Professional Documents

Culture Documents

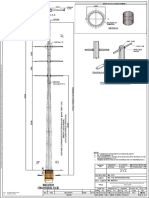

Gi Pipe Shoring

Uploaded by

Agus SudianaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gi Pipe Shoring

Uploaded by

Agus SudianaCopyright:

Available Formats

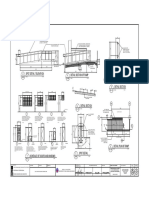

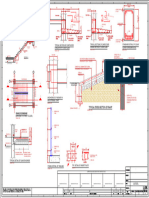

CONCRETE SLAB

General (GI Pipe Shoring)

TO CAST 300MM

300

200

1000 THK MAX. SEE DETAIL A

1. Gravlock coupler arrangements attached

to a horizontal “I beam” steelwork lower

position. This arrangement can also be an

upper position.

2. Gravlock couplers must be used in

250

TIE TO opposing pairs or box the beam with tube

STRUCTURE to prevent movement.

EVERY TIE TO STRUCTURE 3. Check fittings require to be installed

2 BAY EVERY 2 BAY AND 2 immediately above the suspension point

1500

AND 2 LIFTS and immediately below the bottom ledger.

LIFTS (2 OPPOSITE SIDES) 4. To lengthen a standard, additional

6000 Max.

6000 Max.

6000 Max.

standard to be attached to a minimum of 2

horizontal ledger or guardrails within

300mm from the standard. Check clips are

used above the ledger and below the

ledger supporting the standard.

DIAGONAL BRACE 5. ‘T bar’ type arrangement can be used

(All Sides) approximately 1.0m below the bottom

ledger for scaffolder to stand or sit on

1500

1500

1500

while the base lift of scaffold is erected

and dismantle.

6. At Least one Diagonal braces shall be

250

provided at every axis and properly

clamped at both ends.

7. Installation of guardrails, toe boards and

1200 1200 1200 1200 1200 1200 1000 1500 1500 1500 1500

(max.) steel ladder shall deem to be included

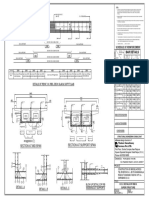

Shoring Support for Beam although they may not be shown on

Shoring Support for Beam Shoring Support for Slab drawings.

(Along Beam) 8. Single guardrail can be installed to replace

(Across Beam) (Leg Spacing Both Directions)

the toe boards should there be frequent

movement of men and materials.

9. No alternation and modification of the

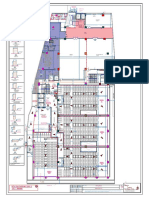

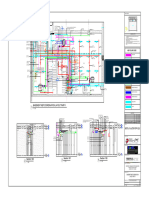

1200 1200 1200 1200 2.0M BLDG. SETBACK LINE scaffold structure is allowed. Any

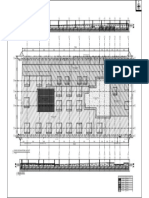

2TW1

day-to-day alternation and modification

(Ø300mm) W4 W5 must be pre informed to PROEN qualified

W3

1000

scaffold supervisor, who shall be

(1000x300) CONCRETE SLAB/BEAM responsible for the work done and verify

2000 (1000x300) 1500

1500 1500 1500 1500 1500 1500 1500

1000 safe for use, prior to accessing the

1200

SECONDARY RUNNER RHS

1000 (200x500) (200x500) scaffold.

LINE

25 50X75X3MM THK @ 300 O.C.

1500

1500

2TC3 2TC4

E LINE

2TC1 2TC2 (200x500) (200x500) WITH 16MM PLYWOOD

K

1200

(200x500) (200x500)

2.0M BLDG. SETBAC

PRIMARY RUNNER

E / ROAD RESERV

1 NO. RHS 50X75X3MM THK

(1000x300)

1500

U-HEAD

1500

1200

JACK STANDARDS

250

200 LW

GI PIPE 48.6mm DIA. X

W7 2.4mm THK (TOP ONLY)

1500

1200

1500

SITE BOUNDARY LIN

LEDGER/TRANSOM

(1000x300) 2TW2 2TW3

(Ø300mm) GI PIPE 48.6mm DIA. X

1000

2.4mm THK (TOP ONLY)

1000

25

(Ø300mm) (Ø300mm) (Ø300mm) W11

2175

2175

1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 TIE TO STRUCTURE

2TC5 2TC6 EVERY 2 BAY AND 2

DETAIL A LIFTS

(Ø300mm) (Ø300mm) 150

PLAN VIEW (2 OPPOSITE SIDES)

ARCHITECH CONSTRUCTION

PTE LTD. 729 MOUNTBATTAN ROAD PROJECT GI PIPE SHORING

Remarks: If any modification is required, only the Structural scaffold material standard : STK 500, O.D 48.6mm

scaffolding supervisor allowed to modify in accordance with X 2.5mm Thickness (Structure)

the WSH scaffolding regulations. And PE instruction Fittings : BS1139 Couplers (PROEN Brand) 729 MOUNTBATTAN ROAD

You might also like

- Typical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamDocument1 pageTypical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamAlbert GalagNo ratings yet

- CBP Wall - DWGDocument1 pageCBP Wall - DWGsambasivammeNo ratings yet

- Ms6001b Operation DescriptionDocument53 pagesMs6001b Operation Descriptionprasad503486% (7)

- Passat No. 13/1: Comfort System, With Alarm SystemDocument16 pagesPassat No. 13/1: Comfort System, With Alarm SystemLuix TiradoNo ratings yet

- Alex FNLDocument1 pageAlex FNLjosephNo ratings yet

- Farmhouse ArchitectureDocument1 pageFarmhouse ArchitectureMANNANo ratings yet

- 5% Slope 5% Slope: Typical Doghouse Detail For Cold Water Pipe Typical Doghouse Detail For Fire Fighting PipeDocument1 page5% Slope 5% Slope: Typical Doghouse Detail For Cold Water Pipe Typical Doghouse Detail For Fire Fighting PipeNitin BuZz100% (1)

- Cross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Document1 pageCross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Atul Kumar MishraNo ratings yet

- Aps 1Document1 pageAps 1Akash MohantyNo ratings yet

- WL100-GA - Rev 01Document1 pageWL100-GA - Rev 01affendy roynNo ratings yet

- Quotation Drawing - 220kV - PDT60+12Document1 pageQuotation Drawing - 220kV - PDT60+12Jaikishan RaiNo ratings yet

- Rly. Platform DrawingDocument1 pageRly. Platform DrawingAtul Kumar MishraNo ratings yet

- Lighting Plan - Unicef Soba WarehouseDocument1 pageLighting Plan - Unicef Soba WarehouseMohammed EL-Montasir AwadallahNo ratings yet

- RB A225 Approval Rev 1 - 13 13Document1 pageRB A225 Approval Rev 1 - 13 13TariqMahmoodNo ratings yet

- Kamalendu Dey & Others (G 3) BabulalDocument1 pageKamalendu Dey & Others (G 3) BabulalSarbani MukhopadhyayNo ratings yet

- Hydraulic Hatch Drawings With Pending ExcelDocument4 pagesHydraulic Hatch Drawings With Pending ExcelTarek TarekNo ratings yet

- Notes:: Water Line Gate Valve DetailDocument1 pageNotes:: Water Line Gate Valve DetailDJNo ratings yet

- 3 Fifth FloorDocument1 page3 Fifth FloorRanu GaurNo ratings yet

- P203 Sie DWG 008 Arc 500001Document1 pageP203 Sie DWG 008 Arc 500001viswanathanNo ratings yet

- ALEXISDocument1 pageALEXISjosephNo ratings yet

- Half Elevation of P.S.C Girder: Construction DrawingsDocument1 pageHalf Elevation of P.S.C Girder: Construction DrawingsAqib JavidNo ratings yet

- Spot Detail 1 Elevation Detail Section of RampDocument1 pageSpot Detail 1 Elevation Detail Section of RampMalson GutierrezNo ratings yet

- DTF Structural DrawingsDocument35 pagesDTF Structural Drawings宋海波No ratings yet

- Fire Fighting ModelDocument1 pageFire Fighting ModelPrashantNo ratings yet

- DJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1Document1 pageDJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1info.infinitytechnicalNo ratings yet

- 4217-Csd-C-1a-0405-Rc-Enlarge Plan & Sections - Entrance GateDocument1 page4217-Csd-C-1a-0405-Rc-Enlarge Plan & Sections - Entrance GateAdi PriyapurnatamaNo ratings yet

- WRN STD 005aDocument1 pageWRN STD 005afekeceh343No ratings yet

- Detail 3 - Stair DetailsDocument1 pageDetail 3 - Stair DetailsManoj JaiswalNo ratings yet

- NP p1b Teth DWG Civ 0112.01.ifr RNCDocument6 pagesNP p1b Teth DWG Civ 0112.01.ifr RNCSipaseut OudomsoukNo ratings yet

- Ngwebu Zaka RDocument1 pageNgwebu Zaka RMunyaradziNo ratings yet

- Proposed Landscape Design For Shailesh CHS, Nerul: Option-2Document2 pagesProposed Landscape Design For Shailesh CHS, Nerul: Option-2shalmi12No ratings yet

- 3.0m Flood Prone Pad Plan BOQDocument3 pages3.0m Flood Prone Pad Plan BOQAngel SalaganNo ratings yet

- Detail Cable Ladder Wall Mounting: Sedimentation TankDocument1 pageDetail Cable Ladder Wall Mounting: Sedimentation TankjackNo ratings yet

- Desalination Plant Asbuilt A1Document1 pageDesalination Plant Asbuilt A1Berlin Andrew SionNo ratings yet

- Section X-X Section Y-Y: Typical Plan of Proposed Construction of Tower Wagon Shed (8-WHEELER)Document1 pageSection X-X Section Y-Y: Typical Plan of Proposed Construction of Tower Wagon Shed (8-WHEELER)Manoj H MNo ratings yet

- Exterior DetailsDocument1 pageExterior DetailsBudi SimatupangNo ratings yet

- GB-1 Beam Details: LevelDocument1 pageGB-1 Beam Details: Levelsoe.earlvincevalerosoNo ratings yet

- Top of Wall: +2370 MM RL 260Document7 pagesTop of Wall: +2370 MM RL 260ascdfgNo ratings yet

- JP305821Document7 pagesJP305821alexanderNo ratings yet

- Auto Paper 01 PDFDocument1 pageAuto Paper 01 PDFAshiraf sserugoNo ratings yet

- A C B A C B: Blow-Up Section of StairsDocument1 pageA C B A C B: Blow-Up Section of Stairsflor johnNo ratings yet

- LUXURIOUS ELEVATORS BOSS RESIDENCY CEIG DRG PAGE 02-Layout1Document1 pageLUXURIOUS ELEVATORS BOSS RESIDENCY CEIG DRG PAGE 02-Layout1Sarfaraz ShaikhNo ratings yet

- Floor Plan Layout: HallwayDocument1 pageFloor Plan Layout: HallwayClynne Jay DespiNo ratings yet

- Crif Door Window Detail-601Document1 pageCrif Door Window Detail-601surbhi aggarwalNo ratings yet

- ARGARIN HAWS AR2 Layout2Document1 pageARGARIN HAWS AR2 Layout2Angely LudoviceNo ratings yet

- 6904132-ELE (1) 11-06 LRDocument8 pages6904132-ELE (1) 11-06 LRЭрнест БекировNo ratings yet

- DW Asme Bpe Us 0Document37 pagesDW Asme Bpe Us 0Haries Bugarin Garcia100% (2)

- Basic Structuraaal-20x30.3Document1 pageBasic Structuraaal-20x30.3Jom Asagra100% (1)

- SSS5434 - CC-05-SECOND FLOOR FRAMING PLAN - Rev 5Document1 pageSSS5434 - CC-05-SECOND FLOOR FRAMING PLAN - Rev 5PEng. Tech. Alvince KoreroNo ratings yet

- 206-Sheet - S 100 C - Excavation Layout-Layout1Document1 page206-Sheet - S 100 C - Excavation Layout-Layout1sameer khanNo ratings yet

- Teja Restaurant: BonfireDocument3 pagesTeja Restaurant: BonfireKomang Capung SugiartaNo ratings yet

- Tanvi Charde WD - 6th SemDocument11 pagesTanvi Charde WD - 6th SemAparna MahajanNo ratings yet

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 page04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiNo ratings yet

- Community Water Point - and Washing PlaceDocument1 pageCommunity Water Point - and Washing PlaceRic ReeNo ratings yet

- Maddy 4Document1 pageMaddy 4madhuvanthis21No ratings yet

- 473 2016 - Addendum - 4 Drawing - C2 BS 003 R1Document1 page473 2016 - Addendum - 4 Drawing - C2 BS 003 R1abdelhakNo ratings yet

- APT Shoring Drawings From Various ProjectDocument15 pagesAPT Shoring Drawings From Various ProjectBinSayeedNo ratings yet

- OMBURU - Platform For BESS - RevE - 220930Document1 pageOMBURU - Platform For BESS - RevE - 220930Young R-j MafaraNo ratings yet

- gnss-sp-26.790 - Model - PDF GenDocument1 pagegnss-sp-26.790 - Model - PDF GenviswanathNo ratings yet

- Section 1-1 Section 2-2: Detail - A Detail - BDocument1 pageSection 1-1 Section 2-2: Detail - A Detail - BRutik PatelNo ratings yet

- B787-9 VistaraDocument8 pagesB787-9 VistaraSandmanNo ratings yet

- PLAN - 160 SIN MING 05-12 - 03 - Type A1b - SPDocument1 pagePLAN - 160 SIN MING 05-12 - 03 - Type A1b - SPAgus SudianaNo ratings yet

- 1 Column 1C9Document71 pages1 Column 1C9Agus SudianaNo ratings yet

- 1 Design Calculation Cover AccessDocument5 pages1 Design Calculation Cover AccessAgus SudianaNo ratings yet

- Horizontal Vertical Horizontal Moment FX KN Fy KN FZ KN MX-KN.MDocument4 pagesHorizontal Vertical Horizontal Moment FX KN Fy KN FZ KN MX-KN.MAgus SudianaNo ratings yet

- Horizontal Vertical Horizontal Moment FX KN Fy KN FZ KN MX-KN.MDocument4 pagesHorizontal Vertical Horizontal Moment FX KN Fy KN FZ KN MX-KN.MAgus SudianaNo ratings yet

- Boiling MechanismDocument16 pagesBoiling MechanismherawanadifNo ratings yet

- Assignment 2 Ce Law Ethics Contracts Midterm - 103742Document13 pagesAssignment 2 Ce Law Ethics Contracts Midterm - 103742Myka SanchezNo ratings yet

- Roof Manual p10Document1 pageRoof Manual p10AllistairNo ratings yet

- Pre Accion PDFDocument8 pagesPre Accion PDFjhoger2012No ratings yet

- Projects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationDocument2 pagesProjects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationAjay DuranNo ratings yet

- Overview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Document3 pagesOverview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Sravan Kumar PendyalaNo ratings yet

- QC of Continuous Flight Auger PilesDocument1 pageQC of Continuous Flight Auger Pilesnischal_babuNo ratings yet

- AEC UPS Catalogue 2020Document46 pagesAEC UPS Catalogue 2020Алексей БабинNo ratings yet

- Raymond Scott - Cindy ElectroniumDocument2 pagesRaymond Scott - Cindy ElectroniumJen HillNo ratings yet

- StoichiotryDocument57 pagesStoichiotryJezriel Theana SisonNo ratings yet

- HPSIM Command Line InterfaceDocument107 pagesHPSIM Command Line Interfacegverma80No ratings yet

- Using CHEMCAD For Piping Network Design and AnalysisDocument51 pagesUsing CHEMCAD For Piping Network Design and AnalysisRawlinsonNo ratings yet

- FRP Fish TanksDocument33 pagesFRP Fish TanksA.Subin DasNo ratings yet

- Vineeth - Curriculum VitaDocument8 pagesVineeth - Curriculum VitaVineeth NBNo ratings yet

- Revision Question Bank ME 2204Document11 pagesRevision Question Bank ME 2204Rajendra Kumar YadavNo ratings yet

- Build Your First Mobile Flex Application: Lab ExercisesDocument37 pagesBuild Your First Mobile Flex Application: Lab ExercisesSrdjan MarjanovicNo ratings yet

- Manhattan Associates Technical Placement Paper Level1Document7 pagesManhattan Associates Technical Placement Paper Level1placementpapersampleNo ratings yet

- Engineering Journal::Review On Cold Rolling Mill Roll DeformationDocument8 pagesEngineering Journal::Review On Cold Rolling Mill Roll DeformationEngineering JournalNo ratings yet

- LCD Monitor DC T201WA 20070521 185801 Service Manual T201Wa V02Document59 pagesLCD Monitor DC T201WA 20070521 185801 Service Manual T201Wa V02cdcdanielNo ratings yet

- Chapter 4. FRC Manufacturing - Fundamental ConceptsDocument5 pagesChapter 4. FRC Manufacturing - Fundamental ConceptsNarendra GadkariNo ratings yet

- Paver BlockDocument16 pagesPaver BlockRavinder Singh100% (1)

- Finals DSP WithMinimalErrors PDFDocument64 pagesFinals DSP WithMinimalErrors PDFanembam putobungbongNo ratings yet

- Maryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIIDocument12 pagesMaryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIISourabh PradhanNo ratings yet

- What We Offer.: RemunerationDocument8 pagesWhat We Offer.: Remunerationsurabhi mandalNo ratings yet

- FRA5310 TechDocument2 pagesFRA5310 TechBash MatNo ratings yet

- Classification Matter Flow ChartDocument1 pageClassification Matter Flow ChartKiera CeelyNo ratings yet

- HARMAN Infinity Processing White PaperDocument2 pagesHARMAN Infinity Processing White PaperSound Technology LtdNo ratings yet

- PRO-II Thermodynamic Model SelectionDocument79 pagesPRO-II Thermodynamic Model Selectionchemsac2100% (1)