Professional Documents

Culture Documents

Risk Assessment of Installation of Chilled Water Pipes

Uploaded by

Vlad KaroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment of Installation of Chilled Water Pipes

Uploaded by

Vlad KaroCopyright:

Available Formats

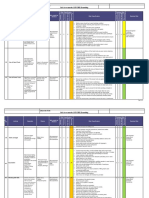

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Delivery/ collection drivers shall be subject to

McLaren induction/Training with regards to traffic

management.

Plant and Traffic 2)Ensure exclusion zone is set up around the

movement preparation work area and all plant

movement and checked by supervisor

3) Always use the pedestrian access provided

Run over by

4) Traffic light batons shall be provided for banks

vehicles/plants

man at night

Hit by reversing

5) All plant to have a fully trained banks man

equipment

present all times.

Delivering, Overhead

6) No plant to reverse without banks man.

unloading and obstructions

Operatives 7) Ensure access route are sufficient and safe to Site Eng.

storing of MS Pipes Vehicle break

1 Staff/visitors Medi use. Supervisor,

and pipe fitting down 3 4 12 1 4 4 Low

using pickup and

um 8) Do not take rest in or under vehicles Foreman,

Property damage

unloading by 9) Proper barricade and safety

Collision with

manual handling signboard provided on open excavation

other

10) All vehicles must be fitted with reverse alarm

vehicles

/ Flashing light.

Personal injury 11) The work place and all access to be well

Fatality illuminated.

Accident due to 12) Ensure close supervision, Effective

poor lighting and Communication & Coordination with McLaren

visibility (operation 13) Enforce Speed limit

at night 14) Ensure all vehicles entering the site is

properly maintained and reported if found any

defect

15) Ensure materials are secured/tied in pallet

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

trolley to avoid fall from trolley.

16) Do not ride or horse play with pallet trolley.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Eliminate the need for manual handling by

using mechanical aid.

2)Reduce the weight of a load to limit

force exertion

3) If unsure of the load weight, check with

supervisor.

5) Ensure proper manual handling procedure Supervisor,

musculoskeletal

Manual Handling Operatives Med 6) Identify and eliminate sharp edges before any Foreman,

2 disorders, Hand Low

involved in work 3 4 12 ium manual lift 1 4 4 Site Eng.

injuries, cut , bruises

7) Ensure adherence with sufficient and

Sharp edges

appropriate PPE.

8) Limit load carrying to 20kg per person

9) Supervisor must make sure while manual

handling load individual task and environment

to be considered to reduce the risk of manual

handling.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Ensure accesses are kept clear at all times.

2)Housekeeping to be carried out regularly

throughout the day when required

3)Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a safe

condition Supervisor,

Operatives

Slips, Trips and fall 4) Provide adequate lighting especially

Staff/storekeeper Med Foreman,

3 Material storing Poor house keeping 3 4 12 during night hours 1 4 4 Low

ium Site Eng.

5) Appropriate space is allowed around storage

areas for employees to move around safely

without the risk being trapped between

stacked materials.

6) Maintain good housekeeping.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

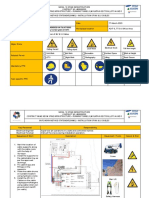

1. Ensure grinding /cutting disks are appropriate

to application and do not use if date is

expired.

2. Ensure that wheel speed marked on

disk should greater than grinder

machine

3. Ensure that grinder have safety guard

4. Operatives must use face shield and

eye protection

5. Ensure that grinding/cutting area free from

Grinder/cutter combustible materials

Eye injury 6. Hot work permit must be obtained for

Arc Welding any type of hot work.

Fabrication of Involved all work 7. Welding area must be barricaded and fire Site Eng.

Threading

Chilled water force and watcher should actively inspect the hot

4

piping

Noise supervisor/forem

4 4 16 High

work area

1 4 4 Low Supervisor

arrangements Metal waste an 8. Fire blanket must use for spark and Foreman

Electric shock welding flux protection.

Fire 9. Ensure Fire Extinguisher and sand bucket

in place.

10. Ensure all electrical cables are in good

condition and away from hot work

area.

11. Welding Machine must calibrated and

welder must certified by 3rd party.

12. Use Proper hand gloves to protect

finger during using threading die set.

13. Welder must use welding aprons

and necessary PPE

14. Use ear protection for noise control

15. Ensure there is no loose connection and no

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

damage electrical cable or socket for

preventing electric shock.

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

16. Ensure Proper earthling and use of

industrial socket only.

17. Operatives must aware of voltage and

use accordingly the socket considering

colour.

18. Fire watcher must ensure hot work area

have no fume or spark or any smoke before

leave the work area

19. Ensure that operative’s cloths not to

entanglement with rotating tools and

injury.

20. Work area must clean and tidy to avoid

slip trip or fire.

21. Ensure adequate earthleakge protections

are provided.

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

1) Only trained and authorised personnel to

carry out the task.

2) Ensure the PTW in place.

3) Ensure proper working platform with complete

Work at height fall protection

4) Ensure Full body harness and 100% Tie off

Fall form height 5) Ensure the scaffold platform is properly

erected with "Safe to use" tag.

6) Ensure castor wheels are locked and out rigger

Falling objects in place.

7) Hand tools must be secured/tethered

Installation of Operatives/Staff/

Supervisors

Chilled water Visitors 8) Work materials strictly not allowed to be

5

Others

4 4 16 High 1 4 4 Low Foreman,

Pipes using stored on platform except for working tools

Over loading Site Eng.

Mobile tower 9) Always comply with the WLL & man

loading capacity

10) Ensure unauthorised person not allowed to

modify the scaffolding and if needed to any

changes then must be modified by trained and

certified scaffolder.

11) Must clean the work area after completion

Access & egress the job.

12) Ensure safe access to the working platform

13)Scaffold access must be free from obstruction

14) Maintain 3 point contact while accessing vertical

ladder

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Only light work, off short duration and work in

which the operative can maintain secure hand

and foot hold can be undertaken form a ladder

2) Never try to overreach with any ladders

Falling from height 3) Check the ladder is of suitable quality

for industrial use and is in good condition

4) Maintain a minimum of 3 points of contact

with stepladders at all times

(feet/thighs/hands) If possible avoid the use of

stepladders at a working height of 2 meters and

more.

5) Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

Operatives/ Supervisor

Use of Ladder Med maintain maximum base dimensions and the step

6 Staff/ 3 4 12 1 4 4 Low Site Eng.

Working on Uneven ium ladder is orientated to provide maximum

Foreman,

ground stability.

6) Stepladders/ladders has to be used on

leveled ground/firm base

7) Ensure that during using ladder from the top

2 step is blocked to avoid climb on that.

8) The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

Falling objects 9) Person must hold the ladder while

another operative working on it

8) Materials should not be placed above

the thread of ladders/step ladders

9) Do not carry any materials in one hand while

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

climbing or getting down from ladder

10) Ensure the area under the ladder is

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

barricaded especially if it is being used in a public

area.

11) Ensure the ladder is electrical insulated

podium type if working in live services

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) All portable electrical equipment must be PAT

tested and color coded. Make sure the test dates

are visible on the equipment.

2) Ensure all power tools are 110 volt and

adequate earth leakage protection is provided.

Periodic inspections shall by qualified electrician

and maintain records.

Damaged cable

3) PTW to be obtained, prior to commencing

insulation,

the task

Sockets.

4) Damaged industrial sockets and power

Electrocution

Electric cables must be removed.

shock Short 5) Ensure the electrical cable is not damaged

Use of power and has not been repaired with insulating tape or Supervisor

circuit

tools such as Operatives Med

7 Electric burn 3 4 12 unsuitable connectors. 1 4 4 Low Foreman

angel grinder,

Trip/Fall

and staff ium

Drill machine, 6) Ensure cables from power tools shall be Site eng.

Noise organized so as not to present a tripping hazard

Hearing loss

7) Only trained competent operatives to operate

Vibration

the power tools.

Dust

8) Ensure proper and regular maintenance

of equipment that takes account of noise

9) Ensure proper hearing protection always.

10) Make sure people use the right tool for the

job and are trained to use it correctly

11) Ensure defective tools that require

maintenance is reported for repair or

replacement.

12) Instruct workers to keep their hands warm

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

and dry, and to not grip a vibrating tool too

tightly. Workers should allow the tool or machine

to do the work.

13) Ensuring proper job rotation and limiting

time operatives working with power tools and

hand tools.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1.Arrange adequate drinking water and rest shelter

2.Drink plenty of water with electrolyte

3. If feel something unusual immediately

Heat exhaustion, inform supervisor and report to site clinic.

Working under Heat stroke, 4.Make shift to operate the routine work

High temperature Dehydration, Site Eng.

Workers 5.Do not allowed alone work

8 Direct sun light Personal injuries 4 4 16 High 1 4 4 Low Supervisors,

6. Frequent breaks

Dusty due to high Foreman

7. Proper supervision

High wind temperature, Burn,

Tiredness available 8.Correct PPE must

use 9.Provide heat stress

training 10.Conduct tool box

talk

11.Proper signage for drinking water

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Ensure proper night work permit is obtained

2) Proper lighting system should be in place

3) Ensure proper Communication / Coordination

and close supervision

4) Industrial safe torches to be available

Operatives/staff

Poor visibility due to for emergency situations Site Engr

Working at night darkness / poor Med 5) High visibility Traffic Vest for personnel’s in

9 time 3 4 12 1 4 4 Low Supervisor

illumination night shift

ium Foreman

Lone worker 6) Avoid lone working and always ensure

buddy system while working at night

7) Employees to be trained and

understand McLaren Crises plan.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Hand tools should be visually inspected

Improper selection for defects, prior to use.

of hand tools. 2) Never use damaged, blunt or broken tools to

Damaged and avoid injury.

Defective Hand 3) Select right tools for right Job Site engg

tools Operatives/Staf 4) Ensure no Homemade or makeshift tools to be Supervisor

Hand injuries f Med used at site Foreman

10 Use of Hand tools 3 3 9 5) Remove from service any tool that shows 1 3 3 Low

Pinch point ium

Ergonomics signs of damage or defect

Repetitive strain 6) Ensure Hand tools are Stored in accordance

injury with the manufacturer’s instructions.

7) Ensure hands are not in direct line of fire while

working with hand tools

6) Ensure appropriate PPE at all times.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

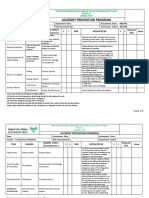

Use of Solvent, 1. 1)Ensure that all chemical substances

Chemicals and have a COSHH assessment

oil (Hazardous 2. Refer SDS prior to any handling of

Substance) hazardous substances and ensure SDS is

easily accessible at site while working

with chemicals.

3. Ensure chemicals are properly stacked.

Spillage/ soil 4. Ensure all chemical containers are

contamination properly labeled.

5. Spill kits to be available at site.

6. Ensure operatives use the correct PPE

Burns 7. Competent person to oversee the

Contact with skin storage, use and disposal of hazardous

All Supervisors

Med materials.

11 operatives/Sta 3 4 12 1 4 4 Low Foreman,

Acute/Chronic ium 8. Ensure that correct welfare/first aid

adverse heath ff facilities are available in the area i.e. Site Eng

effect. washing facility/eye wash.

9. Ensure all chemical containers are

Fire properly labeled.

10. 11)Isolate or enclose the process

11. 12) Adjust work schedules so that

workers are not overexposed to

a hazardous chemical.

12. 13) Wear respiratory protection

13. 14) Ensure proper ventilation

14. 15) Ensure proper and adequate PPE to

be used always.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1. 16)Ensure smoking only in

designated area

2. 17) Ensure appropriate Firefighting

equipment’s are in place and

easily accessible

3. 18) Ensure chemicals are not placed in

the immediate proximity of hot work

activities

4. 19) Ensure drip tray available in work

area.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

Pressure Testing 1. Risk assessment must brief to the operatives.

2. Ensure permit obtained for pressure test.

3. All pressure tests must be conducted with

due regard for the safety of life and

property.

4. Precautions should be taken to see that

people not directly engaged in the testing

operations remain out of the test area

during the test period.

5. During pressure testing events, distinct

warning signs, such as DANGER – HIGH

PRESSURE TESTING IN PROGRESS must be

Hydro test posted at the test work area with

High-pressure leak exclusion zone .

of water All operatives 6. Check that all high points have a tap or Site eng

12 Failure of hydraulic involved in 4 4 16 High vent to facilitate removal of air during filling 1 4 4 Low Supervisor

test pump work and that these are all closed. Foreman

Electric shock 7. Blank, plug or seal any open ends and

Electrocution close all valves at the limits of the test

section of the piping.

8. Start to fill the piping and then ‘walk’ the

route of the piping under test, continuously

visually checking for leaks and by listening

for the sound of escaping air

9. Release air from all the high points

systematically through the system to

completely fill it with water

10. Check that the test gauge is functioning

correctly has been calibrated and has

the correct range of the test pump.

11. Check that a suitable hose is available for

draining the system

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT GEMC-MC-A-MST -009

Rev. No. Rev. Date

00 04/03/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Chilled Water Pipes & Fittings Prabir

Safety

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

12. Before attempting test, Supervisor will review

the test specifications and procedures with

the Test Inspector and any other relevant

personnel to be certain that all equipment is

adequate, and duties are organized and

understood

13. All the electric live service must be

temporary isolate to avoid electric shock and

electrocution

14. STARRT talk must conduct by supervisor

15. PPE must in use with face shield

16. Ensure proper grounding and earthling.

17. After completion of the pressure test, release

the water and disconnect all the temporary

connections and close both ends

18. Exclusion zone must be remove and

remove the danger signage after

completion of pressure test.

Approved By: Name Position Signature

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

RISK ASSESSMENT & CONTROL GUIDELINES

1. Executing Steps:

1.1. Planning

a) Construction and HSE team must ensure that hazard identification is complete.

b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks have

well established legal requirements, potentially high risks).

c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these potential

high risks.

1.2. Risk Assessment

Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The hazard is the

potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an event occurring, but also the

outcome will be in terms of injury, loss, damage or harm.

1.3. Risk Assessment Process

The process of carrying out a risk assessment should be as follows.

1. Identify the hazards.

2. Identify who might be harmed and how.

3. Evaluate the risk and implement the control measures.

4. Record the significant findings.

5. Review the assessment and update if necessary.

1.4. Examination of the Hazards and Risk Associated

Competent staff must be used in examining the risk associated with the identified hazard.

Competent staff should examine following aspect to determine the risk involved:

o Examine the existing control measures in place.

o Identify employees at risk.

o Likelihood of risk.

o Severity

o Risk level and their tolerability.

1.5. Evaluating the risk:

Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to access the risks.

1.5.1. Risk Rating Score

Risk rating score is a combination of two factors.

The severity of the risk that could injure persons or cause damage to plant.

The likelihood of the risk that it could happen (Probability).

RISK RATING = LIKELIHOOD X SEVERITY

NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in the table below.

No Injury Minor Moderate Major

Catastrophic (5)

(1) Injury (2) Injury (3) Injury (4)

1 2 3 4 5

Rarely (1)

Unlikely (2) 2 4 6 8 10

LIKELIHOOD

Possible (3) 3 6 9 12 15

Likely (4) 4 8 12 16 20

RISK LEVEL: Almost

5 10 15 20 25

Certain (5)

Low Medium High

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust FanDocument10 pagesRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilNo ratings yet

- Hyundai Engineering & Construction Co., Ltd. Hamad Bin Khalifa Medical City Construction Package Cp-300B Hospital Fit Out ProjectDocument4 pagesHyundai Engineering & Construction Co., Ltd. Hamad Bin Khalifa Medical City Construction Package Cp-300B Hospital Fit Out ProjectYounis KhanNo ratings yet

- Mobilization and Installation of CHW PipesDocument8 pagesMobilization and Installation of CHW PipesYounis KhanNo ratings yet

- Installation Testing Commisiioning of LPG SYSTEMDocument12 pagesInstallation Testing Commisiioning of LPG SYSTEMYounis KhanNo ratings yet

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

- Job Safety Analysis (JSA) - HVAC Ducting DateDocument1 pageJob Safety Analysis (JSA) - HVAC Ducting DatenabeelNo ratings yet

- 2 - Risk AssessmentDocument4 pages2 - Risk AssessmentNangyal KhanNo ratings yet

- RAMS For Pressure TestingDocument21 pagesRAMS For Pressure TestingAnandu AshokanNo ratings yet

- MSRA For Testing and Flushing of FF Sprinkler SystemDocument22 pagesMSRA For Testing and Flushing of FF Sprinkler SystemkiranramNo ratings yet

- Wah InductionDocument38 pagesWah InductionkashralNo ratings yet

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- Method Statement For Erection of Transformer Shed Structure & Pipe Spools Installation and Support Erection in Phase 1 Location FORDocument23 pagesMethod Statement For Erection of Transformer Shed Structure & Pipe Spools Installation and Support Erection in Phase 1 Location FORAbdul HadiNo ratings yet

- WMS Infineon Project Tower ( Lifting Activities)Document14 pagesWMS Infineon Project Tower ( Lifting Activities)tanaNo ratings yet

- Risk Assessment (5x5 Matrix) : R.A Team Leader / Members: Name: Designation: Signature: Approved By: Reference NumberDocument27 pagesRisk Assessment (5x5 Matrix) : R.A Team Leader / Members: Name: Designation: Signature: Approved By: Reference NumberMd ShahinNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- Risk Assessment - Installation of Safety Zone Wolf AreaDocument10 pagesRisk Assessment - Installation of Safety Zone Wolf AreaJIHUL GEORGENo ratings yet

- HSE Hazards and Effects Management for Wood Cutting MachinesDocument7 pagesHSE Hazards and Effects Management for Wood Cutting Machinessaravana.bNo ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- Risk Assessment for Corian at Mozoon Towers ProjectDocument12 pagesRisk Assessment for Corian at Mozoon Towers Projectadeoye AdeyemiNo ratings yet

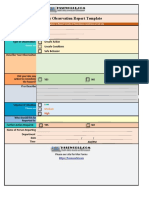

- Safety Observation Report Template - Report Unsafe ConditionsDocument1 pageSafety Observation Report Template - Report Unsafe ConditionsRaju GayakNo ratings yet

- Delfix 8-10Document2 pagesDelfix 8-10FAIYAZ AHMEDNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- J718 SCX1800a RA 220322 Rev02Document13 pagesJ718 SCX1800a RA 220322 Rev02Ion Domnari100% (1)

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- Method Statement RISK ASSESSMENT For Mechanical Piping CompressDocument41 pagesMethod Statement RISK ASSESSMENT For Mechanical Piping CompressVlad KaroNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- Evr J0100 Msra CL 02Document10 pagesEvr J0100 Msra CL 02Marwan NizarNo ratings yet

- OHS Site Safety HandbookDocument40 pagesOHS Site Safety Handbooksalman ahmed0% (1)

- Construction Assessment Checklist: Green TagDocument2 pagesConstruction Assessment Checklist: Green TagRyan GillespieNo ratings yet

- PTW Audit Report SummaryDocument1 pagePTW Audit Report SummarybhaskarNo ratings yet

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Company Instrumentation Coring Works Risk AssessmentDocument11 pagesCompany Instrumentation Coring Works Risk AssessmentJayson EscamillanNo ratings yet

- Swms For LV, MV Cable Laying 17.12.22Document5 pagesSwms For LV, MV Cable Laying 17.12.22Md Shahbaz AlamNo ratings yet

- 37 Material StorageDocument5 pages37 Material StorageKhuda BukshNo ratings yet

- Permit Work at Qatar FoundationDocument1 pagePermit Work at Qatar FoundationJeffersonDeGuiaNo ratings yet

- JET Fan InstallationDocument2 pagesJET Fan InstallationKrishna Patil100% (2)

- AD Ports Group Project: Document Number: 2106-209-V8-8999-00001Document75 pagesAD Ports Group Project: Document Number: 2106-209-V8-8999-00001NAVEEN VAMADEVAN100% (1)

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 pagesCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazNo ratings yet

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- Fire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpDocument4 pagesFire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpAbeSanNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetYounis KhanNo ratings yet

- Critical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsDocument2 pagesCritical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsdnmuleNo ratings yet

- Risk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Document16 pagesRisk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Mohsin MohdNo ratings yet

- Piping Support Fabrication Safe Work Method StatementDocument8 pagesPiping Support Fabrication Safe Work Method StatementHichem BklNo ratings yet

- RISK ASSESSMENT FOR Ac Cleaning ServicesDocument5 pagesRISK ASSESSMENT FOR Ac Cleaning ServicesEGSC HSENo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresHasanuddin HAMIDNo ratings yet

- Hot Work Safety MeasuresDocument6 pagesHot Work Safety Measurestamoor sarwarNo ratings yet

- Risk Assesssment-Vinyl & Tile Floor InstallationDocument2 pagesRisk Assesssment-Vinyl & Tile Floor InstallationMunaku TafadzwaNo ratings yet

- Ra Lightning Protection SystemDocument16 pagesRa Lightning Protection SystemamalNo ratings yet

- RAMS For Roof Maintenance@AgbaraDocument7 pagesRAMS For Roof Maintenance@AgbaratrendyNo ratings yet

- StudsDocument163 pagesStudsHassanNo ratings yet

- Porsche Panamera Owners ManualDocument343 pagesPorsche Panamera Owners Manualwattafilling100% (1)

- VISSIM Modeling Guidance 9-12-2017Document21 pagesVISSIM Modeling Guidance 9-12-2017Amul ShresthaNo ratings yet

- Environmental Project Proposal-1Document5 pagesEnvironmental Project Proposal-1api-232078794No ratings yet

- Exam3 Communication Skills Fall 2021-2022Document50 pagesExam3 Communication Skills Fall 2021-2022Michel Abou HaidarNo ratings yet

- NEW JKR MANUAL ON FLEXIBLE PAVEMENT DESIGNDocument19 pagesNEW JKR MANUAL ON FLEXIBLE PAVEMENT DESIGNElvic ChiaNo ratings yet

- 10 Traffic Signals Under SCOOT Control Effective Design Principles Jackie DaviesDocument12 pages10 Traffic Signals Under SCOOT Control Effective Design Principles Jackie DaviesKhairul AnuarNo ratings yet

- Stanovi Sa Karakteristikama KucaDocument15 pagesStanovi Sa Karakteristikama KucaKitanovic NenadNo ratings yet

- Overpasses/Underpasses: DescriptionDocument3 pagesOverpasses/Underpasses: DescriptionshafiullahNo ratings yet

- Bishoftu Forem2Document29 pagesBishoftu Forem2Aida Mohammed100% (1)

- Module 6 Traffic ManagementDocument78 pagesModule 6 Traffic ManagementAmber EbayaNo ratings yet

- Timing Traffic Signal Change Intervals Based On Driver BehaviorDocument11 pagesTiming Traffic Signal Change Intervals Based On Driver BehaviorRamadan DurakuNo ratings yet

- 6 Municipality of Tupi v. Faustino, G.R. No. 231896, Aug. 20, 2019Document15 pages6 Municipality of Tupi v. Faustino, G.R. No. 231896, Aug. 20, 2019Chrystelle ManadaNo ratings yet

- Two-laning 106-117km MDR104 Feasibility Report Jodhpur-Balesar-ShergarhDocument155 pagesTwo-laning 106-117km MDR104 Feasibility Report Jodhpur-Balesar-ShergarhPrem0% (2)

- Optimization of Greenwave Traffic Control Systems: A Literature Review and Research DirectionsDocument9 pagesOptimization of Greenwave Traffic Control Systems: A Literature Review and Research DirectionsCaleb NimyelNo ratings yet

- Bicycle Infrastructure Can Good Design Encourage CyclingDocument39 pagesBicycle Infrastructure Can Good Design Encourage CyclingdashakrezubNo ratings yet

- Lesson Plan 4Document2 pagesLesson Plan 4siput09No ratings yet

- Very Important MessageDocument5 pagesVery Important MessageEl D GraciaNo ratings yet

- 35 Cacho v. ManahanDocument3 pages35 Cacho v. ManahanGabrielle Adine SantosNo ratings yet

- Presentation AnalysisDocument17 pagesPresentation Analysisjelita25No ratings yet

- 40-60 Đề Phát Triển Theo Cấu Trúc Đề Minh Họa Của Bgd Ngày 1-3-2023 - Môn Tiếng Anh - Luyện Thi Tốt Nghiệp Thpt (Bản Gv) (Đề 11-20)Document166 pages40-60 Đề Phát Triển Theo Cấu Trúc Đề Minh Họa Của Bgd Ngày 1-3-2023 - Môn Tiếng Anh - Luyện Thi Tốt Nghiệp Thpt (Bản Gv) (Đề 11-20)Dạy Kèm Quy Nhơn OfficialNo ratings yet

- Poisson Distribution and Traffic ApplicationsDocument2 pagesPoisson Distribution and Traffic ApplicationsMomanyi IvyNo ratings yet

- Weinland Park Community Mobility PlanDocument97 pagesWeinland Park Community Mobility PlanWeinland Park Community Civic AssociationNo ratings yet

- Research 1bongathangille Final EsearchDocument26 pagesResearch 1bongathangille Final EsearchLindsymae Sula-sula100% (1)

- City Development Plan (2010-30) : MotihariDocument20 pagesCity Development Plan (2010-30) : MotihariAnonymous Y3g0E9fXRcNo ratings yet

- Rational Approach To Cross-Profile and Rut Depth AnalysisDocument7 pagesRational Approach To Cross-Profile and Rut Depth AnalysisdinoNo ratings yet

- Research Format Sobrang LatestDocument20 pagesResearch Format Sobrang LatestEino DuldulaoNo ratings yet

- 1941 Master Plan Highways County Los Angeles Regional Planning DistrictDocument112 pages1941 Master Plan Highways County Los Angeles Regional Planning DistrictJason BentleyNo ratings yet

- Sandton Rea Vaya BRT Roll-Out Traffic AdvisoryDocument2 pagesSandton Rea Vaya BRT Roll-Out Traffic AdvisoryJDANo ratings yet

- Lesson 5 Activity 1Document1 pageLesson 5 Activity 1tricia onaNo ratings yet