Professional Documents

Culture Documents

Back Filling

Back Filling

Uploaded by

Lasantha WeerasekaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Back Filling

Back Filling

Uploaded by

Lasantha WeerasekaraCopyright:

Available Formats

3.

0 SCOPE OF WORK

Following activities will be carried-out in the soil back-filling process.

• De-watering the excavated pit (If necessary)

• Soil Backfilling

• Manual Leveling

• Soil Compaction (Watering If required)

• Import Soil (if necessary)

• Final leveling for lean concrete

• Anti-termite Treatment (for above water table)

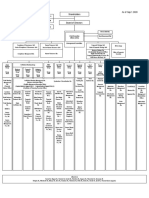

4.0 RESPONSIBILITIES

The following figure (figure-4.1) shows the organizational chart.

Figure 4 1- Organizational Chart

Method statement for backfilling

5.0 BACKFILLING SEQUENCE

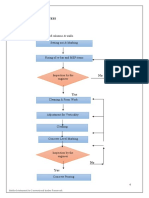

The backfilling will follow the sequence shown below (Figure 5.1).

Building 01 - Back Filling Zone

Building 03 - Back Filling Zone

Building 04 - Back Filling Zone

Building 02 - Back Filling Zone

Building 05 & 06 - Back Filling Zone

Figure 5.1 Back filling Sequence Flow Chart

6.0 WORK PROCEDURE

Clearing of excavated area

• Removal of unsuitable material (e.g. particles in excess of 75mm ,peat, organic

materials and perishable materials and so on)

The backfill will consist of several horizontal layers not exceeding a thickness of

150mm.

Each layer will initially be backfilled by excavators and then manually leveled by

site workers.

This will then allow for the compaction (both in the x and y direction). Depending

on the site condition either allow for the 1 ton roller, plate vibrator and/or rammer

to be used.

During compaction water could be applied if necessary.

Method statement for backfilling

Once this step is complete, the above soil layers are done in the same way.

7.0 QUALITY ASSURANCE / INSPECTIONS

The following points will be carried out to ensure the quality of backfill.

Continuous monitoring shall be carried out to ensure the ground water table is

below from the level of excavation.

The Sand cone test & Standard Proctor Compaction Test will be carried out to

measure the degree of compaction of the layer according to the below location table.

Initially sand cone test will be carried out for one compacted layer of backfill

material with the rammer. Along with the results of Standard Proctor Compaction

Test, this will enable the required compaction to achieve the needed degree of

compaction. Based on above results, similar compaction level will be followed to

the following backfilling layers.

A California Bearing Ratio (CBR) test will be carried out on the request of the

consultant

Required final level will be checked according to the detail drawings and with

referring to TBM.

Anti-termite Treatment shall be done with the guidance of the specialized

contractor, Separate method statement will be provided.

Types of Backfilling (control & uncontrol) in site relevant locations given below,

Control

Backfilling Uncontrol

Location Backfilling

with testing

Underneath Ground supported laboratory slabs √

Underneath Badminton court, Gymnasium √

Along the road’s pavement. √

Along the retaining wall √

Underneath ground supported slabs √

Column/raft footing excavated area backfilling √

General soil filling level from existing level (landscape) √

Underneath Lift pit/sump/Pump rooms √

Carpark area √

Walk paths √

Underneath water feature √

Open air theater √

Method statement for backfilling

8.0 SAFETY PLAN

All dangerous areas must be barricaded

Safe plat-forms for working at higher levels shall be placed and secured.

Safety Guard rails shall be provided along the perimeter.

All the electrical wires and sockets are placed in such a way that it will be covered

so that it will conform to safety regulations.

First aid facilities and vehicles for emergency cases shall be available at site.

Refer the Sanken Lanka Safety Manual for other safety precaution and regulations.

9.0 REFERENCES

Structural Specifications

Method statement for backfilling

You might also like

- Ceres Gardening Company - Spreadsheet For StudentsDocument1 pageCeres Gardening Company - Spreadsheet For Studentsandres felipe restrepo arango0% (1)

- Method Statement For Pile Cap ConcretingDocument8 pagesMethod Statement For Pile Cap ConcretingArifur Rahman Apu100% (6)

- Construction Management Plan For Bund WallDocument14 pagesConstruction Management Plan For Bund WallNoNa Mohammed0% (1)

- EmbankmentDocument5 pagesEmbankmentAmila Priyadarshana Dissanayake100% (1)

- All Pavement MethologiesDocument17 pagesAll Pavement MethologiesCharismatic Srini VasanNo ratings yet

- Method Statement of Open CutDocument7 pagesMethod Statement of Open CutMuditha Indeewarie GunarathnaNo ratings yet

- Method Statement For Aggregate Base CourseDocument3 pagesMethod Statement For Aggregate Base CourseMohaiminul Karim100% (3)

- 04 Under Water EmbankmentDocument3 pages04 Under Water Embankmentvarun sonkarNo ratings yet

- MS For Deep ExcavationDocument8 pagesMS For Deep ExcavationBilalNo ratings yet

- Methodology of Hard Shoulder: - 1 - VKLR - QmeDocument4 pagesMethodology of Hard Shoulder: - 1 - VKLR - QmeBalaji ManneNo ratings yet

- Methodology For Capliary Cut-OffDocument5 pagesMethodology For Capliary Cut-OffMarees KumarNo ratings yet

- Method Statement of Piling Concrete For Fire Water Tank MTDocument15 pagesMethod Statement of Piling Concrete For Fire Water Tank MTahmad100% (1)

- Excavation WorksDocument3 pagesExcavation WorksLasantha WeerasekaraNo ratings yet

- Operating Procedure NDT Department OPN-037 Rev.1 February 7, 2005 Page 1 of 8Document8 pagesOperating Procedure NDT Department OPN-037 Rev.1 February 7, 2005 Page 1 of 8ramalingamNo ratings yet

- Modus Operandi For Rob: (-) in Between - and - Rly. StationsDocument32 pagesModus Operandi For Rob: (-) in Between - and - Rly. StationsRoushan RaiNo ratings yet

- Abc & PrimingDocument4 pagesAbc & Primingsatheek0% (1)

- Aptransco 220.132kV Lines-SS QAP & FormatDocument89 pagesAptransco 220.132kV Lines-SS QAP & Formatbharat_ravulapalli75% (4)

- Case Study - HK Disneyland Reclamation - IntraforDocument51 pagesCase Study - HK Disneyland Reclamation - IntraforAlvinNo ratings yet

- Back FillingDocument2 pagesBack FillingHanmant Mortale PatilNo ratings yet

- Re Con of Ex Pavement MSDocument4 pagesRe Con of Ex Pavement MSAmila Priyadarshana DissanayakeNo ratings yet

- Asphalt Pavement - UpDocument11 pagesAsphalt Pavement - UpMohammad Fikrie Bahrul HayatNo ratings yet

- Method of StatementDocument17 pagesMethod of StatementhanyalramadyNo ratings yet

- PROJECTS: Iridium Tower: Method StatementDocument13 pagesPROJECTS: Iridium Tower: Method StatementAvinash Kumar ChoudharyNo ratings yet

- Field Compaction ControlDocument2 pagesField Compaction ControlEftikarNo ratings yet

- Pile Load TestDocument35 pagesPile Load TestWaqas HassanNo ratings yet

- Shoulder ConstructionDocument3 pagesShoulder ConstructionAmila Priyadarshana Dissanayake100% (1)

- Method Statement For Earth Works For A Road ProjectDocument17 pagesMethod Statement For Earth Works For A Road ProjectMkmKamilNo ratings yet

- Basement Floor Screed ConcreteDocument5 pagesBasement Floor Screed ConcreteQAQC NandanamNo ratings yet

- Flow of Communication: Emergency Response For Oil SpillageDocument5 pagesFlow of Communication: Emergency Response For Oil Spillagenarm nNo ratings yet

- Section 3 - MFL Tank Floor Inspection - Rev 1Document62 pagesSection 3 - MFL Tank Floor Inspection - Rev 1Technical A-Star Testing & Inspection MalaysiaNo ratings yet

- Kia - GT TestsDocument4 pagesKia - GT TestsNishan Lulu Muhamed JaleelNo ratings yet

- SPDC Standard Drilling Procedures Manual Site: CHA Pter 07Document39 pagesSPDC Standard Drilling Procedures Manual Site: CHA Pter 07Agaba Idu100% (1)

- Piling Rigs Overturning On Construction Sites: A Guide To Loss PreventionDocument4 pagesPiling Rigs Overturning On Construction Sites: A Guide To Loss Preventionmohd addinNo ratings yet

- Quality Assurance PlanDocument89 pagesQuality Assurance PlanSai KumarNo ratings yet

- Method Statement For BACK FILLING FinalDocument4 pagesMethod Statement For BACK FILLING FinalEngr Muhammad SohailNo ratings yet

- METHOD STATEMENT FOR DEEP EXCAVATIONS@ MMTH Project1 - R0Document14 pagesMETHOD STATEMENT FOR DEEP EXCAVATIONS@ MMTH Project1 - R0jamil khanNo ratings yet

- Ms For Concrete PilesDocument16 pagesMs For Concrete PilesahmadNo ratings yet

- Hard Shoulder MSDocument4 pagesHard Shoulder MSAmila Priyadarshana DissanayakeNo ratings yet

- Lifting Plan Checklist and Method Statement SkeletonDocument7 pagesLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesNo ratings yet

- Method Statement For Excavation Compaction and BackfillingDocument8 pagesMethod Statement For Excavation Compaction and BackfillingIna RoseNo ratings yet

- Method Statement For Excavation PDF FreeDocument7 pagesMethod Statement For Excavation PDF FreeABDO ALLIANo ratings yet

- 05 Sub-Surface Exploration 04Document29 pages05 Sub-Surface Exploration 04kabir AhmedNo ratings yet

- How Well Is DrilledDocument46 pagesHow Well Is DrilledWilliam EvansNo ratings yet

- BMP #: Subsurface InfiltrationDocument10 pagesBMP #: Subsurface Infiltrationmauriah qibtiNo ratings yet

- Kwrp-Section A' Site Trainning Programe Benkleman Beam Deflection Test LOCATION: CH-43.000 TO 47.000 RHS DATE:04.01.2011Document8 pagesKwrp-Section A' Site Trainning Programe Benkleman Beam Deflection Test LOCATION: CH-43.000 TO 47.000 RHS DATE:04.01.2011Padmavathi KotaNo ratings yet

- Laboratory Ceiling Finish Specifications Criteria) : (DesignDocument15 pagesLaboratory Ceiling Finish Specifications Criteria) : (DesignDevansh ShethNo ratings yet

- Vibro Ground BrochureDocument12 pagesVibro Ground Brochurealphaboi100% (1)

- Excavation, Trenching & Pot HolingDocument1 pageExcavation, Trenching & Pot HolingHafiz SabriNo ratings yet

- 3) Work Method Statement Ground Floor SlabDocument3 pages3) Work Method Statement Ground Floor Slabhks1209No ratings yet

- Airfield Pavement EvaluationDocument28 pagesAirfield Pavement EvaluationDondeti ManideepreddyNo ratings yet

- PilingDocument19 pagesPilingGANGARAJU N BNo ratings yet

- 16 - Roadbase - Pavement WorksDocument4 pages16 - Roadbase - Pavement Worksasr.engineering2023No ratings yet

- Method Statement For Compaction and BackfillingDocument8 pagesMethod Statement For Compaction and BackfillingJohn MofireNo ratings yet

- Keller 10 02E Deep Vibro TechniquesDocument12 pagesKeller 10 02E Deep Vibro TechniquesFabio De Paiva BrumanoNo ratings yet

- Dewatring Method StatementDocument8 pagesDewatring Method Statementreachpunnya5538No ratings yet

- Embankment PDFDocument5 pagesEmbankment PDFTin Win HtutNo ratings yet

- Method Statement Road Work - MORTHDocument18 pagesMethod Statement Road Work - MORTHCivil FundaNo ratings yet

- Procedure - HS011-Rotary-CoringDocument6 pagesProcedure - HS011-Rotary-CoringRasulNezNo ratings yet

- Handout 3 Earthwork OperationsDocument25 pagesHandout 3 Earthwork OperationsthuraiyaNo ratings yet

- 5) Normal DistributionDocument5 pages5) Normal DistributionLasantha WeerasekaraNo ratings yet

- 1) Random VariableDocument6 pages1) Random VariableLasantha WeerasekaraNo ratings yet

- 3) Binomial ExperimentDocument6 pages3) Binomial ExperimentLasantha WeerasekaraNo ratings yet

- Introduction To Project ManagementDocument65 pagesIntroduction To Project ManagementLasantha WeerasekaraNo ratings yet

- Lec Set3Document5 pagesLec Set3Lasantha WeerasekaraNo ratings yet

- Excavation WorksDocument3 pagesExcavation WorksLasantha WeerasekaraNo ratings yet

- Conventional Timber FormworksDocument6 pagesConventional Timber FormworksLasantha WeerasekaraNo ratings yet

- General SurveyingDocument3 pagesGeneral SurveyingLasantha WeerasekaraNo ratings yet

- Termite Treatment WorkDocument2 pagesTermite Treatment WorkLasantha WeerasekaraNo ratings yet

- 8.stocks Below Rs 20 - ScreenerDocument3 pages8.stocks Below Rs 20 - ScreenerVishnu varthanNo ratings yet

- Business Finance: Needs and Sources: Revision AnswersDocument4 pagesBusiness Finance: Needs and Sources: Revision AnswersJuhuNo ratings yet

- T.Me/Micropets WWW - Micropets.Io Contract:: 0XE743Fa9CDocument17 pagesT.Me/Micropets WWW - Micropets.Io Contract:: 0XE743Fa9CMalum TNo ratings yet

- Merge 0005Document55 pagesMerge 0005Hamid JafarimaramNo ratings yet

- Ethics For EntrepreneursDocument7 pagesEthics For EntrepreneursNavaneeth kumarNo ratings yet

- Mini Project of ProjectDocument10 pagesMini Project of ProjectBorisNo ratings yet

- 0 - Revision Batch Compilation Sept 18 Only As Questions-1 PDFDocument14 pages0 - Revision Batch Compilation Sept 18 Only As Questions-1 PDFKunal DhepleNo ratings yet

- Group ReportDocument54 pagesGroup ReportAnh Quân NguyễnNo ratings yet

- Onida FinalDocument13 pagesOnida FinalnitingbuNo ratings yet

- BEMS-Identification of EXport - MktsDocument22 pagesBEMS-Identification of EXport - MktsAKARSH JAISWALNo ratings yet

- S G S G: Mall Iants Mall IantsDocument7 pagesS G S G: Mall Iants Mall IantsSarab MysteryNo ratings yet

- Increasing Efficiency Worksheet For StudentDocument8 pagesIncreasing Efficiency Worksheet For StudentKristjan KunilaNo ratings yet

- Three Trading Tactics For Up To 30% Gains A MonthDocument10 pagesThree Trading Tactics For Up To 30% Gains A MonthBill N.No ratings yet

- Chapter-1 Company Profile: A Study of Industrial Relations in Cadbury India LTDDocument51 pagesChapter-1 Company Profile: A Study of Industrial Relations in Cadbury India LTDAnkit SalujaNo ratings yet

- Group Work - Inventory Cost Flow and LCNRVDocument2 pagesGroup Work - Inventory Cost Flow and LCNRVKawhileonard LeonardNo ratings yet

- PDF of Bank OrganogramDocument1 pagePDF of Bank OrganogramAntar ShaddadNo ratings yet

- HB1465Document6 pagesHB1465Madison HardcastleNo ratings yet

- Needs Analysis - NidiaDocument17 pagesNeeds Analysis - Nidianidia.rizqi.2002128No ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument2 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalancedivaNo ratings yet

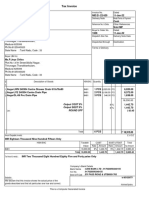

- Tax Invoice: Output CGST 9% Output SGST 9% Round OffDocument1 pageTax Invoice: Output CGST 9% Output SGST 9% Round OffCHETTIKULAM NATHAM projectNo ratings yet

- Chapter 6: Overview of Transaction Processing and Financial Reporting SystemsDocument6 pagesChapter 6: Overview of Transaction Processing and Financial Reporting Systemsmostafakhaled333No ratings yet

- CHAPTER 1 StatisticsDocument41 pagesCHAPTER 1 StatisticsAyushi JangpangiNo ratings yet

- Monthly Test Acc - XiiDocument4 pagesMonthly Test Acc - Xiiramandeep kaurNo ratings yet

- Oriah Mountain Dreamer QuotesDocument8 pagesOriah Mountain Dreamer QuotesRhapsodiac LuthNo ratings yet

- Weekender Business PlanDocument25 pagesWeekender Business PlanhamzahsafyeldinNo ratings yet

- Logi 2Document12 pagesLogi 2DanielaAndreaRoldanNo ratings yet

- Crossword Puzzle - Intro To Cost ManagementDocument2 pagesCrossword Puzzle - Intro To Cost ManagementBSA3Tagum MariletNo ratings yet

- Market SolutionsDocument32 pagesMarket Solutionsjayson RodriguezNo ratings yet

- Ig OutrechDocument4 pagesIg OutrechOP gamingNo ratings yet