0 ratings0% found this document useful (0 votes)

383 views270 pagesPipeline Precommissioning

Uploaded by

Fadillah MarshaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

383 views270 pagesPipeline Precommissioning

Uploaded by

Fadillah MarshaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

Table of Contents

Preface

Purpose

Organization

Chapter 1-Introduction to the Commissioning

Process

1.1 Basic Definitions

1.1.1 Pipeline Owner...

1.1.2 Client or Contractor...

1.1.3 Linepipe

1.1.4 Pipeline

LS Pig

1.1.6 Pig Train...

1.1.7 Pig Trap.

1.1.8 Contractor's Pigging and Testing

1.1.9 Precommissioning :

1.1.10 Commissioning

1.1.11 Drying (Conditioning)

1.1.12 Sour-Gas Pipeline

1.1.13 Restrained and Unrestrained Pipelines

1.2 Precommissioning Operations .

1.2.1 Hyperbaric Weld-Sphere Removal.

1.2.2 Cleaning

1.2.3 Gauging,

1.24 Filling

1.2.5 Pressure Testing ...

1.2.6 Dewatering

1.2.7 Drying (Conditioning)

1.3 Commissioning Operations

1.3.1 Introducing the Product...

1.3.2 Packing of the Pipeline to Operating Pressure

1.4 Servicing Existing Pipelines wn

Chapter 2-Pipeline Features

2.1 Overview...

2.2 Subsea Pipelines

Coico)

January 1997

Table of Contents 1

2.2.1 Subsea Pipeline Components

2.3. Land Pipelines :

2.3.1 Land Pipeline Components nn

24 Pipeline Components and Procedures Requiring Special Attention 2-6

2.4.1 Sphere Tee Pigging

2.4.2 Dewatering and Drying

2.4.3 Pig Signalers ..

24.4 Valves

2.4.5 Pipeline Bore .

2.4.6 Vents and Drains

2.4.7 Pipeline Bends

2.4.8 Pig Traps...

Chapter 3-Barrier Tools

3.1 Introduction .....

3.2. Types of Barrier Tools.

3.2.1 HW Spheres...

3.2.2 HD

3.2.3 Piggable Plug

‘The Purpose of Barrier Tools .

3.3.1 Combining Barrier Tools...

3.3.2 Use of HW Spheres

3.3.3 Effect of Barrier Tools on Precommissioning Work ....

3.3.4 Barrier Tool Removal Requirement (Acceptance Criteria)

3.4 Detailed Preparation for Barrier Tool Removal

3.4.1 Trials...

3.4.2 Barrier-Tool Removal Stages.

Partial Decommissioning Before Isolation with HD Pigs

3.4.4 Recording and Reporting Data...

3.5 Documenting Barrier Tool Removal

3.5.1 Prepare an Overall Schedule.

3.5.2 Start Engineering

3.5.3 Produce a Preliminary Equipment List and Layout Drawing3-11

3.5.4 Produce a Detailed Equipment and Instrumentation List

3.5.5 Produce a Detailed Equipment Layout Drawing...

3.5.6 Produce Equipment and Instrumentation Connection

Points Drawing

3.5.7 Begin Procedure Preparation

3.5.8 Write the Method Statement.

3.5.9 Safety

3.6 Final Reporting

3.7 Barrier Tool Suppliers

Chapter 4—Cleaning, Gauging, and Filling

4.1. Introduction

4.2 Overview

4.2.1 Benefits of Pipeline Cle

4.2.2 Cleaning Methods...

4.2.3 Cleaning and Gauging by Pigging the Pipeline

4.2.4 Post-Installation Cleaning and Gauging.

4.2.5 Precommissioning Cleaning and Gauging

ning Cleaning and Gauging...

Pipeline Commissioning Manual January 1997

4.2.7 Pig Train Configuration

4.2.8 Propelling Media ..

4.2.9 Cleaning and Gauging Requirement (Acceptance Criteria).

4.2.10 Cleaning and Gauging Preparation.

4.2.11 Rate of Cleaning and Gauging Pig Train

4.2.12 Stages of a Cleaning and Gauging Operation ..

4.2.13 Recording and Reporting Data...

4.3. Detailed Preparation for Cleaning, Gauging, and Filling,

4.3.1 Prepare an Overall Schedule .

4.3.2 Design the Job

4.3.3 Produce a Preli

4.344 Produce a Detailed Equipment and Instrumentation List

4.3.5 Produce a Detailed Equipment Layout Drawing

4.3.6 Produce a Drawing ...

4.3.7 Begin Preparing Procedures.

4.3.8 Write the Method Statement..

4.3.9 Safety

4.4 Final Reporting

4.5. References

Chapter 5-Pipeline PressureTesting

5.1 Introduction Sl

5.2 Overview on

5.2.1 Reasons to Pressure Test a Pipeline

5.2.2 Types of Pipeline Pressure Test

5.2.3 Definition of a Pipeline for Test Purposes..

5.2.4 Test Requirements ....

5.2.5 General Preparation for a Pipeline Pressure Test 5-2

5.2.6 Stages of a Pressure Test

5.2.7 Recording and Reporting Data

5.3. Detailed Preparation for the Pipeline Pressure Testi

5.3.1 Prepare an Overall Schedule.

5.3.2 Begin Engineering

5.3.3 Produce a Test Limit Drawing...

5.3.4 Measuring Pipeline Temperature ..

5.3.5 Prepare a Preliminary Equipment List and Layout Drawing .5-6

5.3.6 Prepare Test Procedures

5.3.7 Stages of the Pressure Test

5.3.8 Recording and Reporting Data ..

5.4 Final Reporting

5.5. References ..

Chapter 6—-Dewatering

6.1 Introduction

6.2. Overview

6.2.1 Pig Train Design

6.2.2 Selecting the Propelling Medium for Pig Trains

6.2.3 Effect of Dewatering on Drying Operations,

6.3.4 Dewatering Requirement (Acceptance Criteria)

6.2.5 Velocity of Dewatering Pig Train ...

6.2.6 Accumulated Heads

January 1997 Table of Contents

6.3. General Preparation for Dewatering

64 Detailed Preparation for Dewatering ...

6.4.1 Prepare an Overall Schedule.

6.4.2 Begin Engineering .

6.4.4 Produce a Detailed Equipment and Instrumentation List

6.4.5 Produce a Detailed Equipment Layout Drawing...

6.4.6 Produce a Piping and Instrumentation Diagram ..

6.4.7 Prepare Procedures

65. Stages of a Dewatering Operation.

6.5.1 Bulk Dewatering ...

655.2 Residual Dewatering.

6.5.3 Disposing of Treated Fill Water.

6.5.4 Inerting with Nitrogen

6.5.5 Receiving Pigs into the Pig Trap...

6.5.6 Removing Pigs from the Pig Trap

6.5.7 Accepting the Operation ...

6.5.8 Recording and Reporting Daa.

6.6 Final Reporting .....

Chapter 7-Methanol and Glycol Swab! jing

7.1 Introduction Tl

7.2. Overview ..

7.2.1 Reason for Chemical Swabbing

7.2.2 Process of Chemical Swabbing

7.2.3 Types of Chemicals Used in Swabbing

7.2.4 Pipelines Suitable for Chemical Swabbing

7.2.5 Propellants Available for Chemical Swabbing

7.2.6 Pig Train Design

7.2.7 Chemical Swabbing Requirement (Acceptance Criteria) ....7-4

7.2.8 Rate of Chemical Swabbing Pig Train ..

7.2.9 Accumulated Heads

7.2.10 Launching the Chemical Swabbing Pig Train

7.2.11 Removing the Chemical Swabbing Pig Train

7.2.12 Disposing of Treated Fill Water and Chemicals.

7.2.13 Removal of Pigs from Pig Trap...

7.2.14 Controlling Hydrocarbon Gas Suppl

7.2.15 Recording and Reporting Data

7.3. General Preparation for Chemical Swabbing .... -

7A Detailed Preparation for Methanol and Glycol Swabbing

7.4.1 Prepare an Overall Schedule...

7.4.2 Begin Engineering ....

7.4.3 Prepare a Preliminary Equipment List and Layout

Drawing.

7.4.4 Size the Equipment and Instrumentation

7.4.5 Produce a Detailed Equipment and Instrumentation List.

7.4.6 Produce a Detailed Equipment Layout Drawing...

7.4.7 Produce a Piping and Instrumentation Diagram

7.4.8 Prepare Procedures

7.5. Final Reporting ....

Pipeline Commissioning Manual January 1997

Chapter 8-Air, Nitrogen, and Vacuum Drying

8.1 Introduction ; : er

8.2. Overview 81

8.2.1 Pipelines Requiring Drying to a Specified Moisture Content 8-2

8.2.2 Methods of Drying to a Specified Moisture Content...

8.2.3 Choosing Drying Methods

8.2.4 Acceptance Criteria...

8.2.5 Dry-Air or Nitrogen Drying ..

8.2.6 Nitrogen Drying...

8.2.7 Vacuum Drying,

8.2.8 Phases of Vacuum Drying,

8.2.9 Drying Requirements (Acceptance Criteria) ve

8.2.10 Recommended Number and Velocity of Drying Pigs ..

8.2.11 Recording and Reporting Data

8.3. General Preparation for Drying .

8.4 Detailed Preparation for Air, Nitrogen, and Vacuum Drying

8.4.1 Prepare an Overall Schedule.

8.4.2 Begin Engineering .....

: see Be

8.4.3 Prepare a Preliminary Equipment List and Layout Drawing8-15

815

8.4.4 Size the Equipment and Instrumentation

8.4.5 Produce a Detailed Equipment and Instrumentation List

8.4.6 Produce a Detailed Equipment Layout Drawing.

8.4.7 Produce a Piping and Instrumentation Drawing

8.4.8 Prepare Procedures

8.5. Final Reporting

Chapter 9-Pipelines That Do Not Require Drying

9.1 Introduction

9.2. Overview : 9-1

9.3 Small-Diameter Pipelines SL

9.3.1 Precommissioning Methods... 9-1

Chapter 10—GelTechnology

10.1 Introduction

10.1.1 Definitions

10.1.2 Gel Types

10.2 Gel Requirements..

10.3 Gel Applications

10.3.1 Cleaning

10.3.2 Dewatering

10.3.4 Pipeline Isolation

10.3.5 Valve Testing ..

10.3.6 Pig Recovery .

10.3.7 Fluid Separation...

10.4 Gel Preparation.

10.5 Quality Control.

10.5.1 On-Site Pre-Job Analysis. :

10.5.2 Checks During Job Execution 10-11

January 1997 Table of Contents

10.6 Gel Disposal 0

10.6.1 Summary of UK Pipeline Consent to Discharge

Regulations ... sen

10.6.2 Gels Disposal

Chapter 11-Miscellaneous

11.1 Introduction ...

11.2 Pipeline Bundles

11.2.1 Onshore Precommissioning.

2 Offshore Precommissioning ..

3 Bundle Insulation.

11.3 Pressure Testing Flexible Pipelines ..

11.4 Pressure Testing Insulated Pipelines

11.5 Air or Nitrogen Pressure Tes

11.6 Creating Freeze Plug:

11.7 Chemical Cleaning

1 Introduction..

3 Cleaning In-Service Pipelines

4 Procedure for Cleaning

11.7.5 Equipment Used in Pipeline Cleaning ..

11.7.6 Chemical Requirements.

11.7.7 Communications...

Chapter 12—Equipment

12.1 Equipment Selection

12.2 Pumps

12.2.1 Centrifugal Pumps .

12.2.2 Positive-Displacement Pumps

12.3 Filtration

12.4 Residence Tanks

12.5 Vacuum Pumps..

12.6 Air Compressors, Dryers, and Nitrogen Equipment

12.6.1 General :

12.6.2 Air Compressors

12.6.3 Air Dryers

12.7 Instrumentation

12.7.1 General...

12.7.2 Mechanical Instrumentation ...

12.7.3 Data Acquisition Systems

12.7.4 Parameter Measurement ..

12.7.5 Additional Requirements nm

Chapter 13-Calculations

13.1 Pipeline Fill Volume.

13.2 Frictional Pressure Drop ..

133 Chemical Injection Volumes and Rates

1 Total Volume of Chemicals.

2 Volume per Stroke

3 Pump Strokes per Minute

4 Stroke Length of Chemical Injection Pump.

13.3.5 Actual ppm of Chemical Injected ..

Pipeline Commissioning Manual January 1997

13.4 Filling Pressure Requirements 13-3

13.5 Pressure to Obtain Yield in Pipe 13:3

13.6 Volume of the Pipeline ... 13-4

13.7 Volume to Pressurize 13-5

13.8 Atmospheric Pressure 13.7

13.9 Air Entrainment 13-8

13.10 Pump Requirements to Pressure Pipeline .. 13-9

13.11 Dewatering Pressures .. 13-10

13.12 Other Formulas for Calculating Volume to Pressurize .n..cun 13-12

13.12.1 Volume to Pressurize Restrained Pipetines.. seo 312

13.12.2 Volume to Pressurize Unrestrained Pipelines .. e312

13.12.3 Pressure Change Caused by Temperature

(Restrained Pipelines) 13-13

13.124 Pressure Change Caused by Temperature

(Unrestrained Pipelines) we 1313

Appendix A-Field Report Forms

Introduction...

Daily Operations Report

Pig Launch/Receive Register.

Chemical Dosing Report .. : =

Pipeline Pigging Report Launch/Receive Station AS

Gauge Plate Inspection Report...

Instrumentation Calibration Report.

Leak Check/Repair Log...

Pressurization Report Hydrotest..

Pressure Temperature Log

Hydrotest Report

Air Inclusion Report :

Halliburton Test Acceptance Certificate AB

Personnel Report.

Equipment Report.

Deviation to Procedure Request ..

Appendix B-Miscellaneous Information

Introduction.

Pigs and Associated Equipment

Main Types of Pigs ...

Pig Selection

Pig Tracking Techniques

Pig Launchers and Receivers...

Intelligent Pigs —

Fill and Test Water Treatment Chemicals B9

Introduction.

Reasons for Chemical Treatment

Corrosion Factors..

Use of Trace Dye ..

Codes and Standards.

Suppliers

January 1997 Table of Contents

Appendix C-Conversion Factors

Introduction, aoe crt

Conversion Factor Tables C2

Energy Conversions

Useful Data to Caleulate Lengths, Areas, and Volumes

‘Temperature Conversion Equations.

Air Compressor Output per Hour

Time Required to Pressure

Time Required to Blowdown a Section of Pipe

Water Discharge Measurements

Formulas Useful in Pump Applications .

Abbreviation

Formulas .

Appendix D-Glossary

Pipeline Commissioning Manual January 1997

Illustrations

Chapter 2-Pipeline Features

Figure 2.1-Subsea Trunkline...

Figure 2.2Infield Pipeline.

Figure 2.3-Flowline ..

Figure 2.4-Bundle .

Figure 2.5-Typical Flowline Configuration .

Figure 2.6Typical Land Trunkline Configuration.

Chapter 3-Barrier Tools

Figure 3.1 Hyperbaric Weld Sphere...

Figure 3.2 An HD Plug With Multiple Polyurethane Wear Disks

and Sealing Disks at Each End.

Figure 3.3-Piggable Plug ...

Figure 3.4Isolation Operation Using Three Types of Barrier Tools

Figure 3.5-Hyperbaric Welding Operation Using HW Spheres

Figure 3.6—Typical Equipment Layout Drawing

Chapter 4—Cleaning, Gauging, and Filling

Figure 4.1-Simple and More Complicated Cleaning and Gauging

Pig Trains.

Figure 4.2-Typical Equipment Layout. 4-11

Figure 4.3-Flooding, Cleaning, and Gauging Pig Launcher 4-12

Chapter 5-Pipeline PressureTesting

Figure 5.1~Typical Pig Launcher for Dewatering Purposes .n-nesnon 5-7

Figure 5.2-Pipeline Hydrotesting Subsea Valve Arrangement 5-7

Figure 5.3-Hydrotest Equipment Setup......... 5-9

Chapter 6-Dewatering

Figure 6.1-Typical Dewatering Pig Trains...... 6-3

Figure 6.2-Accumulated Heads Caused by Undulating Elevation

Step Changes ..

Figure 6.3-Dewatering Equipment Layout Using Nitrogen

Figure 6.4Typical Piping and Instrument Diagram...

Chapter 7—Methanol and Glycol Swabbing

Figure 7.1-Examples of Methanol Swabbing Train Configurations ..

Figure 7.2Typical Pig Receiver Methanol Swabbing,

Chapter 8—Air, Nitrogen, and Vacuum Drying

Figure 8.1-Dry-Air Conditioning Operation Curve 85

Figure 8.2-Phases of Vacuum Drying

Chapter 10—GelTechnology

Figure 10.1-An Example of a Typical Dewatering Train,

Figure 10.2-Bidirectional Pig ....

Figure 10.3-Example of a Gel Plug in a Gas Pipeline

Figure 10.4-Pig Receiver with Dump, Drain, Vent, and

Knockout Facil

January 1997 Table of Contents

Chapter 11—Miscellaneous

Figure I 1.1-Bundle Cross-Section .....

Figure 11.2-Scale Volume of Different Scale Thicknesses

Deposited on the Inside of Various Pipe Size

Figure 11.3-Scale Volume of Different Scale Thicknesses

Deposited on the Inside of Various Pipe Sizes

Figure 11.4-Scale Volume of Different Scale Thicknesses

Deposited on the Inside of Various Pipe Size

Chapter 13-Calculations

Figure 13.1-Pressure vs. Volume Chart.

Figure 13.2-Compressibility of Fresh Water

Figure 13.3-Compressibility of Salt Water (Salinity 3.5%)

Figure 13.4~Thermal Expansion Coefficient of Fresh Water

(Salinity 0.0%)...

Figure 13.5—Thermal Expansion Coefficient of Salt Water

(Salinity 3.5%).

Appendix B-Miscellaneous Information

Figure B.1—Two-Cup Mechanical Pig

Figure B.2-Four Sealing Disk, Two Wear Disk, Bidirectional Pig...

Figure B.2-Four-Sealing Disk, Two-Wear Disk, Bidirectional Pig...»

Figure B.4Typical Foam Pig with Criss-Cross Polyurethane Coating . B-4

Figure B.5-Inflatable Sphere 5

Figure B.6-Solid-Polymer Pig

Figure B.7-Subsea Temporary Pig

Appendix C-Conversion Factors

Figure C.1-How to Calculate the Area of a Circle

Figure C.2-How to Calculate the Area of a Sphere .

Figure C.3-How to Calculate the Area of an Ellipse

Figure C.4-How to Calculate the Area of a Cube

Figure C.5-How to Calculate the Area of a Rectangular

Parallelepiped ...

Figure C.6-How to Calculate the Area of a Cone

Figure C.7-How to Calculate the Area of a Cylinder...

Figure C.8-How to Calculate the Area of a Hexagon

Figure C.9-How to Calculate the Area of a Frustum of a Cone.

Figure C.10-How to Calculate the Area of a Trapezoid

Figure C.11-Estimating Flow Out of an Open Pipe 00

Figure C.12-Freeboard/Diameter Ratio for Pipes Less Than Full.

10 Pipeline Commissioning Manual January 1997

Tables

Chapter 2-Pipeline Features

Table 2.1—Types of Subsea Pipeline

Table 2.2-Components of Subsea Pipelines

Table 2.3~Type of Land Pipelines a

Table 2.4-Components of Land Pipelines...

Chapter 3-Barrier Tools

Table 3.1-Data Collected During Barrier Tool Removal ..

Table 3.2-Halliburton Onshore Quality Plan

Chapter 4—Cleaning, Gauging, and Filling

Table 4.1-Information Collected During Cleaning and Gauging sone 9

Table 4.2-Halliburton Onshore Quality Plan... 4-15

Chapter 5-Pipeline Pressure Testing

Table 5.1—Engineering Work Involved in Preparing for

Pressure Testing = seen 3

‘Table 5.2-Charts and Logs for Pressure Testing 5-15

Chapter 6-Dewatering

Table 6.1-Halliburton Onshore Quality Plan ... 611

Table 6.2-Data Collected During Dewatering .. 6-14

Chapter 7—Methanol and Glycol Swabbing

Table 7.1-Advantages and Disadvantages of Methanol and Glycol ....7-3

Table 7.2-Relationship Between Methanol Injected and

Liquid Recovered... seni TA

‘Table 7.3-Data Collected During Chemical Swabbing

Chapter 8—Air, Nitrogen, and Vacuum Drying

Table 8.1-Air Moisture Content... 8-3 and 8-4

Table 8.2-Saturation Vapor Pressure (Ps) and Vapor Density (Pe)

of Water in the Temperature Range of -100°C t0 +49°C rn 8-8 and 8-9

Table 8.3-Data to be Collected During Pipeline Pigging Operations ..8-13

Table 8.4-Data to be collected During Dry-Air or Nitrogen

Drying Operations... 8413

Table 8.5-Data Collected During Vacuum Drying Operations

Chapter 10-GelTechnology

Table 10.1-Gel Properties 10-3

Table 10.2-Example Gel Recipe .. 10-6

Table 10.3-Static Gel Strengths of Common Gels . 10-6

Table 10.4—General Recommendations for Gel 10-8

Chapter 11-Miscellaneous

Table 11.1-Bundle Cross-Section seen WD

Table 11.2-Considerations for Selecting the Proper Insulating

Materials beeen seseeeee A 1-5

January 1997 Table of Contents 17

Appendix B-Miscellaneous Information

Table B.1-Codes and Standards...

‘Table B.2-Suppliers

Appendix C-Conversion Factors

Table C.1-Velocity

‘Table C.2-Energy

‘Table C.3-Length

Table C.4—Area..

Table C.5-Volume ..

Table C.6-Weight ...

Table C.7-Weight/Unit of Area

Table C.8-Weights/Unit of Area, Pressure

Table C.9—Temperature Conversion for °F or °C

Table C.10-Barometric Pressures nn

‘Table C.11-Water Pressure to Feet Head ..

‘Table C.12-Feet Head of Water to psi

‘Table C.13-Average Absolute Atmospheric Pressure and

‘Temperature for Altitudes Above Sea Level.

Table C.13.A-1,000 ft of Free Air/Mile at Sea Level..

Table C.14 Standard Cubic Feet of Nitrogen/1,000 ft

of Pipe (100°F) wren :

‘Table C.15-Standard Cubic Feet of Nitrogen/1,000 ft

of Pipe (80°F)... .

‘Table C.16-Standard Cubic Feet of Nitrogen/1,000 ft

of Pipe (60°F)

‘Table C.17-Estimating Flow Out of an Open Pipe...

Table C.18-Freeboard/Diameter Ratio.

Table C.19-Pipe Size... :

Pressure/100 ft.n

-C-21 to C-28

‘Table C.20-Fri sees C29

‘Table C.21-Friction Pressure/100 ft... sees C30

‘Table C.22-Friction Pressure/100 ft... C31

‘Table C.23-Friction Pressure/100 ft 32

‘Table C.24-Friction Pressure/100 ft c-33

‘Table C.25-Friction Pressure/100 ft C34

Table C.26-Friction Pressure/100 ft.

Table C.27-Friction Pressure/100 ftom.

Table C.28-Friction Pressure/100 ft on...

‘Table C.29-Friction Pressure/100 ft...

‘Table C.30-Friction Pressure/100 ft...

‘Table C.31-Friction Pressure/100 ft

‘Table C.32-Friction Pressure/100 ft

Table C.33-Friction Pressure/Mile..

Table C.34-Friction Pressure/Mile..

Table C.35-Friction Pressure/Mile....

Table C.36-Friction Pressure/Mile

‘Table C.37-Friction Pressure/Mile.

‘Table €.38-Water Friction in 100 ft of Smooth Bore Hose

‘Table C.39-Friction Loss in Pounds Pressure Through

Aluminum Pip

‘Table C.40-Equivalent Length of New Straight Pipe for Valves

and Fittings for Turbulent Flow Only C-42 and C-43,

12 Pipeline Commissioning Manual January 1997

Table C.41-Friction Loss of Water in f1/100 ft Length

of Pipe. —

‘Table C.42-Seamless Steel Pipe

‘Table C.43-ANSI-Forged Steel Flanges -

Table C.44-Seamless Welding Fittings

‘Table C.45—Bolt Dimensions for Steel Flanges

C-44 to C-47

.C-50

.C-51 to C-5S

-56 and C-57

C58

January 1997

Table of Contents

19

Preface

Purpose

This manual provides a detailed description and explanation of the engineering.

and operational procedures required to commission a pipeline. It also introduces

pipeline commissioning to technical people who have no previous pipeline

experience and serves as a useful reference for personnel who are on field duty

Or are too distant from a specialist's advice.

Organization

‘To make this manual useful for both specialists and pipeline novices, definitions

and explanations appear in the first two chapters and in the glossary,

Appendix D. Experienced pipeline workers may consult the manual at Chapter 3

or beyond to find specific engineering, operating, and test information.

January 1997 Praface Pt

2 Pipalina Commissioning Manual slanuary 1997

Chapter}

Introduction to the

Commissioning Process

‘The commissioning process begins immediately on completion of pipeline

construction and includes all the procedures and tests requested to make the line

fully operational. Commissioning processes are generally divided and catego-

rized as precommissioning and commissioning.

‘The following definitions provide a basic understanding of the commissioning

process. The glossary (Appendix D) contains additional definitions

1.1 Basic Definitions

‘The following definitions are terms used most often in pipeline commissioning

operations.

1.1.1 Pipeline Owner

‘The pipeline owner is the owner or operator of the pipeline.

1.1.2 Client or Contractor

‘The client or contractor is the company who has contracted Halliburton for

services. This company could be the pipeline owner or the contractor who

constructed the line.

1.1.3 Linepipe

Linepipe describes the pipe before itis welded into a pipeline.

1.1.4 Pipeline

‘A pipeline extends from pig trap to pig trap including all branch lines up to and.

including the first valve. Pipelines without pig traps extend from the first

‘mainline valve on the platform or in a terminal to the first mainline valve in a

terminal.

January 1997 Chapter? 1-4

1.1.5 Pig

A pig isa device that is propelled through a pipeline to perform one of several

functions. In some cases, several pigs are necessary to perform multiple fune-

tions in the same pass.

A pig requires fluid or gas movement in the line to propel it down the pipeline

and to perform its function. The pig discs, cups, or foam body makes contact

with the wall of the pipeline to provide a seal. This seal prevents fluid from

bypassing the pig as it moves down the pipeline.

Pigs are used to separate fluids, gauge lines, provide magnetic pickup, caliper

the pipeline, provide a temporary barrier, and provide brushes for cleaning.

Foam pigs are used to dry the pipeline. Most pigs are unidirectional. Some pigs

are bidirectional, which means they can be moved in either direction.

1.1.6 Pig Train

Several pigs launched together into the pipeline form a pig train.

1.1.7 Pig Trap

A pig trap is a pipeline facility used for launching or receiving a pig. It usually

becomes an integral part of the pipeline system. In some cases, the pig traps

must be removed or isolated during a hydrotest because of pressure limitations.

Pipeline blinds might be installed to provide the necessary pressure integrity.

‘Some traps are crude in design with nothing but a basket to catch an exiting pig,

during drying operations. Complex traps provide all of the pig launching and

receiving capabilities needed for the pipeline.

Most of the trap designs have an internal diameter larger than the pipeline to aid

in placement and retrieval of the pig from the pig trap and to allow fluids to

bypass around the pig after the pig is received in the pig trap.

1.1.8 Contractor’s Pigging and Testing

Contractor's pigging and testing is performed by the contractor to prove the

integrity of the work. Cleaning, gauging, weld-sphere removal, filling, and

pressure testing can all be involved in the contractor's scope of work. It is not

‘uncommon for the client to call Halliburton to perform the dewatering and

drying after the contractor has completed the cleaning, gauging, and

hydrotesting. In some cases, the contractor will dewater the pipeline and will

only require Halliburton to dry the pipeline (Section 1.3).

1.1.9 Precommissioning

Precommissioning is the series of steps taken to prepare a pipeline for the

introduction of a product. It usually consists of cleaning, gauging, removing the

weld sphere, filling, pressure testing, dewatering, and conditioning (Section 1.2).

Precommissioning is performed by the pipeline owner or operator in some

cases. Precommissioning is performed by the construction contractor in cases

where Halliburton is the subcontractor. Precommissioning begins after comple-

tion of construction activities.

1:2 Pipalina Commissioning Manual January 1997

1.1.10 Commissioning

Commissioning follows precommissioning and begins with the introduction of

the product into the pipeline, followed by packing (raising the pipeline to

‘operating pressure in readiness for production).

1.1.11. Drying (Conditioning)

Drying (conditioning) is a procedure used to dry the inside of the pipeline in

preparation for the introduction of the product to be transported. The level of

dryness required is based on the type of product to be carried. For example, a

pipeline designed to carry wet gas does not need to be dried to the same level of

dryness as one designed to carry dry gas.

‘Some of the different measurements for dryness levels are listed below:

+ dew point in degrees centigrade

‘+ dew point in degrees Fahrenheit

+ ppmby volume

+ ppm by weight

‘+ pounds of water per Mscf of air

Example: A client requires a pipeline to be dried to a dryness level of

-30°C dew point. This requirement could also be expressed as

+ -22°F dew point

+ 378 ppm by volume

+235 ppm by weight

+ 18.9 Ib of water/MMscf of air

1.1.12 Sour-Gas Pipeline

‘A sour-gas pipeline carries gas that contains compounds of sulfur, such as

hydrogen sulfide (H,S). Gas containing a high level of CO, is not sour; however,

the same level of pipeline dryness required for a sour-gas pipeline may also be

required in a pipeline carrying CO, because of its corrosive nature.

1.1.13 Restrained and Unrestrained Pipelines

Restrained Pipelines

Restrained pipelines are lines that are not allowed to move, Tubulars have a

tendency to elongate when pressure rises within the tube. When sealed on both

ends, as in a pipeline, pipe lengthens with increases in internal pressure or

temperature. Because restrained pipelines are covered, anchored, or positioned

in some way, this pipeline elongation is not permitted to occur.

anuary 1997 Chapter? 1-8

Unrestrained Pipelines

Unrestrained pipelines are lines that are allowed to move during pressure and

temperature changes. Unrestrained pipe is theoretically on a slick surface that

allows it to move in reaction to any changes in the forces within the Tine.

Most flexible lines are not covered or anchored and move according to the

forces applied. Flexible lines are considered unrestrained,

Be careful when calculating for unrestrained lines. When performing calcula-

tions, the pipeline has to be in the theoretical position to move. In land lines, if

the line is exposed, the ine must move the soil around it to move. In offshore

lines, the mud that the line is laying in must be fluid enough that it does not

resist the forces being applied.

Note that while unrestrained lines do exist, the temperature effects of fluid in

these lines has more effect on operations than the movement of the line itself.

1.2 Precommissioning Operations

The main precommissioning operations are listed below:

‘+ Hyperbaric weld-sphere removal (in long subsea pipelines)

+ Cleaning

+ Gauging

+ Filling

+ Pressure testing

+ Dewatering

+ Drying

Brief descriptions of each of the precommissioning operations are given in the

following sections.

1.2.1 Hyperbaric Weld-Sphere Removal

The diving contractor uses hyperbaric weld spheres to provide a barrier between,

the subsea welding operations and the pipeline contents (usually water). Remove

weld spheres before pressure testing. Operators normally remove weld spheres

by pumping water through the pipeline, Launch a bidirectional disc pig in the

pipeline during weld sphere removal to push out any spheres that might have

deflated during the removal operations.

1.2.2 Cleaning

‘The pipeline must be internally clean and free from debris. Cleaning often

begins with the linepipe at the pipe mill or the coating yard where contractors

‘may remove rust and mill scale from the pipe. The contractors then coat the pipe

ID to prevent rust from reforming during storage and pipe-laying operations. If

cleaning and coating are not performed during construction, extensive cleaning.

is required after construction,

1-4 Pipeline Cammissianing Manual January 1997

Brush pigs propelled through the pipeline provide post-construction cleaning.

Pickup gels are often used on long or heavily contaminated lines in conjunction

with brush pigs to suspend and carry accumulated debris through the pipeline,

which prevents blockage. Most land lines are cleaned with pigs propelled by air

because water may be limited by availability and handling problems.

1.2.3 Gauging

Use gauge pigs to confirm the mechanical integrity of a pipeline at various

stages of construction. A gauge pig is a bidirectional disc pig with an aluminum

or steel plate that deforms when it comes across an object in the pipeline that is

not within tolerance. The diameter of the gauge plate is a predetermined size to

allow the plate to clear weld beads.

Gauging is performed by a bidirectional pig to permit it to be reversed out if it

becomes stuck. When the gauge pig hits an object, the aluminum plate deforms

and gives a visual indication that the pipeline is not in gauge. Run an “intelligent

pig” to record the location and the severity of the deformation.

On short lines, a blip on the pressure chart during filling helps to estimate the

position of the damaged zone when correlated to the volume of fluid pumped.

1.2.4 Filling

To enable hydrostatic-pressure testing of a pipeline, the pipeline must be full of,

treated water and have a minimal amount of air present in the pipeline. It is good

practice to refill the pipeline after all construction and tie-in operations are

complete. Refilling the pipeline removes gases remaining from tie-in operations.

If more than 0.2% air is in the line, the client will often want to refill the line.

‘Too much air in the line makes dewatering difficult and pressure testing data

inaccurate.

1.2.5 Pressure Testing

Pressure testing includes filling a pipeline with noncompressible fluid (hydro-

static testing) and pressurizing to specifications provided by the contractor. The

test usually includes both a strength test and a leak test. Most pipelines must

undergo both tests. These tests can be combined, or can be conducted separately

to fit into construction schedules. The line is usually pressurized, strength tested,

and leak tested without releasing the pressure back to zero.

Strength Test

‘The strength test finds inherent faults in or damage to the pipeline, relieves

residual stresses remaining from construction operations, and demonstrates that

the pipeline is of adequate strength to transport the product safely. To perform

the strength test, hold the pipe for 24 hours at a pressure just under its yield

pressure. During the 24-hour period, reduce the pressure to the predetermined

amount or bleed off some pressure to maintain the predetermined pressure. Keep

the pressure constant through the test and monitor for leaks and temperature

fluctuations.

anuary 1997 Chapter? 1-5

Leak Test

The leak test proves that the pipeline is free of leaks. For this test, pressurize the

line to a predetermined pressure. This pressure is usually less than the strength

test pressure and sealed with no reinjection. A leak is present if pressure changes

cannot be attributed to environmental changes.

1.2.6 Dewatering

After the pressure test, a gas pipeline is bulk dewatered to prepare for drying.

Dewatering is usually achieved by a train of pigs propelled through the pipeline

by air, nitrogen, or product.

If drying requires chemical swabbing, dewatering can become a part of the

swabbing operation. (See “Chemical Swabbing” in Section 1.2.7.) If the pipeline

will be dried by air, nitrogen, or vacuum, additional dewatering runs with pigs

may be performed. In short lines, the additional dewatering runs are called

residual dewatering and consist of propelling pig trains that contain foam pigs

through the pipeline to remove as much of the free water as possible.

In long lines, water-based gels, methanol-based gels, and glycol-based gels are

ofien used to provide more efficient sealing between the fill water, the chemical

swab, and the propelling medium.

1.2.7 Drying (Conditioning)

Several methods of drying pipeline are available: chemical swabbing, vacuum

drying, air drying, and nitrogen drying. The method chosen depends on the type

of pipeline, location (onshore/offshore), and length of pipeline.

Chemical Swabbing

Chemical swabbing conditions pipelines designed to carry gas or refined prod-

uct. Methanol, glycol, and isopropanol (rarely used) remove as much water as

possible from the pipeline, Any water that remains in the pipeline after chemical

swabbing is mixed with sufficient quantities of the methanol, glycol, or

isopropanol to prevent hydrate formation during gas-up. Before using a chemi-

cal swab, remove as much water as possible during the dewatering stage.

Vacuum Drying

‘Vacuum drying conditions pipelines designed to carry either dry gas or gas

containing corrosive substances, such as H,S or CO,. Vacuum drying lowers the

pressure in the pipeline to a point at which the water left behind from the

dewatering process is “boiled” off into a vapor. The vapor is then removed from

the pipeline with vacuum pumps.

‘Vacuum drying is used to attain the level of dryness needed to avoid one of the

situations described below:

+ formation of hydrates from dry gas

+ formation of carbonic acid from CO,

+ evolution of sulfuric acid from gas containing any sulfur

1-6 Pipalina Commissioning Manual January 1997

‘Vacuum drying is performed often, but this process will take days and some-

times weeks to bring the level of dryness down to the customer's specifications.

Many factors affect the vacuum drying option: temperature of the line, depth of

the line, humidity levels of the atmosphere in the line, type of pipeline insula-

tion, and the surrounding environment. Vacuum drying has the advantage of

allowing the drying of branches, manifolds, variable diameter pipelines, and

‘multiple lines.

On completion of the drying phase, fill the system with nitrogen to a positive

pressure. Use dry air to bring the pressure up to above ambient if the piping

contains a large volume (which would make nitrogen filling too costly) and if

product gas is not available because the Tine will be laid up for some time.

Air Drying

To air dry a pipeline, dewater the pipeline with air and then continually blow air

through the line to absorb and remove water left behind from the dewatering pig,

train. The air being used must be free of oil and dried to at least the dryness

level that the client requires for the final dryness level of the pipeline. With

desiccant dryers, an air dryness level can be obtained down to -60°C dew point.

The process of air drying can take days or weeks depending on the temperature

and length of the line. Ambient humidity and temperature also affect the air

drying unit (ADU) efficiency.

Nitrogen Drying

On short lines, nitrogen is often used instead of air to dry the pipeline. The

advantage of nitrogen drying is that nitrogen does not contain water like air

does. Nitrogen enters the pipeline at a dryness level of -65°C dew point. Nitro-

‘gen handling costs and limited supply (at some locations) make this drying

‘method more costly; however, nitrogen drying is often the only drying means

available at a location.

1.3 Commissioning Operations

‘The main commissioning operations are introducing and filling the pipeline with

the final product and packing the pipeline to operating pressure.

1.3.1 Introducing the Product

For natural gas pipelines, natural gas can be introduced as the propellant for the

pig train during dewatering or chemical swabbing. Care must be taken to ensure

that the gas does not contact air in the pipeline and does not bypass the dewater-

ing/swabbing train and mix with the water.

If gas is not used, the pipeline is usually filled with nitrogen or 10% line spacer

before gas is introduced. Gas can also be introduced directly into the vacuum-

dried pipeline while it is under vacuum because residual air does not pose an

explosive hazard.

Oil products usually do not form hydrates on contact with water; unless gas

expected, no drying operations are necessary. Oil trunklines usually can be made

inert with nitrogen before the introduction of oil. For oil infield lines and land

anuary 1997 Chaptor? 1-7

pipelines, and for all methanol pipelines, the product is sometimes used as the

propellant to dewater the pipeline. In some onshore and offshore situations, the

pipeline is dewatered with air but not dried.

1.3.2 Packing the Pipeline to Operating Pressure

The product is usually introduced to the pipeline at low pressure. After the

product is introduced, the pipeline is packed (slowly brought up to operating

pressure).

1.4 Servicing Existing Pipelines

Existing pipelines may require service for various reasons:

* Cleaning

* Decommissioning

+ Changing use

+ Inerting

+ Tying-in additional pipetines

+ Restrength testing (hydrotesting)

+ Intelligent pigging

‘A wide range of operations may be conducted when existing pipelines are being

serviced. Most operations are similar to the operations performed on a new

pipeline. In general, however, existing pipelines involve more work than new

pipelines. Safety and environmental issues require particular attention on and

around vessels containing hydrocarbons.

1a

Pipeline Cammissioning Manvial January 1997

Pipeline Features

2.1 Overview

This chapter lists the main types of subsea and land pipelines and the different

types of construction materials and terminations. The figures in this chapter

illustrate and identify the various components of pipelines.

‘Some pipeline features require special attention during the planning of

precommissioning and commissioning operations. These features are high-

lighted under Pipeline Components and Procedures Requiring Special Attention

(Section 2.4).

2.2 Subsea Pipelines

Table 2.1 lists the main types of subsea pipeline, construction materials, and

terminations currently used in the pipeline industry.

Table 2.1—Types of Subsea Pipeline

Type Material Terminations

[Trunkline [Carbon Steel Platform to Shore

Platform to Platform

ICarbon Steel Platform to Subsea Tee

Export Pipeline

Stainless Stee!

Manifold to Platform

Manifold to Subsea Tee

Platform to Platform

Chapter}

|Carbon Steel

Infield Pipeline Stainless Steel —_[Fatform to Gubsea Teo

Ean Manifold to Platform

Manifold to Subsea Tee

[Carbon Steel Wellhead to Platform

Fiowiine [Stainless Steel _| Wellhead to Manifold

Flexible Manifold to Platform

[Carbon Steel

Bundle Stainless Stect [Various

anuary 1997, Chapter? 24

2.2.1 Subsea Pipeline Components

The pipeline owner or the contractor usually contracts the initial construction by

parts. Different contractors or subcontractors may be responsible for testing each

part.

Common trunkline parts are listed below:

* Topside facilities including the pig trap and topside riser

+ Subsea riser tie-in spool piece

+ Subsea pipeline

+ Shore approach

+ Land section

+ Terminal facilities and pig trap

* Crossings

+ Free spans (which require grouting and stabilization)

+ Subsea pipeline manifolds (plems)

The usual parts for export and infield pipelines and flowlines are listed below:

+ Topside facilities including the pig traps and risers

+ Subsea manifold or tee spool piece

+ Subsea riser tie-in spool piece

Figure 2.1—Subsea Tunkline

Figure 2.2—Infield Pipeline

2.2 Pipalina Commissioning Manual lanuany 1997

Figure 2.3—Flowline

Figure 2.4—Bundle

+ Subsea risers

+ Subsea pipeline

Figures 2.1 through 2.4 show compo-

nent locations of a subsea trunkline,

an infield pipeline, a flowline, and a

bundle. Components are listed in

Table 2.2.

After components are pressure tested

by the construction contractor, they

may be tested again by both the

prime contractor and the pipeline

‘owner. For example, spool pieces are

tested on the vessel before installa-

tion and are then subjected to at least

one additional test after installation,

The pipeline section is often tested

before and after trenching, To save

time at a later stage in the project, the

pipeline owner can arrange for the

contractor's tests to be combined

strength and leak tests,

Table 2.2—Components of Subsea Pipelines

(Corresponding to Figures 2.1 to 2.4)

[Topside riser, pig trap, and connecting pipework.

Topside riser to subsea riser tie-in joint

[Subsea riser

[Subsea riser

[Subsea valve spool piece

[Subsea pipeline

[Subsea tee

[Subsea pipeline to shore approach tie-in joint

[Shore approach

[Shore approach to land pipeline section tie-in joint

[Land pipeline section

[Land pipeline to pig trap tie-in piece

[Terminal pig trap and connecting pipework.

Pipeline bundle

Flexible pipeline

[Subsea manifold

[Subsea export pipeline tee

o|x]o}v]o]z]z|-]a|_]x]o]-2]m)olol]a|>

[Wellhead connection

lanuany 1997

Chapter 2

2a

The pipeline owner has the option of using a shortened, final leak test if both of

the following requirements have been met:

+ All component parts of the pipeline have been previously strength tested

for a 24-hour period.

* The joining flanges that have not been leak tested are on the platform or

in the terminal and are visible.

2.3 Land Pipelines

Table 2.3 lists the main types of land pipelines, construction materials, and

terminations currently used in the pipeline industry. Trunklines are usually

buried, but flowlines are normally above ground.

Table 2.3—Types of Land Pipelines

Type. [Material [Terminations

[Terminal to Terminal

Terminal to Gas

|Compressor Station

Trunkline ICarbon Stee! Temaalis ase Baer

Valve

{Terminal to Tee

Fiowiine [Carbon Steel [Wellhead to Wellhead

2.3.1 Land Pipeline Components

Figures 2.5 and 2.6 illustrate typical configurations of a land trunkline and a

flowline. Land and infield pipeline components are listed in Table 2.4.

‘The following parts are usually included in a trunkline:

+ Terminal facilities, including the pig traps

+ Land pipeline

+ Compressor, pump, or valve stations

‘The following parts are usually included in a flowline:

+ Terminal facilities

+ Flowline

+ Wellhead manifold

Either the pipeline owner or the contractor usually awards the pipeline construe.

tion contract according to parts. Different contractors or subcontractors may be

responsible for testing each part.

2-4 Pipalina Commissioning Manual January 1997

‘Trunkline pressure testing must be performed in sections if either of the follow-

ing situations exist:

‘+ The distance between compressor, pump, or valve stations exceeds the

specified maximum test section length.

‘+ The elevations produce points on the pipeline where the specified test

pressure is exceeded.

Table 2.4—Components of Land Pipelines

(Corresponding to Figures 2.5 and 2.6)

[Terminal facilities with pig traps

Land pipeline

[Compressor, pump, or valve stations

Fiowiine

Wellhead manifold

[Terminal connection

a|mlolo}a]>

Figure 2.5—Typical Land Trunkline Configuration

Figure 2.6—Typical Flowline Configuration

lanuary 1997 Chapter? 2.5

2.4 Pipeline Components and Procedures

Requiring Special Attention

‘Sphere tees, pig signalers, valves, pipeline bores, vents and drains, pipe bends,

and pig traps require particular attention during precommissioning or commis-

sioning operations.

2.4.1 Sphere Tee Pigging

If pipelines have sphere tees installed, select pigs carefully. The distance be-

tween the front and rear discs of the pig must be large enough to ensure that the

front disc is completely past the tee apertures before the rear disc enters the

aperture area.

2.4.2 Dewatering and Drying

‘A subsea tee sleeve cannot be drained, and as a result, the tee sleeve contains

water after dewatering is complete. During chemical conditioning, water is

treated by chemical slugs that move beyond the tee. The chemicals mix with the

water, leaving a liquid that does not form hydrates during commissioning. The

quantity of chemical required must be increased to allow for treatment of the

water in the tee sleeves.

The tee water problem is more difficult to resolve during air, nitrogen, or

vacuum drying, The reduced surface area of the water contained in the tee

extends the time required to dry the pipeline. Consider surface area when

calculating the total drying time. Refer to Chapter 8 for more information on air,

nitrogen, or vacuum drying.

Many older pipelines have tees without sleeves or sphere bars. Carefully select

the type of pig to use in these pipelines.

2.4.3 Pig Signalers

Pipelines often must be pigged in the direction opposite to normal flow. In these

instances, make sure the pig signaler device is bidirectional. If the signaler is

unidirectional, all parts protruding into the pipeline bore must be removed

before pigging.

2.4.4 Valves

When a check valve is fitted in the pipeline, make sure the valve allows pigs to

pass through the valve in either direction. When planning to pig in the opposite

direction to flow, make sure the distance between the front and rear discs is,

sufficient to allow the front discs to pass through the valve before the first rear

disc enters the valve.

‘As with subsea tees, consider water that remains trapped in valve body cavities

when planning drying operations,

For emergency shutdown (ESD) and other valves, ensure that the valve bore is

the same diameter as the pipeline bore.

2-6 Pipalina Commissioning Manual January 1997

Ensure that valve trims are compatible with any proposed swabbing chemical

and that valve types are compatible with vacuum-drying techniques.

2.4.5 Pipeline Bore

‘Most modem pipelines have constant bores with no ID changes; however, older

pipelines often have diameter changes. Consider diameter changes when plan-

ning pigging operations. Internal upset on the risers to an offshore installation

often results from an increase in wall thickness. This “step” can cause a pig to

hang up.

Diameter changes do occur in modern pipelines that are poorly designed.

‘Thoroughly check the pipeline owner's information on pipeline diameter and

diameter changes to avoid having a stuck pig.

2.4.6 Vents and Drains

Ensure that platform and terminal pipework includes sufficient vents and drains.

Verify this requirement at an early stage of the contract to allow the client time

to arrange for additions.

2.4.7 Pipeline Bends

Pipeline bends normally have a minimum bend radius of three times the pipe

OD to allow pigs to pass safely. If intelligent pigging of a pipeline is planned,

check that all bends, including field bends, have a bend radius sufficiently lange

to permit the intelligent pig to pass. Check the client's pipeline information to

ensure that no bends have a bend radius smaller than the minimum radius

required by the pig.

2.4.8 Pig Traps

Commissioning operations are performed either in the reverse direction to

normal flow or the same direction as normal flow. Check the design of pig traps

and pipework to ensure that pigs can be launched and received in both direc-

tions, that pigs can be safely loaded and retrieved at each end, and that suffi-

ciently large pumps and discharge connections are available (Appendix B).

lanuary 1997

Chapter 2

27

2-8 Pipalina Commissioning Manual January 1997

Chapter}

Barrier Tools

3.1 Introduction

‘The first phase of pipeline precommissioning is removal of the barrier tools used

by welders during construction. This chapter describes the removal process in

three main parts:

+ The Types of Barrier Tools and Purpose of Barrier Tools sections

introduce the types and purposes of barrier tools.

+ The Preparation for Barrier Tool Removal section describes and ex-

plains in detail the engineering and operational procedures that may be

required for some clients. This section should help engineers prepare

documentation,

* The Final Reporting section contains details of information typically

required for the Final Report to the client.

3.2 Types of Barrier Tools

Four types of barrier tools are used in the pipeline industry:

‘* Hyperbaric weld spheres (HW spheres)

+ High-differential pigs (HD pigs)

* Inflatable, piggable plugs (piggable plugs)

* Gels (refer to Chapter 10 for more information)

‘The term barrier tool is used throughout this document except where specific

reference is made to an HW sphere, an HD pig, or a piggable plug.

3.2.1 HW Spheres

An HW sphere is constructed from the following three layers of polyurethane:

+ Acore

‘+ An intermediate layer, which provides strength

lanuany 1997 Chapter? a4

+ A softer outer layer with a waffle-pattemned center band to ensure

absolute sealing quali

An internal tie-rod prevents excessive longi

inal expansion and helps increase

pressure between the internal surface of the pipe and the HW sphere, which

helps ensure a tight seal in the pipe (Figure 3.1). The HW sphere has valves at

each end to permit inflation and deflation. Filling and pressurizing are per-

formed with a liquid.

Figure 3.1—Hyperbaric Weld Sphere

‘Typically, an HW sphere retains a differential

pressure of 1 to 3 bar (14.5 to 43.5 psi) and

requires an initiation pressure of 4 to 6 bar (58

to 87 psi) to remove it from the pipeline.

3.2.2 HD Pigs

An HD pig has a steel body with multiple polyure-

thane wear disks and sealing disks at each end. In

the example shown in Figure 3.2, the wear and

sealing disks are bonded by a natural silicon sealant

to form a solid pack. The disk-retaining bolts are

also coated with the sealant. This treatment helps

prevent bypass of gas or liquid.

An HD pig is custom-designed for each project to

withstand a specific reverse pressure. A single HD

pig can normally withstand a 3-bar (43.5-psi)

differential pressure. When HD pigs are used in a

series, the reverse pressure is cumulative.

item [Description

PU Nose Buffer

[Chamfered Wear Disk

[Sealing Disk

Washer

PU Washer

Bod)

Wear Disk

Bush

[Spacer Disk

Figure 3.2—An HD Pig with Multiple Polyurethane Wear Disks and Sealing Disks at Each End

a2

Pipalina Commissioning Manual

January 1997

3.2.3 Piggable Plug

A typical piggable plug, shown in Figure 3.3, has a steel body fitted with polyure-

thane support disks and sealing disks at each end, Normally, the piggable plug has

‘wo inflatable tires positioned on either side of the support and sealing disks. A

liquid is used to fill and pressurize the tires. A dump valve automatically deflates

the tires at a predetermined increase in pressure before removal of the piggable

plug.

A piggable plug retains an internal differential pressure to seal against the wall of

the pipe. Check with the pig manufacturer to determine the differential pressure

and the pressure needed to move the pig in the line. These pressures are dependent

on the size of the piggable plug.

Umbitical Pressure Activated

Dump Valve Seating/Gripping

Modular Fabricated ‘nae roe

Stee! Body

Stored Cable Radioactive

Discs Umbilicats Fixing Souree Holder

Point

Figure 3.3—Piggable Plug

3.3. The Purpose of Barrier Tools

Barrier tools are used to isolate the contents of a pipeline or section of a pipeline

from a subsea, hyperbaric tie-in operation. Barrier tools are also used to partially

decommission a pipeline. Barrier tools can also provide a primary seal to isolate

the pipeline product from a section of pipe that must be removed for installation

of a safety shut-in valve spool (SIV spool).

HW spheres are used for straightforward tie-ins on new pipelines; however, HD

pigs or piggable plugs are used for special operations (such as when a subsea

check valve is involved or when higher differential pressures are required).

lanuary 1997

Chapter 2

aa

3.3.1 Combining Barrier Tools

Barrier tools are used to partially decommission an existing pipeline. Barrier

tools can provide a seal to enable cutting the pipeline and inserting a spool by

hyperbaric welding. Figure 3.4 shows a typical isolation operation involving all

three types of barrier tools.

Before launching the barrier tool train, the pipeline pressure is reduced to an

amount slightly below the head pressure of the water. A standard, bidirectional

pig is then launched and propelled through the pipeline by nitrogen to a point

approximately 2 km beyond the proposed cut.

‘A train of HD pigs is launched and propelled through the pipeline. The first HD

Outline

‘Seawater

450m 2m = 30m 20m10m 20km

3 bar 8 bar

Piggable Plug Piggable Plug

Hyperbaric Pigs,

Figure 3.4—Isolation Operation Involving Three Types of Barrier Tools

a4

Pipalina Commissioning Manual January 1997

pig is propelled by glycol or a glycol-based gel. Subsequent pigs are propelled

by potable water.

The glycol or glycol-based gel is included in the train to condition the section of,

decommissioned pipeline and helps ensure that the pipeline will be ready to

receive gas after the barrier train has been pushed out of the pipeline.

‘The number of barrier tools and the quantity of glycol or glycol-based gel

required is determined by the pressure to be resisted and the diameter of the

pipeline. For added safety, a final piggable plug is launched and propelled

through the pipeline by seawater. The upper portion of Figure 3.4 shows the

configuration of a typical decommissioning and isolating pig train.

‘The accuracy of pig tracking and location by the divers is very important. Refer

to Chapter 8 for methods of pig tracking and location. The section of pipeline

from the piggable plug to the pig launcher on the platform is filled with filtered

seawater. Divers remove the pipe section and activate the piggable plug.

‘A second piggable plug is inserted into the riser end of the cut pipeline section

and activated. The middle portion of Figure 3.4 shows the insertion and activa-

tion.

‘After the replacement section has been flooded with seawater and plugged with

HW spheres, it is fitted into the opening in the main pipeline. The pipe section is

then welded into position through the employment of standard hyperbaric

techniques. The lower portion of Figure 3.4 shows the fitting and welding,

Pressure is applied from the launcher end of the pipeline to deflate the piggable

plug automatically. Gas pressure from the terminal is used to propel the whole

pig train back to the launcher. The water ahead of the pigs increases the safety of

the operation,

3.3.2 Use of HW Spheres

‘The hyperbaric welding system requires a diver to insert, position, and inflate

the HW sphere or spheres in each end of the pipes to be joined. The diver

positions a habitat around the weld area and expels the water by introducing

helium or a mixture of oxygen and helium. The tight seal produced by the HW

spheres helps ensure that nothing can enter the habitat from the pipeline ends

and that the gas in the habitat does not escape into the pip.

‘Technicians can conduct welding and nondestructive testing (NDT) processes

within the habitat in a dry environment. In harsh environments, such as the UK

North Sea, sets of four HW spheres are usually used (two per side). In shallower,

‘more moderate environments, two HW spheres are sometimes acceptable.

Figure 3.5 shows a typical hyperbaric welding operation that includes HW

spheres.

HD pigs or piggable plugs achieve the same objective as HW spheres but are

used when a check valve or similar subsea valve installation is involved and the

direction of the pig’s travel is opposite to normal flow. If a subsea valve installa

tion is involved and the pig must travel in reverse, do not use HW spheres

because they can become trapped in the valve.

lanuary 1997 Chapter? 3.5

Pipe Sealed with

Hyperbaric Sphere

Figure 3.5—Hyperbaric Welding Operation that Includes HW Spheres

3.3.3 Effect of Barrier Tools on Precommissioning

Work

Barrier tools are used during tie-in of valve assemblies and riser tie-in spools.

Remove barrier tools from the pig trap before cleaning and gauging the pipeline.

Pump water through the pipeline to remove the barrier tools. In some cases, a

sweeping pig may be required to remove barrier tools that have become stuck or

are allowing water to bypass.

3.3.4 Barrier Tool Removal Requirement (Acceptance

Criteria)

For a successful barrier tool removal operation, completely remove all barrier

tools and parts of the barrier tools from the pipeline before starting operations.

To save time, use the cleaning pig train to sweep any remaining parts of the

barrier tools from the pipeline.

3.4 Detailed Preparation for Barrier Tool Removal

Barrier tool removal is normally performed with, but as a separate part of, the

cleaning and gauging operations on a new pipeline. For a job in a pipeline that is

already installed and operating, the only operation required of Halliburton may

be dewatering and isolating the work section with barrier tools.

Required equipment for barrier tool removal is the same as for cleaning and

gauging. In addition, high-pressure backup pumps are required in case removing

the barrier tools becomes difficult. In some instances, gels can also be used

during partial decommissioning and pipeline isolation.

Preparation for barrier tool removal can vary depending on the client's needs

Operations typically follow these steps:

+ Planning

+ Engineering

+ Preparing procedures

3:6 Pipalina Commissioning Manual January 1997

+ Selecting equipment and instrumentation

+ Inspecting equipment

3.4.1 Tr

The client may require Halliburton to assist in the performance of trials to prove

the selected barrier-tool method, In such cases, Halliburton is usually expected

to supply equipment, instrumentation, and personnel to work under the client's

instruction; however, some clients may instruct Halliburton to conduct the trials

on their behalf, Ifa client makes this request, the preparation should be the same

as for a full barrier-tool removal operation.

3.4.2 Barrier-Tool Removal Stages

A barrier-tool removal operation normally consists of the following six main

stages

+ Pressurizing

‘+ Propelling the tools through the pipeline

+ Receiving the tools into the pig trap

+ Removing the tools from the pig trap

+ Accepting the operation

‘+ Disposing of treated fillwater

‘These stages are described in more detail in the following sections.

Pressurizing

To initiate movement of the barrier tools, increase the pressure in the pipeline

until the first tool begins to move. As pressurization continues, the subsequent

tools begin to move until a pressure is reached at which all the tools are moving

at a steady rate through the pipeline.

Propelling the Tools Through the Pipeline

After the barrier tools begin to move, continue pumping at a steady rate until the

tools enter the pig trap and their arrival is verified. If there is any doubt that all

the tools have been received, continue pumping until an agreed, predetermined

‘volume has been pumped (such as 10% of the total pipeline volume).

This preset volume is especially important in long pipelines. Depressurizing the

pipeline to check the number of tools received and then pressurizing the pipeline

to initiate movement of the tools may take a long time. Depressurizing the

pipeline is necessary since isolation valves cannot be closed if a tool is posi-

tioned across a valve.

Repeated movement can damage the tools. Ifa tool is damaged and deflates, a

sweeper pig must be launched from the pumping end to remove it. In pipelines

300 to $00 km long, the time required to propel the sweeper pig through the

pipeline adds considerable time to the program.

lanuary 1997 Chapter? 37

Receiving the Tools into the Pig Trap

Determine how many barrier tools the pig trap can accommodate. If necessary,

stop pumping and remove tools from the trap or insert other tools.

Pig signalers fitted to the approach pipe and to the throat of the trap usually

nal the receipt of tools into the pig trap. Carefully observe changes in the

pumping pressure and backpressure to further verify tool receipt.

Removing the Tools from the Pig Trap

Pig trap barrels are usually oversized to make barrier-tool removal simple.

Deflate the tool to aid removal in these special cases:

+ A temporary pig trap is used and the barrel has the same ID as the

pipeline

+ The tool is sticking in a permanent pig trap

Accepting the Operation

The operation is accepted by the contractor when the assigned contractor

representative has verified that all of the barrier tools and parts of the barrier

tools have been removed from the pipeline

Disposing Treated Fillwater

Use caution when dumping treated fillwater. Refer to Chapter 6 for more

information on disposing treated fillwater.

3.4.3 Partial Decommissioning Before Isolation with

HD Pigs

Only HD pigs are launched from the pig trap. HW spheres and piggable plugs

are inserted into the pipeline by the divers. If HD pigs are used to partially

decommission the pipeline before isolation, the following additional

required before the tie-in operations:

+ Inserting HD pigs into the pig launcher

+ Launching HD pigs

+ Propelling, tracking, and positioning HD pigs

+ Verifying HD pig positions

+ Accepting the operation

These stages are described in more detail in the following sections,

Inserting HD Pigs into the Pig Launcher

Insert each HD pig individually into the pig launcher.

2.8 Pipeline Commissioning Manual January 1997

Do not damage the HD pigs during insertion. The HD pig’s

purpose is to partially decommission the pipeline and assist

in isolating the diver’s habitat from water or gas.

Launching HD Pigs

Launch each HD pig separately. Stop pumping to permit insertion of each HD

pig.

Propelling, Tracking, and Positioning HD Pigs

This operation requires careful monitoring and control. Divers track the HD pigs

along the pipeline and signal to the pumping spread when the HD pigs are in

place. The position of the pigs can be determined by the use of acoustic pingers

and radioactive sources fitted to the pigs before launch (Appendix B).

Verifying HD Pig Positions

Divers verify that the HD pig is positioned correctly. Data gathered by

Halliburton from the pressure and flowmeter instrumentation can also be used as

a rough guide to verify HD pig po:

Accepting the Operation

‘The client is ultimately responsible for accepting that the HD pigs have been

positioned correctly.

3.4.4 Recording and Reporting Data

‘The recording and reporting of data during barrier tool removal is important for

these reasons:

‘+ The recorded data helps track the progress of the tools through the

pipeline.

+ The data helps determine if a tool has ruptured and is bypassing or has

become stuck.

‘The categories of data for barrier tool removal are shown in Table 3-1.

‘Table 3.1—Data Collected During Barrier Tool Removal

[Charts _ [Pipeline pressure

Logs [Events

Volume and time to pressurize

Volume and time to propel the barrier tools through the pipeline

Volume of chemical injected

[Pressure and time at the pumping end

[Pressure and time at the receiving end

Examples of record sheets are included in Appendix A.

lanuary 1997 Chapter? 2.9

‘Typical contents of a final report include the following components:

Summary of operations

+ Copies of all charts,

* Copies of all manual records

+ Equipment and

‘rumentation calibration certificates

* Condition of received barrier tool reports.

+ Photographs of received barrier tools

3.5 Documenting Barrier Tool Removal

NOTE Read the contract. Ensure that nothing is missing. Pay particular

attention to the scope of work and specifications

3.5.1 Prepare an Overall Schedule

Show the amount of time required for these tasks:

+ Engineering

+ Producing procedures, including quality plans and safety procedures

+ Assembling equipment and instrumentation

+ Mobilizing

+ Completing the work

+ Demobilizing

+ Producing the final documentation

‘The dates for submitting key documents and for completing the work are

determined by the client and should be listed in the contract.

3.5.2 Start Engineering

To begin engineering, calculate these data items:

+ Pipeline volume

* Volume per linear meter (or foot) of pipeline

* Chemical injection rates

+ Pressures required to initiate movement and propel barrier tools out of

the pipeline

+ Rates of flow required to propel barrier tools out of the pipeline at a

specified speed

* Quantities of gel ingredients, if required

+ Volumes of nitrogen, if required

8:10 Pipeline Commissioning Manual January 1997

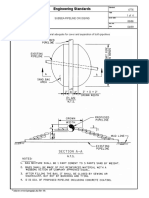

3.5.3 Produce a Prelii

out Drawing

inary Equipment List and Lay-

From the calculations made in the previous step, size the equipment and instru-

‘mentation. Figure 3.5 shows a typical equipment layout.

Instrument

‘mn

a 9 Hed 5,000-gal_

cate

resort Ye

a i

&

2) | cawmea |_| coomea

2 ‘Tank Pump oa

E| Goeae so-mieron Fiter

i chante

Z i e

e

“

< ee ove

ane

You might also like

- SPL-PL01-LA-7880-0004 - 02 Specification For Field Welding and NDTNo ratings yetSPL-PL01-LA-7880-0004 - 02 Specification For Field Welding and NDT34 pages

- Pipeline Design/Construction : Interview Questions ForNo ratings yetPipeline Design/Construction : Interview Questions For2 pages

- Pigging Infrastructure Design OptimizationNo ratings yetPigging Infrastructure Design Optimization237 pages

- Subsea Pipelines Pre Commissioning 1687771720No ratings yetSubsea Pipelines Pre Commissioning 168777172019 pages

- Rastanura Clean Fuels Tie-In Method StatementNo ratings yetRastanura Clean Fuels Tie-In Method Statement17 pages

- Pipeline Expansion Analysis Asap 1X Flowline100% (1)Pipeline Expansion Analysis Asap 1X Flowline7 pages

- iNPIPE Products IPHS Bi-Directional Disc PigsNo ratings yetiNPIPE Products IPHS Bi-Directional Disc Pigs6 pages

- Hydrocarbon Pipelines - Hydrostatic Testing of Pipelines: Company Specification100% (1)Hydrocarbon Pipelines - Hydrostatic Testing of Pipelines: Company Specification34 pages

- Pipeline Pre-Commissioning & Commissioning Philosophy DRAFT100% (1)Pipeline Pre-Commissioning & Commissioning Philosophy DRAFT50 pages

- Pipeline Pre-Commissioning SpecificationsNo ratings yetPipeline Pre-Commissioning Specifications24 pages

- Pipeline Commissioning, Operations, and MaintenanceNo ratings yetPipeline Commissioning, Operations, and Maintenance14 pages

- Start-Up and Commissioning of The Pipeline With PDFNo ratings yetStart-Up and Commissioning of The Pipeline With PDF5 pages

- Chapter 01 - Introduction To The Commissioning ProcessOCR OKNo ratings yetChapter 01 - Introduction To The Commissioning ProcessOCR OK8 pages