Professional Documents

Culture Documents

Cable Epc Girder Reinfor

Uploaded by

shshank guptaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Epc Girder Reinfor

Uploaded by

shshank guptaCopyright:

Available Formats

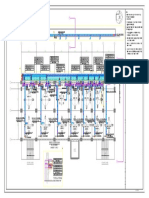

1 2 3 4 5 6 7 8

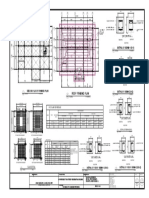

CL OF EXP. JOINT

1500

CL OF BRG. 1500 1500

CL OF GIRDER CL OF GIRDER

A A

220

220

5.25°

4

200

(X=19600

200

450

4.22°

3

450

3.13°

2 4

450

450

2.04°

1

(Y=0)

475

(X=0) 3

150 1500

2300

2300

17200 1000 500

450

B X= 19600 B

X= 150 X= 1500 4 Y= 1687 2

Y= 1825 4 4 Y= 1687

X= 17200

Y= 135.00 1 X= 18200

Y= 375.00 2 4

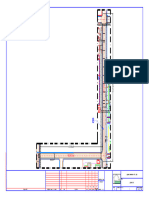

LONGITUDINAL ELEVATION X= 19600

240

3

450

X= 150 X= 1500 (SCALE - 1:50) Y= 615

Y=1375 3 3 Y= 1264 X= 18700

3 3

Y= 615.00 X= 19600

240

X= 150 X= 1500 2 Y= 375 1

Y= 925 2 2 Y= 843 2

X= 19600

240

1

475

X= 150 X= 1500 Y= 135

Y= 475 1 1 Y= 422 1

135

C OF SYMMETRY

400 400

CL OF BRG. 400 400

800

800

C -Z X-SECTION AT END X-SECTION AT CENTER C

(SCALE - 1:25)

(SCALE - 1:25)

1 2 1 2

X

TABLE:- IV

3 4 3 4 LEGEND:

STAGE OF STRESSING

+Z CABLE No. DAYS OF STRESSING INDICATES END OF CURVE

150 4&3 14 IN ELEVATION

PLAN

2&1 21

(SCALE - 1:50) INDICATES START OF CURVE

*AT 1st STAGE OF STRESSING CUBE IN ELEVATION

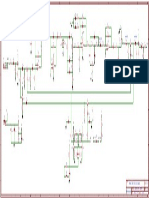

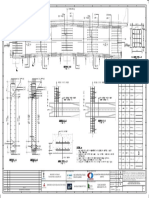

x 0 250 500 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250 3500 3750 4000 4250 4500 5000 STRENGTH SHALL NOT BE LESS THAN INDICATES END OF CABLE

Cab1 475 466.099476 457.1989529 439.3979058 430.4974 421.5974 412.766 404.0729 395.518 387.1013 378.8228 370.6825 362.6804 354.8165 347.0908 339.5033 332.0541 324.743 310.5355 35mpa OR, 14 DAYS , WHICHEVER IS LATER.

D Cab2 925 911.318408 897.6368159 870.2736318 856.592 842.9112 829.3298 815.9483 802.7669 789.7855 777.0042 764.4228 752.0415 739.8602 727.8789 716.0977 704.5165 693.1353 670.9729 D

Cab3 1375 1356.5534 1338.106796 1301.213592 1282.767 1264.321 1246.006 1227.953 1210.161 1192.632 1175.365 1158.359 1141.616 1125.135 1108.915 1092.958 1077.263 1061.83 1031.75 TABLE:- II

Cab4 1825 1802.01422 1779.028436 1733.056872 1710.071 1687.087 1664.26 1641.75 1619.558 1597.684 1576.127 1554.888 1533.966 1513.361 1493.074 1473.105 1453.453 1434.118 1396.402 CABLE LENGTH OF ELONGATION NUMBER OF STRANDS TO JACKING EMRGENCE STAGE OF JACKING ANCHORAGE

No. CABLE (M) (MM) STRESSED IN EACH CABLE FORCE (kN) ANGLE PRESTRESSING END TYPE

x 5250 5500 5750 6000 6250 6500 6750 7000 7250 7500 7750 8000 8250 8500 8750 9000 9250 9500 10000

1 39.209 140 18 3587.64 2.089 1st BOTH END 19K15

Cab1 303.6391 296.8808 290.2608 283.779 277.4354 271.23 265.1628 259.2338 253.443 247.7904 242.276 236.8999 231.6619 226.5622 221.6006 216.7773 212.0921 207.5452 198.866

Cab2 660.1918 649.6107 639.2296 629.0485 619.0675 609.2865 599.7055 590.3245 581.1435 572.1626 563.3817 554.8008 546.42 538.2391 530.2583 522.4775 514.8968 507.516 493.3546 2 39.222 140 18 3587.64 3.132 1st BOTH END 19K15

Cab3 1017.103 1002.718 988.5946 974.7336 961.1346 947.7977 934.7227 921.9098 909.359 897.0701 885.0433 873.2785 861.7757 850.535 839.5563 828.8396 818.3849 808.1923 788.593 39.240 3587.64 4.220 1st BOTH END 19K15

3 140 18

Cab4 1378.02 1359.955 1342.208 1324.778 1307.666 1290.871 1274.394 1258.234 1242.392 1226.868 1211.66 1196.77 1182.198 1167.943 1154.006 1140.386 1127.084 1114.099 1089.082

4 39.264 139 18 3587.64 5.253 1st BOTH END 19K15

x 10250 10500 10750 11000 11250 11500 11750 12000 12250 12500 12750 13000 13250 13500 13750 14000 14250 14500 14750 15000

Cab1 194.7337 190.7396 186.8837 183.166 179.5865 176.1452 172.8422 169.6773 166.6507 163.7622 161.012 158.3999 155.9261 153.5905 151.3931 149.3339 147.4129 145.6301 143.9855 142.4791 (a) LENGTHS AS INDICATED ABOVE ARE EXCLUSIVE 600mm LENGTH OF STRAND IN GRIP LENGTH.

Cab2 486.5739 479.9933 473.6126 467.432 461.4515 455.6709 450.0904 444.7098 439.5294 434.5489 429.7684 425.188 420.8076 416.6272 412.6469 408.8666 405.2862 401.906 398.7257 395.7455 BEYOND THE ANCHORAGES. ADEQUATE CUSHION IN CUTTING LENGTH IS TO BE KEPT.

E IT SHOULD BE SUITABLE AS PER GRIP LENGTH SUGGESTED BY THE SYSTEM PROVIDER. E

Cab3 779.1865 770.0419 761.1594 752.5389 744.1804 736.084 728.2496 720.6772 713.3668 706.3185 699.5322 693.0079 686.7456 680.7454 675.0071 669.531 664.3168 659.3646 654.6745 650.2464 (b) THE EXTENSIONS ARE BASED ON THE FULL CABLE LENGTH BETWEEN JACK POINTS. ANCHORAGE

Cab4 1077.049 1065.334 1053.937 1042.857 1032.094 1021.649 1011.522 1001.712 992.2192 983.0441 974.1865 965.6463 957.4237 949.5185 941.9309 934.6607 927.708 921.0727 914.755 908.7547 SLIP OF 6mm IS INCLUDED IN THE GIVEN EXTENSIONS. EXTENSION OF 7.15mm PER METER LENGTH

FOR ADDITIONAL GRIP LENGTH ABOVE 600mm SHALL BE CONSIDERED IN THE GIVEN EXTENSIONS.

x 15250 15500 15750 16000 16250 16500 16750 17000 17250 17500 17750 18000 18250 18500 18750 19000 19250 19600

Cab1 141.1109 139.881 138.7892 137.8356 137.0203 136.3432 135.8042 135.4035 135.141 135.0151 135 135 135 135 135 135 135 135

Cab2 392.9652 390.3851 388.0049 385.8247 383.8446 382.0645 380.4844 379.1044 377.9243 376.9443 376.1644 375.5844 375.2044 375.0221 375 375 375 375

Cab3 646.0804 642.1763 638.5343 635.1543 632.0364 629.1804 626.5865 624.2546 622.1847 620.3769 618.8311 617.5473 616.5255 615.7658 615.2681 615.0292 615 615

Cab4 903.072 897.7067 892.6589 887.9285 883.5157 879.4203 875.6424 872.182 869.0391 866.2137 863.7057 861.5153 859.6423 858.0868 856.8488 855.9282 855.3252 855.0396 SPECIAL NOTES FOR PRESTRESSING

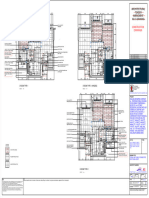

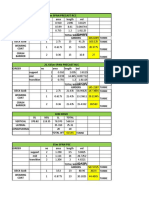

NOTES:- SEQUENCE OF STRESSING OF CABLE

(A). FOR A PROVEN AND PRESTRESSING SYSTEM THE REQUIRED EXTANSIONS

SHOULD NORMALLY BE ACHIEVED AT THE SPECIFIED FORCES AT STRESSING ENDS.

1. ALL DIMENSIONS ARE IN MILLIMETERS. HOWEVER, IN CASE THE REQUIRED EXTENSIONS ARE NOT ACHIEVED AT THE

7. LENGTH OF PRESTRESSING CABLES GIVEN IN TABLE -II EXCLUSIVE AN EXTRA LENGTH CABLE NO 4 3 SHALL BE STRESSED FIRST & THEN CABLE NO. 2 & 1 SHALL SPECIFIED JACKING FORCES THEN THE FOLLOWING MEASURES MAY BE TAKEN.

2. THE EXTENSIONS INDICATED ARE FOR PORTION OF CABLE LYING

BETWEEN MID SPAN AND END FACES OF PRECAST GIRDER ONLY. OF 1000 MM AT BOTH ENDS (TO BE CONFIRMED BY PRESTRESSING JACK SUPPLIER) AT BE STRESSED . I). STRESSING SHOULD BE CONTINUED (WHERE POSSIBLE) TILL THE REQUIRED

EXTENSIONS ARE OBTAINED SUBJECT TO THAT THE JACKING FORCES ARE NOT

F ADDITIONAL EXTENSION FOR PORTION LYING BETWEEN AND FACE & EACH END, REQUIRED FOR ATTACHING THE CABLE TO THE JACK. 15. MAXIMUM ELONGATION OF CABLE AND/OR MAXIMUM JACKING FORCE, IN ANY CASE, EXCEEDING 76.5% OF THE ULTIMATE TENSILE FORCE VALUES OF TENDONS. F

GRIPPING POINT OF JACK IS TO BE ADDED.

8. ABSCISSA ( DISTANCE 'X' ) OF CABLE GIVEN IN THE DRAWING ARE EVALUATED WITH SHOULD NOT EXCEED1.05 TIMES THE CORRESPONDING CALCULATED VALUES GIVEN II). SHOULD THE REQUIRED EXTENSIONS ARE OBTAINED AT JACKING END FORCES

TABLE:- III (CONSTRUCTION SEQUENCE) 3. THE PRESTRESSING STEEL AND ACCESSORIES SHALL BE SUBJECTED

REFERENCE TO CENTER OF THE GIRDER. ORDINATES ( DISTANCE 'Y' ) ARE WITH IN TABLE -II. LOWER THAN THE SPECIFIED VALUES THAN THE STRESSING SHOULD BE CONTINUED

TO ANY ACCEPTANCE TEST PROIR TO THEIR ACTUAL USE OF THE WORKS. REFERENCE TO SOFIT OF THE GIRDER. TILL THE SPECIFIED STRESSING-END FORCES ARE REACHED, PROVIDED THE

(GUIDANCE MAY BE TAKEN FROM BS:4447). ONLY MULTI STRAND JACKS 16. ELONGATION OF CABLE SHALL BE RECHECKED AFTER 24 HOURS OF LOCKING

SR. NO. ITEM DAY NO 9. STRESSING SHALL BE DONS FROM BOTH ENDS SIMULTANEOUSLY USING MULTISTRAND ADDITIONAL EXTENSIONS ARE NOT MORE THAN ABOUT 5% OF THE SPECIFIED

OF WEDGES TO OBSERVE SLOW SLIPPAGE IF ANY AND THE MATTER SHALL BE EXTENSIONS.

SHALL BE USED FOR TENSIONING OF CABLE, DIRECT AND INDIRECT JACKS CAPABLE OF STRESSING TO ATLEAST 10% HIGHER THAN THE REQUIRED JACKING

FORCE MEASURES DEVICE (E.E. PRESSURE GAUGE) TO BE ATTACHED REPORTED TO ENGINEER-IN-CHARGE.

1 COMPLETION OF CASTING OF PSC GIRDER d0 FORCE SHALL BE USED FOR STRESSING OF CABLE. III). TENDONS SPECIFIED THESE PROVISIONS SHOULD BE LOCKED (I.E. ANCHORED).

IN CONSULTATION WITH SYSTEM MANUFACTURER. 17. EXREA LENGTH OF STRANDS PROJECTING BEYOND THE ANCHORAGE SHALL NOT

10. INITIAL SLACKNESS IN CABLES SHALL BE REMOVED BY APPLYING SMALL TENSION. IV). IF THE STRESSING END FORCES IN TENDONS ARE STILL LOWER THAN THE

PRESTRESSING OF TENDON FOR STAGE-1 4. TYPE OF STRANDS-UNCOATED STRESS RELIEVED LOW RELAXATION THE INITIAL TENSION REQUIRED TO REMOVE SLACKNESS SHALL BE TAKEN AS THE BE CUT JUST AFTER THE STRESSING, PRIOR TO THE APPROVAL OF PRESTRESSING SPECIFIED VALUES DESPITE THE 5% INCREASE IN THE SPECIFIED EXTENSIONS,

2 d0+14 7-PLY STRANDS CONFORMING TO CLASS 2 OF IS 14266:1925 STARTING POINT FOR MEASURING ELONGATION AND CORRECTION SHALL BE APPLIED RESULTS. THESE SHALL BE CUT ONLY WHEN INSTRUCTIONS FOR GROUTING ARE THEN THE PARTICULARS OF SUCH TENDONS SHOULD BE REPORTED TO THE

(SEQUENCE CABLE NO. 3&4) WITH U.T.S. OF 261KN. DESIGNER FOR FURTHER INSTRUCTIONS ( 'LOCKING' BUT NOT 'GROUTING' THESE

AS CLAUSE 12.2.1.3 IS:1343:1980. ISSUED.

TENDONS TILL RECEIPT OF INSTRUCTIONS.

PRESTRESSING OF TENDON FOR STAGE-1 5. SHEATHING SHALL BE CORRUGATED HDPE TYPE AND CONFIRM TO 11. ELONGATION GIVEN IN TABLE-II ARE WITHOUT SLIP TO BE MEASURED / ACHIEVED AT 18. GROUTING OF CABLES SHALL BE CARRIED OUT AS PER GUIDELINES IN GIVEN IN

d0+21

3 (SEQUENCE CABLE NO. 1&2) C.L. 13.4.3 OF IRC 112.2011. THE TIME OF STRESSING (BEFORE LOCKING ON ANCHORAGE). LOSS UPTO 6 MM SLIP CL:13.6 OF IRC :112-2011. V). THE SPECIFIED ELONGATION IN EACH TENDON SHALL BE MODIFIED AT THE SITE IN

OF ANCHORAGE IS NOT TO BE COMPENSATED DURING PRESTRESSING. CASE THE ES VALUE OF THE TENDON STEEL ACTUALLY USE AT SITE IS FOUND

6. PERAMETERS ASSUMED FOR DESIGN: 19. ANCHORAGE RECESSES TO BE SEALED WITH PREPACKED NON SHRINK EPOXY MORTAR. TO BE DIFFERENT FROM THAT ASSUMED IN DESIGN CALCULATION OF THE

COMPLETION OF CASTING OF DECK SLAB d0+28 5

12. ELONGATION INDICATED IN TABLE-II GIVEN FOR HALF CABLE.

4 a) MODULUS OF ELASTICITY OF STEEL ---------------1.95x10 MPa SPECIFIED ELONGATION. (THIS IS DONE BY MULTIPLYING THE SPECIFIED)

AND DIAPHRAGH 20. THE WORK OF THE PRESTRESSING SHALL BE CARRIED OUT BY FRESSINET SYSTEM OR ELONGATION: BY THE RATION OF ES ASSUMED IN DESIGN TO ES ACTUAL AT SITE)

G b) CROSS-SECTIONAL AREA OF STRANDS---------- 140.0mm 2 13. IF ACTUAL VALUE OF X-SECTIONAL AREA (A') AND/OR MODULES OF ELASTICITY (E')

ANY OTHER RECOGNIZED SYSTEM AFTER CARRYING OUT NECESSARY MODIFICATION G

OF HIGH TENSILE STRANDS ARE DIFFERENT FROM ASSUMED VALUES, THEORETICAL

CASTING OF WEARING COAT, KERB. HAND d0+42 c) WOBBLE COEFFICIENT OF SHEATHING(K)------- 0.002 PER METER. IN THE DRAWING WITH THE APPROVAL OF ENGINEER-IN-CHARGE. ALL PRESTRESSING (B). ALL TENDONS WHICH SATISFY THE PROVISIONS OF ITEMS (A) (EXCEPT IV) ABOVE

5 ELONGATION SHALL BE MODIFIED AS BELOW:

AND GROUTING WORK BE UNDERTAKEN BY TRAINED PERSONNEL ONLY. A

RAIL AND CRASH BARRIER ..... etc. SHOULD BE GROUTED IMMEDIATELY, TAKING CARE THAT THE TENDONS NOT YET

d) FRICTION COEFFICIENT (µ ) ----------------------- 0.17 PER RADIAN. Δ = Δ x A x E /(A' x E') REPRESENTATIVE OF THE SUPPLIER OF THE PRESTRESSING SYSTEM SHALL BE PRESENT STRESSED ARE NOT ACCIDENTALLY BLOCKED DUE TO GROUT LEAK.

e) SLIP OF EACH END --------------------------------------- 6 MM. WHERE Δ IS THEORETICAL ELONGATION MENSIONED IN TABLE-I, A&E ARE VALUES DURING ALL TENSIONING AND GROUTING OPERATIONS AND SHALL ENSURE, MONITOR

(C). THE PRESTRESSING JACKS AND THEIR GAUGES SHOULD BE REGULARLY CALIBRATED

ASSUMED IN DESIGN WHILE A' & E' ARE ACTUAL VALUES OF THE STEEL USED. AND CERTIFY THEIR CORRECTNESS.

f) ULTIMATE TENSILE FORCE PER STRAND -------261KN. FOR CORRECTIONS AND REMOVAL OF ZERO-ERRORS.

14. TO GET THE REQUIRED ELONGATION COMPENSATED FOR INITIAL TENSIONING THE 21. STRANDS SHALL NOT BE CUT WITH GAS FLAME.

g) JACKING FORCE OF EACH END OF CABLE SHALL BE AS PER (D). 6MM SLIP AT ANCHORAGE AT STRESSING END HAS BEEN CONSIDERED IN DESIGN.

CORRECTION SHALL BE ARRIVED AT BY PLOTTING THE GRAPH WITH GAUGE READING 22. WHEREVER NECESSARY, REINFORCEMENT BARS MAY BE BENT OR SHIFTED LOCALLY TO

TABLE -II.

AS ABSCISSA AND ELONGATION AS ORDINATE. AVOID CLASHING WITH PRESTRESSING TENDONS AND ANCHORAGE.

h) OUTER DIA OF SHEATHING -------------------------- 110mm.

CLIENT: EPC CONTRACTOR: DESIGN CONSULTANT: PROJECT:

APPROVED BY: AA REHABILITATION AND UPGRADATION OF GANGOTRI - DHARASU

CIVILMANTRA INFRACON (NH-108) TO 2- LANE WITH PAVED SHOULDERS FROM KM. 101.06 TO

ABCI INFRASTRUCTURES KM 110.860 (DESIGN CHAINAGE FROM KM 87.730 TO KM 97.400) ON

BORDER ROADS ORGANIZATION PRIVATE LIMITED PRIVATE LIMITED CHECKED BY: SK

EPC MODE UNDER IMPROVEMENT TO NH CONNECTIVITY TO

CHARDHAM IN STATE OF UTTRAKHAND. H

H DESIGNED BY: AS TITLE:

CABLING DETAIL FOR PSC GIRDER SUPER

AUTHORITY ENGINEER: SAFETY CONSULTANT. PROOF CONSULTANT. STRUCTURE OF SPAN LENGTH 38.4M (SHEET 01

DRAWN BY: SS OF 02) AT ABUTMENT LOCATION

MAY 20 D0 NK M.A SOLUTIONS PVT. LTD. G-ENG ADVISORY SERVICES SCALE: DATE:

DRG NO.: REV.

PVT.LTD. CIPL/D1025/STR/DWG /CABLE/ 001 D0

DATE REV DESCRIPTION OF REVISIONS BY AS SHOWN MAY 2020

1 2 3 4 5 6 7 8

You might also like

- Flats Floor PlansDocument1 pageFlats Floor Planslenganji simwandaNo ratings yet

- Bo Cuc Ban Ve Tham KhaoDocument1 pageBo Cuc Ban Ve Tham Khao21149257No ratings yet

- Etihad Rail Network: Longitudinal Section DDocument1 pageEtihad Rail Network: Longitudinal Section DDanielVadjkeVađinaNo ratings yet

- Utility Piping Layout First Floor Sheet-1 of 2Document1 pageUtility Piping Layout First Floor Sheet-1 of 2Sameer ShindeNo ratings yet

- 20PE90 PLAN 1-MidasDocument8 pages20PE90 PLAN 1-MidasGrant LawagueyNo ratings yet

- Elevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageElevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- Etihad Rail Network: Longitudinal Section DDocument1 pageEtihad Rail Network: Longitudinal Section DDanielVadjkeVađinaNo ratings yet

- CR 1Document1 pageCR 1Armand Mikhail TempladoNo ratings yet

- 1310 GEIC TEN AR SS1 100 - Substation AR SS1 100Document1 page1310 GEIC TEN AR SS1 100 - Substation AR SS1 100Mohd AkkiNo ratings yet

- B00802 0036 Layout1Document1 pageB00802 0036 Layout1lucas schneiderNo ratings yet

- VUP - AT CH.217+160 (Recovered 1) (Recovered)Document2 pagesVUP - AT CH.217+160 (Recovered 1) (Recovered)Aerotide InfrastructuresNo ratings yet

- Commercial Building Drainage LayoutDocument1 pageCommercial Building Drainage LayoutDenzelNo ratings yet

- Data Extraction and Multileaders Sample-Layout2Document1 pageData Extraction and Multileaders Sample-Layout2Sunem Rios YañacNo ratings yet

- Pyramids Sections-Sec A-ADocument1 pagePyramids Sections-Sec A-AMAHMOUD HISHAMNo ratings yet

- HB-D1817-AR-131 - Typical Unit Plan of 3room Type With Tiling LayoutDocument1 pageHB-D1817-AR-131 - Typical Unit Plan of 3room Type With Tiling Layoutme kwc36No ratings yet

- Find key details across complex document sectionsDocument1 pageFind key details across complex document sectionsJem CapistranoNo ratings yet

- Existing building floor plan dimensionsDocument1 pageExisting building floor plan dimensionsAlvaroSartoNo ratings yet

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliNo ratings yet

- Pci202h - Pci Pre 2 - Mp3000Document1 pagePci202h - Pci Pre 2 - Mp3000AdeniltonNo ratings yet

- Steel railing and wall details for building projectDocument1 pageSteel railing and wall details for building projectJem CapistranoNo ratings yet

- Str.09-Foundation Layout-Bored Pile Reinforement of M3Document1 pageStr.09-Foundation Layout-Bored Pile Reinforement of M3Khoi DuongNo ratings yet

- LD PC CH.219+483Document4 pagesLD PC CH.219+483SJPL NH965No ratings yet

- P2 Reaction PileDocument1 pageP2 Reaction Pilebejay bermudezNo ratings yet

- Section A-A: Issued For ConstructionDocument1 pageSection A-A: Issued For ConstructionjafarNo ratings yet

- KC Me Eer 031 Rev. 1Document9 pagesKC Me Eer 031 Rev. 1danielNo ratings yet

- Str.04-Design of Frame C-B2 To F2-2Document1 pageStr.04-Design of Frame C-B2 To F2-2Khoi DuongNo ratings yet

- Drawing For Lubrication MillDocument2 pagesDrawing For Lubrication MillDeepakNo ratings yet

- Note:: Scaleplate DescriptionDocument1 pageNote:: Scaleplate DescriptionAlbet MulyonoNo ratings yet

- Road 8M: 500 MT SolarDocument1 pageRoad 8M: 500 MT SolarryosastradipuraNo ratings yet

- 1700 43D1 0010 - A PDFDocument1 page1700 43D1 0010 - A PDFTonee Rose Reyes AdvientoNo ratings yet

- Fender Rumble 100 V3 TDA8950-88534Document7 pagesFender Rumble 100 V3 TDA8950-88534Claudio Ariel Vera trussy100% (1)

- Rumble 200 V3 Schematics-DiagramsDocument4 pagesRumble 200 V3 Schematics-DiagramsOrlandd Sanchezz100% (1)

- Fender Rumble 40 v3 SCHDocument7 pagesFender Rumble 40 v3 SCHCarlos ZaninNo ratings yet

- 220 M6 0330 00006Document1 page220 M6 0330 00006jhonNo ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- Commercial Building Floor PlanDocument1 pageCommercial Building Floor PlanParisGeronimoNo ratings yet

- Schematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Document1 pageSchematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Marcus FeilNo ratings yet

- Festival Mall - Asbuilt PlanDocument1 pageFestival Mall - Asbuilt PlanArmando RodriguezNo ratings yet

- 1251 A 301 Sections A 3011410933459381Document1 page1251 A 301 Sections A 3011410933459381Fadi AlatrashNo ratings yet

- 13 211002 4800000206 Nap Avc SHD 127180 - DRG - 02Document1 page13 211002 4800000206 Nap Avc SHD 127180 - DRG - 02mir sadat aliNo ratings yet

- View Looking North On Gridline CDocument1 pageView Looking North On Gridline CVinay SharmaNo ratings yet

- Roof Framing Plan: Detail of Beam-1 (B-1)Document1 pageRoof Framing Plan: Detail of Beam-1 (B-1)Eury AlzagaNo ratings yet

- Archtctrl P3 - UpdtdDocument1 pageArchtctrl P3 - Updtdchedita obiasNo ratings yet

- 1 2 A B C E D: H Bo EmtbDocument2 pages1 2 A B C E D: H Bo EmtbHoward RoarkNo ratings yet

- Detail A Option 2 Option 1: 5000 12cm 12cmDocument1 pageDetail A Option 2 Option 1: 5000 12cm 12cmCasmir TayagNo ratings yet

- 5 Volt 10aDocument2 pages5 Volt 10aamitNo ratings yet

- Redes Acueducto Plancha: Rio BogotaDocument1 pageRedes Acueducto Plancha: Rio BogotaJOSE RODRIGO TORRES CORREANo ratings yet

- 150 A Introducción: Standard TuningDocument2 pages150 A Introducción: Standard TuningFelipe JuarezNo ratings yet

- Peavey 6505PLUS 112 SchematicDocument9 pagesPeavey 6505PLUS 112 SchematicR .GNo ratings yet

- How to configure a complex electronic circuitDocument7 pagesHow to configure a complex electronic circuitSanjeev smith100% (1)

- SampleDocument1 pageSamplebetha rufinNo ratings yet

- Schedule of loads for unit 1 & 2Document1 pageSchedule of loads for unit 1 & 2Lhewiz BrionesNo ratings yet

- Indus Hospital Floor Plans - 08.06.2020Document13 pagesIndus Hospital Floor Plans - 08.06.2020Ritika AnandNo ratings yet

- Substation design and build documentDocument2 pagesSubstation design and build documentKs MuraliNo ratings yet

- P4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011Document1 pageP4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011ManojNo ratings yet

- 3 2 N Pdms X (Left) Navis Pdms X (Right) Navis E: Pt. Mcdermott IndonesiaDocument1 page3 2 N Pdms X (Left) Navis Pdms X (Right) Navis E: Pt. Mcdermott IndonesiaAmri RsylnaNo ratings yet

- Second Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayDocument1 pageSecond Floor Plan (Main Building) : Stair Lobby Connecting Walk/PathwayCarl Justin AzucenaNo ratings yet

- 10 723711 4800000299 PCC Ict DRG 102403 - DWG - 05 PS06Document1 page10 723711 4800000299 PCC Ict DRG 102403 - DWG - 05 PS06Zeeshan YasinNo ratings yet

- Building design plan detailsDocument1 pageBuilding design plan detailsraymond erasmoNo ratings yet

- BBSDocument1 pageBBSshshank guptaNo ratings yet

- RSS Wall ConstructionDocument17 pagesRSS Wall Constructionshshank gupta100% (1)

- CH-127+550 Longitudinal GirderDocument1 pageCH-127+550 Longitudinal Girdershshank guptaNo ratings yet

- Soil Mechanics and Foundation by B.C. Punmia PDFDocument990 pagesSoil Mechanics and Foundation by B.C. Punmia PDFsawanNo ratings yet

- Reinforcement A2 PDFDocument1 pageReinforcement A2 PDFshshank guptaNo ratings yet

- General Arrangement Drawing PDFDocument1 pageGeneral Arrangement Drawing PDFshshank guptaNo ratings yet

- CH-127+550 Longitudinal GirderDocument1 pageCH-127+550 Longitudinal Girdershshank guptaNo ratings yet

- CH-127+550 Longitudinal GirderDocument1 pageCH-127+550 Longitudinal Girdershshank guptaNo ratings yet

- Gad of MNB Ch. 127+550Document6 pagesGad of MNB Ch. 127+550shshank guptaNo ratings yet

- Cable Epc Girder Reinfor-2Document1 pageCable Epc Girder Reinfor-2shshank guptaNo ratings yet

- Cipld-1036-Rob-Str-P1-P4-Dwg-401-404 R3 PDFDocument5 pagesCipld-1036-Rob-Str-P1-P4-Dwg-401-404 R3 PDFshshank guptaNo ratings yet

- CH-127+550 End CROSS GIRDER SPAN 40.8MDocument1 pageCH-127+550 End CROSS GIRDER SPAN 40.8Mshshank guptaNo ratings yet

- Drainage spout & crash barrier detail for Gangotri-Dharasu road projectDocument1 pageDrainage spout & crash barrier detail for Gangotri-Dharasu road projectshshank guptaNo ratings yet

- CH-127+550 Longitudinal GirderDocument1 pageCH-127+550 Longitudinal Girdershshank guptaNo ratings yet

- Cover Page GangotariiDocument1 pageCover Page Gangotariishshank guptaNo ratings yet

- Irc 2011 112Document296 pagesIrc 2011 112ErSoravNo ratings yet

- Pre Camber PDFDocument5 pagesPre Camber PDFshshank guptaNo ratings yet

- Subscribe to Our YouTube Channel for Civil Engineering VideosDocument1 pageSubscribe to Our YouTube Channel for Civil Engineering Videosshshank guptaNo ratings yet

- Girder WTDocument6 pagesGirder WTshshank guptaNo ratings yet

- Steel Table SectionsDocument24 pagesSteel Table Sectionsshshank guptaNo ratings yet

- Checked & Updated The DesignDocument1 pageChecked & Updated The Designshshank guptaNo ratings yet

- Checked & Updated The DesignDocument1 pageChecked & Updated The Designshshank guptaNo ratings yet

- Box Culvert-Ch-329+495Document1 pageBox Culvert-Ch-329+495shshank guptaNo ratings yet

- Hydrological calculations for minor bridgeDocument30 pagesHydrological calculations for minor bridgeshshank guptaNo ratings yet

- WW Tcs SchduleDocument9 pagesWW Tcs Schduleshshank guptaNo ratings yet

- Checked & Updated The DesignDocument1 pageChecked & Updated The Designshshank guptaNo ratings yet

- Hydrological calculations for minor bridgeDocument30 pagesHydrological calculations for minor bridgeshshank guptaNo ratings yet

- Question Answer of ComplexometryDocument19 pagesQuestion Answer of ComplexometryNahzim RahmatNo ratings yet

- (STATISTICS & PROBABILITY) Unit II - Lesson 1 Understanding The Normal Curve DistributionDocument14 pages(STATISTICS & PROBABILITY) Unit II - Lesson 1 Understanding The Normal Curve DistributionVany SpadesNo ratings yet

- Boxford Lathe Manual Download 2Document8 pagesBoxford Lathe Manual Download 2Hans RijndersNo ratings yet

- Time Series (Sudhanshu Singh)Document18 pagesTime Series (Sudhanshu Singh)SUDHANSHU SINGHNo ratings yet

- SmartAir EHVAC System Rev10 Jun2019 2Document40 pagesSmartAir EHVAC System Rev10 Jun2019 2Andy degolNo ratings yet

- GPIB Communication and Hardware SpecificationsDocument5 pagesGPIB Communication and Hardware Specificationsshofika SelvarajNo ratings yet

- MRI ScriptDocument1 pageMRI ScriptPeter BolocelliNo ratings yet

- PVF Pvaf CVF Cvaf Tables For Financial ManagementDocument11 pagesPVF Pvaf CVF Cvaf Tables For Financial Managementvikas25% (4)

- Altivar 71 ManualDocument286 pagesAltivar 71 ManualShantanu Deshpande100% (1)

- Micron NAND Flash MLC 16-32-64 - 128GbDocument115 pagesMicron NAND Flash MLC 16-32-64 - 128GbSatya NarayanaNo ratings yet

- Short Questions... DbmsDocument10 pagesShort Questions... DbmsMuhammad Jamal ShahNo ratings yet

- Bios Cmos MemoryDocument23 pagesBios Cmos MemoryEmman BalicoNo ratings yet

- Wearable Textile Antennas Examining The Effect of Bending On Their PerformanceDocument6 pagesWearable Textile Antennas Examining The Effect of Bending On Their PerformanceKhaleda AliNo ratings yet

- Fiitjee Class 5 Sample PaperDocument18 pagesFiitjee Class 5 Sample PaperPremta Kumari100% (1)

- Oxford Science 8Document258 pagesOxford Science 8Emily NuttingNo ratings yet

- Energy Balance in A Solid Oxide Fuel CellDocument8 pagesEnergy Balance in A Solid Oxide Fuel CellAshik AhmedNo ratings yet

- Electrostatic Fields: ! R R R ! R Separation Distance (M) Between Q R /RDocument72 pagesElectrostatic Fields: ! R R R ! R Separation Distance (M) Between Q R /RRia Maria GeorgeNo ratings yet

- ASTM D70 DensityDocument4 pagesASTM D70 DensityPedro AlvelaisNo ratings yet

- Aerodynamics and Aircraft Design SoftwareDocument13 pagesAerodynamics and Aircraft Design SoftwareAnonymous 1rLNlqUNo ratings yet

- DIAGPROG4: PROFESSIONAL DIAGNOSTIC TOOL FOR AUTOMOTIVE REPAIR AND MAINTENANCEDocument8 pagesDIAGPROG4: PROFESSIONAL DIAGNOSTIC TOOL FOR AUTOMOTIVE REPAIR AND MAINTENANCENeile CasaliNo ratings yet

- Checklist Design ReviewDocument2 pagesChecklist Design Reviewmuhannad11061975100% (1)

- Financial DistressDocument9 pagesFinancial Distressvierya_ableNo ratings yet

- Brochure Allweiler AllfuelDocument12 pagesBrochure Allweiler AllfuelbalramkinageNo ratings yet

- Essential Safety GuideDocument112 pagesEssential Safety GuideKVD100% (1)

- Properties of Solids and LiquidsDocument18 pagesProperties of Solids and LiquidsGen PriestleyNo ratings yet

- Analysis of tapping process in three types of cast iron focusing on torque, axial force and tool wearDocument8 pagesAnalysis of tapping process in three types of cast iron focusing on torque, axial force and tool wearFlorin MilasNo ratings yet

- SE Fly SC Plus E 150dpiDocument2 pagesSE Fly SC Plus E 150dpitun tunNo ratings yet

- Transformer Winding Resistance and Equivalent CircuitDocument10 pagesTransformer Winding Resistance and Equivalent CircuitM7MD ACADEMIANo ratings yet

- Ryebrassware 0505Document40 pagesRyebrassware 0505api-36492444No ratings yet

- Tachyhydrite Camg CL 12H O: Crystal Data: Physical PropertiesDocument1 pageTachyhydrite Camg CL 12H O: Crystal Data: Physical Propertieskittipun khamprasoetNo ratings yet