Professional Documents

Culture Documents

Melt Clarification

Uploaded by

RizvanVavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Melt Clarification

Uploaded by

RizvanVavanCopyright:

Available Formats

Melt Clarification Process

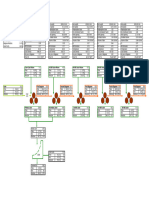

List of Additional equipments for 2200TPD RSO

S.No. Addition Particulars

Qty

1 0 Buffer Tank

2 0 Buffer Tank Agitator

3 2 Untreated Liquor Pumps

4 1 Liquor Heater

5 1 Reaction & Aeration Tank

6 2 Reaction Tank Agitator

7 1 Aerator

8 1 Floatation Clarifier

9 1 Clarifier Stirrer

10 1 Clarifier Scraper

11 0 Clarified Liquor Tank

12 2 Clarified Liquor Pumps

13 0 Flocculant Vibrating Hopper

14 0 Flocculant Preparation Tank

15 0 Flocculant Holding Tank

16 2 Flocculant Dosing Pumps

17 0 Lime Sucrate Preparation Tank

18 0 Lime Sucrate Prep. Tank Agitator

19 0 Lime Sucrate Holding Tank

20 2 Lime Sucrate Dosing Pumps

21 0 Phosphoric Acid Holding Tank

22 2 Phosphoric Acid Dosing Pumps

23 0 Colour Precipitant Holding Tank

24 2 Colour Precipitant Dosing Pumps

25 0 Strainer for Flocculant and Lime Sucrate

Control & Instrumentation

1 1 Control System/Panel

2 1 Level Transmitter

3 1 Flow Transmitter

4 1 Flow Control Valve

5 1 Temperature Transmitter

6 1 Steam Flow Control Valve

7 1 pH Transmitter

2200TPD RSO SUGAR REFINERY

Melt Clarification Process

1 1 Buffer Tank

Welded Steel Plates, reinforced with sectional steel of

rectangular shape

2.25 Length approx., m

3 Width approx., m

4 Height approx., m

27 Volume, approx. ,m3

With cover, manhole and level indicator. The tank is

fitted with agitator

2 1 Buffer Tank Agitator

5 Motor, kW

1440 Motor, RPM

10 Gear Ratio

144 Output RPM

3 2 Untreated Liquor Pumps

154 Capacity, m3/hr

40 Head, m

With motor, flexible coupling, base plate for pump and

motor

4 1 Liquor Heater

Juice heater is laid out for interchangeability of

operation, each heater provided with double beat valve

and the standard fittings and accessories

202.5 Required Heating surface, m2

135 Heating Surface of Individual Heater, m2

270 Heating Surface Operation, m2

42 Tube size, ID mm

45 Tube size, OD mm

4000 Tube size, L mm

256 Number of tubes

16 Number of Passes

Two working and one standby

5 1 Reaction & Aeration Tank

5.00 Capacity, m3

SS Material of Construction

Mixing of chemicals with agitation

2200TPD RSO SUGAR REFINERY

Melt Clarification Process

6 2 Reaction Tank Agitator

2.2 Motor, kW

7 1 Aerator

Small disc with hollow shaft with specific holes

designed for aeration in the forrmed flocs after reaction

tank

1.5 Motor, kW

8 1 Floatation Clarifier

24.60 Volume of Clarifier, m3

1.75 Hight of Clarifier, m

4.23 Diameter of Clarifier, m

29 Retention time, minutes

CS Material of Construction

9 1 Clarifier Stirrer

1.5 Motor kW

As per Clarifier

1 Clarifier Scraper

10 1.5 Motor kW

As per Clarifier

11 No addtion Clarified Liquor Tank

Capacity, m3

Length, m

Width, m

Height to increase, m

Material of construction

12 2 Clarified Liquor Pumps

154 Capacity, m3/hr

25 Head, m

With motor, flexible coupling, base plate for pump and

motor

13 No addtion Flocculant Vibrating Hopper

Small SS vibtating hopper with funnel on top

Length of hopper, mm

Width of hopper, mm

2200TPD RSO SUGAR REFINERY

Melt Clarification Process

14 No addtion Flocculant Preparation Tank

Modification

With air sparger

Capacity, m3

1.15 Height to increase, m

Diameter, m

Material of construction

15 No addtion Flocculant Holding Tank

Modification

With air sparger

Capacity, m3

1.15 Height to increase, m

Diameter, m

Material of construction

16 2 Flocculant Dosing Pumps

2000 Capacity, litres/hour

Screw type pump

1.5 Motor,kW

17 No addtion Lime Sucrate Preparation Tank

Modification

Capacity, m3

1.15 Height to increase, m

Diameter, m

Material of construction

18 No addtion Lime Sucrate Prep. Tank Agitator

1.5 Motor, kW

19 No addtion Lime Sucrate Holding Tank

Modification

With agitator, kW

Capacity, m3

1.15 Height, m

Diameter, m

Material of construction

20 2 Lime Sucrate Dosing Pumps

2700 Capacity, litres/hour

Screw type pump

1.5 Motor,kW

2200TPD RSO SUGAR REFINERY

Melt Clarification Process

21 No addtion Phosphoric Acid Holding Tank

Capacity, m3

Height, m

Diameter, m

Material of construction

22 2 Phosphoric Acid Dosing Pumps

50.0 Capacity, litres/hour

0.5 Motor,kW

23 No addtion Colour Precipitant Holding Tank

Capacity, m3

Height, m

Diameter, m

Material of construction

24 2 Colour Precipitant Dosing Pumps

40.0 Capacity, litres/hour

0.5 Motor,kW

25 No addtion Strainer for Flocculant and Lime Sucrate

Diameter approx. mm

Height approx. mm

Welded of mild steel plates, reinforced with sectional

steel.

With cover, removable screen.

2200TPD RSO SUGAR REFINERY

You might also like

- 1st Appraisal Presentation 2Document17 pages1st Appraisal Presentation 2Talha Jamil MalikNo ratings yet

- BoilerDocument60 pagesBoilermuhammad aliNo ratings yet

- B Refinery Section Cost (Rs in Lakh: Double Effect Falling Film Evaporator (3 X 450 M Hsa)Document6 pagesB Refinery Section Cost (Rs in Lakh: Double Effect Falling Film Evaporator (3 X 450 M Hsa)Yadav ShwetaNo ratings yet

- List of Existing Plant & Machineries of TSM Project: S.No Description Quantity A Milling PlantDocument3 pagesList of Existing Plant & Machineries of TSM Project: S.No Description Quantity A Milling Plantruhul01No ratings yet

- FGD Presentation (ILFS)Document40 pagesFGD Presentation (ILFS)proloy12100% (2)

- Wakra Equipment Boq Rev-1Document5 pagesWakra Equipment Boq Rev-1Hemant KaleNo ratings yet

- Coal MillDocument22 pagesCoal Millritesh MishraNo ratings yet

- Total Lubricating Oil and Grease Demand StatisticsDocument85 pagesTotal Lubricating Oil and Grease Demand StatisticsAdjie SetiawanNo ratings yet

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- Boiler: Brief IntroductionDocument73 pagesBoiler: Brief IntroductionIlhamNo ratings yet

- Lyn Pure 1000LPH Ro Plant WaterDocument7 pagesLyn Pure 1000LPH Ro Plant Watersairamwatersolutions2017No ratings yet

- WTP Structure & Pumps SpecificationDocument9 pagesWTP Structure & Pumps Specificationsanju middyaNo ratings yet

- WWTP System (BOP)Document22 pagesWWTP System (BOP)robiansah100% (1)

- Technical Documents of The BoilerDocument20 pagesTechnical Documents of The BoilerMatias Mancilla0% (1)

- Cs of Clarification System With Filtration System at Feni River ...Document24 pagesCs of Clarification System With Filtration System at Feni River ...Tusher SahaNo ratings yet

- Vinayak Green 50 KLD Civil.....Document8 pagesVinayak Green 50 KLD Civil.....Tech MongerNo ratings yet

- Boiler PresentationDocument73 pagesBoiler PresentationSatyakam100% (3)

- Equipment Boq Rev1Document5 pagesEquipment Boq Rev1Hemant KaleNo ratings yet

- JRK Marurti Nagar Vijay Singh Ji - 120 KLD ..Document8 pagesJRK Marurti Nagar Vijay Singh Ji - 120 KLD ..Tech MongerNo ratings yet

- Bab 3Document18 pagesBab 3trisnadewiNo ratings yet

- DesignDocument23 pagesDesignCH030 Kamal ChavdaNo ratings yet

- Barwa Equipment BoqDocument1 pageBarwa Equipment BoqHemant KaleNo ratings yet

- Steam Condensates and LossDocument120 pagesSteam Condensates and LossMubarik Ali100% (1)

- Design STP 2019Document16 pagesDesign STP 2019Abhiraj AbhirajNo ratings yet

- Lyn Pure 250lph Smu Ro PlantDocument7 pagesLyn Pure 250lph Smu Ro Plantsairamwatersolutions2017No ratings yet

- Annex 1 Technical Scope of WorkDocument5 pagesAnnex 1 Technical Scope of WorkabasoudaNo ratings yet

- 2016 Boiler Safety Checklist and Preventative MaintenanceDocument185 pages2016 Boiler Safety Checklist and Preventative MaintenanceAcid Burns100% (1)

- Tco 2013 240 Rajni AutomationDocument8 pagesTco 2013 240 Rajni AutomationSatyam PandeyNo ratings yet

- Reverse Osmosis 500 LPH 1Document7 pagesReverse Osmosis 500 LPH 1sairamwatersolutions2017No ratings yet

- Boq of Technical Description of Proposed System.Document5 pagesBoq of Technical Description of Proposed System.M.A. MonimNo ratings yet

- Final Bop TDDocument79 pagesFinal Bop TDsuleman247No ratings yet

- PROPOSAL Nickel SmelterDocument16 pagesPROPOSAL Nickel Smelterzmahfudz100% (1)

- Op Eff 16 12 2023Document45 pagesOp Eff 16 12 2023Sharath BogaNo ratings yet

- Compile ScheduleDocument68 pagesCompile ScheduleManekGorisNo ratings yet

- 50 KG Per H Liquid Co2Document11 pages50 KG Per H Liquid Co2AhNo ratings yet

- J J Water Tech 2023Document3 pagesJ J Water Tech 2023oliviaNo ratings yet

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- High Pressure Boilers: Modern Steam Power PlantDocument33 pagesHigh Pressure Boilers: Modern Steam Power PlantShiv MishraNo ratings yet

- Parryware Pressure PumpDocument4 pagesParryware Pressure Pumpsathish kumarNo ratings yet

- Zarjis Composite Knit Ind LTD PDFDocument3 pagesZarjis Composite Knit Ind LTD PDFMd. Suruz ZamanNo ratings yet

- Pharma Engg. Ideal Distillation SetupDocument3 pagesPharma Engg. Ideal Distillation SetuppratikNo ratings yet

- Pharma Engineering: Ideal Distillation Setup Based On Required Boil-UpDocument3 pagesPharma Engineering: Ideal Distillation Setup Based On Required Boil-UpRavindra V. LakhapatiNo ratings yet

- 2000 LPH Ro PlantDocument17 pages2000 LPH Ro PlantKamatchi NathanNo ratings yet

- STBF Citrus Farm ProposalDocument8 pagesSTBF Citrus Farm ProposalGarry PonferradaNo ratings yet

- Refinery Overview FinalDocument65 pagesRefinery Overview FinalasifNo ratings yet

- FGD Dual Alkali Data Sheet FilledDocument5 pagesFGD Dual Alkali Data Sheet FilledowngauravNo ratings yet

- CASE STUDY On Phosphoric Acid Plant ProcessDocument3 pagesCASE STUDY On Phosphoric Acid Plant ProcessIsrael NarvastaNo ratings yet

- 200kld STP Proposal FOR Bhumi AssociatesDocument6 pages200kld STP Proposal FOR Bhumi AssociatesTech MongerNo ratings yet

- 3000 LTR RO PLANT ISI PLANT R KDocument17 pages3000 LTR RO PLANT ISI PLANT R KVidya SinghNo ratings yet

- 8.water CirculationDocument33 pages8.water CirculationSatadru HalderNo ratings yet

- 9 IER Training Make Up Water Nigeria KompatibilitaetsmodusDocument135 pages9 IER Training Make Up Water Nigeria KompatibilitaetsmodusRamon Esteban Martinez AvalosNo ratings yet

- Boiler TrainingDocument21 pagesBoiler TrainingYadav GaneshNo ratings yet

- Contoh Anggaran Capex PKS Tahun 2012Document2 pagesContoh Anggaran Capex PKS Tahun 2012Malik100% (1)

- 1m3-Calculation Design - AnzirDocument8 pages1m3-Calculation Design - AnzirMohammad MahediNo ratings yet

- Pipings The Saga EndsDocument86 pagesPipings The Saga EndsCharles MayoNo ratings yet

- 2SBR REACTOR - 1MLD - BOD Only PDFDocument7 pages2SBR REACTOR - 1MLD - BOD Only PDFHRK65No ratings yet

- HRSCCDocument4 pagesHRSCCPandiaraj MkNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- 2018 Mishasha T Et Al - Short Paper - PHENOTYPIC CORRELATIONS AMONG CANE QUALITY TRAITS MEASURED FROM UNSELECTED SUGARCANE BREEDING FAMILY PLOTSDocument4 pages2018 Mishasha T Et Al - Short Paper - PHENOTYPIC CORRELATIONS AMONG CANE QUALITY TRAITS MEASURED FROM UNSELECTED SUGARCANE BREEDING FAMILY PLOTSRizvanVavanNo ratings yet

- Mill BalanceDocument1 pageMill BalanceRizvanVavanNo ratings yet

- 1919 The Color of Sugar Cane Products and Decolorization in The FactorDocument33 pages1919 The Color of Sugar Cane Products and Decolorization in The FactorRizvanVavanNo ratings yet

- Faktor Yang Mempengaruhi Kinerja Ekonomi GKPDocument1 pageFaktor Yang Mempengaruhi Kinerja Ekonomi GKPRizvanVavanNo ratings yet

- Determination of Reducing Sugars, Total Reducing Sugars, Sucrose and StarchDocument18 pagesDetermination of Reducing Sugars, Total Reducing Sugars, Sucrose and StarchProcess R&D Sin A 615No ratings yet

- Farmnote SugarCane EquationsDocument4 pagesFarmnote SugarCane EquationsRizvanVavanNo ratings yet

- 2009-M-13-King SPRI Conference On Sugarcane ResearchDocument11 pages2009-M-13-King SPRI Conference On Sugarcane ResearchRizvanVavanNo ratings yet

- 2008 Cost of Electrical Energy by Cogen in SugarmillDocument6 pages2008 Cost of Electrical Energy by Cogen in SugarmillRizvanVavanNo ratings yet

- Optimalisasi JurnalDocument8 pagesOptimalisasi JurnalWisnuKusumaAtmajaNo ratings yet

- Diesel Engine - Technical ManualDocument356 pagesDiesel Engine - Technical Manualجمال مصالحه100% (5)

- GRUNDFOS Product LineDocument40 pagesGRUNDFOS Product LinezaidosamaNo ratings yet

- Bunding and Spill Management SADocument7 pagesBunding and Spill Management SAEvodius RweyemamuNo ratings yet

- Pump RFQDocument18 pagesPump RFQboiporaNo ratings yet

- Truck Pump: Key Technologies Key TechnologiesDocument2 pagesTruck Pump: Key Technologies Key TechnologiesBambang WisnuNo ratings yet

- ZTND Sihi PDFDocument19 pagesZTND Sihi PDFVladimir Illich Pinzon BallenNo ratings yet

- Hydraulic Jack For AutomobileDocument44 pagesHydraulic Jack For Automobileinfo svmelectromechNo ratings yet

- Thermodynamic HWDocument9 pagesThermodynamic HWMuzamil ShahNo ratings yet

- Selection Data - Veritcal Turbine Fire Pumps 914 60HzDocument21 pagesSelection Data - Veritcal Turbine Fire Pumps 914 60HzOmarGReyesNo ratings yet

- Pulsafeeder OMNI DC2-DC6 Pump Manual PDFDocument46 pagesPulsafeeder OMNI DC2-DC6 Pump Manual PDFRoberto MejiaNo ratings yet

- Hanil Product Catalog 2017-2018 LowresDocument36 pagesHanil Product Catalog 2017-2018 LowresCESPI-PERUNo ratings yet

- Kral-KDocument16 pagesKral-KHema IbraNo ratings yet

- M-00-d07 Urs Thermic Fluid Heater-R0Document12 pagesM-00-d07 Urs Thermic Fluid Heater-R0dhanu_lagwankarNo ratings yet

- Rice List: January 2014 - N°1439Document122 pagesRice List: January 2014 - N°1439Mary FloriánNo ratings yet

- TEPZZ 8576Z A - T: European Patent ApplicationDocument11 pagesTEPZZ 8576Z A - T: European Patent ApplicationbrunosamaeianNo ratings yet

- Compressors - Working and CharacteristicsDocument7 pagesCompressors - Working and CharacteristicsibnuharyNo ratings yet

- S Pumps Ranges LowDocument20 pagesS Pumps Ranges LowjuanNo ratings yet

- COELBO Speedmatic ManualDocument28 pagesCOELBO Speedmatic ManualdemonarundoNo ratings yet

- Hydraulic Failure AnalysisDocument93 pagesHydraulic Failure AnalysisJoseph Jose83% (6)

- Solar Water Pumping PDFDocument9 pagesSolar Water Pumping PDFsalem BEN MOUSSANo ratings yet

- Troubleshooting Engine CAT C7.1Document125 pagesTroubleshooting Engine CAT C7.1falah100% (3)

- Boomer 104 - 9851 2509 01b PDFDocument3 pagesBoomer 104 - 9851 2509 01b PDFPablo Luis Pérez PostigoNo ratings yet

- Hydraulics Pipeline Systems: Bruce E. Larock Roland W. Jeppson Gary Z. WattersDocument9 pagesHydraulics Pipeline Systems: Bruce E. Larock Roland W. Jeppson Gary Z. WattersNiyanthan InthirakumarNo ratings yet

- Series 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Document68 pagesSeries 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Jose Manuel Barroso PantojaNo ratings yet

- Boiler Feed Pumps Boiler Feed Water Pumps Page 1 Castle PumpsDocument5 pagesBoiler Feed Pumps Boiler Feed Water Pumps Page 1 Castle PumpsAmit ChourasiaNo ratings yet

- Activity & Briefing On Simulation Test: A. Prior To DrillingDocument2 pagesActivity & Briefing On Simulation Test: A. Prior To DrillingBoedi SyafiqNo ratings yet

- HPX Oh2 Api610 New enDocument8 pagesHPX Oh2 Api610 New enAlexander RivillasNo ratings yet

- Mine Machinery-1 SyllabusDocument3 pagesMine Machinery-1 SyllabusrrathoreNo ratings yet

- No Description Maintenance Schedule Quarterl y Semi AnnuallyDocument4 pagesNo Description Maintenance Schedule Quarterl y Semi AnnuallyBóngMAẨnDậtNo ratings yet

- Transfluid Fluid Coupling CatalougeDocument32 pagesTransfluid Fluid Coupling CatalougeNaeem KhanNo ratings yet