Professional Documents

Culture Documents

MH Wheel Start-Up & Shutdown

MH Wheel Start-Up & Shutdown

Uploaded by

Elisette RahantamalalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MH Wheel Start-Up & Shutdown

MH Wheel Start-Up & Shutdown

Uploaded by

Elisette RahantamalalaCopyright:

Available Formats

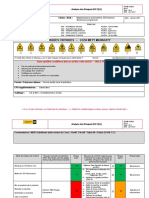

MATERIAL HANDLER - WHEELED

Start-Up & Shutdown Procedures

M313D-M325D (GC), M318F-3024F (GC), MH3037-MH3059 (HC)

Inspector ___________________________________________ Evaluator ________________________________________

MOUNTING AND DISMOUNTING

• Mount or dismount the machine only at locations that have steps and/or handholds. Before you mount the machine, clean and Inspect the steps and handholds.

Make all necessary repairs.

• Always face the machine whenever you get on or off the machine.

• Maintain three-point contact with the steps and with the handholds. (Three-point contact can be 2 feet and 1 hand or 1 foot and 2 hands).

• DO NOT mount or dismount a moving machine. Never jump off the machine. Do not carry tools or supplies when you try to mount the machine or when you try to

dismount the machine.

Was procedure step completed properly? √ Evaluator Comments

BEFORE STARTING THE MACHINE

Inspect the condition of the seat belt and mounting hardware

Regardless of appearance, replace the seat belt after three years of use

Adjust the seat so that full pedal travel can be achieved with the operator’s back against the back

of the seat

Make sure the machine is equipped with a lighting system that is adequate for the job conditions

Make sure all machine lights are working properly

Before you start the engine and before you move the machine, make sure that no one is underneath the

machine, around the machine, or on the machine

STARTING THE MACHINE

Turn the battery disconnect switch to ON (if equipped)

Ensure that the reset button for the circuit breaker remains depressed (if equipped)

Ensure that the engine shutdown switch is in the ON position

Adjust seat, adjust mirrors, fasten seat belt

Move hydraulic lockout control to the LOCKED position, engage parking brake

Move the joysticks to HOLD

Ensure all personnel are clear of machine

Sound horn

Turn engine start switch to ON

Observe monitoring system self-test, add fluids if necessary

In cold-weather conditions, wait until the indicator light for the starting aid equipment is in the

OFF position (refer to O&MM)

Turn engine start switch to START and crank engine

MACHINE WARM-UP

Allow machine to warm up (per O&MM)

Engage and disengage joystick controls to help speed up warmup of hydraulic components

Raise cab before machine operation

Turn engine speed dial to medium, run engine for 5 minutes, engage joystick controls and disengage

joystick controls to speed up the warm-up of the hydraulic components

Turn the engine speed dial to the maximum engine speed and move joystick from BUCKET DUMP

to HOLD to attain relief pressure

Cycle all hydraulic controls to allow warm oil to circulate through all cylinders and lines

Check gauges, indicators, and action light frequently

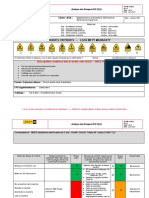

MATERIAL HANDLER - WHEELED

Start-Up & Shutdown Procedures

M313D-M325D (GC), M318F-3024 (GC), MH3037-MH3059 (HC)

Was procedure step completed properly? √ Evaluator Comments

MOVING THE MACHINE

Make sure area is clear by sounding horn and waiting 3-5 seconds before moving machine

Select the appropriate engine speed or throttle function from the main display screen on the monitor.

Move hydraulic lockout control to UNLOCKED position

Raise boom to provide sufficient ground clearance

Fully retract the cab riser. The cab must be fully retracted in order to use the boom, swing, and

travel functions.

Raise all of the stabilizers to the full UP position.

Depress service brake pedal

Disengage parking brake

Select required transmission gear

Release service brake pedal

Move travel speed pedal to the desired direction and to the desired speed

MACHINE SHUT DOWN

Park machine on smooth, level area

To slow the machine, release travel pedal and depress service brake pedal

Lower all hydraulic implements, lower cab

Move hydraulic lockout control to the LOCKED position

Run engine at low idle for 5 minutes to allow engine to cool

Turn key start switch to OFF and remove key

Utilize correct delayed engine shutdown procedure if equipped

Note: Overriding delayed engine shutdown may reduce engine & machine system component life

Use for emergency situations only

Turn battery disconnect switch to OFF

Do not turn off the battery disconnect switch until the “wait to disconnect” lamp has turned off. If

the switch is turned off when the indicator lamp is illuminated the Diesel Exhaust Fluid (DEF) system

will not purge the DEF. If the DEF does not purge, DEF could freeze and damage the pump and lines

(if equipped).

Dismount machine using 3-point contact

Block wheels and remove disconnect switch key if parking for extended period

Conduct post-operation walk-around inspection

NOTES:

Inspected by: ______________________________________________________________________ Date: ______________________ Time: ______________________

© 2016 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow,” the “Power Edge” trade

dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MH - Wheel - Safety & Maint. InspectionDocument2 pagesMH - Wheel - Safety & Maint. InspectionElisette RahantamalalaNo ratings yet

- Test Symboles ADTDocument1 pageTest Symboles ADTElisette RahantamalalaNo ratings yet

- MH - Tracked - Safety & Maint. InspectionDocument2 pagesMH - Tracked - Safety & Maint. InspectionElisette RahantamalalaNo ratings yet

- MH Tracked Start-Up & ShutdownDocument2 pagesMH Tracked Start-Up & ShutdownElisette RahantamalalaNo ratings yet

- Tibu5104 740 Stall TestDocument5 pagesTibu5104 740 Stall TestElisette RahantamalalaNo ratings yet

- SSDP Practical TestDocument4 pagesSSDP Practical TestElisette RahantamalalaNo ratings yet

- KARCHERDocument1 pageKARCHERElisette RahantamalalaNo ratings yet

- ENTRETIEN PM Palan - VerinDocument1 pageENTRETIEN PM Palan - VerinElisette RahantamalalaNo ratings yet

- Check List MachineDocument1 pageCheck List MachineElisette RahantamalalaNo ratings yet

- Pupitre1500 (v6.0) .CWK (TEXTE)Document2 pagesPupitre1500 (v6.0) .CWK (TEXTE)Elisette RahantamalalaNo ratings yet

- SSDP Master AnswersDocument3 pagesSSDP Master AnswersElisette RahantamalalaNo ratings yet

- Cartech1500 (v6.0) .CWK (TEXTE)Document5 pagesCartech1500 (v6.0) .CWK (TEXTE)Elisette Rahantamalala100% (1)

- Eval Sheet French VersionDocument1 pageEval Sheet French VersionElisette RahantamalalaNo ratings yet

- Eval SheetDocument1 pageEval SheetElisette RahantamalalaNo ratings yet

- M02 - SIS Orientation and IntroductionDocument3 pagesM02 - SIS Orientation and IntroductionElisette RahantamalalaNo ratings yet

- External Assessment SpecificationsDocument8 pagesExternal Assessment SpecificationsElisette RahantamalalaNo ratings yet

- SSDP QuestionnaireDocument4 pagesSSDP QuestionnaireElisette RahantamalalaNo ratings yet

- QualificationDocument7 pagesQualificationElisette RahantamalalaNo ratings yet

- Exercise 2Document3 pagesExercise 2Elisette RahantamalalaNo ratings yet

- SIS Test-LearnDocument3 pagesSIS Test-LearnElisette RahantamalalaNo ratings yet

- SIS Test Master-InstrDocument3 pagesSIS Test Master-InstrElisette RahantamalalaNo ratings yet

- Exercise 1Document3 pagesExercise 1Elisette RahantamalalaNo ratings yet

- 03 SIS - InstrDocument45 pages03 SIS - InstrElisette RahantamalalaNo ratings yet

- A701LDocument2 pagesA701LElisette RahantamalalaNo ratings yet

- House Rules For Apprentices 2017 - ApprenticeDocument1 pageHouse Rules For Apprentices 2017 - ApprenticeElisette RahantamalalaNo ratings yet

- BUS001-Instructor Guide-V5Document28 pagesBUS001-Instructor Guide-V5Elisette RahantamalalaNo ratings yet

- WS002 PM 250 HeuresDocument6 pagesWS002 PM 250 HeuresElisette Rahantamalala100% (1)

- TAAL 01 Workplace Performance Rating FormDocument6 pagesTAAL 01 Workplace Performance Rating FormElisette RahantamalalaNo ratings yet

- WS003 PM 500 HeuresDocument8 pagesWS003 PM 500 HeuresElisette RahantamalalaNo ratings yet

- Live Work Elimination FRSDocument9 pagesLive Work Elimination FRSElisette RahantamalalaNo ratings yet