Professional Documents

Culture Documents

Qpro 4aa Engls 120401

Uploaded by

Mehar Tariq GoheerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qpro 4aa Engls 120401

Uploaded by

Mehar Tariq GoheerCopyright:

Available Formats

Chapter

4Aa Drum

Sec 1 Adjustment Standard

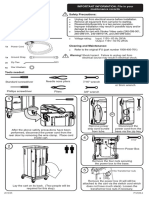

1-1 Removing & Mounting the Drum

1. Remove A and loosen B on the drum wheel Drum nut

setting screw.

Screw A

2. Remove the three screws C.

3. Pull off drum wheel. Screw B

* If the drum wheel is secured too tightly and cannot

be pulled off, refer to the section below “When the Drum wheel

drum wheel is hard to pull off.”

4. Remove drum nut (left screw) using the drum 1

Sec

nut wrench and pull off the drum.

* To mount the drum, perform the removal procedure

in reverse order. Screw C

During the mounting procedure, be

sure to follow the steps in order (in Drum nut

reverse): 2., 1., etc. If the steps are wrench

not followed in order, it could strain

the drum motor and lead to damage

or failure.

When the Drum Wheel is Hard to Pull Off Wheel removal tool

1. Fix the drum wheel with the three screws C,

using the special “wheel removal” tool. Screw C

2. Support the “wheel removal” tool using a

rod-shaped tool such as a screwdriver or a

wrench, and screw in the bolt (HC M8 × 50).

Bolt

* If there is a risk of the drum wheel breaking when

screwing in the bolt (HC M8 × 50), use the three

bolts (HC M5 × 8) to screw in the side E of the

wheel removal tool in the figure on the right. E

3. Remove the drum wheel while holding onto the

“wheel removal” tool.

- Do not use or tap with a hammer to remove the drum.

- Do not disassemble the internal part of the drum motor.

- Make sure the setting screws are positioned precisely and fastened securely on

the D cut side of the drum motor shaft when mounting the drum wheel. If they

are not positioned precisely or fastened securely, it could cause the drum to

accidentally stop or malfunction. In addition, when removing the drum, the drum

wheel sometimes gets stuck and is hard to pull off.

1 Doc No. P205

Chapter 4Aa Version 120401

1-2 Drum Pulse Sensor

If a drum sensor alarm occurs, loosen and adjust the

setting screw so the space between the drum pulse

sensor and the sensor magnet is between 0.1 and 0.3

mm.

Pulling off the connector when

the power is on can damage the

parts. 0.1 to 0.3 mm

When pulling off the connector

during a sensor replacement or

during a motor removal, first be

sure to turn OFF the main switch

on the machine.

1

Sec

Setting screw

1-3 Switching the Pac Wind

Pac Wind Overview

The traverse solenoid for the drum wind can be switched ON and OFF in the VOS settings under “Pac21 Basic

Drum.”

For high speed unwinding, the traverse solenoid turns ON and OFF depending on the ribbon diameter, and as

a result, a ribbonless package can be produced.

(For Pac-A, C and D)

[Wind Switching & Winding Settings] (For Pac-A, C and D)

“Pac21 Basic Drum” settings

Traverse solenoid operation Winding

(VOS settings)

2.5 W Always OFF 2.5 W

2W Always ON 2W

* For Pac-B, it turns ON with 2 W and OFF with 1.5 W.

Traverse solenoid

Yarn guide

If the “Pac21 Basic Drum” in the VOS

settings is 2 W, it moves to the left

position, and in the case of 2.5 W, it

moves to the right position.

2 Doc No. P205

Chapter 4Aa Version 120401

Pac Wind Fitting Position

When the traverse solenoid turns ON and OFF, the

yarn guide position is determined by the traverse guide

position.

[Reference Position]

Length A A

Drum Traverse guide

Pac-A Pac-A, C 57 mm

Pac-B Pac-B, D 57.5 mm

Pac-C Pac-A, C 57 mm

Pac-D Pac-B, D 57.5 mm Traverse guide

6" 2 W 6" 2 W

57 mm

5" 3/4 2 W 5" 3/4 2 W

1

Sec

* The configuration of each traverse guide varies as shown below.

Pac-A, C Pac-B, D 6" 2 W

5" 3/4 2 W

There is a D

mark.

3 Doc No. P205

Chapter 4Aa Version 120401

1-4 Drum Feeler

The drum feeler detects drum lapping or entanglement when there is a yarn break near the drum.

Feeler lever

1

Sec

1. Put the feeler lever in the “bracket lock

position” (figure on right), and adjust bolt A

so the space between the feeler lever and the

drum is between 0.3 and 0.5 mm. 0.3 to 0.5 mm

* If the lever is not put in the “bracket lock position,”

the bolt may become loose.

2. When the drum rotates, make sure that the

feeler lever does not vibrate or come into

contact with the drum.

Bracket lock position B

Bolt

4 Doc No. P205

Chapter 4Aa Version 120401

You might also like

- Drum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumDocument4 pagesDrum 1 Adjustment Standard: 1-1 Removing & Mounting The DrumMd. Hanif SanketNo ratings yet

- DRRM 31Document32 pagesDRRM 31Yurii LembergNo ratings yet

- Retroactive S System InstructionsDocument2 pagesRetroactive S System InstructionsErnesto Amezcua100% (1)

- V LogoDocument3 pagesV LogoAdrián CasarrubiasNo ratings yet

- RX-8 Propeller Shaft and Rear Drive Shaft GuideDocument43 pagesRX-8 Propeller Shaft and Rear Drive Shaft GuidefuckoffalreadyNo ratings yet

- Toshiba VTW2887Document105 pagesToshiba VTW2887thomas-stentzelNo ratings yet

- Detachable WindshieldDocument8 pagesDetachable WindshieldherbstNo ratings yet

- Front Derailleur: Dealer's ManualDocument29 pagesFront Derailleur: Dealer's Manualtester1972No ratings yet

- FCC Installation ManualDocument34 pagesFCC Installation ManualFred Van MadeNo ratings yet

- Installation Manual PDFDocument20 pagesInstallation Manual PDFAprajita KayasthaNo ratings yet

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- Guitare K&K DefinityDocument5 pagesGuitare K&K DefinityMrFerailleNo ratings yet

- Manual KTM 350 SXFDocument12 pagesManual KTM 350 SXFLeonardo LinaresNo ratings yet

- Sony XM7547 CarampDocument28 pagesSony XM7547 CaramproskobyNo ratings yet

- Cushcraft LFA-6M4EL ManualDocument12 pagesCushcraft LFA-6M4EL ManualLeonardus Suryo SuhartoNo ratings yet

- Instruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Document3 pagesInstruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Quang Pham100% (1)

- Instruction Manual-Smc 33KVDocument9 pagesInstruction Manual-Smc 33KVRAKESH CHANDRA PATRANo ratings yet

- B.Y.O.C. Wah Kit Instructions For Older Version InstructionsDocument13 pagesB.Y.O.C. Wah Kit Instructions For Older Version InstructionsCavinti LagunaNo ratings yet

- 1.8m Dual Separate (English)Document8 pages1.8m Dual Separate (English)roger23007No ratings yet

- 7t94a Technical GuideDocument15 pages7t94a Technical GuideHemanth KumarNo ratings yet

- Toshiba VTW2187 Service ManualDocument101 pagesToshiba VTW2187 Service ManualDavid MaidmentNo ratings yet

- Rosemount 5400 Series Spare Part InstructionDocument14 pagesRosemount 5400 Series Spare Part InstructionEdinsonUribeTorresNo ratings yet

- Denon AVR-4810 - CIDocument245 pagesDenon AVR-4810 - CIrd6i100% (1)

- Align AL CE500P ManualDocument15 pagesAlign AL CE500P Manualreginaldo020471No ratings yet

- C653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageDocument2 pagesC653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageAyub SetiawanNo ratings yet

- Despiece Samsung WD6500Document10 pagesDespiece Samsung WD6500MartinianoNo ratings yet

- Chrome Handlebar Switch Cap Kits: GeneralDocument5 pagesChrome Handlebar Switch Cap Kits: GeneralPhillAv1No ratings yet

- Shimano Tiagra 4600Document1 pageShimano Tiagra 4600Florian JurinNo ratings yet

- Power Cord REF 240-099-069: in This KitDocument2 pagesPower Cord REF 240-099-069: in This KitRaymundo Olayo EspírituNo ratings yet

- Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXXDocument16 pagesHhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXXAnthony ColemanNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- Kenwood DV-403 DVD Player SMDocument48 pagesKenwood DV-403 DVD Player SMRoger Martínez BermúdezNo ratings yet

- Technics sl1200 Service ManualDocument6 pagesTechnics sl1200 Service ManualCarpet DriverNo ratings yet

- 03 Disassembly and ReassembleDocument6 pages03 Disassembly and ReassembleLuisMiguelCalvoNo ratings yet

- Canonet GIII 17Document4 pagesCanonet GIII 17Jose Paulo Martins NarcisoNo ratings yet

- 90 MM 1Document6 pages90 MM 1Pedro PgNo ratings yet

- SD 951Document11 pagesSD 951Stirban RaulNo ratings yet

- Service Information: Trek Madone 7-Series Brake AssemblyDocument4 pagesService Information: Trek Madone 7-Series Brake AssemblyLucasNo ratings yet

- 2005 S60 Front Cig Socket RemoveDocument2 pages2005 S60 Front Cig Socket RemoveЙордан ПетровNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- E600 User Manual v1.04 enDocument4 pagesE600 User Manual v1.04 enluisNo ratings yet

- Maestro Owners ManualDocument35 pagesMaestro Owners ManualDomenico RaffaNo ratings yet

- Samsung UE65HU7500L Chassis U8GADocument68 pagesSamsung UE65HU7500L Chassis U8GALuiz Roberto Honório Alves FilhoNo ratings yet

- Installation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselsDocument6 pagesInstallation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselscarteauNo ratings yet

- Power Booster: Section 4CDocument13 pagesPower Booster: Section 4CJarry PotterNo ratings yet

- 3-1. Tools For Disassembly and ReassemblyDocument19 pages3-1. Tools For Disassembly and ReassemblyMhooMOoChaappHteenNo ratings yet

- Exel Spring Reel IomDocument12 pagesExel Spring Reel IomstephenNo ratings yet

- Tilt Steering Column Removal and Disassembly GuideDocument12 pagesTilt Steering Column Removal and Disassembly GuideNicolás CastiblancoNo ratings yet

- Raymariner ManualDocument8 pagesRaymariner ManualMarcel SchumannNo ratings yet

- Control Panel: Installation and User's Manual Installasjon Og Brukermanual InstallationsanleitungDocument16 pagesControl Panel: Installation and User's Manual Installasjon Og Brukermanual InstallationsanleitungAsep TatangNo ratings yet

- EG-112 ManualDocument14 pagesEG-112 ManualpetropaoNo ratings yet

- Ap900 Manual - enDocument32 pagesAp900 Manual - enCarlos Javier MirandaNo ratings yet

- Sangean 803A FAQDocument43 pagesSangean 803A FAQAntonius HaryantoNo ratings yet

- Description: WarningDocument7 pagesDescription: WarningmaxNo ratings yet

- Raystar 125 - 81247 - 3Document8 pagesRaystar 125 - 81247 - 3CARDONNo ratings yet

- Chain (11-Speed) : Dealer's ManualDocument10 pagesChain (11-Speed) : Dealer's ManualCNo ratings yet

- Imo-202en 01-12Document8 pagesImo-202en 01-12HASBUL AZIZI BIN MAHMUNNo ratings yet

- Horns: Section 9CDocument5 pagesHorns: Section 9CJarry PotterNo ratings yet

- PROCESS CONER II Maintenance GuideDocument24 pagesPROCESS CONER II Maintenance GuideMd. Hanif SanketNo ratings yet

- Re-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionDocument4 pagesRe-Tie Pipe 1 Adjustment Standard: 1-1 Clamp Angle & PositionMd. Hanif SanketNo ratings yet

- PC Sensor: WarningDocument2 pagesPC Sensor: WarningMd. Hanif SanketNo ratings yet

- Inverter MannualDocument35 pagesInverter MannualMehar Tariq GoheerNo ratings yet

- Adjust compressed air and winding parts on packaging machineDocument10 pagesAdjust compressed air and winding parts on packaging machineMd. Hanif SanketNo ratings yet

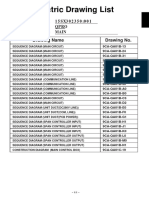

- Electric DrawingsDocument34 pagesElectric DrawingsMehar Tariq GoheerNo ratings yet

- 7 Fuel SystemDocument21 pages7 Fuel SystemMehar Tariq GoheerNo ratings yet

- 8-Lubricating Oil SystemDocument20 pages8-Lubricating Oil SystemMehar Tariq GoheerNo ratings yet

- Qpro 4fa Engls 120401Document2 pagesQpro 4fa Engls 120401Mehar Tariq GoheerNo ratings yet

- 9 Cooling SystemDocument11 pages9 Cooling SystemMehar Tariq GoheerNo ratings yet

- 5-Cameshaft Drive Train & Tappet BlockDocument23 pages5-Cameshaft Drive Train & Tappet BlockMehar Tariq GoheerNo ratings yet

- 15-Parts List ELS12 MK2Document150 pages15-Parts List ELS12 MK2Mehar Tariq GoheerNo ratings yet

- 2 Technical DataDocument10 pages2 Technical DataMehar Tariq GoheerNo ratings yet

- 6-Air Inlet & Exhaust SystemDocument10 pages6-Air Inlet & Exhaust SystemMehar Tariq GoheerNo ratings yet

- 3-Crankcase & CrankshaftDocument41 pages3-Crankcase & CrankshaftMehar Tariq GoheerNo ratings yet

- 0 Instruction ManualDocument419 pages0 Instruction ManualMehar Tariq Goheer100% (2)

- Temp 1000 New ManualDocument54 pagesTemp 1000 New ManualMehar Tariq GoheerNo ratings yet

- 4-Cylinder Head Piston Coneecting Road & LinerDocument44 pages4-Cylinder Head Piston Coneecting Road & LinerMehar Tariq GoheerNo ratings yet

- Index: User's Manual Fully Automatic Washing MachineDocument16 pagesIndex: User's Manual Fully Automatic Washing MachineMehar Tariq GoheerNo ratings yet

- Washing Machine: Installation, 2-3 F ARDocument36 pagesWashing Machine: Installation, 2-3 F ARMehar Tariq GoheerNo ratings yet

- 1-Introduction ESL12 MK2Document9 pages1-Introduction ESL12 MK2Mehar Tariq GoheerNo ratings yet

- Manual Temp R Tron 620 en 23dec2016Document56 pagesManual Temp R Tron 620 en 23dec2016Mehar Tariq GoheerNo ratings yet

- Temp O Tron User Manual UrduDocument6 pagesTemp O Tron User Manual UrduMehar Tariq GoheerNo ratings yet

- Temp R-Tron 612 Version 2.2 U Operation ManualDocument41 pagesTemp R-Tron 612 Version 2.2 U Operation ManualMehar Tariq GoheerNo ratings yet

- Honda CG125Document2 pagesHonda CG125Mehar Tariq Goheer100% (3)

- Manual Temp R Tron en 01 Sep 2016Document23 pagesManual Temp R Tron en 01 Sep 2016Mehar Tariq GoheerNo ratings yet

- UN1020 User ManualDocument172 pagesUN1020 User ManualMehar Tariq GoheerNo ratings yet

- Electrical Engineer: Tariq Maqsood TabassamDocument5 pagesElectrical Engineer: Tariq Maqsood TabassamMehar Tariq GoheerNo ratings yet

- Honda CD 70 Urdu-2Document30 pagesHonda CD 70 Urdu-2Mehar Tariq Goheer100% (7)

- 555-Timer AStable and MonostableDocument13 pages555-Timer AStable and MonostableenzuekNo ratings yet

- Solahart Domestic Heat Pump - Sample CatalogueDocument2 pagesSolahart Domestic Heat Pump - Sample CatalogueManju NaikNo ratings yet

- Technical Service Information: THM 4T65EDocument10 pagesTechnical Service Information: THM 4T65EJose garcua vargas 2006401321No ratings yet

- Accident StoryDocument2 pagesAccident StoryMa. Aiza SantosNo ratings yet

- Sanyo Denki 1Document351 pagesSanyo Denki 1kaosdelosandesNo ratings yet

- 5MP76341Document64 pages5MP76341eliminar2024No ratings yet

- Allen Bradley Catalog Wiring SystemsDocument189 pagesAllen Bradley Catalog Wiring SystemsAlphaNo ratings yet

- Digital Rheostat DS1669 Technical OverviewDocument10 pagesDigital Rheostat DS1669 Technical Overviewpedro santosNo ratings yet

- VX 2628 Water TruckDocument2 pagesVX 2628 Water TruckTiago Alves0% (1)

- HP 2509m Flat Panel Monitor DesarmadoDocument27 pagesHP 2509m Flat Panel Monitor DesarmadoEdwin EliasNo ratings yet

- KAMAI 500: Quick Connect GuideDocument1 pageKAMAI 500: Quick Connect GuideIonNo ratings yet

- Float Type Level SwitchDocument8 pagesFloat Type Level SwitchRupesh Kumar SINGHNo ratings yet

- Exhaust+manifold+isx+15 PDFDocument10 pagesExhaust+manifold+isx+15 PDFPototoNo ratings yet

- Electrical ReviewerDocument16 pagesElectrical ReviewerPrincess Diana ArrojadoNo ratings yet

- M Series Spares Catalogue - Issue 7Document6 pagesM Series Spares Catalogue - Issue 7luongnamNo ratings yet

- Zenit Steel Series Electric Submersible Pumps enDocument2 pagesZenit Steel Series Electric Submersible Pumps enedekovacsNo ratings yet

- 110V DC Battery Sizing Calculation For 132/11kV Primary Substation For Tender Purpose OnlyDocument10 pages110V DC Battery Sizing Calculation For 132/11kV Primary Substation For Tender Purpose OnlyDundikumarNo ratings yet

- Shihlin Temperature Controler WT Series ManualDocument110 pagesShihlin Temperature Controler WT Series ManualKristine Grace LimatoNo ratings yet

- BT Lecture Notes 11102020Document14 pagesBT Lecture Notes 11102020Junell LimNo ratings yet

- Motors MAN Part Books PDFDocument158 pagesMotors MAN Part Books PDFAli Gujir100% (3)

- PL Valve & FittingDocument11 pagesPL Valve & FittingHasanNo ratings yet

- AC Compressor PAG Oil Application ChartDocument1 pageAC Compressor PAG Oil Application ChartDraganNo ratings yet

- Brkarc-3470Document58 pagesBrkarc-3470Dicky ArdiansyahNo ratings yet

- Ford Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Document4 pagesFord Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Alex CastilloNo ratings yet

- Diagaram Panel RtuDocument16 pagesDiagaram Panel Rtusayful ykNo ratings yet

- Tranquility 27 (TT) Series Tranquility 20 (TS) Series Tranquility 16 (TC) Series Tranquility (TR) SeriesDocument84 pagesTranquility 27 (TT) Series Tranquility 20 (TS) Series Tranquility 16 (TC) Series Tranquility (TR) SeriesMichael MartinNo ratings yet

- ns2584 BollardsDocument1 pagens2584 Bollardscoc verificationNo ratings yet

- Product - Information - MI06-S-XX-400 V1.6Document2 pagesProduct - Information - MI06-S-XX-400 V1.6Jorge MorenoNo ratings yet

- Push-Pull ConverterDocument3 pagesPush-Pull ConverterBill YoungNo ratings yet

- Part Service Sany SY55Document1 pagePart Service Sany SY55Iman SantosaNo ratings yet