Professional Documents

Culture Documents

Cons.1 - Design of Column Formwork

Uploaded by

Khoi DuongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cons.1 - Design of Column Formwork

Uploaded by

Khoi DuongCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

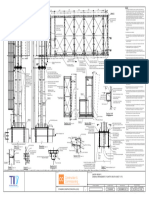

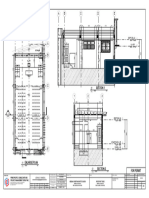

A A

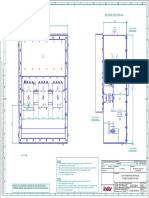

Casting concrete by

570

Concrete Hopper

1250

1244

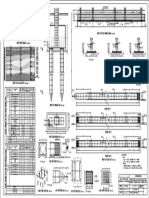

Purlin ☐50×50×2@250 Purlin ☐50×50×2@250

Plywood formwork 18mm Purlin ☐50×100×2@500 Purlin ☐50×100×2@500

Triangle Jack

Tie Ø16@500 Tie Ø16@500 Tie Ø16@500

1075

B B

Purlin 50×50×2@250 Longitudinal Plywood formwork 18mm Plywood formwork 18mm

Reinforcement

Purlin 50×100×2@500 Stirrup Working Deck Working Deck

400

400

Working Deck Vibrating rod

296

388

418

Working Deck

250

560

750

C 5 C

250

418

388

290

400

400

1080

D D

Working Deck

1250

1250

554

E E

150 1350 296 250 250 250 250 243 1350 150

1512 488 560 488 1500

2000 560 2000

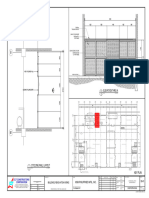

B B1 Rebar Erection Formwork Installation Concrete Casting

1 2 3

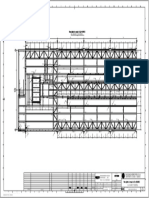

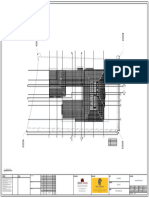

Column Construction plan layout

F 4 F

1 : 25

5

B1 B

+29.800 +29.800

Floor 8 Floor 8

Scaffodlding Working Deck

170 Hopper Specifications

Working Stair

Dimension of funnel (D × R × C): 1.7 ×

468

Purlin 50×100×2@500 Bracing

298

668

G

Working deck 1.6 × 2.3m G

203

Tie Ø16@500

Volume: 1.5m3

322

332

Purlin 50×100×2@500

Purlin 50×50×2@250 Diameter of outlet: Ø270

500

537

Purlin 50×50×2@250

Pouring type: valve wiper

500

500

Triangle Jacking Tie Ø16@500 Elephant trunk pipe: 3m

L-Anchorage

500

500

Triangle Jack

3400

3400

H H

Bracing cable

500

500

2180

2192

500

500

60°

60°

60°

60°

500

500

I I

+26.400 +26.400

108

100

Floor 7 Floor 7

50

102

250 1250 100193100 750 150143103 1250 250 275 1300 388 560 388 1300 275 102

1250 2190 1250

1500 488 280 280 491 1250 50

200 4690

4548

K K

Column - Side Elevation Column - Front Elevation

6 5

1 : 25 1 : 25

3D- Working Deck- Column Concrete Hooper

7 8

NOTE:

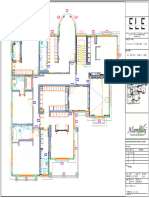

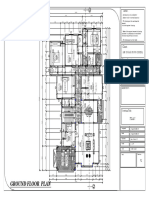

• Column concrete is used as fresh concrete, is produced at the factory and shipped to the construction site by vehicles transporting concrete. BACHELOR DISSERTATION OF CIVIL ENGINEERING K2016

• Time of concrete for producing, transporting to the factory must be less than 4 hours to avoid harden concrete before applying. If concrete is hardened, it shall not be used for construction, must return to the

HO CHI MINH CITY UNIVERSITY OF TECHNOLOGY

L factory. FALCUTY OF CIVIL ENGINEERING OFFICE OF THE PARTY L

DEPARTMENT OF STRUCTURAL

• Concrete after being transported to the construction site, must be carried out sampling and testing before conducting slump concrete. ENGINEERING

CITY

• Casting concrete is carried out after rebar erection and formwork installation are completed, then acceptance is carried out by documents. When pouring concrete for wall, concrete is pumped into the funnels wall COMMITTEE

by tower crane or the pipe from truck. Workers in concreting area adjusted for concrete falling into the wall to create thickness of concrete based on the design, workers use vibrator down to vibrate the concrete, Head of dept Assoc Prof NGO HUU CUONG

period for vibrating at each position is 25 seconds. Vibrator always submerged in concrete before concreting 10cm. DESIGN OF COLUMN FORMWORK

Structural

• Concrete must be cured after casting to ensure there is no dehydration caused surface cracking. After pouring the concrete, maintaining concrete by watering outside of formwork and continue watering after the Instructor

Assoc Prof HO DUC DUY

M concrete is hardened. In the first two days, need to water it 1 time for every 2 hours. In the next days, need to water it 1 time for every 3 to 10 hours. Concrete must be cured for at least 7 days. In the process of Construction

Instructor

Dr NGUYEN ANH THU START 30/3/2020 DRAWING M

curing concrete, need to process immediately the defects if there is any problem. Student NGUYEN NGOC ANH TRAM 1652622 FINISH 17/7/2020 CONS.01

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- C 1263 0911 15232 - R9 - Lay.Document2 pagesC 1263 0911 15232 - R9 - Lay.SANJAY PRAKASHNo ratings yet

- Overhead Gantry Sign BoardDocument1 pageOverhead Gantry Sign Boardrao shoaib100% (5)

- Bus ShelterDocument1 pageBus ShelterCHVN NH173No ratings yet

- 7Document1 page7Modasser NewazNo ratings yet

- Manual Secador CD 550+Document1 pageManual Secador CD 550+Paulo GarciaNo ratings yet

- PRI Sections - GF To &FLDocument1 pagePRI Sections - GF To &FLbert cruzNo ratings yet

- 2021 Columbary 12nov A01Document1 page2021 Columbary 12nov A01ice creaNo ratings yet

- Drawing For Lubrication MillDocument2 pagesDrawing For Lubrication MillDeepakNo ratings yet

- Pemindahan PV InverterDocument1 pagePemindahan PV Inverterfandy mustafaNo ratings yet

- 10-5-2023 - Banquet Hall..Document1 page10-5-2023 - Banquet Hall..ds18.albertcastroNo ratings yet

- Assignment 2: Door Window ScheduleDocument1 pageAssignment 2: Door Window ScheduleShubham KhuranaNo ratings yet

- Settingout Plan 1Document1 pageSettingout Plan 1Shubham KhuranaNo ratings yet

- Elevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageElevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- Str.06-Design of Frame C-F6 To F11Document1 pageStr.06-Design of Frame C-F6 To F11Khoi DuongNo ratings yet

- Cascadia Roads 11092019-Layout1Document1 pageCascadia Roads 11092019-Layout1Daniel KariukiNo ratings yet

- Bureau of Design: Spot Detail (Media Agua)Document1 pageBureau of Design: Spot Detail (Media Agua)Marcjun Colmo AlegradoNo ratings yet

- Male&Female PWD Layout-224 - 2fDocument1 pageMale&Female PWD Layout-224 - 2fEmmanuel TamayoNo ratings yet

- J-DMS: H400x400 (H-400x400x13x21) H450x300 (H-440x300x11x18) H500x300 (H-488x300x11x18)Document1 pageJ-DMS: H400x400 (H-400x400x13x21) H450x300 (H-440x300x11x18) H500x300 (H-488x300x11x18)Mary DenizeNo ratings yet

- Existing Section A-ADocument1 pageExisting Section A-AHamid ElmyNo ratings yet

- CC SCD 01822 0zaDocument1 pageCC SCD 01822 0zaocampoprescious1No ratings yet

- 336 557 Outlet Dn50 Pn16: Confidentiality Class Acc. To 1102 KDocument1 page336 557 Outlet Dn50 Pn16: Confidentiality Class Acc. To 1102 Krogerroman24No ratings yet

- BERAWA CRUISE SHIP - 1ST FLOOR - Rooms Elevations - 1B (2) - 37 - UNIT 1B PLAN-1 BEDROOMDocument1 pageBERAWA CRUISE SHIP - 1ST FLOOR - Rooms Elevations - 1B (2) - 37 - UNIT 1B PLAN-1 BEDROOMKevin KurniawanNo ratings yet

- Fadil 2013 Fix-A3 (Plot)Document1 pageFadil 2013 Fix-A3 (Plot)Dimas WiryaNo ratings yet

- Pbr2-3 Pbr2-3: El.+130.300平台平面布置图 (1) A A1 ADocument1 pagePbr2-3 Pbr2-3: El.+130.300平台平面布置图 (1) A A1 AJesus Manuel Juarez MamaniNo ratings yet

- Planta Niv+11.95: 2 e X Is Te N TeDocument1 pagePlanta Niv+11.95: 2 e X Is Te N TeMarco Andres Ortiz TitoNo ratings yet

- Computer Aided Design AssignmentDocument1 pageComputer Aided Design AssignmentsilasbyarugNo ratings yet

- Bus Shelter - Option 3Document1 pageBus Shelter - Option 3Manish KapadneNo ratings yet

- Plan-Right bank-ALL MICRO PILE CABLE ANCHOR 11.08.2017 - Copy-ModelDocument1 pagePlan-Right bank-ALL MICRO PILE CABLE ANCHOR 11.08.2017 - Copy-ModelSantosh K SatiNo ratings yet

- Wa0000.Document3 pagesWa0000.nmarozhe_225151671No ratings yet

- Vill477-Dig-A0-17-Existing Site PlanDocument1 pageVill477-Dig-A0-17-Existing Site PlanDivya SajivNo ratings yet

- 0-ModelDocument1 page0-Modeljoselito navarroNo ratings yet

- Bai Tap Kiem Tra Be Nuoc MaiDocument1 pageBai Tap Kiem Tra Be Nuoc MaiTiêu Dao ca caNo ratings yet

- MPB Arc-8Document1 pageMPB Arc-8Jay Mark GastonesNo ratings yet

- Cable Epc Girder ReinforDocument1 pageCable Epc Girder Reinforshshank guptaNo ratings yet

- Off R1Document1 pageOff R1Josphat benzNo ratings yet

- JP305821Document7 pagesJP305821alexanderNo ratings yet

- Festival Mall - Asbuilt PlanDocument1 pageFestival Mall - Asbuilt PlanArmando RodriguezNo ratings yet

- A-2 Enlarge Plan & SectionDocument1 pageA-2 Enlarge Plan & SectionarjayymerleNo ratings yet

- 0546 MR Hisham Al Gurg FF Shop Draoing Daet 10-04-2023 Book - #2023-254Document30 pages0546 MR Hisham Al Gurg FF Shop Draoing Daet 10-04-2023 Book - #2023-2540988624395hamzaNo ratings yet

- H 5125610 3D251 R2 PDFDocument2 pagesH 5125610 3D251 R2 PDFomarNo ratings yet

- KingstonDocument1 pageKingstonBearNo ratings yet

- P.HM5L 20-M0300 LAY001lDocument1 pageP.HM5L 20-M0300 LAY001lĐứcNo ratings yet

- Bulandshahr PlanDocument1 pageBulandshahr PlanVishal shuklaNo ratings yet

- S 5 PDFDocument1 pageS 5 PDFlovely caturanNo ratings yet

- A-06 DOORS AND WINDOW SCHEDULE, STAIR DETAILSfDocument1 pageA-06 DOORS AND WINDOW SCHEDULE, STAIR DETAILSfX XNo ratings yet

- MSM - Cyclonewall Rev.1Document1 pageMSM - Cyclonewall Rev.1Kurt Ross RicamaraNo ratings yet

- Planta: 25635-320-C4K-0220-000140s1 - 0220 - 25635-320-G83-GCE-12548Document1 pagePlanta: 25635-320-C4K-0220-000140s1 - 0220 - 25635-320-G83-GCE-12548julio1051No ratings yet

- Nenmong Tranphucduy FinallyDocument1 pageNenmong Tranphucduy FinallyPhúc DuyNo ratings yet

- Etihad Rail Network: Longitudinal Section DDocument1 pageEtihad Rail Network: Longitudinal Section DDanielVadjkeVađinaNo ratings yet

- Str.08-Design of StairDocument1 pageStr.08-Design of StairKhoi DuongNo ratings yet

- SieyuanDocument4 pagesSieyuandanny maciasNo ratings yet

- Working Drawing PortfolioDocument15 pagesWorking Drawing PortfolioDimple PrasadNo ratings yet

- Angle Column, Post, Brace Column, Post, Brace Tee Shape Beam Column, Post, Brace H-ShapeDocument1 pageAngle Column, Post, Brace Column, Post, Brace Tee Shape Beam Column, Post, Brace H-ShapeAbid AyubNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80541Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80541Kumudu PereraNo ratings yet

- A Seccion / Section A-ADocument1 pageA Seccion / Section A-AomarNo ratings yet

- AS 8 Ø16 @300 AS 4 Ø20 @300: C of Roadway LDocument1 pageAS 8 Ø16 @300 AS 4 Ø20 @300: C of Roadway LEmmanuel CristobalNo ratings yet

- B2 Turret Cladding PlanDocument1 pageB2 Turret Cladding PlanCatalin HagiNo ratings yet

- Architecture DrawingDocument1 pageArchitecture DrawingJuicy LipsNo ratings yet

- Str.05-Design of Frame C-F3 To F5Document1 pageStr.05-Design of Frame C-F3 To F5Khoi DuongNo ratings yet

- Str.14-Design of Composite Structure-Design of Secondary BeamDocument1 pageStr.14-Design of Composite Structure-Design of Secondary BeamKhoi DuongNo ratings yet

- Str.13-Design of Composite Structure-Design of SlabDocument1 pageStr.13-Design of Composite Structure-Design of SlabKhoi DuongNo ratings yet

- SCHEDULE-TCTC (1222) .MPPDocument1 pageSCHEDULE-TCTC (1222) .MPPKhoi DuongNo ratings yet

- Annex ADocument178 pagesAnnex AKhoi DuongNo ratings yet

- Str.04-Design of Frame C-B2 To F2-2Document1 pageStr.04-Design of Frame C-B2 To F2-2Khoi DuongNo ratings yet

- RC1 Chapter 5Document40 pagesRC1 Chapter 5Khoi DuongNo ratings yet

- Str.02-Design of Post-Tensioned BeamDocument1 pageStr.02-Design of Post-Tensioned BeamKhoi DuongNo ratings yet

- Choose The Best Answer For Each Question and Explanation:: Assignment 3Document1 pageChoose The Best Answer For Each Question and Explanation:: Assignment 3Khoi DuongNo ratings yet

- Assignment 1: For Chapter 2Document2 pagesAssignment 1: For Chapter 2Khoi DuongNo ratings yet

- RC1 Chapter 6Document23 pagesRC1 Chapter 6Khoi DuongNo ratings yet

- Assignment 2: For Chapter 3Document1 pageAssignment 2: For Chapter 3Khoi DuongNo ratings yet

- RC1 - Chapter 3ADocument26 pagesRC1 - Chapter 3AKhoi DuongNo ratings yet

- Group 5 AssignmentDocument38 pagesGroup 5 AssignmentKhoi DuongNo ratings yet

- RC1 - Chapter 1Document27 pagesRC1 - Chapter 1Khoi DuongNo ratings yet

- RC1 - Chapter 4Document57 pagesRC1 - Chapter 4Khoi DuongNo ratings yet

- Structures 1 - Ci2091: Reinforced ConcreteDocument21 pagesStructures 1 - Ci2091: Reinforced ConcreteKhoi DuongNo ratings yet

- RC1 - Chapter 3BDocument30 pagesRC1 - Chapter 3BKhoi DuongNo ratings yet

- A Answer: Answer: Answer:: o A o A o ADocument1 pageA Answer: Answer: Answer:: o A o A o AKhoi DuongNo ratings yet

- Howework and Exercises in Chapters 2-7Document7 pagesHowework and Exercises in Chapters 2-7Khoi DuongNo ratings yet

- Deep Cement Mixing MethodDocument14 pagesDeep Cement Mixing MethodKhoi DuongNo ratings yet

- Manual Sharp CMS-R600XDocument64 pagesManual Sharp CMS-R600Xjca16100% (1)

- IWE SyllabusDocument4 pagesIWE Syllabusmdasifkhan2013No ratings yet

- BS0 1Document36 pagesBS0 1qaisarmehboob82No ratings yet

- Service Manual Dptv305 Dptv310 Dptv315 Dptv330 Dptv335 Dptv340 Dptv345 51mp392h-17 Chassis Mag01 7Document1,848 pagesService Manual Dptv305 Dptv310 Dptv315 Dptv330 Dptv335 Dptv340 Dptv345 51mp392h-17 Chassis Mag01 7brianatwoodNo ratings yet

- A Guide For Using PTM and The CIBANO 500 To Test Circuit Breakers in North AmericaDocument36 pagesA Guide For Using PTM and The CIBANO 500 To Test Circuit Breakers in North AmericaargaNo ratings yet

- PD Smart PDFDocument2 pagesPD Smart PDFAriel Leandro Toro MuñozNo ratings yet

- LM341/LM78MXX Series 3-Terminal Positive Voltage Regulators: Features DescriptionDocument18 pagesLM341/LM78MXX Series 3-Terminal Positive Voltage Regulators: Features Descriptiondasch7788No ratings yet

- Maintenance Policy 2Document80 pagesMaintenance Policy 2fernandoabel01No ratings yet

- ConveyersDocument10 pagesConveyersSai Srinivas BodapatiNo ratings yet

- Supply Chain IntegrationDocument9 pagesSupply Chain IntegrationJohn SujithNo ratings yet

- The Effect of Heavy Equipment Management On The PeDocument8 pagesThe Effect of Heavy Equipment Management On The PeGary NashNo ratings yet

- Java Card TechnologyDocument26 pagesJava Card Technologypr18sainiNo ratings yet

- DH Xvr4b16Document3 pagesDH Xvr4b16Jumar JumadiaoNo ratings yet

- Asptilsand DarshanDocument47 pagesAsptilsand DarshanMaju KingNo ratings yet

- Course Outline - 975676461building Material and Construction IVDocument2 pagesCourse Outline - 975676461building Material and Construction IVEndalkchew FentahunNo ratings yet

- Role of Project Management Consultancy in ConstructionDocument4 pagesRole of Project Management Consultancy in Constructionmnahmed1972No ratings yet

- Artist II PreampDocument1 pageArtist II PreampSteve MashiterNo ratings yet

- Assignment1 Microsoft WordDocument9 pagesAssignment1 Microsoft Wordmamadila1056No ratings yet

- Natron BlueTray 4000 V3.0 - User's Manual v1.4-07272020Document18 pagesNatron BlueTray 4000 V3.0 - User's Manual v1.4-07272020Ayan PownNo ratings yet

- Panduan TimeTrexDocument53 pagesPanduan TimeTrexAdi Wibowo Yudo Pranoto100% (1)

- ST Vid10523-St444Document65 pagesST Vid10523-St444Sistel HuanucoNo ratings yet

- Huawei Parameter Strategy: Security LevelDocument22 pagesHuawei Parameter Strategy: Security Leveloshwa_ishNo ratings yet

- Best Practices For Vsphere (ESX 4) Service Console Partitions - VM - ETCDocument14 pagesBest Practices For Vsphere (ESX 4) Service Console Partitions - VM - ETCKritchatach WanichanonNo ratings yet

- Tarek SayedDocument5 pagesTarek SayedطارقمجدىNo ratings yet

- Grounding Considerations For Large kVA Pad-Mount TransformersDocument4 pagesGrounding Considerations For Large kVA Pad-Mount TransformersRuwan DeegayuNo ratings yet

- 2Document5 pages2api-552490808100% (2)

- Process Models: Dr. Hameedur RahmanDocument15 pagesProcess Models: Dr. Hameedur RahmanOrhan rumiNo ratings yet

- Lab Exercise - Ethernet: ObjectiveDocument11 pagesLab Exercise - Ethernet: ObjectiveTakaskiNo ratings yet

- Debug Steps For LACPDocument8 pagesDebug Steps For LACPEsteban MNo ratings yet

- DC Power Potential Applications.Document24 pagesDC Power Potential Applications.siva anandNo ratings yet