Professional Documents

Culture Documents

TAP July 2019 Pigging and ILI Savcor Products

Uploaded by

Trieberson Sihotang0 ratings0% found this document useful (0 votes)

5 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageTAP July 2019 Pigging and ILI Savcor Products

Uploaded by

Trieberson SihotangCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

PIGGING AND ILI

Pigging with multiphase corrosion inhibitors

Corrosion is a common pipeline issue that can prove exceedingly harmful to an asset. As is this case with many

potentially damaging pipeline matters, the best measures are often the ones that help prevent the problem

before it occurs, rather than tackle it once it’s already begun.

P

igging has many useful purposes,

including applying a corrosion inhibiting

film to pipeline internals before layup.

This helps protect the pipeline against

corrosion and its associated problems while the

pipeline sits unused.

Traditional corrosion inhibitors only protect

metal surfaces in direct contact with the

inhibitor carrier fluid; however, Cortec’s

multiphase corrosion inhibitors, applied by

pigging, offer enhanced protection by forming a

protective molecular layer on all metal surfaces

inside the pipeline, even those in the airspace

above the fluid.

Top of the line protection

Cortec’s VpCI®-637 is a multiphase package

A corrosion inhibitor can be applied by slugging it through the pipeline between two pigs.

of corrosion inhibitors used to combat the

Image courtesy Cortec/Adobe Stock.

broadest range of corrosive attack from moisture

and condensation, oxygen, carbon dioxide, inhibitors cannot reach (i.e. the top of the line). technique to mothball a pipeline, the key is to

hydrogen sulfide and other corrosive After the inhibitors are applied, the pipeline choose a material that will provide thorough

contaminants in natural gas and petroleum. can be closed and protected for an extended protection to allow the pipeline to be as free of

The non-emulsifying formulation offers the period of layup. Engineers should always check corrosion as possible when it is brought back

benefits of corrosion inhibitors that form a compatibility of VpCI-637 (or any inhibitor) into use. Cortec products, such as VpCI-637,

tenacious protective film on metal surfaces, with the final pipeline product before can be applied by pigging or other methods

neutralising inhibitors that combat corrosive application. and offer this multiphase protection to allow

fluid formation and vapour phase inhibitors that If this has been verified, the pipeline may not better 360° surface coverage for protection of

reach areas inaccessible by direct contact. even need to be flushed before it is pipe internals.

VpCI-637 can be applied by slugging a dose recommissioned, making startup much easier. This product is available through

between two batching pigs and the concentrated If compatibility has been confirmed, VpCI-637 Savcor Products Australia in Australia and

product can be diluted to stretch farther for may also be injected into the pipeline during New Zealand.

more economical protection. As the product operation to combat top of the line corrosion

flows along the pipe, it leaves behind a corrosion caused by condensation in the pipeline

inhibiting film and also emits vapour phase headspace where contact-only inhibitors For more information visit

corrosion inhibitors that protect the areas of the cannot reach. www.savcorproducts.com.au

pipeline that typical film-forming corrosion Whether using pigging or some other

Products for the Pipeline Industry

www.savcorproducts.com.au

Call: 1800 SAVCOR

Cathodic Protection Materials: Pipeline Fittings & Equipment:

Cortec VpCI Preservation Materials Surge Protectors

Sacrificial anodes (Zn, Mg, Al) Borin Permanent & Portable electrodes Pipeline pigs and equipment including: Wachs Pipe Cutting and Beveling

Corrosometer resistance probes Loresco Coke Backfill Foam, Poly Coated & Wire Brush Pigs Pipe Seals, Pipe Clamps, Leak Repair

Gypsum bentonite backfill APS Flange Insulation Kits Monolithic Insulating Joints APS Casing Spacers

Dehn & Sohne IEC Certified Spark Radolid Nuts Protectors Hot Tapping Equipment Impressed Current & Sacrificial Anodes

Gap Arresters

Trusted Supplier of Cathodic Protection & Prevention materials in Australia.

Melbourne Sydney Brisbane Perth

T: 03 9764 2651 T: 02 9807 4542 T: 07 5549 2248 T: 08 6240 3900

E: melbourne@savcor.com.au E: sydney@savcor.com.au E: brisbane@savcor.com.au E: perth@savcor.com.au

38 The Australian Pipeliner | July 2019 Follow us on Twitter @AussiePipeliner | www.pipeliner.com.au

You might also like

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- Carmagen 09 14Document2 pagesCarmagen 09 14NAMONo ratings yet

- External Corrosion of Pipelines PDFDocument9 pagesExternal Corrosion of Pipelines PDFRangga AfyanNo ratings yet

- VESBO Technical Data SheetDocument6 pagesVESBO Technical Data Sheettintitn larayaNo ratings yet

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDocument3 pages001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- Infill Liner PipelineDocument12 pagesInfill Liner PipelineKhairul AshrafNo ratings yet

- Electric Electronics BrochureDocument8 pagesElectric Electronics BrochurejolualNo ratings yet

- Push-Fit System For Metal Plastic PipesDocument2 pagesPush-Fit System For Metal Plastic PipesRUDI YANTONo ratings yet

- VpCI 309 PouchDocument2 pagesVpCI 309 PouchREHITH RAJNo ratings yet

- CPT Brochure 1Document12 pagesCPT Brochure 1jose antonio becerra mosqueraNo ratings yet

- Kanatpaints PipelineDocument16 pagesKanatpaints PipelineMekineNo ratings yet

- CMP RapidEx 12pp Single Apr 11Document12 pagesCMP RapidEx 12pp Single Apr 11rocket-vtNo ratings yet

- Inspection Techniques For Detecting CorrosionDocument6 pagesInspection Techniques For Detecting CorrosionCepi Sindang KamulanNo ratings yet

- BR CiDocument8 pagesBR CiJose MuikeNo ratings yet

- Electrical Conduit Installation Aboveground & Undergroud Techniques - PAKTECHPOINTDocument12 pagesElectrical Conduit Installation Aboveground & Undergroud Techniques - PAKTECHPOINTtaibi aliNo ratings yet

- PDFMerge 52a7dDocument90 pagesPDFMerge 52a7dabdalla el-saadaneyNo ratings yet

- A New Versatile Concept in Cathodic Protection: RonmentaDocument4 pagesA New Versatile Concept in Cathodic Protection: RonmentaoptimeatvaleriaNo ratings yet

- Oil&Gas BrochureDocument8 pagesOil&Gas BrochurefadjarsuryanaNo ratings yet

- VpCI Shrink Film BrochureDocument8 pagesVpCI Shrink Film Brochuremohamed elmasryNo ratings yet

- Asset Intelligence Report: A Primer On Corrosion Under Insulation (CUI)Document5 pagesAsset Intelligence Report: A Primer On Corrosion Under Insulation (CUI)dzamir203No ratings yet

- Corrosion Control Linings and Coatings NWP BrochureDocument5 pagesCorrosion Control Linings and Coatings NWP BrochureAndrew ChenNo ratings yet

- Protecting Plant Piping From CUI With Water RepellencyDocument2 pagesProtecting Plant Piping From CUI With Water RepellencySergey KichenkoNo ratings yet

- Corrosion Under Insulation of Plant and Pipework v3Document6 pagesCorrosion Under Insulation of Plant and Pipework v3patrick6364No ratings yet

- Keystone Prefabricated CableDocument23 pagesKeystone Prefabricated CableAntonius AjalahNo ratings yet

- VapproVCI-746 For FoggingDocument2 pagesVapproVCI-746 For FoggingAbdulrehmanNo ratings yet

- Aqua Aero CaseStudy - Folder - Cancun - Feb - 2019Document4 pagesAqua Aero CaseStudy - Folder - Cancun - Feb - 2019Tô Thiên ĐăngNo ratings yet

- Jining QiangkeDocument35 pagesJining QiangkeCobu LamNo ratings yet

- Product Data Sheet Anodeflex 3000 Ti Core Rev. 0 04NOV20Document2 pagesProduct Data Sheet Anodeflex 3000 Ti Core Rev. 0 04NOV20Fareed KhanNo ratings yet

- Parker Hose Technical Handbook PDFDocument63 pagesParker Hose Technical Handbook PDFAnonymous HvDSpkgV100% (1)

- 100% Polyurethane - IndiaDocument9 pages100% Polyurethane - Indiaeric paglinawanNo ratings yet

- Inspection Techniques For Detecting Corrosion Under InsulationDocument4 pagesInspection Techniques For Detecting Corrosion Under Insulationsllim776100% (3)

- Sop Magnesium Anode Installation - ThiessDocument10 pagesSop Magnesium Anode Installation - ThiessbonnicoNo ratings yet

- Rumaila Project: Document NumberDocument12 pagesRumaila Project: Document Numbernoor.albseerawiNo ratings yet

- Burried Piping SpecDocument9 pagesBurried Piping Specsada sivaNo ratings yet

- English 20131104 Rev1 - AshtronDocument16 pagesEnglish 20131104 Rev1 - AshtronDavid RodriguesNo ratings yet

- THE RAPID Sealing System: Rise Multi-Cable TransitsDocument44 pagesTHE RAPID Sealing System: Rise Multi-Cable Transitsbakien-canNo ratings yet

- uPVC Fittings: For Drainage ApplicationsDocument24 pagesuPVC Fittings: For Drainage ApplicationsMiguel GualdaNo ratings yet

- Indal Steel PipeDocument9 pagesIndal Steel Pipemailmaverick8167No ratings yet

- Electric BrochureDocument12 pagesElectric Brochurearif ihwandaNo ratings yet

- ASTAVA BV Holland CatalogDocument28 pagesASTAVA BV Holland CatalogXavierNo ratings yet

- Revista MP Diciembre 2022Document68 pagesRevista MP Diciembre 2022María Vaquero TxapartegiNo ratings yet

- Dobro PDFDocument8 pagesDobro PDFbaneNo ratings yet

- Anti Corrossion Technology Case StudyDocument3 pagesAnti Corrossion Technology Case StudyHendyAPNo ratings yet

- Pyro Mi Specifiers GuideDocument12 pagesPyro Mi Specifiers Guideashley_moseley1918No ratings yet

- Brands You Trust.: Industrial Diaphragm ValvesDocument20 pagesBrands You Trust.: Industrial Diaphragm ValvesShayan Hasan KhanNo ratings yet

- Catalogo SintecDocument24 pagesCatalogo SintecJuan MansillaNo ratings yet

- Cortec Electronics - VpCI-105 & VpCI-111Document4 pagesCortec Electronics - VpCI-105 & VpCI-111congnghiephoachat01No ratings yet

- Astral Aquarius Plumbing SystemDocument36 pagesAstral Aquarius Plumbing SystemUnna MalaiNo ratings yet

- Underground Cable InstallationDocument9 pagesUnderground Cable Installationbhaskar_dandapathak100% (1)

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- Migratory Vci Inhibitors For Wet Thermal Insulation byDocument4 pagesMigratory Vci Inhibitors For Wet Thermal Insulation byHuynh Phuc PhungNo ratings yet

- Medium - Voltage (Oman Cables)Document82 pagesMedium - Voltage (Oman Cables)pk 2625No ratings yet

- Viega Profipress ManualDocument16 pagesViega Profipress Manualhasmit1No ratings yet

- 16124s01 MV CableDocument3 pages16124s01 MV CableVICTOR JOSE VILORIANo ratings yet

- Xplore Orld Iping: Materials - Corrosion Under InsulationDocument3 pagesXplore Orld Iping: Materials - Corrosion Under InsulationcelonevesNo ratings yet

- What Is Corrosion Under InsulationDocument7 pagesWhat Is Corrosion Under Insulationanggara_nurrachman123No ratings yet

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- Cathodic Protection of Reinf. Concrete OverviewDocument8 pagesCathodic Protection of Reinf. Concrete OverviewvolkanNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- NumaConcert ManualDocument96 pagesNumaConcert ManualPippo GuarneraNo ratings yet

- Ab 1486 Developer Interest ListDocument84 pagesAb 1486 Developer Interest ListPrajwal DSNo ratings yet

- Sparse ArrayDocument2 pagesSparse ArrayzulkoNo ratings yet

- Visa Requirements Austrian EmbassyDocument2 pagesVisa Requirements Austrian Embassyadalcayde2514No ratings yet

- UK LL M Thesis - Builders' Liability in UK Law Under TortDocument16 pagesUK LL M Thesis - Builders' Liability in UK Law Under TortRajan UppiliNo ratings yet

- Maths VIII FA4Document3 pagesMaths VIII FA4BGTM 1988No ratings yet

- Suggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Document8 pagesSuggested Answers Spring 2015 Examinations 1 of 8: Strategic Management Accounting - Semester-6Abdul BasitNo ratings yet

- Techgig Open Round CompetitionDocument6 pagesTechgig Open Round CompetitionAnil Kumar GodishalaNo ratings yet

- Evaluation of Performance of Container Terminals T PDFDocument10 pagesEvaluation of Performance of Container Terminals T PDFjohnNo ratings yet

- Transportation and Academic Performance of Students in The Academic TrackDocument3 pagesTransportation and Academic Performance of Students in The Academic TrackMary-Jay TolentinoNo ratings yet

- AMCHAM Press ReleaseDocument1 pageAMCHAM Press ReleaseAnonymous FnM14a0No ratings yet

- (1895) Indianapolis Police ManualDocument122 pages(1895) Indianapolis Police ManualHerbert Hillary Booker 2ndNo ratings yet

- Release ACOS 4.1.4-GR1-P10 IssuesDocument241 pagesRelease ACOS 4.1.4-GR1-P10 IssuesdanielatellaNo ratings yet

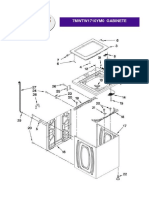

- 7MWTW1710YM0Document8 pages7MWTW1710YM0Izack-Dy JimZitNo ratings yet

- RA 9184 & RA 3019 NotesDocument5 pagesRA 9184 & RA 3019 Notesleng_evenNo ratings yet

- Add New Question (Download - PHP? SC Mecon&id 50911)Document9 pagesAdd New Question (Download - PHP? SC Mecon&id 50911)AnbarasanNo ratings yet

- French Revolution EssayDocument2 pagesFrench Revolution Essayapi-346293409No ratings yet

- Estanislao Vs CADocument2 pagesEstanislao Vs CAChammy0% (1)

- VKC Group of Companies Industry ProfileDocument5 pagesVKC Group of Companies Industry ProfilePavithraPramodNo ratings yet

- Exercise Guide - Broad Crested WeirDocument18 pagesExercise Guide - Broad Crested Weirvipul anandNo ratings yet

- What Is EBSD ? Why Use EBSD ? Why Measure Microstructure ? What Does EBSD Do That Cannot Already Be Done ?Document5 pagesWhat Is EBSD ? Why Use EBSD ? Why Measure Microstructure ? What Does EBSD Do That Cannot Already Be Done ?Zahir Rayhan JhonNo ratings yet

- Instructions For The Safe Use Of: Web LashingsDocument2 pagesInstructions For The Safe Use Of: Web LashingsVij Vaibhav VermaNo ratings yet

- Statement 1577731252322 PDFDocument11 pagesStatement 1577731252322 PDFPriyanka ParidaNo ratings yet

- Cap. 1Document34 pagesCap. 1Paola Medina GarnicaNo ratings yet

- Pfmar SampleDocument15 pagesPfmar SampleJustin Briggs86% (7)

- Sahara International Petrochemical Company (SIPCHEM)Document2 pagesSahara International Petrochemical Company (SIPCHEM)shahbaz1979No ratings yet

- Resume (Suyash Garg)Document1 pageResume (Suyash Garg)Suyash GargNo ratings yet

- 1100D Fuel System Installation Guide PDFDocument18 pages1100D Fuel System Installation Guide PDFjAVIER GARCIA MORIANANo ratings yet

- 50 Hotelierstalk MinDocument16 pages50 Hotelierstalk MinPadma SanthoshNo ratings yet

- ASTM A586-04aDocument6 pagesASTM A586-04aNadhiraNo ratings yet