeasuresDocument3 pagesLinks For Hazard Identification and Control MeasuresAsim aliNo ratings yet

- Asim CVDocument2 pagesAsim CVAsim aliNo ratings yet

- New Asimali ResumeDocument1 pageNew Asimali ResumeAsim aliNo ratings yet

- Report Checklist-1Document2 pagesReport Checklist-1Asim aliNo ratings yet

- UntitledDocument1 pageUntitledAsim aliNo ratings yet

- Qasim Ali CVDocument1 pageQasim Ali CVAsim aliNo ratings yet

- Sir SDocument3 pagesSir SAsim aliNo ratings yet

- UntitledDocument1 pageUntitledAsim aliNo ratings yet

- Taxing System in PakistanDocument3 pagesTaxing System in PakistanAsim aliNo ratings yet

- The University of FaisalabadDocument10 pagesThe University of FaisalabadAsim aliNo ratings yet

- Apparatus: Wetted Wall ColumnDocument3 pagesApparatus: Wetted Wall ColumnAsim aliNo ratings yet

- Scheme of Work (1) GRADE 10Document2 pagesScheme of Work (1) GRADE 10Asim aliNo ratings yet

- BabaDocument1 pageBabaAsim aliNo ratings yet

- Encircle The Correct AnswerDocument1 pageEncircle The Correct AnswerAsim aliNo ratings yet

- FOUZIA 3E Annual ConsoliDocument7 pagesFOUZIA 3E Annual ConsoliAsim aliNo ratings yet

- Chapter 02: MCQS: Mathematics (Science Group) : 9Document2 pagesChapter 02: MCQS: Mathematics (Science Group) : 9Asim aliNo ratings yet

- A Boiler Is Defined As "A Closed Vessel in Which Water or Other Liquid Is Heated, Steam or VaporDocument3 pagesA Boiler Is Defined As "A Closed Vessel in Which Water or Other Liquid Is Heated, Steam or VaporAsim aliNo ratings yet

- BabaDocument1 pageBabaAsim aliNo ratings yet