Professional Documents

Culture Documents

Structural Damage Report Form: SDR No

Uploaded by

Dewin SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Damage Report Form: SDR No

Uploaded by

Dewin SilvaCopyright:

Available Formats

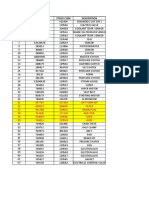

Number painted on the aircraft (Damage Item on AMOS system): ____________

WORK ORDER

STRUCTURAL DAMAGE REPORT FORM SDR No

A/C REGISTRATION: A/C S/N: A/C W V (ONLY AIRBUS): DATE

DD MM YYYY

A/C HOURS: A/C CYCLES: STATION:

NON ROUTINE No, A/C LOG BOOK REPORT, WORK ORDER: HIL :

COMPONENT: P/N: S/N:

Note: Write the P/N and S/N for all nacelle structural components and flight controls surfaces (Rudder, slats, flaps, elevators, spoilers, Nose Cowl, Fan cowls, Thrust reverser etc.)

DAMAGE DESCRIPTION:

TECHNICIAN SUP / INSP

GAIN INTERNAL AND EXTERNAL ACCESS TO THE DAMAGE AS REQUIRED PER SRM, AMM, ETC, AND CLEAN AND

PREPARE SURFACE FOR EVALUATION AS REQUIRED (REMOVE SEALANT, PAINT, ETC)

1 For scratches, corrosion, gouges, nicks, you must remove (clean-up) the damage down to a smooth contour and compare with the

allowable damage limits in the SRM, AMM, etc. After rework, the damaged area must be checked to make sure

that the allowable limits have not been exceeded.

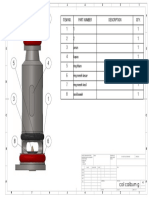

DAMAGE SKETCH include all dimensions in accordance with applicable SRM / AMM, etc. e.g.: length, width, depth, diameter,

distance from edge, area, mods or production joints, original thickness, material removed, affected fasteners, distance fastener to fastener

from adjacent repair, fasteners type.

Select and overwrite

the aplicable arrows

direction

OTHER DIMENSIONS AS REQUIRED PER SPECIFIC

DIMENSIONS DEPTH WIDTH LENGTH DIAMETER

SRM/AMM/CMM CHAPTER eg: Area, A/Y, A, B.

Millimeters (mm)

3 inches (in)

Original thickness: Remaining thickness: % Material removed:

Note: The dimensions depends on the SRM chapter requirements, write the additional dimensions required to evaluate the damage.

RECORD THE EXACT DAMAGE LOCATION:

STA/FRAME/RIB: to STA/FRAME/RIB: STRINGER: to STRINGER:

4 O'CLOCK POSITION* ACCESS: LH

OTHER: RH

* To report at O´Clock position, you must be positioned like Captain seated position (only for damages on Inlet Cowl, Thrust Reverser, CNA)

DAMAGE TYPE

DENT HOLE PUNCTURES BURN MARK / LIGHTNING STRIKE

5 SCRATCH CRACK NICK CORROSION

ABRASION GOUGE DELAMINATION MISSING FASTENER

OTHER:

DAMAGE NOMENCLATURE:

SKIN* WEB FITTING STRINGER

FASTENER HEAD DOUBLER FRAME RIB

6

FASTENER HEAD & SKIN

OTHER:

* Specify if the damage is in the upper, lower or both skins (only for flaps, slats, elevator, leading edge)

F-ENG-094A R0 APR 10, 2015 CONTINUE…

TECHNICIAN SUP / INSP

TYPE OF INSPECTION USED TO EVALUATE THE DAMAGE:

DVI - EXTERNAL DVI - INTERNAL

HFEC - EXTERNAL UT RDC

7 HFEC - INTERNAL TAP TEST X-RAY

ROTO - PROBE LFEC THERMOGRAPHY OTHER:

MANUAL REF.: NDT REPORT# (IF APPLICABLE):

EVALUATE THE DAMAGE IN ACCORDANCE WITH SRM, AMM, OR ANY OTHER APPLICABLE DOCUMENT:

IS THE DAMAGE WITHIN ALLOWABLE LIMITS? YES NO

When the damage is out of limits a repair is necessary, go to step 9.

8 If the damage is within allowable limits, then go to step 10 and sign step 9 as N/A (Not Applicable).

MANUAL REF.:

FOR DAMAGES OUT OF ALLOWABLE LIMITS: Accomplish the applicable repair per SRM, AMM, CMM, SR, TD as applicable.

CAUTION: Before you do this repair, read the Operator Implementation Plan Manual, refer to applicable Operator

regulatory manual, ensure that damage tolerance data is obtained and applied to embody repairs affecting any fatigue

NOTE: If you cannot find any applicable repair or if you have any question, contact Support Engineering Department.

MANUAL / JIC, USED TO PERFORM THE REPAIR:

REPAIR DOUBLER / PLY MATERIAL AND THICKNESS:

9 FASTENERS TYPE:

COLD WORKING*: YES NO IF YES, WRITE THE STDN

SKIN CUT-OUT? YES NO IF YES, DIAMETER: OR, LENGHT: WIDTH:

PROXIMITY TO ADJACENT REPAIR: YES NO

IF YES, RECORD THE DISTANCE FASTENER TO FASTENER FROM ADJACENT REPAIR:

RECORD OTHER REVELANT INFORMATION:

REPAIR SKETCH , include as many dimensions as possible e.g: length, width, diameter, distance from edge, other repairs etc .

Select and overwrite

the aplicable arrows

direction

10

DAMAGE / REPAIR CLASSIFICATION:

ALLOWABLE DAMAGE PERMANENT REPAIR WITHOUT INSPECTIONS

TEMPORARY/TIME LIMITED REPAIR PERMANENT REPAIR/ALLOWABLE DAMAGE WITH INSPECTIONS

11 WRITE THE FURTHER ACTION (Specify Threshold and Manual to accomplish the Further Action):

Note: For temporay repairs, write the threshold to accomplish the permanent repair.

For allowable damages within limits, write the threshold to accomplish inspection and/or repair, if applicable.

For permanent repairs with inspections, write the future inspection reference according to the specific SRM chapter.

12 Add this damage or repair in the structural book list aboard the aircraft by hand and write the new item

Paint or paste the consecutive number on the affected area.

13 Note: If for any reason it is not possible to paint the consecutive number, inform to the MCC in order to program the number painting at next

maintenance convenience.

14 Mark the Work Order as Structural and fill out required information on AMOS system

REMARKS:

ACRONYMS

AD: Airworthiness Directive FR: Frame S/B: Service Bulletin STDN: Standard Tool Diameter Number

A/C: Aircraft HFEC: High Frequency Eddy Current S/N: Serial Number UT: Ultrasonic

CMM: Component Maintenance Manual LFEC: Low Frequency Eddy Current SRM: Structural Repair Manual WV: Weight Variant only for Airbus A/C

DVI: Detailed Visual Inspection RDAS: Repair Design Approval Sheet STA: Station

F-ENG-094A R0 APR 10, 2015

You might also like

- Piper 753-689 Six - Lance Parts v2009Document637 pagesPiper 753-689 Six - Lance Parts v2009Dave SchallNo ratings yet

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- Commodore 64 Assembly Language Programming PDFDocument243 pagesCommodore 64 Assembly Language Programming PDFbandihoot100% (1)

- AanDocument9 pagesAanPocs MadarNo ratings yet

- Bell 47D1 RFM Rev.04 (1963)Document45 pagesBell 47D1 RFM Rev.04 (1963)mike archungNo ratings yet

- TM 9-1725 Ordnance Engine Model R975-C4 (Continental) 1944Document272 pagesTM 9-1725 Ordnance Engine Model R975-C4 (Continental) 1944beppefranzNo ratings yet

- CAMP Status CessnaDocument95 pagesCAMP Status CessnaKritz FritzNo ratings yet

- Naca TM 1169Document24 pagesNaca TM 1169Margaret FordNo ratings yet

- Piper Warrior (PA-28-151, PA-28-161, PA-28-161) PCDocument420 pagesPiper Warrior (PA-28-151, PA-28-161, PA-28-161) PCJackson ChildressNo ratings yet

- Structural Geology CompiledDocument381 pagesStructural Geology CompiledLen-Len Cobsilen100% (2)

- 2018 HondaJet HA 420 SN 42000090 Available Through Jetcraft 1 PDFDocument10 pages2018 HondaJet HA 420 SN 42000090 Available Through Jetcraft 1 PDFio kNo ratings yet

- FRF-104G Starfighter Operations ManualDocument6 pagesFRF-104G Starfighter Operations ManualJoe Tateau100% (1)

- Archive 1988Document112 pagesArchive 1988c737100% (1)

- Generating a GFEM for Stress Analysis of an Aircraft Conversion ProjectDocument18 pagesGenerating a GFEM for Stress Analysis of an Aircraft Conversion ProjectbarracudacemNo ratings yet

- Cessna Cessna Hydro Test Manual SE588 ModelsDocument11 pagesCessna Cessna Hydro Test Manual SE588 ModelsFranco Puga100% (2)

- MTA Capital Program 2015-19Document239 pagesMTA Capital Program 2015-19jcm23100% (1)

- Airstar 995Document43 pagesAirstar 995Fernando FerreiraNo ratings yet

- Be 76 Duchess HandbuchDocument338 pagesBe 76 Duchess HandbuchBlueSkyMasterNo ratings yet

- Piper Twin Comanche PA-30 PA-39 Airplane Series Service Manual 753-645 (Oct 1, 1998)Document863 pagesPiper Twin Comanche PA-30 PA-39 Airplane Series Service Manual 753-645 (Oct 1, 1998)Héctor SánchezNo ratings yet

- All-Metal Junkers Airplane Type F 13ADocument17 pagesAll-Metal Junkers Airplane Type F 13Arritter78No ratings yet

- Cessna Part 2 PDFDocument263 pagesCessna Part 2 PDFrobbertmdNo ratings yet

- Flysimware's CESSNA 441 ManualDocument19 pagesFlysimware's CESSNA 441 ManualJosé A. Montiel QuirósNo ratings yet

- Piper PA-46-350P Inspection Report 767-011 - February 2020Document6 pagesPiper PA-46-350P Inspection Report 767-011 - February 2020NDUTESCU100% (1)

- Amcar 28Document42 pagesAmcar 28Sergio GoncalvesNo ratings yet

- Frequency GeneratorDocument2 pagesFrequency GeneratormindchiNo ratings yet

- 2006 08 15 Bellanca ChecklistDocument34 pages2006 08 15 Bellanca ChecklistglmedinaNo ratings yet

- Piper 761-640 - Lance2 - PC - v2009Document408 pagesPiper 761-640 - Lance2 - PC - v2009Dave SchallNo ratings yet

- Earth Retaining Structures GuideDocument36 pagesEarth Retaining Structures GuideHarpreet Singh100% (1)

- ICS PlusDocument12 pagesICS PlusbbilledeauxNo ratings yet

- MEL A320 VivaDocument962 pagesMEL A320 VivaDewin SilvaNo ratings yet

- BD-700 MMEL Ver9Document165 pagesBD-700 MMEL Ver9ShinYamaNo ratings yet

- A700 Parts ManualDocument162 pagesA700 Parts Manualmdhelicopters100% (1)

- A/M 32A-86D GeneratorDocument20 pagesA/M 32A-86D GeneratorDavid HermannNo ratings yet

- SSP-384 2nd Edition Lycoming Engine ToolsDocument53 pagesSSP-384 2nd Edition Lycoming Engine ToolsKamal Jit DhimanNo ratings yet

- Dynamic WT9 Flight ManualDocument70 pagesDynamic WT9 Flight ManualzupanmNo ratings yet

- Difence CatalogDocument5 pagesDifence CatalogRavishankarNo ratings yet

- To 00-25-172 Ground Servicing of AircraftDocument100 pagesTo 00-25-172 Ground Servicing of AircraftFranciscoVicenteNo ratings yet

- AJS37 Viggen Weapon Chart and Targeting OptionsDocument1 pageAJS37 Viggen Weapon Chart and Targeting OptionsÁngel Cruz ArrayzNo ratings yet

- Continued Aiirworthiness - Model 200 SériesDocument129 pagesContinued Aiirworthiness - Model 200 SériesGabriel vieiraNo ratings yet

- 2007 04 19R1Document24 pages2007 04 19R1Yaşar AkyıldızNo ratings yet

- Airworthiness LimitationsDocument5 pagesAirworthiness LimitationsCharles PereiraNo ratings yet

- Powertrim PumpeDocument26 pagesPowertrim PumpeBilly12369No ratings yet

- A-65 & A-75 SeriesDocument77 pagesA-65 & A-75 SeriesRicardo UrioNo ratings yet

- pc-6 Tcds f56-107Document27 pagespc-6 Tcds f56-107Charles Francesc XavierNo ratings yet

- Saturn Eng PDFDocument51 pagesSaturn Eng PDFJavier PcNo ratings yet

- Anti-Collision Light Systems Installation and Service Manual PDFDocument60 pagesAnti-Collision Light Systems Installation and Service Manual PDFjorge furtado de freitasNo ratings yet

- Rocker Gear and ValvesDocument10 pagesRocker Gear and ValvesBharatiyulamNo ratings yet

- Section 6 - Weight and Balance: Z 242 L Flight ManualDocument22 pagesSection 6 - Weight and Balance: Z 242 L Flight ManualJuan Carlos Sanchez MaldonadoNo ratings yet

- Brantly Helicopter ReportDocument4 pagesBrantly Helicopter Reportjorge paezNo ratings yet

- MOTORFALKE SF25B FLIGHT MANUAL TRANSLATIONDocument26 pagesMOTORFALKE SF25B FLIGHT MANUAL TRANSLATIONDanielC SpiesNo ratings yet

- 707 300 LimitationsDocument24 pages707 300 LimitationsMatias Javier AlvarezNo ratings yet

- Claudel Hobson CarburettorDocument34 pagesClaudel Hobson Carburettorballot100% (1)

- Service Bulletin: TitleDocument12 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Q:) Eechcraft: Shop ManualDocument2 pagesQ:) Eechcraft: Shop ManualVIMAER Vidotti Manutenção Aeronáutica LTDANo ratings yet

- Toc 2Document87 pagesToc 2Zefrin ParkerNo ratings yet

- Jochman clc210bDocument12 pagesJochman clc210bSaori CruzNo ratings yet

- J3 Gross WT IncreaseDocument18 pagesJ3 Gross WT Increaseagpilot19yahoo.comNo ratings yet

- Special Airworthiness Information Bulletin: Federal Aviation AdministrationDocument3 pagesSpecial Airworthiness Information Bulletin: Federal Aviation Administrationrnordell0% (1)

- FlightCom IIsx ManualDocument8 pagesFlightCom IIsx ManualAdrian TodeaNo ratings yet

- Cessna 150 Technical Publications Updates ListDocument5 pagesCessna 150 Technical Publications Updates ListElmer VillegasNo ratings yet

- CN235 Platform BrochureDocument1 pageCN235 Platform BrochureMeingkarNo ratings yet

- MOJAVE PA 31P-350: How It ComparesDocument1 pageMOJAVE PA 31P-350: How It ComparesMonica EninNo ratings yet

- P-16 Aircraft Historical AnalysisDocument96 pagesP-16 Aircraft Historical AnalysisGiuseppe Zan ZaniniNo ratings yet

- Pressure Wiring PDFDocument51 pagesPressure Wiring PDFDinesh meemanageNo ratings yet

- Aircraft vibration troubleshooting decision tableDocument1 pageAircraft vibration troubleshooting decision tableDewin SilvaNo ratings yet

- AMM - 01-Nov-2021 - 53-15-11-700-002-A - Tap Test of The RadomeDocument2 pagesAMM - 01-Nov-2021 - 53-15-11-700-002-A - Tap Test of The RadomeDewin SilvaNo ratings yet

- Antenna Pointing GuideDocument47 pagesAntenna Pointing GuideasepNo ratings yet

- User Guide Android: MWM - Edjing, 54/56 Avenue Du Général Leclerc 92100 Boulogne-Billancourt - FRANCEDocument17 pagesUser Guide Android: MWM - Edjing, 54/56 Avenue Du Général Leclerc 92100 Boulogne-Billancourt - FRANCEDewin SilvaNo ratings yet

- Kodak X-Omat Multiloader 300 Film Feeder - User ManualDocument10 pagesKodak X-Omat Multiloader 300 Film Feeder - User ManualNikolay PenevNo ratings yet

- Determination of HCV of Solid or Liquid Fuel Using Bomb CalorimeterDocument11 pagesDetermination of HCV of Solid or Liquid Fuel Using Bomb CalorimeterRavi PatilNo ratings yet

- AMI Pen TestingDocument10 pagesAMI Pen TestingcutenemesisNo ratings yet

- SAFIR 2011 ManualDocument58 pagesSAFIR 2011 ManualCZengenhariaNo ratings yet

- AminesDocument21 pagesAminesDEVIKAA ARUNNo ratings yet

- For Drifting and Tunneling: Sandvik RT300-seriesDocument6 pagesFor Drifting and Tunneling: Sandvik RT300-seriesДамир НазиповNo ratings yet

- Amzad Ali BillDocument2 pagesAmzad Ali BillAamir KhanNo ratings yet

- Unit I Acoustics Planning For Noise, STC, NRCDocument9 pagesUnit I Acoustics Planning For Noise, STC, NRCKavya DesaiNo ratings yet

- Torsion of SectionsDocument3 pagesTorsion of SectionsanilmaviNo ratings yet

- CD 109 Highway Link Design-Web PDFDocument106 pagesCD 109 Highway Link Design-Web PDFAriel Zeballos LeañoNo ratings yet

- Optibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Document52 pagesOptibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060SafiaMohamedNo ratings yet

- Searchq Cache JK76 QUqg RF8 JWWWDocument36 pagesSearchq Cache JK76 QUqg RF8 JWWWSajuSadasivanNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- P16NF06FP STMicroelectronicsDocument9 pagesP16NF06FP STMicroelectronicsSoniaNo ratings yet

- A03 02 05 07Document3 pagesA03 02 05 07Oscar ItzolNo ratings yet

- AN2085Document9 pagesAN2085ahseerhsgNo ratings yet

- SLM in TOPdesk 5.4: A Straigtforward Way To Set Up Your SLAsDocument3 pagesSLM in TOPdesk 5.4: A Straigtforward Way To Set Up Your SLAsTOPdeskNo ratings yet

- D12 1Document8 pagesD12 1jamesabowdenNo ratings yet

- Propeller Tolerances and Inspection - John Carlton PDFDocument17 pagesPropeller Tolerances and Inspection - John Carlton PDFhenryNo ratings yet

- Data StructuresDocument41 pagesData StructuresSree Charan ReddyNo ratings yet

- Coil Caliburn GDocument1 pageCoil Caliburn GLukman Arsyanto WibowoNo ratings yet

- Samputensili Tools en v007Document24 pagesSamputensili Tools en v007M.NatarajanNo ratings yet

- Eee342 hw2 Solution PDFDocument7 pagesEee342 hw2 Solution PDFRedion XhepaNo ratings yet

- LED TV Service ManualDocument54 pagesLED TV Service ManualJuan Jose100% (1)

- LinkDocument2 pagesLinkFresh aliveNo ratings yet