Professional Documents

Culture Documents

Class Drives

Class Drives

Uploaded by

JonatasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Class Drives

Class Drives

Uploaded by

JonatasCopyright:

Available Formats

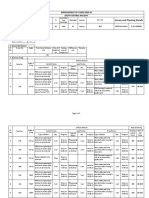

TECHNICAL SHEET

MATCHING & TAGGING

OF CHAINS

Chain Strand

MATCHING AND TAGGING OF CHAINS A B C D E

Class 1 – Tag

Chains are not measured,

MATCHING AND TAGGINGbut the chains (strands, sections or

OF CHAINS

Chain Strand

1 A B C D E

both) will be tagged: LH, RH, Lead End, etc., and/or tied together

Class 1 – Tag

as requested.

Chains are not measured, but the chains (strands, sections or

Class 2 – Measure, Match & Tag

both) will be tagged: LH, RH, Lead End, etc., and/or tied together 1 Consecutive

E1 & E2

All requested.

as chain strands(1) are assembled as multiple sections of 10 feet or

10 ft. Section 10 ft. Section

less(2), measured, and tagged with that measurement. These sections 2 Parallel

Class 2 – Measure,

are arranged Match

to incorporate & Tag

a parallel and consecutive match. Consecutive

A2, B2, C2,

E1

D2,&E2

E2

•

All chain strands

Parallel:

(1)

are assembled

The sections as multiple

are assembled sections

such of 10 feet or

that sections

Consecutive

lessdirectly

(2)

, measured,

across and tagged

from eachwith thathave

other measurement. These

a difference of sections

less 2 Parallel

E2 &E3

arethan

arranged to incorporate a parallel and consecutive match.

06-21 Order No. 11373 | Drives ® is a registered trademark of The Timken Company. | © 2021 The Timken Company

0.030 in. A2, B2, C2,

D2, E2

• Parallel: The sections

Consecutive: areare

The chains assembled

arrangedsuch

suchthat

thatsections

a “short” 3

Consecutive

directly is

section across from each

not directly other have

assembled to a a“long”

difference of less

section. This E2 &E3

than 0.030 in.

results in having a difference between matched strands (for

• any given totalThe

Consecutive: lengths)

chainsofare

less than 0.030

arranged in. that a “short”

such 3

etc.

section

Class 3 –isMeasure,

not directly Match

assembled & to a “long”

Tag section. This

(Customer Fig. 7. Matching and tagging of chains.

results in having a difference between matched strands (for

Specified Match)

any given total lengths) of less than 0.030 in. All match/tag chains are within ANSI standard length tolerances.

etc.

All chain strands(1) are assembled as multiple sections of 10 feet or Matching measured sections (10 feet or shorter sections) ensures

Class

less (2) 3 – Measure,

, measured, Match

and tagged &measurement.

with that Tag (Customer These sections Fig. 7. Matching and tagging of chains.

that attachments are aligned across the parallel chain strands.

Specified

are arranged Match)

to incorporate a parallel and consecutive match. Thismatch/tag

optimizedchains

matchare

alsowithin

results in parallel strand lengths being

All ANSI standard length tolerances.

•

All chain strands

Parallel:

(1)

are assembled

The sections as multiple

are arranged suchsections of 10 feet or

that sections extremelymeasured

Matching close to one another.

sections (10 feet or shorter sections) ensures

lessdirectly

(2)

, measured,

across and tagged

from with

each thathave

other measurement. These

a difference of sections

less that attachments are are

aligned

All match/tag chains built across the parallel

using same chaintostrands.

batch parts ensure

arethan

arranged to incorporate

a Class 2 match. a parallel and consecutive match. This optimized match also results in parallel strand lengths being

the least amount of variance between strands. Reference to

• Parallel: The sections

Consecutive: The chainsareare

arranged such

arranged thatthat

such sections

a “short” extremely

“short” orclose to sections

“long” one another.

simply refers to the minimum and

directly is

section across from each

not directly other have

assembled to a a“long”

difference of less

section. This maximum

All match/tagsidechains

of thatare particular batch

built using length

same range.

batch parts to ensure

than a Class 2 match.

results in having a difference between matched strands the least amount of variance between strands. Reference to

(1)

Strand: total chain length

• (for any givenThe

Consecutive: totalchains

lengths)

areofarranged

less thansuch

a Class

that2amatch.

“short” “short” or “long” sections simply refers to the minimum and

(2)

(3)

Section: part of the

Customer specified

total chain length – 10 ft. long or less

section is not directly assembled to a “long” section. This maximum side of that particular batch length range.

results in having a difference between matched strands (1)

Strand: total chain length

(for any given total lengths) of less than a Class 2 match. (2)

Section: part of the total chain length – 10 ft. long or less

(3)

Customer specified

The Timken team applies their know-how to improve the reliability and performance of machinery in diverse markets worldwide.

The company designs, makes and markets bearings, gear drives, automated lubrication systems, belts, brakes, clutches,

chain, couplings, linear motion products and related power transmission rebuild and repair services.

www.driveschain.com

You might also like

- Ansi Aisc 341-10 Pags58-59Document2 pagesAnsi Aisc 341-10 Pags58-59Jhonny GarciaNo ratings yet

- Idoc - Pub - Philips 28pfl2908h 12 Chassis Vem11ela 17mb82s PDFDocument43 pagesIdoc - Pub - Philips 28pfl2908h 12 Chassis Vem11ela 17mb82s PDFQuiteNo ratings yet

- Tarea de Aprendizaje #1 - Bilinguismo - C Integral 2021-1Document5 pagesTarea de Aprendizaje #1 - Bilinguismo - C Integral 2021-1katherineNo ratings yet

- Cleaning of Dairy EquipmentDocument20 pagesCleaning of Dairy Equipmentmilind_vetyNo ratings yet

- Cosmological Perturbation Theory, Part 1 - Hannu Kurki PDFDocument97 pagesCosmological Perturbation Theory, Part 1 - Hannu Kurki PDFherkike01No ratings yet

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table9Document1 pageEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table9yw_oulalaNo ratings yet

- AQA - IAL - Chem CH1 Practice Question AnswersDocument2 pagesAQA - IAL - Chem CH1 Practice Question AnswersMahebul MazidNo ratings yet

- Greenfield International Airport at Mopa, Goa: DSGN DRWN CHKD AppdDocument1 pageGreenfield International Airport at Mopa, Goa: DSGN DRWN CHKD AppdAditya KNo ratings yet

- Structural Sections Presentation Slides PPTSTSEN21Document17 pagesStructural Sections Presentation Slides PPTSTSEN21kumarmohit0203No ratings yet

- Imm Ex260 SPNX Tfn34gbDocument1 pageImm Ex260 SPNX Tfn34gbPedroAntunesNo ratings yet

- Slab Checklist Translation in ArabicDocument1 pageSlab Checklist Translation in ArabicTariq HassanNo ratings yet

- Electronic Circuit Symbols PosterDocument1 pageElectronic Circuit Symbols PosterMohit Singh MahiNo ratings yet

- KLEA Hızlı KurulumDocument8 pagesKLEA Hızlı Kurulummuhammad.wajahat194No ratings yet

- 16M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages16M Motor Grader Electrical System: Harness and Wire Electrical Schematic SymbolsMauricio CarvajalNo ratings yet

- T12 Power Rating Basic Table Reduction TablesDocument8 pagesT12 Power Rating Basic Table Reduction Tableschinnathambij0% (1)

- Pipe & Pipe Rack Analysis: No. Description Est Tot. DayDocument1 pagePipe & Pipe Rack Analysis: No. Description Est Tot. DayirvanNo ratings yet

- Traffic Light Strain Pole Analysis RevCDocument13 pagesTraffic Light Strain Pole Analysis RevCEliNo ratings yet

- Iv. Networks and Network Solutions Ii. Mesh AnalysisDocument5 pagesIv. Networks and Network Solutions Ii. Mesh AnalysisKuroshiro YamedaNo ratings yet

- d5h 8rj Schematic Cat WiringDocument2 pagesd5h 8rj Schematic Cat WiringjulianNo ratings yet

- JKO Yard Improvements Survey DSCDocument3 pagesJKO Yard Improvements Survey DSCraju aketiNo ratings yet

- Stroemvaerdib T12Document1 pageStroemvaerdib T12Ahmed BeshnaNo ratings yet

- Simulation of Turbulent Flow in An Asymmetric Diffuser: 1. PurposeDocument13 pagesSimulation of Turbulent Flow in An Asymmetric Diffuser: 1. Purposealagarg137691No ratings yet

- Code of Practice For Concrete Road Bridges Irc:112: ULS For Linear ElementsDocument6 pagesCode of Practice For Concrete Road Bridges Irc:112: ULS For Linear ElementsSony JsdNo ratings yet

- Dsu 2023 Summer Model Answer PaperDocument25 pagesDsu 2023 Summer Model Answer Papershantanukapse76No ratings yet

- VKK2-8, VKK2R-8: Junction BoxesDocument2 pagesVKK2-8, VKK2R-8: Junction BoxesLuis Fernando Peres GutierrezNo ratings yet

- 22207-2022-Winter-Model-Answer-Paper (Msbte Study ResourDocument10 pages22207-2022-Winter-Model-Answer-Paper (Msbte Study ResourMustfa MujawarNo ratings yet

- 5 Wiring Recommendations: 5.1 Signal ClassesDocument4 pages5 Wiring Recommendations: 5.1 Signal ClassesJosé Roberto CervantesNo ratings yet

- SWTH, D120 - TS5-01, Issue 05Document10 pagesSWTH, D120 - TS5-01, Issue 05droftahsps4No ratings yet

- Flow Chart: Element Elastic Design, Uniform Sections (Rafter or Column)Document3 pagesFlow Chart: Element Elastic Design, Uniform Sections (Rafter or Column)Anonymous RrPSDPatRONo ratings yet

- EVALUATIVE ASSESSMENT Designing A TW0-STOREY SPLITLEVEL RESIDENCEDocument4 pagesEVALUATIVE ASSESSMENT Designing A TW0-STOREY SPLITLEVEL RESIDENCEhallisaalabandNo ratings yet

- FGDHDocument21 pagesFGDHkishorshinde75No ratings yet

- Chapter 14: Screws and FastenersDocument10 pagesChapter 14: Screws and FastenersEnginBenerNo ratings yet

- SESSION PLAN - RigorsorianoDocument13 pagesSESSION PLAN - RigorsorianoKuya Rigor SorianoNo ratings yet

- Recommended Unit Symbols, SI Prefixes, and Abbreviations: A VIIDocument3 pagesRecommended Unit Symbols, SI Prefixes, and Abbreviations: A VIIBOURAS Ihabe - بوراس إيهابNo ratings yet

- 2.6 - HydraulicsDocument11 pages2.6 - HydraulicsFrancisco AriasNo ratings yet

- Shared Memory ArchitectureDocument2 pagesShared Memory ArchitectureNeethu RajeshNo ratings yet

- 10EC/TE61: Answer Any FIVE Full Questions, Selecting at Least TWO Questions From Each PartDocument2 pages10EC/TE61: Answer Any FIVE Full Questions, Selecting at Least TWO Questions From Each PartdonyarmstrongNo ratings yet

- Work-Report: Dimensioning of DC Power Cables 220V and 24VDocument9 pagesWork-Report: Dimensioning of DC Power Cables 220V and 24VahmedNo ratings yet

- B. Sc. Special Honours Degree/ Diploma in Information TechnologyDocument5 pagesB. Sc. Special Honours Degree/ Diploma in Information TechnologyHarshagayan90No ratings yet

- 320C Excavator Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pages320C Excavator Electrical System: Electrical Schematic Symbols and DefinitionsDiego Orlando Santos BuitragoNo ratings yet

- TeB1 TEB2Document4 pagesTeB1 TEB2Luiz AlmeidaNo ratings yet

- Day 1Document15 pagesDay 1Jayakrishnan P SNo ratings yet

- Notes 2 Distribution Line ConstructionDocument7 pagesNotes 2 Distribution Line ConstructionRandy jr. WacasNo ratings yet

- Motor Grader - Motoniveladora 24M Plano Electrico 2016 SISDocument2 pagesMotor Grader - Motoniveladora 24M Plano Electrico 2016 SISFabrizio Jesus Morales SalirrosasNo ratings yet

- Testing and Modeling With TDLDocument88 pagesTesting and Modeling With TDLKi KiNo ratings yet

- v6 HalalDocument1 pagev6 HalalEDGARDO DIGAL JR.No ratings yet

- Coil Lifters & Upenders: Model 82NC - Narrow Coil C-HookDocument1 pageCoil Lifters & Upenders: Model 82NC - Narrow Coil C-HookRUD Lifting MexicoNo ratings yet

- Stub 1.1Document9 pagesStub 1.1BrcakNo ratings yet

- ELEC212 Revision+Design+AssignmentDocument15 pagesELEC212 Revision+Design+Assignmentkhan aliNo ratings yet

- 85010-0111 - Battery Distribution UnitDocument2 pages85010-0111 - Battery Distribution UnitmohammadNo ratings yet

- Reader-Interface-Module Installation GuideDocument3 pagesReader-Interface-Module Installation GuidekkkhattabbbNo ratings yet

- EPC Method For Delamination Assessment of Basalt FRP Pipe: Electrodes Number EffectDocument16 pagesEPC Method For Delamination Assessment of Basalt FRP Pipe: Electrodes Number EffectPankaj MunjalNo ratings yet

- V-Link: 924G Wheel Loader Electrical System IT28G Integrated Toolcarrier 928G Wheel LoaderDocument4 pagesV-Link: 924G Wheel Loader Electrical System IT28G Integrated Toolcarrier 928G Wheel LoaderAlex San TanaNo ratings yet

- Moment DistributionDocument13 pagesMoment DistributionSarah HaiderNo ratings yet

- 988GDocument2 pages988GEduardo Macaya ANo ratings yet

- 18EVE322Document2 pages18EVE322Vinay JavalkarNo ratings yet

- Lecture12 - FET Small SignalDocument5 pagesLecture12 - FET Small SignalArvin TanNo ratings yet

- Mario Associates Eng. ConsultancyDocument3 pagesMario Associates Eng. Consultancywalid MegahedNo ratings yet

- GATE Lectures by KN Rao: Machines Problem Set - Synchronous MachinesDocument8 pagesGATE Lectures by KN Rao: Machines Problem Set - Synchronous MachinesGUJJALA TARUN MANIKYA KIRANNo ratings yet

- June 2019 MS - Component 1 WJEC Geography (A) GCSEDocument17 pagesJune 2019 MS - Component 1 WJEC Geography (A) GCSERiskyRoadzNo ratings yet

- Costa DataDocument85 pagesCosta DatasamftaylorNo ratings yet

- DRRR Quarter 1 Module 4 - Lecture Notes 4 DRRR Quarter 1 Module 4 - Lecture Notes 4Document25 pagesDRRR Quarter 1 Module 4 - Lecture Notes 4 DRRR Quarter 1 Module 4 - Lecture Notes 4Eunel PeñarandaNo ratings yet

- Science 5 Module 3Document9 pagesScience 5 Module 3Zyre MendozaNo ratings yet

- Lecture 2Document51 pagesLecture 2degife deshaNo ratings yet

- GreaseDocument3 pagesGreaseWac GunarathnaNo ratings yet

- JEE 2025 Starter Pack: Best BooksDocument5 pagesJEE 2025 Starter Pack: Best Booksdevpradhan258No ratings yet

- POWER8 Overview v50 PDFDocument262 pagesPOWER8 Overview v50 PDFJohansen LeeNo ratings yet

- Be Prepared With Lutz: Safety Is Our ConcernDocument16 pagesBe Prepared With Lutz: Safety Is Our ConcernJhonatan QuispeNo ratings yet

- Berkeley Math Circle: Monthly Contest 2 SolutionsDocument3 pagesBerkeley Math Circle: Monthly Contest 2 SolutionshungkgNo ratings yet

- Wisdom Philo TruthDocument10 pagesWisdom Philo Truthdan agpaoaNo ratings yet

- Monica Chirila 1Document5 pagesMonica Chirila 1Anonymous 9qxwyKLqNo ratings yet

- 9053 Sonadih Cement Plant (Technical Offer)Document6 pages9053 Sonadih Cement Plant (Technical Offer)Nitesh KhamariNo ratings yet

- SavedrecsDocument132 pagesSavedrecsLoReeRoJasNo ratings yet

- Overcoming Learning Disabilities-Cambridge University Press (2012)Document320 pagesOvercoming Learning Disabilities-Cambridge University Press (2012)Al GNo ratings yet

- Canon Ir2200 BrochureDocument6 pagesCanon Ir2200 BrochureskiyajudeenNo ratings yet

- Product Information: Valvoline™ Heavy Duty Gear Oil Pro 75W-80 LDDocument2 pagesProduct Information: Valvoline™ Heavy Duty Gear Oil Pro 75W-80 LDTiago FreireNo ratings yet

- Connectionism TheoryDocument5 pagesConnectionism TheoryKaterina LawrenceNo ratings yet

- Rightway Catalog 2019 Official PDFDocument67 pagesRightway Catalog 2019 Official PDFKuriee ZamzuriNo ratings yet

- Theoretical Physics: Course Codes: Phys2325Document36 pagesTheoretical Physics: Course Codes: Phys2325kavimat20089274No ratings yet

- Astm D6038 - 2014Document4 pagesAstm D6038 - 2014alferedNo ratings yet

- RW - Persuasion - Lesson 7Document18 pagesRW - Persuasion - Lesson 7AhmadNo ratings yet

- Theories and Manifestoes of ContemporaryDocument157 pagesTheories and Manifestoes of Contemporaryfaraz janatraNo ratings yet

- Uttarakhand Power Corporation Limited: Released Connections BetweenDocument27 pagesUttarakhand Power Corporation Limited: Released Connections BetweenAshwani SharmaNo ratings yet

- Distilling ParrotDocument18 pagesDistilling Parrotapi-1821010100% (2)

- EPA Method 7420Document4 pagesEPA Method 7420Wilder Mancilla GómezNo ratings yet

- SEL-TCIP1-S - Selenio Media Convergence Platform MCP - Single-Channel TICO Mezzanine Format For UHD 3G-SDI and 10 Gig-EDocument4 pagesSEL-TCIP1-S - Selenio Media Convergence Platform MCP - Single-Channel TICO Mezzanine Format For UHD 3G-SDI and 10 Gig-EJewan RamlalNo ratings yet