Professional Documents

Culture Documents

Ifc300 Pa

Uploaded by

Leandro Santos da SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ifc300 Pa

Uploaded by

Leandro Santos da SilvaCopyright:

Available Formats

© KROHNE 01/2006 7025552100

Supplementary

Installation and Operating

Instructions

IFC300 PROFIBUS

with

MBP Physical Interface and

PA Profile 3.0

(“Profibus PA Device”)

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

CONTENTS:

1

TU UT GENERAL

TU UT 3

2

TU UT ITEMS INCLUDED WITH SUPPLY

TU UT 3

3

TU UT SOFTWARE HISTORY

TU UT 3

4

TU UT PROFIBUS-PA DEVICE WITH MBP INTERFACE

TU UT 3

4.1

TU UT PROFILES

TU UT 4

4.2

TU UT GSD FILES

TU UT 4

4.2.1

TU UT Manufacturer specific GSD file: KR024501.GSD

TU UT 5

4.2.2

TU UT Manufacturer specific GSD file: YP024501.GSD

TU UT 6

4.2.3

TU UT Manufacturer specific GSD files “KROHF401.GSD”/“YP01F401.GSD” of an “IFC090PA”

TU UT 6

4.2.4

TU UT Profile specific GSD file: PA139740. GSD

TU UT 8

4.3

TU UT CYCLIC DATA EXCHANGE

TU UT 8

4.4

TU UT DATA STRUCTURE OF FUNCTION BLOCK OUTPUT VALUES

TU UT 8

4.4.1

TU UT Float Value

TU UT 8

4.4.2

TU UT Status Value

TU UT 8

4.5

TU UT DIAGNOSIS

TU UT 9

5

TU UT ELECTRICAL CONNECTION

TU UT 10

5.1

TU UT PROFIBUS-PA CONNECTION

TU UT 10

6

TU UT MENU SETTINGS

TU UT 11

6.1

TU UT USING THE DISPLAY MENU TO DISTINGUISH THE CURRENT REVISION OF THE DEVICE

TU UT 17

7

TU UT TECHNICAL DATA

TU UT 18

8

TU UT DEVICE DESCRIPTION FOR THE SIMATIC PROCESS DEVICE MANAGER (PDM)

TU UT 18

8.1

TU UT INSTALLATION

TU UT 18

8.2

TU UT OPERATING

TU UT 18

9

TU UT ATTACHMNET A

TU UT 19

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 2/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

1 General

These Instructions are supplementary to the “IFC 300 (OPTIFLUX) Handbook”. The details given there, in particular

the Safety Information are valid and should be adhered to. These Supplementary Instructions provide only additional

information for device operation and connection to a PROFIBUS fieldbus.

2 Items included with supply

In addition to the standard scope of supply, these Supplementary Instructions for the IFC300 PROFIBUS MBP

Interface will be included.

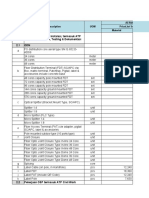

3 Software history

Configuration Tool

Issued Signal Converter User Program

(Add-On)

Month/ Hardware Firmware Hardware Software GSD GSD

Year

Model name adopted in the File name in the GSD

GSD compilation*:

01/06 IFC300 PROFIBUS MBP V2.0.0 / 060112 PC DTM > --/--

U U “IFC300 (MBP) Rev. 2” KR024501.GSD

Interface with PA Profile 3.0 V2.0.0 / 060126 ”YP0 IFC300 (MBP) Rev. 2” YP024501.GSD

Device Description (Ident No

& Dev.Rev. & DDRev.): “Flow with 1 AI, 1 TOT (PhyL 1)” PA139740.GSD

4501030002

PDM ≥ 6.0

* -> see detailed description depicted below (Chapter 4.4 GSD Files)

4 PROFIBUS-PA Device with MBP Interface

(MBP == Manchester Coded Bus Powered)

U U U U U U

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 3/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

The diagram above depicts a typical network configuration with PROFIBUS-PA devices with MBP interface in

hazardous and non-hazardous environment.

As a rule, the PROFIBUS-PA segment is connected to a coupler which, among other things, provides the conversion

to the PROFIBUS-DP bus line. It should be mentioned that the segment coupler is normally set to a fixed baud rate

on the DP side.

Additional information on the configuration and operation of PROFIBUS-PA networks is to be found in the KROHNE

brochure “Fundamentals PROFIBUS” which can be downloaded from the KROHNE homepage

http://www.krohne.com ( following the path: Service -> Download Center -> select “Brochures and Catalogues” ->

HTU UTH

choose “Fundamentals PROFIBUS”) or contact “KROHNE Marketing”.

4.1 Profiles

The IFC300 PROFIBUS MBP interface supports the PROFIBUS-PA Profile Version 3.0. Additionally, all relevant

parameters of the device are accessible via the PROFIBUS interface.

The IFC300 PROFIBUS MBP interface with PA Profile 3.0 supports the following blocks:

• One physical block.

This block contains the parameters defined in PA Profile 3.0.

• One transducer block for electromagnetic flow devices.

This block provides the parameters and functions defined in PA Profile 3.0.

• Five “Analog Input (AI)” function blocks: by default “Volume Flow”, “Mass Flow”, “Speed Flow”, “Coil

Temperature” and “Conductivity”.

• Three “Totalizer (TOT)” function blocks: by default the first two totalizers will integrate “Volume” and third one will

integrate “Mass”.

4.2 GSD Files

A “PROFIBUS GSD ZIP” file (e.g. GSD-31777813.zip) including both all KROHNE GSD files and additional data files

can be downloaded from the KROHNE homepage http://www.krohne.com ( following the path: Service -> Download

HTU UTH

Center -> select “Software” -> choose “PROFIBUS GSD”) or contact “KROHNE Marketing”. The GSD file contains

information that will be needed for project planning of the PROFIBUS-DP communication network. The relevant data

files (e.g. ifc300_n.bmp; ifc300_n.dib) must be loaded into the bus configuration system/master system before start-

up of the bus system.

The IFC300 PROFIBUS MBP Interface is based on the PROFIBUS-PA Profile V 3.0. The device supports three

Ident-Nos.:

• Ident-No. “4501hex”: this Ident-No. belongs to the KR024501.GSD / YP024501.GSD and includes the

complete functionality of the electromagnetic flow meter.

U U

• Ident-No. “9740hex”: the application of the manufacturer independent Ident-No. “9740hex” (GSD file

“PA139740.GSD”) provides interchangeability of devices, i.e. an exchange of electromagnetic flow

meters of different vendors.

• Ident-No. “F401hex”: this Ident-No. supports a compatibility mode concerning the cyclic data transfer

(cyclic measurement values and diagnosis) if the “IFC300 with PROFIBUS MBP Interface” will be used for

replacement of an “IFC090PA”. It is not necessary to adapt the PLC configuration. Communication

U U

functions are restricted to those functions supported by IFC090 converters. Take care to set the “IFC300

PROFIBUS MBP interface” parameters in a way to get the same behavior as of “IFC090PA” concerning

calculation of measuring values and totalizers.

Please follow the instructions in the manual of the host supplier when installing the GSD File you need and the

additional files (IFC300_n.bmp and IFC300_n.dib) into the PLC. If separated by the bus configuration system the

device entry of the IFC300 PROFIBUS MBP Interface with PA Profile 3.0 will be located within the slave family

PROFIBUS-PA.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 4/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

4.2.1 Manufacturer specific GSD file: KR024501.GSD

This GSD file is for use with standard DP/PA segment coupler. KROHNE delivers the GSD files with the entire device

functionality which is listed below:

Block Number Standard-Configuration KR024501.GSD Default unit:

(function block output: value + status) Ident-No. 4501

1 Volume Flow AI-FB m3/h

2 Volume Totalizer Totalizer-FB m3

3 Volume Totalizer Totalizer-FB m3

4 Mass Totalizer Totalizer-FB kg

5 Mass Flow AI-FB kg/s

6 Speed Flow AI-FB m/s

7 Coil Temperature AI-FB K

8 Conductivity AI-FB S/m

AI = Analog Input Function Block

FB = Function Block

There will be two additional output values available by changing the function block channel parameters of the above

mentioned “Analog Input Function Blocks”:

X Temperature AI-FB °C

(electronic temperature)

X Supply AI-FB V

(the internal supply voltage for the

PROFIBUS Interface)

X == Block Number 1, 5, 6, 7 or 8 may be used

There are separate settings to select the units for local display and PROFIBUS. Modifications of the units of the

display will have no effect on the data transferred via PROFIBUS. A master class 2 tool is required to modify the

units for PROFIBUS transfer.

Important Notes:

U

During network configuration the user has to define which function block outputs of the “IFC300 PROFIBUS MBP

interface” should be transferred cyclically to the master. This is performed by a bus configuration tool (e.g. “HW-

Config” for PC-S7 from Siemens). This tool offers the functions described as follows:

1. It is possible to configure an “Empty” block (the code of an “Empty” block is defined as 0x00) on each block

number. This implies that no data are transmitted in the cyclic data telegram for this block.

2. There is NO “Totalizer (TOT)” function block allowed on block position 1, 5, 6, 7 and 8! On these positions, only

an “Analog Input (AI)” function block or an “Empty” block is allowed!

Note: All codes supported by “Analog Input (AI)” - and “Totalizer (TOT)” – function blocks will be found in the

corresponding GSD files.

3. There is NO “Analog Input (AI)” function block allowed on block position 2, 3 and 4! On these positions , onla a

“Totalizer (TOT)” function block or an “Empty” block is allowed!

4. There is a choice of 7 different totalizer functions, which can be allocated to the blocks 2, 3 and / or 4. The 7

functions are defined as follows:

“Total” cyclic transfer of the totalizer value with status to the master

“SetTot + Total” cyclic transfer of the totalizer value with status to the master + cyclic control data

from master to the device via the parameter SetTot

“ModeTot + Total” cyclic transfer of the totalizer value with status to the master + cyclic control data

from master to the device via the parameter ModeTot

“SetTot+ModeTot+Total” cyclic transfer of the totalizer value with status to the master + cyclic control data

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 5/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

from master to the device via the parameters SetTot and ModeTot (in the given

order)

“SetTot” cyclic control data from master to the device via the parameter SetTot

“ModeTot” cyclic control data from master to the device via the parameter ModeTot

“SetTot + ModeTot” cyclic control data from master to the device via the parameters SetTot and ModeTot

(in the given order)

Both, the Byte SetTot and ModeTot are cyclically sent from the Master to the device if these bytes are inserted

as output data via the PLC configurator. The meaning of these control bytes are as follows:

SetTot:

SetTot =0: Totalizer is totalizing.

SetTot =1: Totalizer will be reset to 0 and stays at 0 until SetTot is switched back again to 0. If the value of

SetTot changes from “1” to “0” the totalizer starts counting from 0.

SetTot =2: Totalizer is set to the value defined by PresetTot. PresetTot can be written via a acyclic master

(totalizer in block 2 = Slot 2 Index 32; totalizer in block 3 = Slot 3 Index 32; totalizer in block 4 =

Slot 4 Index 32). If the value of SetTot changes from “2” to “0” the totalizer starts counting from

the current value defined by PresetTot.

SetTot > 2: not allowed. Value is ignored; totalizer remains in its last valid setting.

ModeTot:

ModeTot = 0 totalizer totalizes positive and negative values.

ModeTot = 1 totalizes only positive values.

ModeTot = 2 totalizes only negative values.

ModeTot = 3 totalizer is stopped, no totalization will be done.

ModeTot = 248 totalizes all values as positive (negative values will be multiplied with “-1.0”)

ModeTot = 249 totalizes all values as negative (positive values will be multiplied with “-1.0”)

All other values of ModeTot not allowed. Value is ignored; totalizer remains in its last valid setting.

5. The standard block configuration may be changed by the customer but using the default settings is highly

recommended. If the standard block configuration should be changed by the customer an acyclic master tool

must be used to change the “channel parameter” value of the block which should be connected to another

transducer output value.

4.2.2 Manufacturer specific GSD file: YP024501.GSD

This GSD file is for use with the transparent DP/PA coupler SK2 of Pepperl&Fuchs (up to 12 MBaud on the DP

segment) and supports the same device functionality as listed above (Manufacturer specific GSD file:

KR024501.GSD ).

Note: This is true for all KROHNE PROFIBUS devices with MBP interface: there are always two types of GSD files in

our GSD compilation:

• One standard GSD file for a standard DP/PA segment coupler: file name: “KR….GSD”

• One special GSD file specific for the segment coupler SK2 of Pepperl&Fuchs file name: “YP….GSD”

4.2.3 Manufacturer specific GSD files “KROHF401.GSD”/“YP01F401.GSD” of an “IFC090PA”

The “IFC300 PROFIBUS MBP Interface” offers a compatibility mode ensuring operation when being connected to a

PLC with software parameters based on the “IFC090PA”. This option is important for those customers who do not

want to change the parameters in the PLC software after having replaced the “IFC090PA” by an “IFC300 with

PROFIBUS MBP Interface”. In this application, the compatibility mode has to be selected in the service menu of the

“IFC300 with PROFIBUS MBP Interface”; some other entries have to be performed in a next.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 6/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

The overall situation is described using the following example: Consider an “IFC090PA” standard configuration based

on IFS…FLUX* flow sensor and “IFC090PA” flow converter. Consider the following two options for replacements

(IFS….FLUX* = IFS sensor compliant with “IFC090PA”):

I. the “IFC090PA” flow converter will be replaced by an “IFC300 PROFIBUS MBP Interface” flow converter. The

IFS…FLUX flow sensor is kept

II. In addition to I, also the IFS…FLUX flow sensor will be replaced by an OPTIFLUX flow sensor

Integration into the PLC via PLC

Options for “IFC300 PROFIBUS

a) “IFC090PA” GSD or The PROFIBUS PA

Sensor Installation: MBP Interface” converter

b) “IFC300 (MBP)” GSD parameter set in the Ctrl

Device PROFIBUS PA Software of the PLC

- Option I: IFS…FLUX Software Software

a) does not need to be

- Option II: OPTIFLUX changed

b) has to be changed

For both replacements I and II, there are 2 options how to deal with the GSDs. In order to provide communication

between “IFC300 with PROFIBUS MBP Interface” and the PLC, you may - in principle – use the GSD of the

“IFC090PA” (”KROHF401.GSD” or ” YP01F401.GSD”) and –alternatively - the GSD of the “IFC300 with PROFIBUS

MBP Interface” (“KR024501.GSD” or “YP024501.GSD”). However, both GSDs, when applied, do not provide the U U

same level of functionality in the PLC. The available PROFIBUS functionality of the “IFC300 with PROFIBUS MBP

Interface” in the PLC as function of installed flow sensor and GSD used for integration into the PLC is as follows:

Integration

“IFC090PA” GSD “IFC300 with PROFIBUS MBP Interface”

into the PLC GSD

(KROHF401.GSD)

via

(KR024501.GSD)

Installed

Sensor

“IFC300 with PROFIBUS MBP Interface”

IFS…FLUX flow sensor “IFC090PA” profile 2 functionality functionality (Some “IFC300 with

(Option I) PROFIBUS MBP Interface” self-test

functions not available)

OPTIFLUX flow sensor “IFC090PA” profile 2 functionality “IFC300 with PROFIBUS MBP Interface”

(Option II) functionality

How to deal with the PA The “IFC090PA” Parameter Set for The “IFC090PA” Parameter Set for the

parameter set in the the PLC Ctrl Software can be used Ctrl. Software has to be adapted with

PLC Ctrl Software: as existing in the PLC reference to the interface of “IFC300 with

PROFIBUS MBP Interface”

• If the GSD of the “IFC090PA” (”KROHF401.GSD” or ” YP01F401.GSD”) is used….

- The “IFC090PA” parameter set for the PLC control software will be maintained, i.e. there is no adaptation

needed with reference to the replaced interface of the “IFC300 with PROFIBUS MBP Interface”.

- In this usage of the GSD the PA Profile 2.0 functionality is provided in the PLC for both replacements, i.e. it is

not possible to reset the PA totalizer via the PLC.

• If the GSD of “IFC300 with PROFIBUS MBP Interface” (KR024501.GSD or YP024501.GSD) is used….

- The “IFC090PA” Parameter set for the PLC control software has to be adapted with reference to the

IFC300 PROFIBUS MPB interface.

- In this usage of the GSD the PA Profile 3.0 functionality is provided and all diagnostic features of the “IFC300

with PROFIBUS MBP Interface” are being made available.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 7/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

4.2.4 Profile specific GSD file: PA139740. GSD

The functionality of the profile specific GSD file is limited. This GSD file includes only two blocks:

Volume Flow and Volume Totalizer.

Block Number Standard-Configuration PA139740. GSD Default unit:

(function block output value) Ident-No. 9740

1 Volume Flow AI-FB m3/h

2 Volume Totalizer Totalizer-FB m3

The device has to be switched from “full functionality” to “interchangeable basic configuration” by using a master

class 2 tool (IDENT_NUMBER_SELECTOR: Slot 0, Index 40 change byte value to 0). In the next step, the device

has to be configured using the PA139740.GSD file.

4.3 Cyclic data exchange

During network configuration the user has to define which function block outputs of the IFC300 PROFIBUS MBP

Interface should be transferred cyclically to the master. Network configuration will be done using one of the GSD files

described above. The order of transmission of the function blocks always remains the same even if a function block

is defined as an “Empty” block (if so no function block output data will be send to the master and all function block

outputs following the “Empty” block will move up one position).

4.4 Data Structure of Function Block Output Values

The data structure of function block outputs consists of 5 bytes: a 4 byte float value (Float Format according IEEE U

Standard 754 Short Real Number) followed by a 1 byte status value. If all 8 function block outputs have been U

configured (see above), 40 byte will be transmitted.

4.4.1 Float Value

First an example of the float format:

Byte n Byte n+1 Byte n+2 Byte n+3

Bit7 Bit6 Bit7 Bit6 Bit7 Bit7

VZ 27 26 25 24 23 22 21 20 2-1 2-2 2-3 2-4 2-5 2-6

P P P P P P P P P P P P P P P P P P P P P P P P P P P P 2-7 2-8 2-9 2-10 2-11 2-12 2-13 2-14 2-15 2-16 2-17 2-18 2-19 2-20 2-21 2-22 2-23

P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P

Exponent Mantisse Mantisse Mantisse

Example: 40 F0 00 00 (hex) = 0100 0000 1111 0000 0000 0000 0000 0000 (binary)

Formula: Value = (-1)VZ * 2 (Exponent - 127) * (1 + Mantisse)

P P P P

Value = (-1)0 * 2 (129 - 127) * (1 + 2-1 + 2-2 + 2-3)

P P P P P P P P P P

Value = 1 * 4 * (1 + 0,5 + 0,25 + 0,125)

Value = 7,5

4.4.2 Status Value

You will find the meaning of the status byte (unsigned integer) by looking at the tables down below:

Quality Quality-Substatus Limits

Gr Gr QS QS QS QS Qu Qu

7 6 5 4 3 2 1 0

2P 2

P P P 2P 2

P 2 2 P P P P P P 2 2 P P P P

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 8/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

Status = bad

0 0 0 0 0 0 = non-specific

0 0 0 0 0 1 = configuration error

0 0 0 0 1 0 = not connected

0 0 0 0 1 1 = device failure

0 0 0 1 0 0 = sensor failure

0 0 0 1 0 1 = no communication (last usable value)

0 0 0 1 1 0 = no communication (no usable value)

0 0 0 1 1 1 = out of service

Status = uncertain

0 1 0 0 0 0 = non-specific

0 1 0 0 0 1 = last usable value

0 1 0 0 1 0 = substitute-set

0 1 0 0 1 1 = initial value

0 1 0 1 0 0 = sensor conversion not accurate

0 1 0 1 0 1 = engineering unit violation (unit not in the valid set)

0 1 0 1 1 0 = sub-normal

0 1 0 1 1 1 = configuration error

0 1 1 0 0 0 = simulated value

0 1 1 0 0 1 = sensor calibration

Status = good (Non-Cascade)

1 0 0 0 0 0 = ok

1 0 0 0 0 1 = update event

1 0 0 0 1 0 = active advisory alarm (priority < 8)

1 0 0 0 1 1 = active critical alarm (priority > 8)

1 0 0 1 0 0 = unacknowledged update event

1 0 0 1 0 1 = unacknowledged advisory alarm

1 0 0 1 1 0 = unacknowledged critical alarm

1 0 1 0 0 0 = initiate fail safe

1 0 1 0 0 1 = maintenance required

Status = Limits

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

Check the first two quality bits in order to get the quality information of the measurement value:

Good (non Cascade) function block output value is ok and can be used without restrictions

Good (Cascade) will not be supported, because it is not applicable for the device

Uncertain function block output value can be used but the accuracy can not be guaranteed (e.g. function

block outputs value has been frozen or A/D converter is saturated or out of range)

Bad function block output value is bad - don’t use it for process control!

The „Quality-Substatus“- and „Limit“-Bits will be used for further diagnostics or limit checking.

Attention: The status should be watched always because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the transmitted

measurement values.

4.5 Diagnosis

If the device internal diagnostic functions will detect an error some additional information will be sent to the Master

(for further information have a look at the UNIT_DIAG_BIT(i) definitions of the corresponding GSD-file)

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 9/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

5 Electrical Connection

For a detailed description please check the ”IFC 300 (OPTIFLUX) Handbook”. Refer also to the “PROFIBUS PA User

and Installation Guideline Version 2.2 February 2003 ” (PNO Order Number 2.092).

5.1 PROFIBUS-PA connection

The next figures explain the wiring options, based on four terminals with the following notations:

Note: The current linkage between the device and the PROFIBUS-PA bus cable is independent of polarity. This

implies the wiring shown below is also possible:

Note: The “IFC300 PROFIBUS MBP interface” will operate only if the additional power supply for the device is

connected / available.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 10/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

6 Menu Settings

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

For a detailed description please see ”IFC 300 (OPTIFLUX) Handbook”. Some special settings concerning the

PROFIBUS features are easily entered via the local display:

A -> QUICK SETUP

A3 -> Reset

A3.1 -> Reset Errors this menu function can be used to reset all errors that are not removed

automatically (power fail, counter overflow)

step 1: reset? no: exit the function

yes: resets the errors and exits the function.

Note:

The following reset menus for the counters (totalizer) are only available,

if the quick access has been activated in the menu setup > device >

quick setup. Each counter (totalizer) can be activated for quick access

independently.

A3.2 -> FB2 totalizer (for PROFIBUS Devices) the counter can be reset to zero in this menu

step 1: reset counter? no: exits the function without reset

yes: resets the counter and exits the function

A3.3 -> FB3 totalizer (for PROFIBUS Devices) the counter can be reset to zero in this menu

step 1: reset counter? no: exits the function without reset

yes: resets the counter and exits the function

A3.4 -> FB4 totalizer (for PROFIBUS Devices) the counter can be reset to zero in this menu

step 1: reset counter? no: exits the function without reset

yes: resets the counter and exits the function

A4 -> Station Address (only for PROFIBUS devices)

A4 -> Station Address selects the address of the device at the PROFIBUS DP interface.

Note:

The PROFIBUS address can also be changed using the PROFIBUS

service “set_slave_add”. The input range is 0...125 according to the

PROFIBUS specification. Address 126 is the default address and

cannot be set via the PROFIBUS service “set_slave_add” - use menu

instead to reset to default address.

B -> TEST

B3 -> Information

B3.5 -> PROFIBUS available if there is existing a PROFIBUS interface; displays the

information about the PROFIBUS interface mentioned below:

KROHNE Ident No.

Software Revision of the PROFIBUS software

Date of Production

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 11/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

C -> SETUP

C3 -> I/O counter

Using the menu functions mentioned below you will be able to control basically the three counters of this

PROFIBUS device (IFC300 with RS-485 and PROFIBUS-PA Profile 3.0). These three menus are

identical so they are grouped together and their functions are described simultaneously as follows.

C3.1 -> FB2 totalizer

C3.2 -> FB3 totalizer

C3.3 -> FB4 totalizer

C3.#. 1 -> function of totalizer (function select of this totalizer)

sum counter: totalizes positive and negative values

+ counter: totalizes only positive values

- counter: totalizes only negative values

hold counter: totalizer is stopped, no totalization will be done

all as positive: neg. input values will be multiplied with "-1.0"

all as negative: pos. input values will be multiplied with "-1.0"

C3.#.2 -> measurement (measurement selection for this totalizer)

volume flow

mass flow

C3.#.3 -> preset totalizer (predefines a “threshold” using the High Limit value and the Low Limit

value of the totalizer affected; the “THRESHOLD” bit will be set in the

long status information bytes of the PROFIBUS interface if the actual

value of the totalizer is outside these limits. This can be also used as a

status output choosing the function "preset counter X”

C3.#.4 -> reset totalizer (the current value of the totalizer can be set to zero)

step 1: reset totalizer? no: exits the function without reset

yes: resets the totalizer to zero and exits the

function; totalizer will restart counting at

once

C3.#.5 -> error behavior (defines the behavior of this function block in case of errors)

hold meas. value: totalization is continued based on the last

incoming value with good status before the

first occurrence of bad status

ignore error: totalization is continued using the input values

despite the bad status. The status is ignored

stop totalizer: totalization is stopped during occurrence of

bad status of incoming values

C3.#.6 -> information (the serial Number of the circuit board, the software version number and

the production date of the circuit board will be displayed)

Note: if you choose “#” = 1 all settings done will concern FB 2 (Totalizer 1)

if you choose “#” = 2 all settings done will concern FB 3 (Totalizer 2)

if you choose “#” = 3 all settings done will concern FB 4 (Totalizer 3)

C4 -> I/O PROFIBUS

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 12/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

This feature will be available for PROFIBUS devices only.

Using the menu functions mentioned below you will be able to control basically the five analogue input

blocks of this PROFIBUS device ((IFC300 with RS-485 and PROFIBUS-PA Profile 3.0). These five

menus are identical so they are grouped together and their functions are described simultaneously as

follows:

C4.1 -> FB1 analog inp.

C4.2 -> FB5 analog inp

C4.3 -> FB6 analog inp

C4.4 -> FB7 analog inp

C4.5 -> FB8 analog inp

C4.#. 1 -> measurement (selects the measurement (channel) for the analogue input block for the

PROFIBUS interface)

flow speed:

volume flow:

mass flow:

coil temperature:

conductivity:

temperature: this is the electronic temperature

supply: the internal supply voltage for the PROFIBUS

interface

C4.#. 2 -> time constant (time constant for this function block)

C4.#.3 -> error behavior (defines the behavior of this function block in case of errors)

hold value: last valid OUT value stored will be used as

OUT value

ignore error: OUT has the wrong calculated value and

status Bad as calculated

replace value: the “replacement value” will be used as OUT

value

C4.#.4 -> replacement value (available, if the error behavior "replace value" is selected. Defines

the value that replaces the measured value at this function block in

case of an error)

Note: if you choose “#” = 1 all settings done will concern FB 1 (Analog Inp.1)

if you choose “#” = 2 all settings done will concern FB 5 (Analog Inp.2)

if you choose “#” = 3 all settings done will concern FB 6 (Analog Inp.3)

if you choose “#” = 4 all settings done will concern FB 7 (Analog Inp.4)

if you choose “#” = 5 all settings done will concern FB 8 (Analog Inp.5)

C5 -> Device

In this menu all functions are grouped that have no effect on the measurement or any output directly.

C5.3 -> 1. meas. page

Here are all settings for the first measurement.

C5.3.1 -> function

two lines: display shows two lines of measurement on

this page

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 13/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

three lines: display shows three lines of measurement on

this page

one line: display shows one line of measurement on

this page

C5.3.2 -> measurement 1.line

flow speed:

volume flow:

mass flow:

coil temperature:

conductivity:

diagnosis value:

C5.3.8 -> measurement 2.line (only available if this line is activated)

bargraph: analogue display of the value selected for the

first line

flow speed:

volume flow:

mass flow:

coil temperature:

conductivity:

diagnosis value:

FB2 totalizer:

FB3 totalizer:

FB4 totalizer:

operating hours:

C5.3.10 measurement 3.line (only available if this line is activated)

flow speed:

volume flow:

mass flow:

coil temperature:

conductivity:

diagnosis value:

FB2 totalizer:

FB3 totalizer:

FB4 totalizer:

operating hours:

C5.4 -> 2. meas. page

In case of a PROFIBUS device the second measurement page is meant to check the output

values of the different function blocks. Only PROFIBUS values can be selected here. The

analogue inputs are shown with exactly the value, seen on the PROFIBUS.

C5.4.1 -> measurement 1.line

FB1 analog inp.:

FB2 totalizer 1:

FB3 totalizer 2:

FB4 totalizer 3:

FB5 analog inp.:

FB6 analog inp

FB7 analog inp.:

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 14/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

FB8 analog inp.:

C5.4.2 -> format 1.line (fixed number of digits after the decimal point or automatic, where the

number of digits is automatically adjusted to the available space)

C5.4.3 -> measurement 2.line

FB1 analog inp.:

FB2 totalizer 1:

FB3 totalizer 2:

FB4 totalizer 3:

FB5 analog inp.:

FB6 analog inp.:

FB7 analog inp.:

FB8 analog inp.:

C5.4.4 -> format 2.line (fixed number of digits after the decimal point or automatic, where the

number of digits is automatically adjusted to the available space)

C5.4.5 -> measurement 3.line

FB1 analog inp.:

FB2 totalizer 1:

FB3 totalizer 2:

FB4 totalizer 3:

FB5 analog inp.:

FB6 analog inp.:

FB7 analog inp.:

FB8 analog inp.:

C5.4.6 -> format 3.line (fixed number of digits after the decimal point or automatic, where the

number of digits is automatically adjusted according to the available

space)

C5.6 -> special functions

C5.6.1 -> reset errors (this menu function can be used to reset all errors, that are not removed

automatically (e.g. power fail))

step 1: reset: no: exit the function

yes: resets the errors and exits the function.

C5.6.2 -> save settings (in this menu all settings can be saved in different storage places)

step 1: save settings:

break (exit the menu without saving)

backup 1 (saves the settings in the backup 1

storage place)

backup 2 (saves the settings in the backup " storage

place)

step 2: go on with copy? (Note: There is no possibility to undo this

command!)

no: exit function without saving

yes: copy the actual settings to the selected storage

place and exits the function.

Note: PROFIBUS interface settings will not be saved.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 15/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

C5.6.3 -> load settings (in this menu all settings can be loaded from different storage places,

where settings have been saved before)

step 1: load settings:

break (exits the menu without loading)

factory settings (loads the settings from the delivery)

backup 1 (loads the settings from the backup 1

storage place)

backup 2 (loads the settings from the backup 2

storage place)

step 2: go on with copy? (Note: There is no possibility to undo this

command!)

no: (exit function without saving)

yes: (copy the actual settings to the selected

storage place and exits the function)

Note: PROFIBUS interface settings will not be loaded.

C5.8 -> physical block

This menu is only available, if a PROFIBUS interface is present.

C5.8.1 -> station address (selects the PROFIBUS station address of the device)

Note: The PROFIBUS address can also be changed using the

PROFIBUS service “set_slave_add”. The input range is 0...125

according to the PROFIBUS specification. Address 126 is the default

address and cannot be set via the PROFIBUS service “set_slave_add” -

use menu instead to reset to default address.

C5.9 -> quick setup

In this menu some settings in the Quick Setup can be activated. In the default configuration the

settings in the Quick Setup are activated.

C5.9.1 -> reset counter 1 (the reset can be activated in the Quick Setup to get a quick access of

the function)

yes: quick access activated

no: quick access not activated

C5.9.2 -> reset counter 2 (the reset can be activated in the Quick Setup to get a quick access of

the function)

yes: quick access activated

no: quick access not activated

C5.9.3 -> reset counter 3 8the reset can be activated in the Quick Setup to get a quick access of

the function)

yes: quick access activated

no: quick access not activated

D -> SERVICE

This menu is in any case only to be entered by a password. This password can also be entered, when a

password for setup or quick setup is asked for. Thus this password can also be used to change forgotten

passwords.

D2 -> service parameters

In this menu all functions related to different data sets can be found.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 16/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

D2.1 -> cold start (a reset of the IFC300 can be done here, all actual changes up to this

moment are automatically stored and no undo is possible any more, this

function is helpful to reset an F error)

step 1: reset? no: terminates the function

yes: performs the reset and leaves the programming

mode

D2.1 -> save factory data (copies the actual data into the factory setting, this overwrites the factory

settings done during calibration)

step 1: save settings

break: exits the menu without saving

factory settings: saves the settings as factory

settings

step 2: go on with copy? (there is no possibility to undo this command)

no: exit menu without saving

yes: copy the actual settings to the selected storage

place.

D2.9 -> Identification No. (sets a different device modes for the cyclic communication of the

PROFIBUS interface)

IFC090: compatibility mode for the IFC300 used for replacing

the IFC090

IFC300: the normal setting (all manufacturer specific

parameters supported)

Profile: uses only the profile defined functions - no extras

(profile specific parameters supported only)

D2.10 -> PB cold start (initiates a PROFIBUS cold start)

reset? no: terminates the function

yes: PROFIBUS cold start will be carried out at once;

the programming mode is terminated

Note: during a PROFIBUS cold start nearly all

parameter values of the whole device will be

set to their default values (the PROFIBUS

address will not be changed) without

disconnecting an already established

connection to a PROFIBUS Master system

6.1 Using the display menu to distinguish the current revision of the device

Use the display of the “IFC300 with PROFIBUS MBP Interface” to open the path:

“test\information\Profibus” ( == menu B3.5)

This menu will provide the following information:

KROHNE Ident No.

Software Revision of the PROFIBUS software

Date of Production

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 17/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

7 Technical Data

Hardware Software

Physical IEC 61158-2; 31,25kbit/s; GSD GSD file can be downloaded from the KROHNE Homepage

voltage mode http://www.krohne.com

Connection independent of polarity Device profile PA Profile compact class B, V3.0

Base current 10,5 mA Address range 0...126; default 126

0 to 125 via “set_slave_add”

0 to 126 via “Local Display”

126 via “FACTORY_RESET = 2712”

FDE yes: separate fault disconnection Local control local display and operator interface at device.

electronics provided

Fault current 6 mA; (fault current = max. SAPs 2 MS1 SAPs - acyclic interface to PLC

continuous current – base current).

3 MS2 SAPs - the number of MS2 ServiceAccess Points is typically

equal to the maximum number of master class 2

tools

Starting current < 12mA Function Blocks 1 PB

1 TB

5 AI

“Ex“ approval EEx ia IIC or EEx ib IIC/IIB,

3 TOT

FISCO device

(details see “IFC 300 (OPTIFLUX)

Handbook”

8 Device Description for the SIMATIC Process Device Manager (PDM)

8.1 Installation

If the IFC 300 Device Description is not already installed on the PDM System a so called Device Install IFC 300

PROFIBUS-PA PDM is needed (available as download from KROHNE ‘Download Centre’ on the internet or on CD-

ROM / floppy disk from KROHNE).

For installing the DD on PDM V 5.2 refer to the “PDM Manual” section 11.2:”Device Install / Integrating Devices in

SIMATIC PDM with 'Device Install'".

For installing the DD on PDM V 6.0 refer to the “PDM Manual” section 13:”Integrating Devices”.

Please read also the “readme.txt”, which is also contained in the Device Install.

8.2 Operating

Refer to the IFC 300 Menu Tree PDM (Attachment A).

Due to PROFIBUS and PDM requirements and conventions the IFC 300 operation differs from operation via local

keypad and the following special features should be kept in mind:.

• The online help of those parameters which are accessible at the device's display menu contain the function

number as a reference to the menu position.

• If the device is operated via its local keypad no write operation can be performed via the PROFIBUS interface at

the same time.

• In order to find out whether the setting of the device is still the same as the parameter set stored in PDM

compare the ‘Static Revision No.’ of the respective PROFIBUS Block. (The current Static Revision No. is

displayed on the window ‘View / Device Status / <block name>’).

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 18/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

9 Attachmnet A

IFC 300 Menu Tree PDM

Menu Bar

1

File Device View Options Help

Measured Values

Display

coil temperature

volume flow • coil temperature electronics temperature

• volume flow • coil temperature status • electronics temperature

• volume flow status conductivity • electronics temp. status

mass flow • conductivity supply voltage

• mass flow • conductivity status • supply voltage

• mass flow status flow speed • supply voltage status

• flow speed

• flow speed status

-----------------------------------

Y t Diagram

Y t Diagram • volume flow

• mass flow

Overview Opt

• FB1: Output value • Quality • Simulation • Actual Mode

• ... ... ... ...

Function Block Outputs • FB8: Output value • Quality • Simulation • Actual Mode

FB8: AI- channel Opt FB4: TOT-channel Opt

FB7: AI- channel Opt FB3: TOT-channel Opt

FB6: AI- channel Opt

FB5: AI- channel Opt FB2: TOT-channel

FB1: AI-channel • Channel

• Channel

• Bargraph Output AI Output TOT

• Output Value

Output AI • Quality

• Output Value • Status

• Quality

• Status

Simulation

• Simulation

• Actual Mode

Overview Opt

Overview Opt • FB1: Current State Alarm Sum

Alarm States FB1: AI-channel • ...

FB2: TOT- channel • FB8: Current State Alarm Sum

Device Status FB3: TOT- channel Opt

3 FB4: TOT- channel Opt

Circuit Board Info

FB5: AI- channel Opt Lower Limit Alarm

-----------------------------------

Toolbar FB6: AI- channel Opt

Lower Limit Warning

Status Bar FB7: AI- channel Opt

----------------------------------- FB8: AI- channel Opt Upper Limit Warning

Update

Alarm Summary Upper Limit Alarm

• Current State Alarm Sum • Unacknowledged Alarms

Designations:

Opt Optional, dependent on device

• Unreported St. Al. Sum • Status

• Cause

implementation / configuration

Rd Read-only

• Upper Limit Alarm

Loc Local PDM, affects only PDM views

• Alarm Output Value

KROHNE IFC300 PA 45000002 (2/5)

02.06

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 19/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

IFC 300 Menu Tree PDM

Menu Bar

1

File Device View Options Help

Display

General Details Details (Service) Opt

-----------------------------------

Y t Diagram

2 • Tag • C number Unm. Diagnosis Opt

Function Block Outputs

• Manufacturer • Firmware Ident Number • Manufacturer Ident No.

Alarm States

• Product Designation • Station Address Diagnosis

• Device Variant • Operating Time

• Device Serial Number • EEPROM Cycles

• Software Revision • PROFIBUS Interface IFC 090 Mode Opt

• Hardware Revision Revision

Device Status Unm. Diagnosis Opt

• Installation Date • GDC Interface Revision

• PROFIBUS Ident No. • Diagnosis Extension 1 • Manufacturer Ident No

• Parameter Protection • Diagnosis Extension 2 Diagnosis

• Diagnosis

Messages on Device’s GDC Long Status Opt

Display

• errors • LS0 Long Status • LS0 No. of New Values

• application • ... • ...

• out of specification • LS10 Long Status • LS10 No. of New Values

• checks

• information

Block Overview Opt

• PB: Tag • Static Rev. Counter • Actual Mode

• TB: Tag ... ...

• FB1: Tag • Channel • Simulation

• ... ... ...

• FB8: Tag • Channel • Static Rev. Counter • Actual Mode • Simulation

FB4: AI-channel Opt

FB2: AI-channel FB5: TOT-channel Opt

Transducer Block

FB1: AI-channel FB3: TOT-channel

Physical Block • Tag • Tag

• Tag • Static Revision No. • Static Revision No.

• Static Revision No. • Simulation • Actual Mode

• Actual Mode • Actual Mode

Circuit Board Info Display / IO1 Profibus module

----------------------------------- • ident no. • ident no.

Toolbar • index • index

Status Bar • hardware id • hardware id

----------------------------------- • software version • software version

Update • production date • production date

• calibration date • calibration date

Designations: • board serial no. • board serial no.

Opt Optional, dependent on device

implementation / configuration

Rd Read-only

Loc Local PDM, affects only PDM views

KROHNE IFC300 PA 45000002 (3/5)

02.06

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 20/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

IFC 300 Menu Tree PDM

Parameter Table

Identification Identification Calibration

• zero point offset Rd

Operation Unit Operation Unit

• size entry Opt

• Tag • size

Device

• Descriptor

• GK selection

----------------------------------- • Message

• GK

Mask Bits for Diagnosis Opt • GKL

Device • coil resistance Rsp

Mask Bits for IFC 090 • Manufacturer Rd • density

Diagnosis Opt • Product Designation Rd • target conductivity

• Device Serial Number Rd • number of electrodes

-----------------------------------

• Software Revision Rd • field frequency

Input • Hardware Revision Rd • select settling

• Profile Revision Rd • settling time Opt

Measuring Limits

• Static Revision Number Rd • line frequency

Calibration • PROFIBUS Ident Number

• Installation Date Filter Process Input

Filter Process Input

• Write Locking Rd • limitation min

Self Test • Parameter Protection Rd • limitation max

• Device Type Rd • flow direction

Information

• C number Rd • time constant

----------------------------------- • Firmware Ident Number Rd • pulse filter

• PROFIBUS Interface Rev. Rd • pulse width Opt

Output

• GDC Interface Rev. Rd • pulse limitation Opt

FB1: AI-channel • Warm Start Timeout Opt • noise filter

• Warm Start Timeout Max Opt • noise level Opt

FB2: TOT- channel

• noise suppression Opt

FB3: TOT- channel Opt • lfc threshold

Input • lfc hysteresis

FB4: TOT- channel Opt

5 • Tag

FB5: AI- channel Opt • Static Revision No. Rd Self Test

• Gain Compensation Factor Rd • empty pipe

FB6: AI- channel Opt

• Low Flow Cut Off • limit empty pipe Opt

FB7: AI- channel Opt • Low Flow Cut Off Hysteresis • full pipe Opt

• Sample Rate Rd • limit full pipe Opt

FB8: AI- channel Opt

• Mode • linearity

----------------------------------- • Flow Direction • gain

• coil current

Mechanical Construction Measuring Limits • flow profile

Process Connection volume flow • limit flow profile Opt

• Unit • electrode noise

-----------------------------------

• Lower Value Min Rd • limit electrode noise Opt

Human Interface • Upper Value Max Rd • settling of field

mass flow

Local Display Information

• ...

coil temperature • liner

• ... • electrode material

conductivity • serial no. sensor Rd

• ... • V no. sensor Rd

flow speed

• ...

electronics temperature

• ...

supply voltage

Designations: • ...

Opt

Optional, dependent on device density

implementation / configuration • ...

Rd Read-only

Loc

Local PDM, KROHNE IFC300 PA 45000002 (4/5)

affects only PDM views 02.06

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 21/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

IFC 300 Menu Tree PDM

Parameter Table

FB8: AI-channel Opt FB4: TOT-channel Opt

Identification FB7: AI-channel Opt FB3: TOT-channel Opt

Operation Unit 4 Opt

FB6: AI-channel FB2: TOT-channel

Device Opt

• Tag

FB5: AI-channel

• Static Revision No. Rd

-----------------------------------

FB1: AI-channel • Channel

Mask Bits for Diagnosis Opt • Tag • Unit

• Static Revision No. Rd • Strategy

Mask Bits for IFC 090

• Channel • Alert Key

Diagnosis Opt

• Unit

----------------------------------- • Out Unit Text Batch Information

• Filter Time Constant • Batch ID

Input • Batch Unit

• Strategy

Measuring Limits • Alert Key • Batch Operation

• Batch Phase

Calibration Batch Information

Filter Process Input 4 • Batch ID Totalizer Settings

• Batch Unit • Totalizer Value

Self Test • Batch Operation • Mode

Information • Batch Phase • Fail Safe Mode

• Preset Value

----------------------------------- Process Value Scale • History Control

Output • Lower Value

• Upper Value Output Limits

FB1: AI-channel • Lower Limit Alarm

FB2: TOT- channel Output Scale • Lower Limit Warning

• Lower Value • Upper Limit Warning

FB3: TOT- channel Opt • Upper Value • Upper Limit Alarm

FB4: TOT- channel Opt • Limit Hysteresis

Output Limits

FB5: AI- channel Opt • Lower Limit Alarm

FB6: AI- channel Opt • Lower Limit Warning

• Upper Limit Warning

FB7: AI- channel Opt • Upper Limit Alarm

FB8: AI- channel Opt • Limit Hysteresis

Fail Safe Mode

• Fail Safe Mode

• Fail Safe Default Value

Human Interface

• Decimal Point

-----------------------------------

Mechanical Construction Mechanical Construction Human Interface

Process Connection Process Connection • Overview Views Loc

• Nominal Size Rd • Check serial no. sensor Loc

-----------------------------------

• Write sensor parameters Loc

Human Interface 1. measurement page

Local Display • display 1. line Rd

• display 2. line Rd

• display 3. line Rd

2. measurement page

• display 1. line

Designations:

Opt • display 2. line

Optional, dependent on device

• display 3. line

implementation / configuration

Rd Read-only

Loc

Local PDM, KROHNE IFC300 PA 45000002 (5/5)

affects only PDM views 02.06

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 22/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

Supplementary Installation and Operating Instructions

(IFC300 PROFIBUS MBP Interface with PA Profile 3.0)

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg 23/23

Tel.: 0203-301 0 Fax: 0203-301 389 · e-mail: krohne@krohne.de

You might also like

- Essay 1 DraftDocument1 pageEssay 1 Draftgdx3100% (3)

- Faster and Cheaper - How Ride-Sourcing Fills A Gap in Low-Income Los Angeles NeighborhoodsDocument29 pagesFaster and Cheaper - How Ride-Sourcing Fills A Gap in Low-Income Los Angeles NeighborhoodsSam StecklowNo ratings yet

- Product Name Product Number Cantidad: Fiberclamp, 3Fiber-3Powercable, 10PcsDocument1 pageProduct Name Product Number Cantidad: Fiberclamp, 3Fiber-3Powercable, 10PcsSuhailer BoscanNo ratings yet

- Lighting Control: Dimmerpacks ProdigiDocument1 pageLighting Control: Dimmerpacks Prodigiwcma570% (1)

- Transistor Power MOSFETs in DPAK 5N52SUDocument19 pagesTransistor Power MOSFETs in DPAK 5N52SUHERNANDO A BECERRANo ratings yet

- T Rec G.832 199311 S!!PDF eDocument20 pagesT Rec G.832 199311 S!!PDF eJuvenal GalarceNo ratings yet

- Buf634 - 250-Ma High-Speed BufferDocument33 pagesBuf634 - 250-Ma High-Speed BufferRaviNo ratings yet

- Ucc 25705Document23 pagesUcc 25705josue pintoNo ratings yet

- IBM System Storage TS1130 Tape Drive - Machine Type 3592, Model E06 Security PolicyDocument22 pagesIBM System Storage TS1130 Tape Drive - Machine Type 3592, Model E06 Security Policyfarkli88No ratings yet

- Technical Description: Fastrax UP500 GPS ReceiverDocument15 pagesTechnical Description: Fastrax UP500 GPS ReceiverAnkur KunduNo ratings yet

- Riser Monitoring SystemDocument15 pagesRiser Monitoring Systemchimmy chinNo ratings yet

- TPS40305Document37 pagesTPS40305gjsmoNo ratings yet

- Type Examination Certificate: Ii 3 G Ex Ec Iic GCDocument3 pagesType Examination Certificate: Ii 3 G Ex Ec Iic GCabdur rafayNo ratings yet

- Not AvailableDocument3 pagesNot AvailableMuhammad IsmailNo ratings yet

- Tpdxeusb30 2-, 4-Channel Esd Protection For Super-Speed Usb 3.0 InterfaceDocument22 pagesTpdxeusb30 2-, 4-Channel Esd Protection For Super-Speed Usb 3.0 InterfaceIulia AdrianaNo ratings yet

- BUF634 DatasheetDocument30 pagesBUF634 DatasheetRene BesanaNo ratings yet

- STD10P6F6, STF10P6F6, STP10P6F6, Stu10p6f6Document24 pagesSTD10P6F6, STF10P6F6, STP10P6F6, Stu10p6f6Ikram BalochNo ratings yet

- Nals-A Aa Uds 3fe61233aaaatqzza03Document18 pagesNals-A Aa Uds 3fe61233aaaatqzza03Akm AnisuzzamanNo ratings yet

- Ucc280X Low-Power Bicmos Current-Mode PWM Controllers: 1 Features 3 DescriptionDocument61 pagesUcc280X Low-Power Bicmos Current-Mode PWM Controllers: 1 Features 3 Descriptionsajad hejaziNo ratings yet

- Manual CS 800 From SN 1557040811 en PDFDocument61 pagesManual CS 800 From SN 1557040811 en PDFСергей МустафинNo ratings yet

- NALSDocument14 pagesNALSroswind77No ratings yet

- TG1 - 7UM621 V4 - 7 - PRN - 10 - 02 - 31Document14 pagesTG1 - 7UM621 V4 - 7 - PRN - 10 - 02 - 31PABITRA PATRANo ratings yet

- Appendix 03 Equipment List (Total Scope of Supply)Document30 pagesAppendix 03 Equipment List (Total Scope of Supply)Anish SinghNo ratings yet

- RF - ZE520KL Trouble Shooting Guide - 0714Document31 pagesRF - ZE520KL Trouble Shooting Guide - 0714Luiz BeltrameNo ratings yet

- Exposición HuaweiDocument32 pagesExposición HuaweimendietagomezsergioNo ratings yet

- Calculation and Selection ResultDocument18 pagesCalculation and Selection ResultNery TorresNo ratings yet

- PS 43045 001Document21 pagesPS 43045 001ovNo ratings yet

- Psp534w, Lubuk Barumun, Rbs6601 Duw30 Rrus2100 EnclDocument7 pagesPsp534w, Lubuk Barumun, Rbs6601 Duw30 Rrus2100 EnclFred AksoNo ratings yet

- All Pricelist SubconDocument30 pagesAll Pricelist SubcondaniNo ratings yet

- SPEC-50247-xxxxx-xxx Rev-BDocument9 pagesSPEC-50247-xxxxx-xxx Rev-BMarcos HereNo ratings yet

- Instrument MTO Rev. 24-08-2023Document4 pagesInstrument MTO Rev. 24-08-2023iqtm36No ratings yet

- p4nk60zfp STDocument16 pagesp4nk60zfp STCahemlNo ratings yet

- Ds - ft600q-Ft601q Ic DatasheetDocument37 pagesDs - ft600q-Ft601q Ic DatasheetlucribasNo ratings yet

- GS34P02Q13 01eDocument24 pagesGS34P02Q13 01eosmondmanurungNo ratings yet

- Phoenix Contact 3031225 enDocument5 pagesPhoenix Contact 3031225 enDGNo ratings yet

- Attachment 3B YKTN Government Furnished InformationDocument8 pagesAttachment 3B YKTN Government Furnished InformationRebecca JohnsonNo ratings yet

- ASU2 / Local Oscillator & Tune User Manual: BrukerDocument21 pagesASU2 / Local Oscillator & Tune User Manual: BrukerFer GuNo ratings yet

- Asus Zc553Kl RF Hardware Trouble Shooting Guide: Inspiring Innovation Persistent PerfectionDocument57 pagesAsus Zc553Kl RF Hardware Trouble Shooting Guide: Inspiring Innovation Persistent PerfectionMTec EletrônicosNo ratings yet

- UF-850XTD Catalog 12PDocument6 pagesUF-850XTD Catalog 12PHuỳnh Bảo SơnNo ratings yet

- PSP552W, Papaso, RBS6601 DUW30 RRUS2100 EnclDocument1 pagePSP552W, Papaso, RBS6601 DUW30 RRUS2100 EnclFred AksoNo ratings yet

- Met One Instruments BAM-1020 PM-Coarse Measurement SystemDocument4 pagesMet One Instruments BAM-1020 PM-Coarse Measurement SystemMohamad AzlanNo ratings yet

- FTTX Standard Installation Guideline Add Com and Troubleshooting V1.7Document95 pagesFTTX Standard Installation Guideline Add Com and Troubleshooting V1.7suraphonNo ratings yet

- PSP987W, Bulu Barumun, RBS6601 DUW30 RRUS2100 EnclDocument2 pagesPSP987W, Bulu Barumun, RBS6601 DUW30 RRUS2100 EnclOkas PaskalNo ratings yet

- Phoenix Contact 3044542 enDocument6 pagesPhoenix Contact 3044542 enDGNo ratings yet

- PSP986W, Sipirok Kota, RBS6601 DUW30 RRUS2100 Encl-RBSDocument2 pagesPSP986W, Sipirok Kota, RBS6601 DUW30 RRUS2100 Encl-RBSOkas PaskalNo ratings yet

- Phoenix Contact 3044571 enDocument6 pagesPhoenix Contact 3044571 enDGNo ratings yet

- 250 KW Soalr SparesDocument1 page250 KW Soalr SparesRAJENDRA PRASADNo ratings yet

- OptiX OSN 8800 10-Port 10G Tributary Board TTXDocument38 pagesOptiX OSN 8800 10-Port 10G Tributary Board TTXThunder-Link.com100% (1)

- Phoenix Contact 3031225 enDocument4 pagesPhoenix Contact 3031225 enDGNo ratings yet

- T6T Mk3 50 W VHF TransmitterDocument128 pagesT6T Mk3 50 W VHF TransmitterJr KalemNo ratings yet

- General Specifications: FCN-RTU Low Power Autonomous Controller HardwareDocument24 pagesGeneral Specifications: FCN-RTU Low Power Autonomous Controller HardwareEdén Paz TadeoNo ratings yet

- Ucc 28750Document52 pagesUcc 28750eneas.baroneNo ratings yet

- Boq Minilink TN R4 Etsi: 7Ghz General SpecificationsDocument9 pagesBoq Minilink TN R4 Etsi: 7Ghz General SpecificationsAkhtar RasoolNo ratings yet

- STGB 7 H 60 DFDocument25 pagesSTGB 7 H 60 DFFernando MadeiraNo ratings yet

- NMEA CommandManual - (FTX HW 13002)Document41 pagesNMEA CommandManual - (FTX HW 13002)Linggar UmardiNo ratings yet

- TISP4360H3BJ Overvoltage Protector SeriesDocument14 pagesTISP4360H3BJ Overvoltage Protector SeriesIgor PNo ratings yet

- KB3930 ENEerDocument199 pagesKB3930 ENEerJuan Carlos Guerra MansoNo ratings yet

- I en 007 2019 Apt Wmbus Na 1Document29 pagesI en 007 2019 Apt Wmbus Na 1thenixruleNo ratings yet

- Phoenix Contact 3044076 enDocument56 pagesPhoenix Contact 3044076 enBambang AmingNo ratings yet

- K9F1G08U0D SamsungDocument38 pagesK9F1G08U0D SamsungAndyNo ratings yet

- Terminations: Underground Electric Distribution StandardsDocument20 pagesTerminations: Underground Electric Distribution StandardsHendrix LevaNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Connection-Oriented Networks: SONET/SDH, ATM, MPLS and Optical NetworksFrom EverandConnection-Oriented Networks: SONET/SDH, ATM, MPLS and Optical NetworksNo ratings yet

- Human Resource ManagementDocument86 pagesHuman Resource ManagementK V S PRASD REDDYNo ratings yet

- 11th Bio Botany Important Questions For Volume 1 PDFDocument6 pages11th Bio Botany Important Questions For Volume 1 PDFNaren44% (9)

- ٣. المنقذ (١٠٠ سؤال)Document44 pages٣. المنقذ (١٠٠ سؤال)ايمان عبد الشافىNo ratings yet

- Design Calculation of Gantry GirderDocument7 pagesDesign Calculation of Gantry GirderKushal ChhetriNo ratings yet

- Sheet #6 Ensemble + Neural Nets + Linear Regression + Backpropagation + CNNDocument4 pagesSheet #6 Ensemble + Neural Nets + Linear Regression + Backpropagation + CNNrowaida elsayedNo ratings yet

- India: "Truth Alone Triumphs"Document103 pagesIndia: "Truth Alone Triumphs"Rajesh NaiduNo ratings yet

- CH 4 Network SecurityDocument37 pagesCH 4 Network SecurityHirko GemechuNo ratings yet

- Bicol State College of Applied Sciences and Technology: JANUARY 2021Document11 pagesBicol State College of Applied Sciences and Technology: JANUARY 2021Jay Dela CruzNo ratings yet

- Azam in 30 DuaDocument3 pagesAzam in 30 DuafaizaninNo ratings yet

- Lenovo Ideapad V110-15AST - LV114A (15270-1 08A03)Document64 pagesLenovo Ideapad V110-15AST - LV114A (15270-1 08A03)Mahmut KaralarNo ratings yet

- Tutorial ControlDocument161 pagesTutorial ControlQuangNguyenDuy100% (1)

- Infinitive and Gerunds - Ingles III - Valeria Kasabji PDFDocument7 pagesInfinitive and Gerunds - Ingles III - Valeria Kasabji PDFValeria KasabjiNo ratings yet

- Tarea 2 TermodinamicaDocument2 pagesTarea 2 TermodinamicaMario GonzalezNo ratings yet

- Thesis Statement, Topic Sentence, and Supporting Details: Paul Christian Reforsado AbadDocument29 pagesThesis Statement, Topic Sentence, and Supporting Details: Paul Christian Reforsado AbadMicole BrodethNo ratings yet

- How To ApplyDocument129 pagesHow To ApplySasa KasaNo ratings yet

- Bausch Lomb Sight Saver SDSDocument10 pagesBausch Lomb Sight Saver SDSsigurdur hannessonNo ratings yet

- .50 BMG - Wikipedia PDFDocument13 pages.50 BMG - Wikipedia PDFAce ActionNo ratings yet

- Type Approval Certificate: ABB AB, Control ProductsDocument3 pagesType Approval Certificate: ABB AB, Control ProductsDkalestNo ratings yet

- The Revenge of The SerpentDocument2 pagesThe Revenge of The SerpentMiyamoto MusashiNo ratings yet

- FORD Vs GMDocument14 pagesFORD Vs GMMahboob Reza100% (1)

- Carboxylic Acids and Their DerivativeDocument43 pagesCarboxylic Acids and Their DerivativenathasyaNo ratings yet

- CSN-261: Data Structures Laboratory: Lab Assignment 5 (L5)Document3 pagesCSN-261: Data Structures Laboratory: Lab Assignment 5 (L5)GajananNo ratings yet

- Safety StockDocument8 pagesSafety StockIwan NovaNo ratings yet

- Wa0009 PDFDocument22 pagesWa0009 PDFRameshwari ChaudharyNo ratings yet

- Speech Analysis Guidelines: The ContentDocument1 pageSpeech Analysis Guidelines: The ContentChristian MorenoNo ratings yet

- Dematron 60 70 Parlour Sheet 1.03Document1 pageDematron 60 70 Parlour Sheet 1.03Andrés HurtadoNo ratings yet

- How Fractions, Decimals and Percentages Work TogetherDocument9 pagesHow Fractions, Decimals and Percentages Work TogetherjohnteecubeNo ratings yet