Professional Documents

Culture Documents

Process Flow of Outgoing Inspection Rev0

Uploaded by

Aisyah ZinfazliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Flow of Outgoing Inspection Rev0

Uploaded by

Aisyah ZinfazliCopyright:

Available Formats

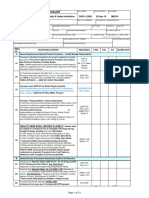

PROCESS FLOW OF OUTGOING INSPECTION

START

INPUT

Physical part , Label packaging, Order Card, Drawing

PART IDENTIFICATION

Verified information on order card matched with drawing and label packaging

1) Part No. & Part Name , Drawing Revision , Surface Treatment , Quantity

UNDERSTAND DRAWING REQUIREMENT

GD&T , tolerance specification , laser marking instruction , other

drawing requirement ; Polish / Milled after tenifer treatment

PHYSICAL PART VERIFICATION

1) Check part is correct as per drawing (Actual / Mirror)

2) Physical feature complete (Holes / Screwholes / Lead-in)

3) Laser marking as per laser marking instruction

4) Drawing requirement ; Polish / Milled after tenifer treatment

5) Quantity

6) Surface treatment coating

DIMENSION INSPECTED VERIFICATION

1) Inspect critical area to validate part is correct ; track width / thickness / etc

2) Verified part inspected as per AMM-WKI-SOP-G-18 & AMM-WKI-SOP-Q-28

3) Verified all dimension within drawing specification

4) Inspect holes & screwholes

ASSEMBLY PART (IF APPLICABLE)

1) Inspect part assembled as per assembly drawing

2) Verified all part complete as per assembly drawing and BOM list

APPEARANCE CHECK

1) Inspect appearance under microscope with 10X magnification

(No cosmetic defect allowed and extra material - step

2) Focus on lead-in , functional area

PACKAGING VERIFICATION

1) Verified part packed securedly and no missing part & wrong part

2) Verified label packaging as per physical part and order card

END INSPECTION

Part passed for delivery

1) Stamp Appearance Checked on order card

2) Stamp Outgoing Checked on order card

3) Stamp OG CHECKED on label packaging to indicate part has been inspected

You might also like

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- GM 1927-16b Injection Molding Process AuditDocument6 pagesGM 1927-16b Injection Molding Process AuditfernandoNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- Type of Company Ownership:: Forging ProcessDocument17 pagesType of Company Ownership:: Forging Processsureshkumar silvernitz100% (1)

- BOQ Metal WorksDocument2 pagesBOQ Metal Workskrishnashankar9_3743100% (2)

- Methodology For FabricationDocument35 pagesMethodology For FabricationBhushan KumarNo ratings yet

- ITP PaintingDocument1 pageITP PaintingYash Sharma100% (3)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Inspection and Test Procedure and Plan Rev 0 Commented by HDECDocument16 pagesInspection and Test Procedure and Plan Rev 0 Commented by HDECarchalys4u100% (4)

- Method Statement-Ext Pipe FittingsDocument13 pagesMethod Statement-Ext Pipe FittingsSam JoseNo ratings yet

- Work Instruction: Item Inspection Characteristics Defect Limit Sample No. 1Document4 pagesWork Instruction: Item Inspection Characteristics Defect Limit Sample No. 1Đỗ Thành NhươngNo ratings yet

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionFrom EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Technical Spec AgitatorDocument74 pagesTechnical Spec Agitatornaresh kumarNo ratings yet

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDocument7 pagesShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTNo ratings yet

- Painting Procedure For Field Erected Tank FINAL (13850)Document22 pagesPainting Procedure For Field Erected Tank FINAL (13850)Parthiban NCNo ratings yet

- Saic A 2001Document21 pagesSaic A 2001Dilshad AhemadNo ratings yet

- 8.3.3.2 - Process Design Input & Verification SheetDocument3 pages8.3.3.2 - Process Design Input & Verification SheetSafety DeptNo ratings yet

- Technical Bid Evaluation Sheet For Fuel Gas ScrubberDocument3 pagesTechnical Bid Evaluation Sheet For Fuel Gas ScrubberSiva baalanNo ratings yet

- Forging Process Audit Check ListDocument15 pagesForging Process Audit Check ListKeerthivasan NNo ratings yet

- Technical Specification - LPG HeaterDocument94 pagesTechnical Specification - LPG Heaterhbsheen100% (1)

- ASME Awareness Program - 5Document40 pagesASME Awareness Program - 5Gaurav KhamkarNo ratings yet

- Flowchart Work Piping in Shop and Site AreaDocument16 pagesFlowchart Work Piping in Shop and Site Areasmartz inspectionNo ratings yet

- ReportDocument3 pagesReportAli KianersiNo ratings yet

- Forming Head ProcedureDocument8 pagesForming Head ProcedureLuhur PrandikaNo ratings yet

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoNo ratings yet

- Pnae G-7-016-89Document7 pagesPnae G-7-016-89ASME TURKEYNo ratings yet

- FSGP & PT370 - Pipe FittingsDocument6 pagesFSGP & PT370 - Pipe FittingsgerrydimayugaNo ratings yet

- 00 Specification CableDocument3 pages00 Specification CableLino AbetoNo ratings yet

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- BPVC Iii-A nm-1Document1 pageBPVC Iii-A nm-1Emma DNo ratings yet

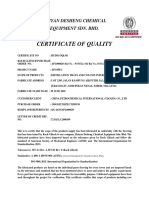

- Certificate of Quality (TRAY)Document2 pagesCertificate of Quality (TRAY)avinash bahadurNo ratings yet

- FORM Q-120 Procedure Specification For Class Ii Vessels (Revision C - 2017) Part I - FabricationDocument10 pagesFORM Q-120 Procedure Specification For Class Ii Vessels (Revision C - 2017) Part I - FabricationEmma DNo ratings yet

- Lesson 10 Materials, Name Plates, and Data Reports UG-77 Material IdentificationDocument1 pageLesson 10 Materials, Name Plates, and Data Reports UG-77 Material IdentificationAnil KulkarniNo ratings yet

- Painting Procedure - Rev.1Document30 pagesPainting Procedure - Rev.1didi sudiNo ratings yet

- Identification For Plumbing Piping and EquipmentDocument5 pagesIdentification For Plumbing Piping and EquipmentEN LeedNo ratings yet

- MPP & Itt - Internal Epoxy PaintDocument12 pagesMPP & Itt - Internal Epoxy PaintSiswo YuwonoNo ratings yet

- 1.1 Signing Off The ProductDocument3 pages1.1 Signing Off The ProductJSG GroupNo ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- Senior Welding Inspector Signing Off Handout Appendix 1 PDFDocument3 pagesSenior Welding Inspector Signing Off Handout Appendix 1 PDFkatfy1No ratings yet

- QAR-QD#419-2 Single PartsDocument2 pagesQAR-QD#419-2 Single PartsIrwanto ManafNo ratings yet

- QM and Process Flow Chart BKT SideDocument3 pagesQM and Process Flow Chart BKT SideDebashis SarkarNo ratings yet

- WIS QCWT GE 15 Rev.1 - Painting InspectionDocument6 pagesWIS QCWT GE 15 Rev.1 - Painting Inspectionfajar aljogjaNo ratings yet

- NDI EquipmentDocument20 pagesNDI EquipmentswenthomasNo ratings yet

- Description Inspection File Assembly InstructionsDocument2 pagesDescription Inspection File Assembly InstructionsAmitNo ratings yet

- Qap Rap PDFDocument1 pageQap Rap PDFtrushalpanchalNo ratings yet

- Inspection and Test Procedure FR1672A - ApprvdDocument10 pagesInspection and Test Procedure FR1672A - ApprvdSavvas KatemliadisNo ratings yet

- Inspection Procedure For KEC Remediation ProjectDocument6 pagesInspection Procedure For KEC Remediation ProjectgoyalmanojNo ratings yet

- Asnt 8Document8 pagesAsnt 8amin.adineh97No ratings yet

- Surveillance of Painting Activity: Ref # Requirements ComplianceDocument2 pagesSurveillance of Painting Activity: Ref # Requirements ComplianceAravind KNo ratings yet

- Saic A 2001Document21 pagesSaic A 2001GanesanNo ratings yet

- Site Lab Checklist1Document4 pagesSite Lab Checklist1layaljamal2No ratings yet

- B2020-TDC-DEF-005 Dished End Forming R0Document2 pagesB2020-TDC-DEF-005 Dished End Forming R0Ramalingam PrabhakaranNo ratings yet

- 3.2 Bill of QuantitiesDocument24 pages3.2 Bill of QuantitiesNazakat HussainNo ratings yet

- LA ChecklistDocument4 pagesLA Checklistmohammed nayeemNo ratings yet

- Painting Specfication ASSENT Doc No: PR-2019-05-007: 076551C-0000R-MR 1 8 0 0 1 0 1Document23 pagesPainting Specfication ASSENT Doc No: PR-2019-05-007: 076551C-0000R-MR 1 8 0 0 1 0 1j fNo ratings yet

- Navicp RT QaliDocument5 pagesNavicp RT QaliAmandeep SinghNo ratings yet

- ASME V Art 28 VTDocument18 pagesASME V Art 28 VTnaoufel1706No ratings yet

- Review Flame ArrestorDocument1 pageReview Flame ArrestorJoko SchumacherNo ratings yet