Professional Documents

Culture Documents

Sec D BC Seasoning

Uploaded by

Ines delcianeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec D BC Seasoning

Uploaded by

Ines delcianeCopyright:

Available Formats

Slickline – Wireline – Well Services www.slk-connect.

com

SLICKLINE CONNECT

Braided Cable

Seasoning

Braided Cables are supplied in one of two formats,

Standard with round strands in both the inner and outer layers with the two layers wrapped in

opposite directions, either as a RH over LH lay or LH lay over RH lay. The standard cable has a

single core, 6 strands in the inner layer and 9 strands in the outer layer and the construction is

referred to 1x16

Formed cables where the assembled cable has been run through a die to reshape the outer layer

and compact the material into a smaller diameter. The process results in a much stronger cable

but because the layers are wrapped in the same direction, RH over RH lay or LH over LH lay the

resultant cable is unbalanced. A formed cable has a single strand core, 9 strands in the inner layer

and 9 compacted strands in the outer layer and the construction is referred to as 1x19.

Due to the torque that always builds up in a cable, to a certain extent through manufacturing, but mainly due

to spooling it is necessary to season or normalise a cable at the beginning of its working life. A properly

seasoned cable will have an extended life whereas a cable which hasn’t been seasoned correctly is highly

likely to fail fairly quickly. It cannot be stressed enough how important the seasoning process is. The torque

in the cable is not particularly an issue as long it is managed correctly and the cable is worked under tension.

Once a cable enters operations it immediately sees conditions it hasn’t been exposed to before:

High tensions

High temperatures

Free to rotate

Seasoning needs to be performed over several runs under the best

conditions possible. Extreme temperatures, high pressures and high

tensions should be avoided. Low pressure, fluid filled well bores are

preferable as it will only require low grease and line wiper pressure

to control well pressure.

Running speeds and well pressure are two factors which can

‘unbalance’ a cable and must remain a focus during cable seasoning.

High pressure wells can cause cable issues with the high line wiper

and grease injection pressures required for well control which cause

torque to build up in the cable as a result of passing through the

grease injection assembly. Twisted Over Torqued Cable

Running into a well too fast at low tension does not allow the cable to rotate and balance torque

Pulling out too fast can result in bird caging or stranded wire as the cable tends to unwrap itself below

the grease injection head

Doc # slkc-0043 Page 1 of 3 ©slk-c2019 - www.slk-connect.com

Slickline – Wireline – Well Services www.slk-connect.com

Seasoning

The cable should be run with a heavy tool string which is free to rotate and ideally run in a vertical well,

deviated wells add frictional forces to the cable which will limit rotation.

It is recommended that two swivel joints are used below the rope socket during seasoning.

Wells with high well pressures should also be avoided as high line wiper and grease injection pressures will

cause sudden tension changes as the cable passes through the grease injection head, firstly at a point directly

below the lowest flow tube where well pressure tries to lift the cable and also directly below the wireline

wiper, resulting in low cable tension areas. A cable passing through a pressurised restriction will tend to

unwind itself. Extreme over pressuring in the GIH will result in a loose outer layer which will lead to bird

caging and/or stranded cable.

Wireline wiper pressure must be carefully monitored throughout the operation, it should be maintained at a

pressure that is sufficient to control well pressure with over stressing the cable. A correctly applied line wiper

should as a rule of thumb add 100lbs tension to the cable

Running and pulling speeds are critical to the life of the cable and should be clearly defined prior to starting

the operation. Guideline maximum speeds would be within the range of 100-300ft/min

The cable tension guideline should follow the rule of

thumb 80/120 rule, when running in the well maintain a

tension of 80% of static tension, when pulling out

maintain a tension of 120% of static tension and

adjusting cable speed to meet these tensions. Plus,

always slow down for restrictions in the well bore, for

instance SSSVs, landing nipples etc. and always slow

down well in advance of reaching surface, a good

guideline would be to reduce line speed at 300ft and

‘walk’ the toolstring up to and into the lubricator

assembly with a crew member holding down the cable to

feel when the rope socket bumps up against the top of

the lubricator assembly. Stranded Braided Cable

A typical seasoning procedure is in effect a yoyo process moving the tools up and down the well bore getting

progressively deeper in the well and exposing more cable with each yoyo cycle. At pre-determined depths

stopping and pulling the tools back up. For instance, the tools are run to 500ft, stop for 30 seconds which

allows the cable to rotate and making a note of the static cable tension. Then pull up 200ft not exceeding

120% of the static weight. The tools are then lowered to a 1000ft, stop for 30 seconds again allowing the

cable to rotate and noting the static cable tension. Then pull up to 800ft not exceeding 120% of the static

weight. This step by step procedure will continue down the well. In perfect circumstances a new cable should

be seasoned over 20 runs.

In addition to normalising the torque, seasoning also beds in the layers of the cable which will in effect reduce

the OD of the cable. A heavy toolstring as opposed to a light toolstring accelerates the bedding process.

Doc # slkc-0043 Page 2 of 3 ©slk-c2019 - www.slk-connect.com

Slickline – Wireline – Well Services www.slk-connect.com

Flow tube selection is very important and the diameter of the cable must be monitored through the seasoning

period to ensure the correct flow tubes are being used. Flow tube clearance should be between 0.004 –

0.008” for a standard the cable, and 0.010” for a formed cable.

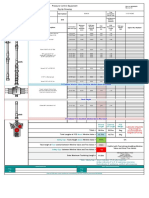

All runs should be recorded using a ZChart which has been set up to reflect the seasoning steps that will be

used. The ZChart provides a positive record of the seasoning procedure and should be added to the cable

history file. In addition, it is always good practice to use a ZChart for braided cable runs as a back-up depth

reference.

It should be noted that new cables are more susceptible to torque issues than a used cable. In a new cable the

strands and the interstitial spaces are clean and free from any well debris, grease, or even surface corrosion.

These will build up with exposure to well fluids and operations and provide a certain amount of friction in the

strands and layers which in effect reduces cable rotation.

Doc # slkc-0043 Page 3 of 3 ©slk-c2019 - www.slk-connect.com

You might also like

- Vdocuments - MX MCR Training ManualDocument71 pagesVdocuments - MX MCR Training ManualLina Marcela Monares ToroNo ratings yet

- Pre-Inspection Safety Valve 2.81 FxeDocument3 pagesPre-Inspection Safety Valve 2.81 FxeNasrien Kadir100% (1)

- Reporting StandardDocument4 pagesReporting StandardBasel SaidawiNo ratings yet

- Standing ValvesDocument12 pagesStanding ValvesAli AliNo ratings yet

- SLK-PR-06.00 Procedure For Tubing PuncherDocument3 pagesSLK-PR-06.00 Procedure For Tubing PuncherDonald TchiroueNo ratings yet

- (I) SLP22 ct09-LMDocument36 pages(I) SLP22 ct09-LMMohammed Anis FortasNo ratings yet

- Presentasi Coiled Tubing - Virnando Batu AraDocument20 pagesPresentasi Coiled Tubing - Virnando Batu AraVirnando NainggolanNo ratings yet

- PART I (Basic Midwest Wireline Course)Document324 pagesPART I (Basic Midwest Wireline Course)Hedi ChhidiNo ratings yet

- Fs2 Isolation Barrier ValveDocument12 pagesFs2 Isolation Barrier Valvehamed66652No ratings yet

- Microsoft Word - Slickline Mechanical CapibilitiesDocument7 pagesMicrosoft Word - Slickline Mechanical CapibilitiesRangga DraApNo ratings yet

- Wireline Equipment Checks: - 2. Wire HistoryDocument10 pagesWireline Equipment Checks: - 2. Wire HistoryRio de MarioNo ratings yet

- Catalogue: Flow Control EquipmentDocument19 pagesCatalogue: Flow Control EquipmentFranklin NavarroNo ratings yet

- RP-002986 J BPV TWCV and 10K Lubricator With 2IN Polished RodDocument34 pagesRP-002986 J BPV TWCV and 10K Lubricator With 2IN Polished RodSebastin DrignyNo ratings yet

- Wireline (Rev.15.8.12)Document5 pagesWireline (Rev.15.8.12)hNo ratings yet

- 4-06 Tandem Side Loading Stripper PackerDocument14 pages4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- Hydraulic JarDocument2 pagesHydraulic JarDragonNo ratings yet

- Slickline Basics.11 20Document10 pagesSlickline Basics.11 20Rio de MarioNo ratings yet

- 6 MandrelsDocument17 pages6 MandrelsEduardoWireNo ratings yet

- GasGun-BrochureDocument34 pagesGasGun-BrochureJorge Arraiz SanchezNo ratings yet

- Slick Line Rig UpDocument1 pageSlick Line Rig UpWookie VanNo ratings yet

- Enerjet Spare Part Selection V1.1: General Tool StringDocument1 pageEnerjet Spare Part Selection V1.1: General Tool StringJose Antonio AcostaNo ratings yet

- SSP Plug Presentation For CourseDocument21 pagesSSP Plug Presentation For CourseSlim.BNo ratings yet

- Well Intervention CoilHose A4Document2 pagesWell Intervention CoilHose A4William EvansNo ratings yet

- SSP Plug Presentation For CourseDocument21 pagesSSP Plug Presentation For Courseyacine up100% (1)

- Kea Oilfield Engineering Pte LTDDocument9 pagesKea Oilfield Engineering Pte LTDFabio ParceroNo ratings yet

- Completion Fluid 2Document45 pagesCompletion Fluid 2Waled Fekry100% (2)

- Capillary Injection Sytem Halib ValveDocument26 pagesCapillary Injection Sytem Halib Valvebahar1991No ratings yet

- Flow Control Devices Standing Valves / Test Tools: Europe Learning Centre WCP Training SchlumbergerDocument12 pagesFlow Control Devices Standing Valves / Test Tools: Europe Learning Centre WCP Training SchlumbergerAli Ali100% (1)

- Slickline Tool String: Khathayut Senitantikun Completion EngineerDocument80 pagesSlickline Tool String: Khathayut Senitantikun Completion EngineerSarawut AssavamateerungrojNo ratings yet

- SPE-108284-Sucker RodDocument14 pagesSPE-108284-Sucker RodRuben ChirinosNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- CatalogDocument120 pagesCatalogTaras ByloNo ratings yet

- Am3K Combined Depth/Tension Measurement Device: With Differential Tension AmplifierDocument139 pagesAm3K Combined Depth/Tension Measurement Device: With Differential Tension AmplifiermarcioNo ratings yet

- 09 Subsurface Safety Equip PDFDocument40 pages09 Subsurface Safety Equip PDFFalokid RaboNo ratings yet

- Winch Operators Slickline Cased Hole Analog PanelDocument2 pagesWinch Operators Slickline Cased Hole Analog PanelHenry FuentesNo ratings yet

- PART II (Intermediate & Advanced Wireline Course)Document465 pagesPART II (Intermediate & Advanced Wireline Course)Hedi ChhidiNo ratings yet

- Model E Hydraulic Setting ToolDocument1 pageModel E Hydraulic Setting ToolrezaNo ratings yet

- Wireline Solutions LLC 7Document1 pageWireline Solutions LLC 7DragonNo ratings yet

- Slickline and Strand CareDocument10 pagesSlickline and Strand Carehesam abbaszadehNo ratings yet

- 7 Conductor Procedimiento de Rehead Manual - D00667626 - 1Document31 pages7 Conductor Procedimiento de Rehead Manual - D00667626 - 1felipeNo ratings yet

- Orifice Meter & Barton RecorderDocument46 pagesOrifice Meter & Barton RecorderNoor AliNo ratings yet

- Corrosive EnvironmentsDocument2 pagesCorrosive EnvironmentsRio de MarioNo ratings yet

- Catalog - H Hydraulic Setting ToolDocument1 pageCatalog - H Hydraulic Setting ToolCarlos Alberto Aguilera MendezNo ratings yet

- Plug CementingDocument50 pagesPlug Cementingfauzan kartiyasaNo ratings yet

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDocument6 pages29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNo ratings yet

- Wellhead Products Catalog vFEB2015 PDFDocument20 pagesWellhead Products Catalog vFEB2015 PDFRatnakar PatilNo ratings yet

- Tubing Cutter Radial Cutting TorchDocument2 pagesTubing Cutter Radial Cutting Torcharvandi_mahryNo ratings yet

- TOS Slickline SOP V1.0Document16 pagesTOS Slickline SOP V1.0Donald TchiroueNo ratings yet

- Wireline Jars PDFDocument12 pagesWireline Jars PDFfelipeNo ratings yet

- Titan Energetics Spectra2 Coiled Tubing Cutters Flyer3Document2 pagesTitan Energetics Spectra2 Coiled Tubing Cutters Flyer3faiz bugtiNo ratings yet

- 3 Slickline CapabilitiesDocument14 pages3 Slickline CapabilitiesHedi ChhidiNo ratings yet

- Coiled Tubing Surface Equipment PPTDocument75 pagesCoiled Tubing Surface Equipment PPTBolsec14No ratings yet

- 350 Direct Pump Setting tool-DPSTDocument2 pages350 Direct Pump Setting tool-DPSTAdarsh HegdeNo ratings yet

- TDRDocument1 pageTDRJones LakerNo ratings yet

- W CT HT Downhole Electric Cutting Tool DECT200Document2 pagesW CT HT Downhole Electric Cutting Tool DECT200casda73No ratings yet

- Animacion SartasDocument23 pagesAnimacion SartasPierre MejiaNo ratings yet

- 09 Subsurface Safety EquipDocument40 pages09 Subsurface Safety EquipMuhammad AbubakarNo ratings yet

- CT D - Ploy Velocity StringDocument2 pagesCT D - Ploy Velocity StringAlejandro MonroyNo ratings yet

- Hydraulic Oil JarDocument3 pagesHydraulic Oil JarYermi ParabangNo ratings yet

- Getting The Most From Your Cable Part 1 Cable SeasoningDocument2 pagesGetting The Most From Your Cable Part 1 Cable SeasoningMaaz Bin FurqanNo ratings yet

- Street Rehabilitation Program ReportDocument2 pagesStreet Rehabilitation Program ReportWCPO 9 NewsNo ratings yet

- SB-165 - ASME BPVC 2021 Sección II Part BDocument6 pagesSB-165 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Omm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretDocument663 pagesOmm Tank, Combat, Full Tracked 105-MM Gun, M60a3 and TTS TurretSTGN100% (1)

- Performance Evaluation of TDL Channels For Downlink 5G MIMO SystemsDocument4 pagesPerformance Evaluation of TDL Channels For Downlink 5G MIMO SystemspruxmanNo ratings yet

- MKTED208071EN CatalogueDocument618 pagesMKTED208071EN Cataloguecarlos augustoNo ratings yet

- FC9170 02Document14 pagesFC9170 02ВладимирNo ratings yet

- SENIOR HIGH SCHOOL-English For Academic and Professional PurposesDocument7 pagesSENIOR HIGH SCHOOL-English For Academic and Professional Purposesjoshua herreraNo ratings yet

- Book v. Movie Rubric Eng 11 - Rev. 12 - 19Document2 pagesBook v. Movie Rubric Eng 11 - Rev. 12 - 19Lucia Perez ValenciaNo ratings yet

- Introducing The Open Banking StandardDocument12 pagesIntroducing The Open Banking StandardOpen Data Institute96% (25)

- Solidworks Inspection Data SheetDocument3 pagesSolidworks Inspection Data Sheetradule021No ratings yet

- STS Module 9Document14 pagesSTS Module 9Claire Jacynth FloroNo ratings yet

- TEST PearsonsDocument4 pagesTEST Pearsonsazertytyty000No ratings yet

- Cat Reforming Part 2 3 PDF FreeDocument68 pagesCat Reforming Part 2 3 PDF FreeLê Trường AnNo ratings yet

- USGSPP610 Gold Districts United StatesDocument291 pagesUSGSPP610 Gold Districts United StatesDave VW100% (1)

- AutoDocument5 pagesAutohem1980No ratings yet

- Hot Water Atmospheric BOILERDocument3 pagesHot Water Atmospheric BOILERcarlossandovalhdzNo ratings yet

- S1-1054/2 10kV Digital Insulation Tester: User ManualDocument24 pagesS1-1054/2 10kV Digital Insulation Tester: User ManualHoracio BobedaNo ratings yet

- Vilta-S: Stabilizer For SmartphoneDocument28 pagesVilta-S: Stabilizer For SmartphoneNivin KumarNo ratings yet

- Prelim MMW Lpu 2020 2021Document2 pagesPrelim MMW Lpu 2020 2021Noemi NadadoNo ratings yet

- Synopsis Format-Practice SchoolDocument4 pagesSynopsis Format-Practice SchoolArjun GoyalNo ratings yet

- Domain 2 Communication and Interpersonal SkillsDocument4 pagesDomain 2 Communication and Interpersonal SkillsLip StickNo ratings yet

- NCh204 1977Document15 pagesNCh204 1977Cristian A. Rivera S.No ratings yet

- MBSImP Assignment RubricDocument3 pagesMBSImP Assignment RubricmahdislpNo ratings yet

- BEE MCQ Unit IVDocument16 pagesBEE MCQ Unit IVUmesh PatilNo ratings yet

- Fredkin Introduction To Digital PhilosophyDocument59 pagesFredkin Introduction To Digital PhilosophyEdoardo MatteiNo ratings yet

- Nursing ResumeDocument2 pagesNursing Resumeapi-655558844No ratings yet

- 4401 SyllabusDocument1 page4401 SyllabusTony LeungNo ratings yet

- Shaker SK L180 SDocument1 pageShaker SK L180 SUPT LABKESDA KAB PADANG PARIAMANNo ratings yet

- Principles of Engineering Thermodynamics - SI Version 8th EditionDocument47 pagesPrinciples of Engineering Thermodynamics - SI Version 8th EditionanabNo ratings yet

- Fishbone Rawat Inap PDFDocument2 pagesFishbone Rawat Inap PDFAbdul NasirNo ratings yet