100% found this document useful (3 votes)

4K views3 pagesPipe Stacking

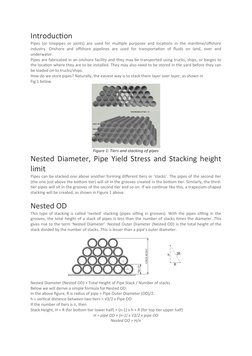

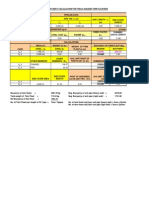

Pipes are commonly stacked in layers when being transported or stored before installation. The nested stacking method involves pipes sitting in grooves created by the pipes in the layer below. This results in a trapezoidal stack with a total height less than the number of layers times the pipe diameter, known as the nested diameter. The maximum safe stacking height is determined by calculating the bending stress on the bottom layer of pipes and ensuring it does not exceed the allowable stress of the pipe material. Various load cases are considered, including weight of overlying layers and self-weight, and stress equations from strength of materials are used to derive a formula for the maximum number of allowable layers based on parameters like pipe geometry and material properties.

Uploaded by

nyak kinahCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

4K views3 pagesPipe Stacking

Pipes are commonly stacked in layers when being transported or stored before installation. The nested stacking method involves pipes sitting in grooves created by the pipes in the layer below. This results in a trapezoidal stack with a total height less than the number of layers times the pipe diameter, known as the nested diameter. The maximum safe stacking height is determined by calculating the bending stress on the bottom layer of pipes and ensuring it does not exceed the allowable stress of the pipe material. Various load cases are considered, including weight of overlying layers and self-weight, and stress equations from strength of materials are used to derive a formula for the maximum number of allowable layers based on parameters like pipe geometry and material properties.

Uploaded by

nyak kinahCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd