Professional Documents

Culture Documents

Best Practices - Design - Loads On Pin Covers

Uploaded by

dheeraj SureshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Best Practices - Design - Loads On Pin Covers

Uploaded by

dheeraj SureshCopyright:

Available Formats

BEST PRACTICE

Subject Design load on pin covers / pin fixation Date 15 May 2018 Page 1/4 Sap nr. 6000167569

Doc. nr. 050200006 Region Europe Rev. 00

Design load on pin covers / pin fixation

This best practice provides a guideline to determine the design load on pin covers / pin fixations.

Conditions / Description of situation

Within Mammoet pins are commonly used as connection element between different structural members. Pin

fixation typically is used to prevent sideways movement of the pin (some examples are shown below). A

guideline is given on how to determine the design load for such pin fixations.

Bolted cover plate Locking pin Fixation clip

Content

On the following page a flowchart is given to determine the design load on a pin fixation, followed by an

example. Note: for a standard bolted cover plate design Mammoet Excel sheet 3.7 can be used.

For information 15 May WJon MCri WJon

00

only 2018 903245 903121 903245

Approved Owner

Rev. Description Date Author

(By subject matter expert) (For questions)

Without authorized signature(s) this document is uncontrolled, not binding and for indicative purposes only

NOTE

THIS BEST PRACTICE GUIDELINE IS PREPARED BASED ON THE BEST KNOWLEDGE AT THE TIME OF

WRITING AND SUBJECTED TO NEW INSIGHTS. FOR ALTERATIONS CONTACT THE OWNER.

Status For information only

BEST PRACTICE

Subject Design load on pin covers / pin fixation Date 15 May 2018 Page 2/4 Sap nr. 6000167569

Doc. nr. 050200006 Region Europe Rev. 00

Flowchart to determine sideload on pin fixation

2.0% = Basic starting value

Rigging or crane Yes Wind ≤10m/s Yes

component? Sidelead/offlead ≤1.0%

No

No

-1.0%

Pin rotation expected? Yes

Pin with bushing or Yes

(either many small or

properly greased?

few large rotations)

No

+2.0%

No

+1.0%

Operational time > 3 Yes Yes

Pin with bushing or

months and/or > 100 lift

properly greased?

cycles?

+2.0% No

No

+1.0%

Use figure 2 to calculate Total sideload

Round up to the

extra sideload due to Minimum = 1.0%

first integer

connection geometry Maximum = 10.0%

Figure 1: Flowchart to determine design load (in %) on pin fixation

Note:

The sideload (ULS) in [kN] on the pin fixation is found by multiplying [%] x ULS force acting on the pin.

Status For information only

BEST PRACTICE

Subject Design load on pin covers / pin fixation Date 15 May 2018 Page 3/4 Sap nr. 6000167569

Doc. nr. 050200006 Region Europe Rev. 00

d pin / ttotal 1.00 [% extra ] 0%

d pin

d pin / ttotal 1.00 [% extra ] 4 4

ttotal

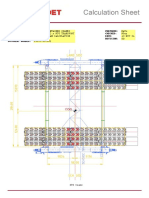

Figure 2: Additional sideload on pin fixation due to connection geometry

Status For information only

BEST PRACTICE

Subject Design load on pin covers / pin fixation Date 15 May 2018 Page 4/4 Sap nr. 6000167569

Doc. nr. 050200006 Region Europe Rev. 00

Example: Design of cover plates for tailing frame pin

Based on the following inputs the design load (in %) for the cover plates shall be determined:

- One time use / operation

- Tailing angle = 90 degree

- Cheap practical design:

no bushings / no grease provisions

- Force (ULS) acting on pin = 900 kN

Solution: follow the flowchart; start with 2.0% sideload (=basic starting value)

Q: Is it a crane or rigging component? -> No -> stay at 2.0%

Q: Is pin rotation expected? -> yes, due to the tailing action the pin could rotate 90°

Q: Does the pin use a bushing or grease? -> No -> 2.0% extra, 2.0 + 2.0 = 4.0%

Q: Operational time > 3 months and/or 100 cycles? No, one time use -> stay at 4.0%

T: Use figure 2 + formula -> dpin/ttotal =120/200 = 0.60 -> 1.6% -> round of 2.0% -> 4.0 + 2.0 = 6.0%

Design load for the cover plates (pin fixation) is determined to be 6.0% -> 0.06 x 900 kN = 54 kN (ULS).

(The Mammoet Excel sheet 3.7 from the calculation handbook could be used for further detailed design)

Status For information only

You might also like

- 050200003-Best Practices - Design - Second Order CalculationsDocument11 pages050200003-Best Practices - Design - Second Order Calculationsdheeraj SureshNo ratings yet

- Best Practices - Design - Load IntroductionDocument14 pagesBest Practices - Design - Load Introductiondheeraj SureshNo ratings yet

- Best Practices - Design - Stacked BeamsDocument4 pagesBest Practices - Design - Stacked Beamsdheeraj SureshNo ratings yet

- Best Practices - Design - Wind LoadsDocument10 pagesBest Practices - Design - Wind Loadsdheeraj SureshNo ratings yet

- aaac32c291cb346be27f496586018bd7Document16 pagesaaac32c291cb346be27f496586018bd7Mohd FadliNo ratings yet

- RF Joints Manual enDocument128 pagesRF Joints Manual enGero FacultadNo ratings yet

- Distribution of Support Reaction Against A Steel Girder On A Launching ShoeDocument26 pagesDistribution of Support Reaction Against A Steel Girder On A Launching Shoedavidan76100% (1)

- SHEQ Policy Statement 1Document2 pagesSHEQ Policy Statement 1yuqwaszxNo ratings yet

- 1.1 General Information SPMT'sDocument4 pages1.1 General Information SPMT'sSky MoonNo ratings yet

- PERI UP Rosett Shoring Towers Type Test US1 enDocument60 pagesPERI UP Rosett Shoring Towers Type Test US1 enSanja RadovicNo ratings yet

- Sample Route SurveyDocument11 pagesSample Route SurveyShridhar BabuNo ratings yet

- Project Sheet Tennet A12 - 2 PDFDocument2 pagesProject Sheet Tennet A12 - 2 PDFduongpnNo ratings yet

- Abb Rev AtionsDocument7 pagesAbb Rev AtionsPonniyin SelvanNo ratings yet

- Goldhofer Accessories-Eu en A4Document17 pagesGoldhofer Accessories-Eu en A4Gers LdENo ratings yet

- VSL Construction SystemDocument62 pagesVSL Construction SystemLAM CONo ratings yet

- TELESCOPIC TOWER FACILITATING INSTALLATION OF 12 MW OFFSHORE WIND TURBINES. Dissertation in Partial Fulfillment of The CourseDocument178 pagesTELESCOPIC TOWER FACILITATING INSTALLATION OF 12 MW OFFSHORE WIND TURBINES. Dissertation in Partial Fulfillment of The CourseRaymond CiaoNo ratings yet

- SARENS Company OverviewDocument17 pagesSARENS Company OverviewCharles MouraniNo ratings yet

- Rl04500-D-eqd-0001-00 SPMT Power Pack Unit z350 Da-Rl4500Document1 pageRl04500-D-eqd-0001-00 SPMT Power Pack Unit z350 Da-Rl4500Muhammad Reza PutraNo ratings yet

- The Art of Heavy TransportDocument612 pagesThe Art of Heavy TransportE. Esli Cruz TovarNo ratings yet

- Shore XDocument12 pagesShore XdfNo ratings yet

- The Knowledge CogDocument3 pagesThe Knowledge Cogparamarthasom1974No ratings yet

- ESTA A4versie DEFdigitalHR-pagesDocument36 pagesESTA A4versie DEFdigitalHR-pageszackysipNo ratings yet

- Safe Load Securing of Plant and MachineryDocument6 pagesSafe Load Securing of Plant and MachineryLeonardo SNo ratings yet

- Safety Is Our First Priority: Safety Components For Fall ProtectionDocument124 pagesSafety Is Our First Priority: Safety Components For Fall Protectioningeniera electricaNo ratings yet

- Camelot Brochure Supply Base PDFDocument11 pagesCamelot Brochure Supply Base PDFDimi Jeri TriNo ratings yet

- Stressbar PDFDocument8 pagesStressbar PDFTuan PnNo ratings yet

- The Trestle - St. LouisDocument48 pagesThe Trestle - St. LouisnextSTL.com100% (1)

- 02 Falcone HD23 CTL 400-CTT Soprael 003 eDocument56 pages02 Falcone HD23 CTL 400-CTT Soprael 003 eShailesh KhodkeNo ratings yet

- Rotabolt 007 eDocument15 pagesRotabolt 007 eShailesh KhodkeNo ratings yet

- Momente Strangere Suruburi Americane - ASTM A574Document1 pageMomente Strangere Suruburi Americane - ASTM A574tracam500No ratings yet

- Lashing Project CargoDocument1 pageLashing Project CargoBHAUMIK SOLANKINo ratings yet

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDocument80 pagesPPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiNo ratings yet

- SPMT and Pump Data PDFDocument5 pagesSPMT and Pump Data PDFlipanzyNo ratings yet

- Mammoet SPMT Incident in Thailand On Nov.16,2008Document7 pagesMammoet SPMT Incident in Thailand On Nov.16,2008egy pureNo ratings yet

- Mammoet Tpa BrochureDocument8 pagesMammoet Tpa Brochureasdasd asdasdNo ratings yet

- FEM Overload Testing of Mobile Cranes PDFDocument2 pagesFEM Overload Testing of Mobile Cranes PDFegyinspectoryahooNo ratings yet

- SIWZ RMGs Schedule 5 Technical Specification PDFDocument109 pagesSIWZ RMGs Schedule 5 Technical Specification PDFgafscottNo ratings yet

- Outline: Navigation Engineering: Understanding The BasicsDocument25 pagesOutline: Navigation Engineering: Understanding The BasicsIan WarnerNo ratings yet

- ASME B30.4-2015 - Postal and Pedestal CranesDocument46 pagesASME B30.4-2015 - Postal and Pedestal CranesRosaly100% (1)

- More Than Lifting.: Pfeifer Seil-Und Hebetechnik GMBHDocument60 pagesMore Than Lifting.: Pfeifer Seil-Und Hebetechnik GMBHBronwynne OctoberNo ratings yet

- Sarens SarspinV.11.10.10Document4 pagesSarens SarspinV.11.10.10Rm1262No ratings yet

- PEMA Practical Observations - Rail Mounted Crane InterfacesDocument26 pagesPEMA Practical Observations - Rail Mounted Crane InterfacesShaiju Narayanan100% (1)

- OSST Know Your Steel Guide January 2010Document61 pagesOSST Know Your Steel Guide January 2010vikzefgNo ratings yet

- Quick Lashing Guide ForankraDocument15 pagesQuick Lashing Guide ForankraSebastian ZarzyckiNo ratings yet

- Cometto SYV6 Modular Trailer+SPMTDocument11 pagesCometto SYV6 Modular Trailer+SPMTAllen RenNo ratings yet

- Mammoet 2002 PDFDocument20 pagesMammoet 2002 PDFCuong Dinh100% (1)

- Datasheet SPMT KamagDocument1 pageDatasheet SPMT Kamag허윤호No ratings yet

- Heaviest Loads On Modular Axle Lines: Powered byDocument28 pagesHeaviest Loads On Modular Axle Lines: Powered byTcristomoradoNo ratings yet

- Mobile Cranes: Inspection FormDocument13 pagesMobile Cranes: Inspection FormColter Heavy DutyNo ratings yet

- Scheuerle SPMT 3000 IC Brochure PDFDocument13 pagesScheuerle SPMT 3000 IC Brochure PDFRuben Bartolome GarciaNo ratings yet

- Precast Segmental Bridge Construction: John E. Kristensen PE., PLS., PMPDocument38 pagesPrecast Segmental Bridge Construction: John E. Kristensen PE., PLS., PMPकुँवर विभा पुत्रNo ratings yet

- CM Cady CatalogDocument67 pagesCM Cady Catalogsuperman3kNo ratings yet

- Lift & Lock System: Lift-n-Lock System, Extending The Manual Boom, 1 Stage and 2 Stage BoomsDocument5 pagesLift & Lock System: Lift-n-Lock System, Extending The Manual Boom, 1 Stage and 2 Stage BoomsFakhar Aziz KhanNo ratings yet

- 6785 PDFDocument5 pages6785 PDFSandip SurNo ratings yet

- SPMT, Self Propelled Modular Transporters - CHINA HEAVY LIFT Modular Trailer and SPMTDocument4 pagesSPMT, Self Propelled Modular Transporters - CHINA HEAVY LIFT Modular Trailer and SPMTTawfiqul IslamNo ratings yet

- 5 Technical Data PST-SL-E 4-08x04Document1 page5 Technical Data PST-SL-E 4-08x04Anwar Shan100% (2)

- Sarens Anchors PDFDocument2 pagesSarens Anchors PDFprasetyoNo ratings yet

- 15112739-E-C01 - 00 (Relocation of 1255t STS Crane)Document14 pages15112739-E-C01 - 00 (Relocation of 1255t STS Crane)dheeraj SureshNo ratings yet

- DPR BWPRP4 Ocean303 12.03.18Document1 pageDPR BWPRP4 Ocean303 12.03.18KRISHNAN ELANGOVANNo ratings yet

- DPR BWPRP4 Ocean303 10.04.18Document1 pageDPR BWPRP4 Ocean303 10.04.18KRISHNAN ELANGOVANNo ratings yet

- Beam CheckDocument16 pagesBeam Checkdheeraj SureshNo ratings yet

- Staad Output-1Document533 pagesStaad Output-1dheeraj SureshNo ratings yet

- Stress Summary TableDocument546 pagesStress Summary Tabledheeraj SureshNo ratings yet

- MOVE 2014 01215 EN FinalDocument96 pagesMOVE 2014 01215 EN FinalBranko PulkoNo ratings yet

- Afcon Tower Design-3x3-12m OUTPUTDocument457 pagesAfcon Tower Design-3x3-12m OUTPUTdheeraj SureshNo ratings yet

- Member UC RatioDocument3 pagesMember UC Ratiodheeraj SureshNo ratings yet

- HL707 Aidcg CR 002 R0Document89 pagesHL707 Aidcg CR 002 R0dheeraj SureshNo ratings yet

- Liting Beam Type-1 (8pg)Document8 pagesLiting Beam Type-1 (8pg)dheeraj SureshNo ratings yet

- Liting Beam Type-1 (8pg)Document8 pagesLiting Beam Type-1 (8pg)dheeraj SureshNo ratings yet

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Document8 pagesHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshNo ratings yet

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Document8 pagesHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshNo ratings yet

- 15112739-E-C01 - 00 (Relocation of 1255t STS Crane)Document14 pages15112739-E-C01 - 00 (Relocation of 1255t STS Crane)dheeraj SureshNo ratings yet

- SDSDDocument18 pagesSDSDdheeraj SureshNo ratings yet

- 15112739-D-T01-01 STS Crane (4x24AL PST) - SGNDocument1 page15112739-D-T01-01 STS Crane (4x24AL PST) - SGNdheeraj SureshNo ratings yet

- DasdaDocument1 pageDasdadheeraj SureshNo ratings yet

- 15112739-D-T01-01 STS Crane (4x24AL PST) - SGNDocument1 page15112739-D-T01-01 STS Crane (4x24AL PST) - SGNdheeraj SureshNo ratings yet

- H 54 GDCL CR 01 R3Document33 pagesH 54 GDCL CR 01 R3dheeraj SureshNo ratings yet

- Design Method For End-Plate Bolted ConnectionsDocument12 pagesDesign Method For End-Plate Bolted Connectionsdheeraj SureshNo ratings yet

- SDSDDocument18 pagesSDSDdheeraj SureshNo ratings yet

- SdasdasdDocument18 pagesSdasdasddheeraj SureshNo ratings yet

- SDSDDocument18 pagesSDSDdheeraj SureshNo ratings yet

- SdasdasdDocument18 pagesSdasdasddheeraj SureshNo ratings yet

- Design Document of 24m Guyed MastDocument26 pagesDesign Document of 24m Guyed Mastdheeraj SureshNo ratings yet

- Bye LawsDocument38 pagesBye Lawsdheeraj SureshNo ratings yet

- Unit 9Document31 pagesUnit 9reddi.demullu007No ratings yet

- STAAD - Pro Report: Section PropertiesDocument2 pagesSTAAD - Pro Report: Section Propertiesdheeraj SureshNo ratings yet

- DOT RequirementsDocument372 pagesDOT RequirementsMuhammadShabbirNo ratings yet

- Mossbauer SpectrosDocument7 pagesMossbauer SpectroscyrimathewNo ratings yet

- Using Your Digital Assets On Q-GlobalDocument3 pagesUsing Your Digital Assets On Q-GlobalRemik BuczekNo ratings yet

- The Fastest Easiest Way To Secure Your NetworkDocument9 pagesThe Fastest Easiest Way To Secure Your NetworkMark ShenkNo ratings yet

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet

- Nascsa - Sponsor Solicitation List: January 06, 2021Document35 pagesNascsa - Sponsor Solicitation List: January 06, 2021Prasoon SimsonNo ratings yet

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- Introduction To Microelectronic Fabrication PDFDocument332 pagesIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Class 1 KeyDocument3 pagesClass 1 Keyshivamsingh.fscNo ratings yet

- Macros and DirectiveDocument7 pagesMacros and DirectiveAbdul MoeedNo ratings yet

- Su Poder en El Espiritu Santo Your Power in The Holy Spirit Spanish Edition by John G Lake PDFDocument4 pagesSu Poder en El Espiritu Santo Your Power in The Holy Spirit Spanish Edition by John G Lake PDFRodrigo MendezNo ratings yet

- Literature Review - Part Time Job Among StudentDocument3 pagesLiterature Review - Part Time Job Among StudentMarria65% (20)

- Bearing 1Document27 pagesBearing 1desalegn hailemichaelNo ratings yet

- Krishna TejaDocument71 pagesKrishna TejaHimanshu GaurNo ratings yet

- NamalDocument5 pagesNamalAyusnab KarkiNo ratings yet

- Full Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full ChapterDocument13 pagesFull Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full Chapterpoetrycloudyzjm12q100% (19)

- CHAPTER I Lesson II Seven Environmental PrinciplesDocument17 pagesCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotNo ratings yet

- Product Handbook Arendal 1961 Series SubwoofersDocument44 pagesProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNo ratings yet

- Wiska Varitain - 0912Document18 pagesWiska Varitain - 0912Anonymous hHWOMl4FvNo ratings yet

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocument5 pagesEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiNo ratings yet

- Rosewood Case AnalysisDocument5 pagesRosewood Case AnalysisJayant KushwahaNo ratings yet

- Masking Conventional Metallic Cast Post For Enhancing EstheticsDocument5 pagesMasking Conventional Metallic Cast Post For Enhancing EstheticsleilyanisariNo ratings yet

- Random Questions From Various IIM InterviewsDocument4 pagesRandom Questions From Various IIM InterviewsPrachi GuptaNo ratings yet

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDocument19 pagesC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghNo ratings yet

- Turner Et Al. 1991 ASUDS SystemDocument10 pagesTurner Et Al. 1991 ASUDS SystemRocio HerreraNo ratings yet

- University of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSDocument3 pagesUniversity of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSPhilip Pearce-PearsonNo ratings yet

- On The Wings of EcstasyDocument79 pagesOn The Wings of Ecstasygaya3mageshNo ratings yet

- Elasticsearch, Logstash, and Kibana - CERTDocument35 pagesElasticsearch, Logstash, and Kibana - CERTManuel VegaNo ratings yet

- DeadlocksDocument41 pagesDeadlocksSanjal DesaiNo ratings yet

- STW 44 3 2 Model Course Leadership and Teamwork SecretariatDocument49 pagesSTW 44 3 2 Model Course Leadership and Teamwork Secretariatwaranchai83% (6)