Professional Documents

Culture Documents

Bizhub - c658 INSTALLATION MANUAL

Uploaded by

童子軍Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bizhub - c658 INSTALLATION MANUAL

Uploaded by

童子軍Copyright:

Available Formats

/ /

INSTALLATION MANUAL

Applied Machines: / /

<Important>

Be sure to correctly follow the procedures in order as explained in this Installation Manual.

If you do not follow the procedure in order, the image trouble may occur.

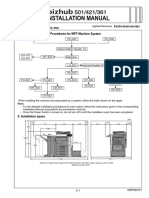

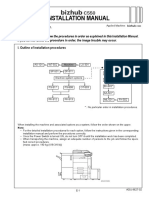

1. Outline of installation procedures

HT-509 MK-734

TK-101

PC-115 PC-215 PC-415 DK-510 DK-705

KP-101 MK-730

Machine Electronic system options

KH-102 LU-207

EK-609*1 EK-608*1

LU-302

SP-501

HD-524*1

UK-501

UK-212*1

Electronic system options

SC-508*1

MK-735

FK-514

AU-102

WT-506

AU-201S IC-416 VI-510

CU-102

*1: No particular order in

FK-515*2 MK-742*2

installation procedures.

*2: Varies depending on the

FS-533*3 JS-506*3 OT-506 RU-513

applicable marketing area

*3:

C558/C458 only

PK-519*3 FS-536 FS-536SD FS-537 FS-537SD

PK-520 ZU-609

PI-507 JS-602

PK-523

When installing the main body and associated options as a system, follow the order shown on the upper.

Caution:

• Lifting the main body in an awkward position or transporting it in a poorly balanced position could result in

personal injury. When transporting the main body, assign an adequate number of persons to the job and

ensure that each person can take a good position of not being excessively loaded.

(mass: approx. 110 kg (242-1/2 lb))

Note:

• For the detailed installation procedures for each option, follow the instructions given in the corresponding

installation manual and perform the procedures correctly.

• When placing the main body on the floor, make sure to use the paper feed cabinet or the desk to secure

the performance and the quality of the product.

• Once the Power Switch is turned ON, do not turn OFF it until the installation work has been completed.

A79J-9601-00

2016. 4 Printed in China E-1

Downloaded from www.Manualslib.com manuals search engine

2. Installation space (unit: mm (inch)) 4. Notes on using touch panel

bizhub C658 + PC-215 + FS-537SD + LU-207 Be sure to instruct users on the following points.

2477 • This machine uses a capacitive touch panel.

(97-1/2) When you touch the touch panel, use your fin-

781 1244 452 ger or the stylus pen supplied with the machine.

(30-3/4) (49) (17-13/16)

If you touch the panel using your nail or a pen

tip instead of using your finger or the stylus pen,

the touch panel does not respond normally.

• Pressing the touch panel hard may cause dam-

age.

• Do not strongly press the panel or press it using

the sharp tip of mechanical pencils.

• The key is a finger tapping (quick light touch

using a finger) operation.

1267

(49-7/8)

420 847

(16-9/16) (33-3/8) 5. Accessory parts

No. Name Q’ty

(13-15/16)

353.5

1. User’s guide holder 1

2. Quick start guide 1

(61-7/16)

1560.5

3. Installation manual 1 set

(37-1/2)

953

4. User’s guide CD 1

5. CD-ROM 1 set

6. Paper size label 1

(10)

254

7. Panel sheet 1

8. Chart 1

9. Cap A (Black) 2

3. Pre-installation check items 10. Cap B (White) 2

(1) Select a level and stable place for installing the 11. Connector cover 1

machine. 12. Duct cover 1

(2) Be sure to use a power source of the voltage and

13. Cord clamp A *

frequency indicated in the product specifications.

1

Ensure that the current carrying capacity of the

power outlet is at least equal to the current listed

in the product specifications. 14. Cord clamp B

(3) Power the machine directly from a dedicated 1

power outlet. (Do not use an extension cord.)

(4) Do not plug or unplug the power cord with wet or 15. Screw A

dirty hands, otherwise you may get an electric (3 x 8 mm) 1

shock.

(5) Avoid a hot and humid environment, or a place 16. Screw B

(3 x 8 mm) 2

exposed to direct sunlight.

(6) Avoid a dusty location, or a place near volatile

17. Screw C

and flammable substances.

(3 x 30 mm) *

(7) Avoid a poorly ventilated place. 1

18. Stylus pen 1

19. Waste toner box 1

* Varies depending on the applicable marketing

area.

E-2

Downloaded from www.Manualslib.com manuals search engine

Note: 6. Installing the main body and the Paper

• Keep the paper size label at hand. It is neces-

sary for mounting the Large Capacity Unit LU- Feed Cabinet (or the Desk)

302. (1) Take the main body and the Paper Feed Cabinet

• Keep the cord clamp B at hand. It is necessary (or the Desk) out from its packaging.

for mounting the Upgrade Kit UK-212, Authenti- Caution:

cation Unit AU-201S, or Authentication Unit Main body mass: approx. 110 kg/242-1/2 lb

AU-102. • Make available collective manpower of an

appropriate size for transporting the main body.

Note:

• Remove the machine, holding it by the handles

Keep this bag away from babies and on the right and left sides as shown in the illus-

children. Do not use in cribs, beds, tration and keeping it level.

carriages, or playpens.

The thin film may cling to nose and

mouth and prevent breathing. This bag is

not a toy. When holding the transportation handles,

be careful not to catch your fingers in the

machine.

If a power cord is not supplied, use only

the power cord that meets the following

conditions.

Failure to do this could result in a fire or

electrical shock.

• The power cord has voltage and current rating

appropriate for the rating plate on this machine.

• The power cord meets regulatory requirements

for the area.

• The power cord is provided with grounding

pin/terminal.

* Power supply:

bizhub C658: 120V 16A, 220-240V 10A

bizhub C558/C458: 120V 12A, 220-240V 9A

Note:

This manual provides the illustrations of the acces-

sory parts and machine that may be slightly differ- (2) Refer to the installation manual for the Paper

ent in shape from yours. In that case, instead of Feed Cabinet (or the Desk) and follow the

the illustrations, use the appearance of your “Installation Procedures.”

machine to follow the installation procedure. This Note:

does not cause any significant change or problem If installing either the Heater HT-509, the Trans-

with the procedure. former kit TK-101, or the Power Supply BOX MK-

734, install them at the same time as the installa-

tion of the Paper Feed Cabinet (or the Desk).

E-3

Downloaded from www.Manualslib.com manuals search engine

7. Removing protective tape, packing and (2) Open the right door and remove the protective

sheet and locking materials.

other shipping materials Note:

(1) Remove the protective tape and the protective • After removing the locking materials, make sure

materials. that the transfer roller assy is secured in place.

Note: In the case of <NG>, press the transfer roller

Be sure to lock the lever after removing the protec- assy into place so that it is secured as shown in

tive tape A. <OK>.

• Save the packaging materials removed in this

and subsequent steps of (6), (8), and (14) for

later use when transporting the machine.

< OK > < NG >

A

(3) Close the right door.

(4) Slide out the tray 1.

(5) Remove the protective tapes from the inside of

the tray 1 and remove accessory parts.

Note:

See the User's Guide CD for instructions on set-

ting paper in each tray and configuring the paper

types.

E-4

Downloaded from www.Manualslib.com manuals search engine

(6) Slide out the tray 2 and remove the tray locking (10) Remove the protective sheets.

materials.

(11) Open the lower front door.

(7) Remove the protective tapes from the inside of

the tray 2 and remove accessory parts.

(12) Remove the protective tape.

(8) Remove the locking screws.

Protective tape

(9) Attach the supplied caps A and B.

E-5

Downloaded from www.Manualslib.com manuals search engine

(13) Remove the protective tape from the develop- (16) Slightly slide the drum unit (K) out and remove

ing units. the protective tape.

Note:

Do not remove the tape A in this procedure.

(17) Slide the drum unit (K) into the machine.

(18) Lock the drum unit (K) with the lever.

(14) Remove the locking materials from the four (19) Install the supplied waste toner box.

places. Note:

Push the areas indicated by the “ ” marks to set

the waste toner box to the machine.

(15) Release the lever of the drum unit (K).

(20) Close the lower front door.

E-6

Downloaded from www.Manualslib.com manuals search engine

8. Installing the toner cartridge (4) Push the toner cartridge all the way in and rotate

it clockwise to lock it.

Note: Note:

Since cartridge is not supplied with the machine, Make sure that the toner cartridge is pushed all the

purchase toner cartridge (of different colors) sepa- way in.

rately.

(1) Shake the toner cartridge up and down and left

to right 5 to 10 times respectively.

Note:

Shake the cartridge adequately. Otherwise, it may

cause trouble.

(5) Using the same procedure, install the toner car-

tridges for other colors of toner.

(6) Close the upper front door.

(2) Open the upper front door.

9. Installing other options

(3) Insert the toner cartridge into the machine. To install other options, refer to the installation man-

Note: ual for each option and follow the “Installation Proce-

• Make sure that the color is same between dures.”

inserting port and the toner cartridge.

• Make sure that the blue label position of the

toner cartridge is matched with the one of the 10. Mounting the accessory parts

machine side.

(1) Remove the protective cover from the supplied

stylus pen.

Note:

Discard the removed protective cover.

E-7

Downloaded from www.Manualslib.com manuals search engine

(2) Set the stylus pen in the place shown in the illus- 11. Connecting the power cord

tration.

Note:

Steps (1) and (2) may be unnecessary depending

on the applicable marketing area.

(1) Connect the power cord.

Use the appropriate power cord.

Failure to do this could result in a fire or

electrical shock.

(3) Attach the supplied connector cover to the

machine. (One supplied screw A)

(2) Fit the supplied cord clamp A over the power

cord. (One supplied screw C)

(4) Attach the supplied duct cover.

(Two supplied screws B)

Tab

(3) Plug the power cord into the power outlet.

E-8

Downloaded from www.Manualslib.com manuals search engine

12. Starting the machine 15. Unit change

Open the lower front door and turn ON the power Note:

switch, then close the lower front door. This function allows the user to select the type of

message that will appear when the replacement

time arrives for each of the different units.

13. Date & Time Setting/Time Zone Setting (1) Select the appropriate message type for each

unit.

(Service Mode) (2) Touch “Service.”

(1) Display the Service Mode screen.

(For details of how to display the Service Mode

screen, see the service manual.)

(2) Display the Date & Time Setting/Time Zone Set-

16. Performing Non-Image Area Erase

ting screen. Check

(To display the Date & Time Setting/Time Zone

Note:

Setting screen, press Stop → 3 on the control

Perform the below at the site where customer

panel.)

uses the machine.

(3) Do not input date and time but touch “Entry” of

the Date & Time Setting. (1) Select the Non-Image Area Erase Check func-

(4) Input the time zone using up/down keys or direct tion as follows:

keys. Machine → Non-Image Area Erase Check.

(5) Touch “Entry” of the Time Zone Setting. (2) Open fully the dual scan document feeder, the

(6) Touch “Apply.” reverse automatic document feeder, or the origi-

(7) Touch “OK.” nal cover if loaded.

(8) Touch “Next.” Note:

• Do NOT place a document on the document

glass.

• Clean the document glass if dirty.

14. Serial number input

Note:

Serial number input is, if necessary, needed only

for the optional devices installed in “9. Installing

other options.”

(1) Touch the item you want to enter and input the

serial number.

(2) Touch “END.”

(3) For other devices, enter their serial number in

the same way.

(4) Touch “END.”

(5) Touch “Next.”

(3) Press the Start key.

(4) Make sure that “Result” is “OK.”

Note:

If “Result” is “NG1” or “NG2”, review the place and

direction of installation, or take measures to block

the light source (by covering it, etc.), then perform

installation checking again.

(If a fluorescent light or other bright light sources

exist right above the machine, the light source can

hinder installation checking and cause operation

errors in the Non-Image Area Erase Check. For

detailed information, see the service manual.)

(5) Touch “OK.”

E-9

Downloaded from www.Manualslib.com manuals search engine

17. Configuring other options (3) Route the network cable.

<When adding no paper feed options/desk or when

(1) If any of the following options are installed, refer using the Desk DK-705>

to the “Configuration procedures” of the installa- a) Route the network cable through the harness

tion manual for each option and configure the guide and pass it through the notch.

option(s).

Note:

• Paper Feed Cabinet PC-415

Leave an appropriate amount of slack in the por-

• Large Capacity Unit LU-207/LU-302

tion of the cable between the plug and the harness

• Stamp Unit SP-501

guide in a manner which does not interfere with

• Double feed detection Kit UK-501

the opening and closing of the cover.

• Punch Kit PK-523/PK-520/PK-519

• Z Folding Unit ZU-609 Leave an appropriate amount of slack.

• Fax Kit FK-515/FK-514

• Local Interface Kit EK-609

• Security Kit SC-508

• Authentication Unit AU-201S/AU-102

• Upgrade Kit UK-212

• Hard Disk HD-524

• Clean Unit CU-102

• Network Fax

(2) Exit from the Service Mode and return to the ini-

tial screen.

18. Connecting the network cable

(1) Connect the main body and networking equip-

<When using the Paper Feed Cabinet PC-415/PC-

ment (HUB) using the network cable.

215/PC-115 or the Desk DK-510>

Note:

a) Remove the rear right cover from the paper

The following shows the recommended network

feed cabinet or the desk. (Two screws)

cables that correspond to each communication

speed.

• 10BaseT/100BaseTX: Category 5

• 1000BaseT: Category 5E, Category 6

LED1

LED2

Networkport b) Remove the knockout from the rear right cover

using nippers.

(2) Check LEDs for lighting conditions.

LED1:

Should light up steadily if the link network con-

nection has been made.

LED2:

Should blink according to the communications

status of the ACT network.

E-10

Downloaded from www.Manualslib.com manuals search engine

c) Route the network cable through the harness 19. Network setting

guide and three wire saddles.

Make the TCP/IP address setting for the network.

Note:

Leave an appropriate amount of slack in the por- Note:

tion of the cable between the plug and the harness Consult the network administrator for the setting

guide in a manner which does not interfere with value to be entered and make settings as

the opening and closing of the cover. required.

Leave an appropriate amount of slack. (1) Select the function to be used as follows:

Menu → Utility → Administrator Settings → Enter

the Administrator Password → Network Settings

→ TCP/IP Settings → IPv4 Settings.

(2) Touch “Manual Input” of IP Application Method

and make the following settings.

IP Address: IP address of the controller

Subnet Mask: Subnet mask of the network, to

which the machine is connected

Default Gateway: IP address of the default gate-

way

(3) Touch “OK.”

(4) Touch “OK” after the “TCP/IP Settings” screen is

displayed.

(5) Select the function to be used as follows:

Forward → Detail Settings → PING Confirma-

tion, and make the operation check of TCP/IP.

20. Restarting the machine

(1) Open the lower front door and turn OFF the

power switch.

d) Route the cable through the notch and attach (2) Turn ON the power switch again after 10 or more

the rear right cover. (Two screws) seconds have passed, then close the lower front

door.

21. Adjusting each option

If any of the following options are installed, adjust

each option as necessary. (Refer to the “Adjustment

procedures” of the installation manual for each

option.)

• Paper Feed Cabinet PC-415/PC-215/PC-115

• Large Capacity Unit LU-207/LU-302

• Double feed detection Kit UK-501

• Finisher FS-537SD/FS-536SD

• Punch Kit PK-523/PK-520/PK-519

• Post Inserter PI-507

• Z Folding Unit ZU-609

22. Confirming the copy sample

After completing all the steps, take a sample copy

and confirm the image. If image troubles occur, first

turn OFF and ON the Main Power Switch, and then

redo the steps from E-9 “13. Date & Time Setting/

Time Zone Setting (Service Mode)” to E-9 “15. Unit

change.”

E-11

Downloaded from www.Manualslib.com manuals search engine

23. Changing the stopper position 24. Affixing the paper size label

Remove the stopper from the hinge of the reverse Affix the paper size labels that correspond to the

automatic document feeder. (One screw each for sizes of paper used in each tray.

right and left)

Change the set position of the stopper to the upper

side and secure it in position.

Paper size label

25. Installing the user’s guide holder

Install the user’s guide holder.

26. Affixing the panel sheet

Affix the supplied panel sheet to the surface of the

operation panel.

Note:

• The panel sheet is affixed on customer request.

• The panel sheet must be kept by the customer.

E-12

Downloaded from www.Manualslib.com manuals search engine

OT-506 Output Tray

INSTALLATION MANUAL

1. Accessory parts 2. Installation procedures

No. Name Shape Q’ty (1) Check whether the output tray has the snap-fit

hook illustrated below or not.

1. Output tray

< With the snap-fit hook >

1

2. Output guide

< Without the snap-fit hook >

Keep this bag away from babies and

children. Do not use in cribs, beds,

carriages, or playpens.

The thin film may cling to nose and

mouth and prevent breathing. This bag is

not a toy.

< If the machine has the snap-fit hook >

Go to step (4).

< If the machine does not have the snap-fit hook >

Go to step (2).

E-13

Downloaded from www.Manualslib.com manuals search engine

(2) Open the upper and lower front door of the (5) Install the output tray.

machine.

(3) Remove the upper left cover from the machine. <With the snap-fit hook>

(Three screws)

<Without the snap-fit hook>

(4) Attach the supplied output guide to the machine.

②

①

(6) Reattach the upper left cover removed in step (3)

to the machine. (Three screws)

(7) Close the upper and lower front door of the

machine.

E-14

Downloaded from www.Manualslib.com manuals search engine

SP-501 Stamp Unit

INSTALLATION MANUAL

1. Accessory parts 2. Installation procedures

No. Name Shape Q’ty (1) Turn OFF the power switch and unplug the

power cord from the power outlet.

1. Stamp unit (2) Remove the stopper from the hinge of the

1 reverse automatic document feeder.

(One screw each for right and left)

Change the set position of the stopper to the

2. Stamp lower side and secure it in position.

1

Note:

Perform this step only when necessary.

3. Installation

manual

1 set

Keep this bag away from babies and

children. Do not use in cribs, beds,

carriages, or playpens.

The thin film may cling to nose and

mouth and prevent breathing. This bag is

not a toy.

E-15

Downloaded from www.Manualslib.com manuals search engine

(3) Open the reverse automatic document feeder, (7) Remove the rear cover.

then remove the six screws.

(8) Remove the screw, then remove the pin.

(4) Close the reverse automatic document feeder. (Front: at two places; rear: at one place)

(5) Remove the front cover.

(9) Open the original tray.

(6) Open the top door.

E-16

Downloaded from www.Manualslib.com manuals search engine

(10) Remove the stamp unit cover. (One screw) (13) Install the stamp unit and the ground terminal.

(One screw removed in step (11))

Note:

Tighten the unit together with the ground terminal.

Ground terminal

Stamp unit

(11) Remove the ground terminal. (One screw)

(14) Connect the stamp unit connector to the main

Ground terminal

body relay connector.

(12) Mount the stamp in stamp unit.

Note:

Align the round pin of the stamp with the slit in the

stamp unit side.

(15) Store the relay connector at the position shown

in the illustration and pass the stamp unit har-

ness through the gap of the rib.

Note:

Make sure that the harness does not interfere with

the roller.

Connector

Rib

(16) To install the covers and other parts removed in

steps (3) to (10), reverse the removal proce-

dure.

E-17

Downloaded from www.Manualslib.com manuals search engine

(17) Remove the stopper from the hinge of the

reverse automatic document feeder.

(One screw each for right and left)

Change the set position of the stopper to the

upper side and secure it in position.

3. Configuration procedures

(1) Plug the power cord into the power outlet and

turn ON the power switch.

(2) Display the Service Mode screen.

(For details of how to display the Service Mode

screen, see the service manual.)

(3) Touch “System 2.”

(4) Touch “Stamp.”

(5) Touch “Set.”

(6) Touch “END.”

(7) Touch “Exit” on the Service Mode screen.

(8) Turn OFF and ON the power switch.

Note:

When displayed the Service Mode screen, be sure

to turn off the power after exiting the Service Mode

screen and wait for 10 seconds or more before

turning on.

E-18

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Installation ManualDocument30 pagesInstallation Manualkhoi vuNo ratings yet

- Profile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997From EverandProfile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997No ratings yet

- Installation Manual SummaryDocument17 pagesInstallation Manual SummaryBizhub Konica MinoltaNo ratings yet

- Bizhubc650i C550i C450iInstallInstrDocument16 pagesBizhubc650i C550i C450iInstallInstrM. SalmanNo ratings yet

- AccurioPress C4070 Parts ManualDocument278 pagesAccurioPress C4070 Parts Manualber82No ratings yet

- Part manual C250i AA2M121Document139 pagesPart manual C250i AA2M121wizartNo ratings yet

- Installation Manual SummaryDocument18 pagesInstallation Manual SummaryАндрей КрупкинNo ratings yet

- A9HJDocument117 pagesA9HJtraminerNo ratings yet

- bizhub 308 Parts Guide ManualDocument117 pagesbizhub 308 Parts Guide ManualtraminerNo ratings yet

- Bizhubc368 C308 C258InstallInstrDocument13 pagesBizhubc368 C308 C258InstallInstrBizhub Konica MinoltaNo ratings yet

- Installation Manual ProceduresDocument13 pagesInstallation Manual Proceduresمصعب الغريبNo ratings yet

- Bizhub C258-PartsDocument117 pagesBizhub C258-PartsPon ThephavongNo ratings yet

- B360i - Parts Manual Jan2022Document140 pagesB360i - Parts Manual Jan2022RayNo ratings yet

- Installation Manual HighlightsDocument12 pagesInstallation Manual HighlightsAlin DoafidriNo ratings yet

- Parts Guide Manual: Bizhub C287 A797Document108 pagesParts Guide Manual: Bizhub C287 A797Артем ИвановNo ratings yet

- Bizhub c368 c308 c258 Spec Sheet enDocument4 pagesBizhub c368 c308 c258 Spec Sheet enjohnik3316No ratings yet

- BizHub 450i Parts ListDocument182 pagesBizHub 450i Parts ListDomenico Di CristofaroNo ratings yet

- Ineo+ 3080P Parts ListDocument260 pagesIneo+ 3080P Parts ListNdikumasabo EtienneNo ratings yet

- Installation ManualDocument27 pagesInstallation ManualionutkokNo ratings yet

- Foliant Bizhub C258-C308-C368 v108R6BEUsrDocument1 pageFoliant Bizhub C258-C308-C368 v108R6BEUsrPaul AlbuNo ratings yet

- Bizhub C368 PartsManualDocument118 pagesBizhub C368 PartsManualLuiz Gonzaga Santos FilhoNo ratings yet

- Ineo+ 3080 Parts ListDocument268 pagesIneo+ 3080 Parts ListNdikumasabo EtienneNo ratings yet

- AccurioPress C3080 Parts ListDocument268 pagesAccurioPress C3080 Parts ListNdikumasabo EtienneNo ratings yet

- Manual Instalare Nou - A0P0 9951 02EDocument23 pagesManual Instalare Nou - A0P0 9951 02EHritcu IulianNo ratings yet

- Installation Manual OverviewDocument12 pagesInstallation Manual OverviewAlexandrNo ratings yet

- Installation Manual / /: I. Outline of Installation Procedures For Bizhub 362/ Bizhub 282/ Bizhub 222Document36 pagesInstallation Manual / /: I. Outline of Installation Procedures For Bizhub 362/ Bizhub 282/ Bizhub 222Radovan JaicNo ratings yet

- BrochureDocument4 pagesBrochurezaheerNo ratings yet

- 1886Document12 pages1886kyungtedNo ratings yet

- 7-0 EpromDocument6 pages7-0 Epromjack michael chang garridoNo ratings yet

- Configurador +2070Document1 pageConfigurador +2070Tony MorillaNo ratings yet

- Parts Guide Manual: Accuriopress C3070 Aac3Document270 pagesParts Guide Manual: Accuriopress C3070 Aac3Gradinaru CristianNo ratings yet

- Parts Guide Manual for bizhub PRESS C1060Document257 pagesParts Guide Manual for bizhub PRESS C1060Владимир Панов100% (1)

- AccurioPressC2060PartsManual PDFDocument266 pagesAccurioPressC2060PartsManual PDFjoseNo ratings yet

- Option Diagram: Original Cover Document Feeder Original CoverDocument2 pagesOption Diagram: Original Cover Document Feeder Original CoverAndrew CamposanoNo ratings yet

- Bizhub4750i 4050iInstallInstrDocument15 pagesBizhub4750i 4050iInstallInstrRobertoNo ratings yet

- Parts Guide Manual: Ineo+ 227 A79812ADocument107 pagesParts Guide Manual: Ineo+ 227 A79812Akhoi vuNo ratings yet

- Parts Guide Manual: Bizhub PRESS C1070 A50UDocument260 pagesParts Guide Manual: Bizhub PRESS C1070 A50UOscar DavilaNo ratings yet

- Bizhub c200 InstalacionDocument14 pagesBizhub c200 InstalacioncopiartekNo ratings yet

- Foliant AccurioPress C4080-C4070-C4065 v1.10R9Document1 pageFoliant AccurioPress C4080-C4070-C4065 v1.10R9ionutkok100% (1)

- Parts Guide Manual: Bizhub C258 A7R0021Document118 pagesParts Guide Manual: Bizhub C258 A7R0021Paul AlbuNo ratings yet

- 6-3 FP4 EpromDocument4 pages6-3 FP4 Epromjack michael chang garridoNo ratings yet

- Installation ManualDocument26 pagesInstallation ManualhashemNo ratings yet

- SY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical ReferenceDocument88 pagesSY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical Referencealopezcuervo82190% (1)

- Service Manual: Conf IdentialDocument15 pagesService Manual: Conf IdentialFrank ElizaldeNo ratings yet

- SD 501InstallInstDocument17 pagesSD 501InstallInstMartin HouleNo ratings yet

- Bizhub C364: Colour A3 Multifunctionality Up To 36 Colour Pages Per MinuteDocument4 pagesBizhub C364: Colour A3 Multifunctionality Up To 36 Colour Pages Per MinuteAlex HaasNo ratings yet

- 500 MK2 User PDFDocument196 pages500 MK2 User PDFYasser AlqadhiNo ratings yet

- Foliant of Ineo 1100: SD-510 IC-309m HD-523 PI-502 Ic-ReaderDocument1 pageFoliant of Ineo 1100: SD-510 IC-309m HD-523 PI-502 Ic-ReaderTony MorillaNo ratings yet

- Installation ManualDocument18 pagesInstallation ManualhashemNo ratings yet

- Bu0040 6070402 en 4923 DeskDocument80 pagesBu0040 6070402 en 4923 Deskolivier.bigouretNo ratings yet

- 2454-6754Document2 pages2454-6754Ferdiansyah AnggoroNo ratings yet

- Bizhub C452 Configuration SheetDocument3 pagesBizhub C452 Configuration SheetmfialloNo ratings yet

- Bizhub C224 BrochureDocument4 pagesBizhub C224 BrochurecarolusNo ratings yet

- SW U801 WinDocument2 pagesSW U801 Wingrand justiceNo ratings yet

- Bizhub C364e: Colour A3 Multifunctional Up To 36 Pages Per MinuteDocument4 pagesBizhub C364e: Colour A3 Multifunctional Up To 36 Pages Per MinuteWilson GilNo ratings yet

- Ultra5000 DeviceNet Expansion Kit InstallationDocument8 pagesUltra5000 DeviceNet Expansion Kit Installationmouhamed abdoulaye niangNo ratings yet

- Ineo+ 3070L Parts ListDocument267 pagesIneo+ 3070L Parts ListNdikumasabo EtienneNo ratings yet

- BC500 Service ManualDocument45 pagesBC500 Service ManualWilson Rodriguez BustamanteNo ratings yet

- AFG81S AFG81D AFG83S AFG83D(11年 第1版)Document5 pagesAFG81S AFG81D AFG83S AFG83D(11年 第1版)赵先生No ratings yet

- 190A1E0336 - ProjectDocument67 pages190A1E0336 - ProjectSrisasthagnaneswarsaikumar KonduruNo ratings yet

- 10 11 Week14 Technology DecipheringcodesDocument21 pages10 11 Week14 Technology DecipheringcodesVipul KumarNo ratings yet

- ZookeeperDocument42 pagesZookeeperTripti Sagar100% (1)

- Final Report AcerDocument69 pagesFinal Report AcerSandeep Parkhe0% (1)

- IT REPORT OF A Cybersecurity StudentDocument35 pagesIT REPORT OF A Cybersecurity StudentJeff EnaefeNo ratings yet

- Digital Display - FA MCR-D-TUI-UI-2REL-UP - 2907064: Key Commercial DataDocument7 pagesDigital Display - FA MCR-D-TUI-UI-2REL-UP - 2907064: Key Commercial DataBambang AmingNo ratings yet

- List of Computer Sales and Services in Pangasinan (Specially, Dagupan)Document2 pagesList of Computer Sales and Services in Pangasinan (Specially, Dagupan)KarlaJoy NephiOnel Tiangson100% (1)

- OKP (Digital Type Bursting Strength Tester)Document1 pageOKP (Digital Type Bursting Strength Tester)swapon kumar shillNo ratings yet

- WT UNIT 1 Lecture 1.6 The Internet and Its ServicesDocument7 pagesWT UNIT 1 Lecture 1.6 The Internet and Its ServicesSACHIDANAND CHATURVEDINo ratings yet

- Venus 30 Commissioning Manual ENDocument29 pagesVenus 30 Commissioning Manual ENWaltinegojiya CadondonNo ratings yet

- Same Day Delivery in Vancouver at BudoraDocument2 pagesSame Day Delivery in Vancouver at BudoraBudoraNo ratings yet

- ParlantesDocument8 pagesParlantesjopsueNo ratings yet

- Login Credential ReportbrCollege Name City Academy Law College, Course Name L.L.B 3 (Year) Semester 3Document12 pagesLogin Credential ReportbrCollege Name City Academy Law College, Course Name L.L.B 3 (Year) Semester 3Venkatesh JaiswalNo ratings yet

- Nse4 FGT-6.4Document85 pagesNse4 FGT-6.4OuryNo ratings yet

- Manual: Movitrac Lte-B/Ltp-B Accessories Option CardsDocument72 pagesManual: Movitrac Lte-B/Ltp-B Accessories Option CardsBella SmithNo ratings yet

- OSINT Handbook 2020Document510 pagesOSINT Handbook 2020Lougan75% (4)

- Database Systems: Design, Implementation, and Management: Normalization of Database TablesDocument53 pagesDatabase Systems: Design, Implementation, and Management: Normalization of Database TablesMiralyn RuelNo ratings yet

- Collaborative Product DevelopmentDocument8 pagesCollaborative Product DevelopmentAbid YusufNo ratings yet

- Computer Fundamentals GuideDocument17 pagesComputer Fundamentals GuideMohit PacharNo ratings yet

- P6 Competency Test Instructions: 1.1 Create A Project With The Following InformationDocument6 pagesP6 Competency Test Instructions: 1.1 Create A Project With The Following InformationCarlos PatiñoNo ratings yet

- CH 03 OOP PDFDocument17 pagesCH 03 OOP PDFHalema DeekNo ratings yet

- cs161 Lecture1notes ClassDocument4 pagescs161 Lecture1notes ClassPawandeep SinghNo ratings yet

- Riso RP Series Technical ManualDocument536 pagesRiso RP Series Technical ManualromicaNo ratings yet

- Prediksi Lanskap Teknologi Masa DepanDocument44 pagesPrediksi Lanskap Teknologi Masa Depanamelia nikoNo ratings yet

- Unit Plan TemplateDocument4 pagesUnit Plan TemplateAoi KitsuneNo ratings yet

- Leach Routing Protocol Implementation in ns2Document38 pagesLeach Routing Protocol Implementation in ns2regragui50% (2)

- Presentation TaCosDocument15 pagesPresentation TaCosRishu KumarNo ratings yet

- Create swipe views with tabs using ViewPagerDocument7 pagesCreate swipe views with tabs using ViewPagerSanjay PatelNo ratings yet

- Construction Document Sheet Numbers and Sheet OrderDocument5 pagesConstruction Document Sheet Numbers and Sheet Orderkajale_shrikant2325No ratings yet

- Motorola Power Controller: by Sasi Kumar C Development EngineerDocument29 pagesMotorola Power Controller: by Sasi Kumar C Development EngineerVenkat RaoNo ratings yet