Professional Documents

Culture Documents

Application Variation - RFI Response 2013 Stack Emission Monitoring Report 2013 Electrolysis A5

Uploaded by

dugongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Variation - RFI Response 2013 Stack Emission Monitoring Report 2013 Electrolysis A5

Uploaded by

dugongCopyright:

Available Formats

STACK EMISSIONS MONITORING REPORT

Unit 5 Crown Industrial Estate

Kenwood Road

Stockport

SK5 6PH

Tel: 0161 443 0980

Fax: 0161 443 0989

Your contact at SOCOTEC LTD

Mark Woodruff

Business Manager - North

Tel: 0161 443 0982

Fax: 0161 443 0989

Email: mark.woodruff@socotec.com

Operator & Address:

Less Common Metals Ltd

Unit 2 Vauxhall Supply Park

North Road

Ellesmere Port

Cheshire

CH65 1BL

Permit Reference:

EPR Permit: EPR/RP3233CZ/V002

Release Point:

Electrolysis

Sampling Date(s):

27th November 2020

SOCOTEC Job Number: LNO 16148

Report Date: 14th January 2021

Version: 1

Report By: Mark Derbyshire

MCERTS Number: MM 02 022

MCERTS Level: MCERTS Level 2 - Team Leader

Technical Endorsements: 1, 2, 3 & 4

Report Approved By: Jonathon Orley

MCERTS Number: MM 08 983

Business Title: MCERTS Level 2 - Team Leader

Technical Endorsements: 1, 2, 3 & 4

Signature:

SOCOTEC UK Reporting Template v7 Page 1 of 26

SOCOTEC UK LTD

www.socotec.co.uk

CONTENTS

EXECUTIVE SUMMARY

Stack Emissions Monitoring Objectives

- Plant

- Operator

- Stack Emissions Monitoring Test House

Emissions Summary

Monitoring Times

Process Details

Monitoring Methods

Analytical Methods

- Sampling Methods with Subsequent Analysis

- On-Site Testing

Sampling Location

- Sampling Plane Validation Criteria

- Duct Characteristics

- Sampling Lines & Sample Points

- Sampling Platform

- Sampling Location / Platform Improvement Recommendations

Sampling and Analytical Method Deviations

APPENDICES

APPENDIX 1 - Monitoring Schedule, Calibration Checklist & Monitoring Team

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

APPENDIX 3 - Measurement Uncertainty Budget Calculations

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 2 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

MONITORING OBJECTIVES

Less Common Metals Ltd operates a vacuum furnaces process at Ellesmere Port which is subject to EPR Permit EPR/RP3233CZ/V002, under the

Environmental Permitting Regulations 2010.

SOCOTEC LTD were commissioned by Less Common Metals Ltd to carry out stack emissions monitoring to determine the release of prescribed

pollutants from the following Plant under normal operating conditions.

The results of these tests shall be used to demonstrate compliance with a set of emission limit values for prescribed pollutants as specified in the

Plant's EPR Permit, EPR/RP3233CZ/V002.

Plant

Electrolysis

Operator

Less Common Metals Ltd

Unit 2 Vauxhall Supply Park

North Road

Ellesmere Port

Cheshire

CH65 1BL

Stack Emissions Monitoring Test House

SOCOTEC - Stockport Laboratory

Unit 5 Crown Industrial Estate

Kenwood Road

Stockport

SK5 6PH

UKAS and MCERTS Accreditation Number: 1015

Opinions and interpretations expressed herein are outside the scope of UKAS accreditation.

MCERTS accredited results will only be claimed where both the sampling and analytical stages are UKAS accredited.

This test report shall not be reproduced, except in full, without written approval of SOCOTEC LTD.

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 3 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

EMISSIONS SUMMARY

Parameter Units Result Calculated Emission Limit Accrediation

Uncertainty Value (ELV)

+/-

Total Particulate Matter mg/m³ 0.80 0.16 5

MCERTS

Particulate Emission Rate g/hr 4.8 1.0 -

Hydrogen Fluoride mg/m³ 0.11 0.01 0.5

MCERTS

Hydrogen Fluoride Emission Rate g/hr 0.64 0.08 -

Moisture % 0.55 0.02 - MCERTS

o

Stack Gas Temperature C 15 - -

Stack Gas Velocity m/s 10 0.24 -

Gas Volumetric Flow Rate (Actual) m³/hr 6532 336 -

MCERTS

Gas Volumetric Flow Rate (STP, Wet) m³/hr 6033 310 -

Gas Volumetric Flow Rate (STP, Dry) m³/hr 5999 308 -

Gas Volumetric Flow Rate at Reference Conditions m³/hr 6033 310 -

ND = None Detected,

Results at or below the limit of detection are highlighted by bold italic text.

The above volumetric flow rate is an average of the data collected during the isokinetic tests. Mass emissions for non isokinetic tests are also

calculated using these values.

Reference conditions are 273K, 101.3kPa without correction for water vapour

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 4 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

MONITORING TIMES

Parameter Sampling Date(s) Sampling Times Sampling Duration

Total Particulate Matter Run 1 27 November 2020 10:35 - 14:35 240 minutes

Hydrogen Fluoride Run 1 27 November 2020 10:35 - 14:35 240 minutes

Preliminary Stack Traverse 27 November 2020 10:10 -

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 5 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

PROCESS DETAILS

Parameter Process Details

Description of process Vacuum Furnaces

Continuous or batch Continuous

Product Details Non ferrous metals

Part of batch to be monitored (if applicable) N/A

Normal load, throughput or continuous rating Normal Load

Fuel used during monitoring N/A

Abatement Wet Scrubber

Plume Appearance None Visible

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 6 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

Monitoring Methods

The selection of standard reference / alternative methods employed by SOCOTEC is determined, wherever possible by the hierarchy of method

selection outlined in Environment Agency technical Guidance 'Monitoring stack emissions: techniques and standards for periodic monitoring'.

MONITORING METHODS

Species Method SOCOTEC UKAS Lab MCERTS Limit of Calculated Calculated

Standard Reference Method / Technical Number Accredited Detection MU MU

Alternative Method Procedure Method (LOD) +/- % Result +/- % ELV

Total Particulate

SRM - BS EN 13284-1 AE 104 1015 MCERTS 0.08 mg/m³ 20% 3.2%

Matter

Hydrogen

SRM - ISO 15713 AE 113 1015 MCERTS 0.001 mg/m³ 13% 2.7%

Fluoride

Moisture SRM - BS EN 14790 AE 105 1015 MCERTS 0.003% 3.4% N/A - No ELV

Velocity SRM - EN ISO 16911-1 AE 154 1015 MCERTS 5 Pa 2.4% N/A - No ELV

Volumetric Flow

SRM - EN ISO 16911-1 AE 154 1015 MCERTS - 5.1% N/A - No ELV

Rate

BS EN 14790 has been validated over a range of 4 - 40%. It is however the prefered method of the Environment Agency for concentrations below 4%

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 7 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

Analytical Methods

The following tables list the analytical methods employed together with the custody details. Unless otherwise stated the samples are archived at the

analysis lab location.

SAMPLING METHODS WITH SUBSEQUENT ANALYSIS

Analytical UKAS Lab UKAS Accredited Analysis Report Archive

Species Analytical Technique Analysis Lab

Procedure Number Lab Analysis number Period

Total Particulate SOCOTEC

Gravimetric AE 106 1015 MCERTS N/A 8 Weeks

Matter (Stockport)

Hydrogen SOCOTEC

Ion Chromatography ASC/SOP/110 1252 MCERTS ASC 47913 8 Weeks

Fluoride (Bretby)

ON-SITE TESTING

Species Analytical Technique Analytical UKAS Lab MCERTS Laboratory Data Archive

Procedure Number Accredited Archive Period

Analysis Location

SOCOTEC

Moisture Gravimetric AE 105 1015 MCERTS - -

(Stockport)

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 8 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

SAMPLING LOCATION

Sampling Plane Validation Criteria Value Units Requirement Compliant Method

Lowest Differential Pressure 82 Pa >= 5 Pa Yes BS EN 15259

Lowest Gas Velocity 9.9 m/s - - -

Highest Gas Velocity 10.2 m/s - - -

Ratio of Gas Velocities 1.0 :1 <3:1 Yes BS EN 15259

Mean Velocity 10.0 m/s - - -

o

Maximum angle of flow with regard to duct axis <15 < 15o Yes BS EN 15259

No local negative flow Yes - - Yes BS EN 15259

DUCT CHARACTERISTICS SAMPLING LINES & POINTS

Value Units Isokinetic Non-Iso &

Shape Circular - Gases

Depth 0.48 m Sample port size 4 inch BSP -

Width - m Number of lines used 1 -

Area 0.18 m2 Number of points / line 4 -

Port Depth 40 mm Duct orientation Horizontal -

Filtration Out Stack -

Filtration for TPM Out Stack -

SAMPLING PLATFORM

General Platform Information

Permanent / Temporary Platform / Ground level / Floor Level / Roof Ground Level

Inside / Outside Outside

M1 Platform requirements

Is there a sufficient working area so work can be performed in a compliant manner Yes

Platform has 2 levels of handrails (approximately 0.5 m & 1.0 m high) N/A

Platform has vertical base boards (approximately 0.25 m high) N/A

Platform has removable chains / self closing gates at the top of ladders N/A

Handrail / obstructions do not hamper insertion of sampling equipment N/A

Depth of Platform = >Stack depth / diameter + wall and port thickness + 1.5m Yes

Sampling Platform Improvement Recommendations (if applicable)

The sampling location meets all the requirements as specified in EA Guidance Note M1.

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 9 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

EXECUTIVE SUMMARY

Sampling & Analytical Method Deviations

Nozzle Size

To maintain an isokinetic ratio a nozzle smaller than the recommended 6mm was used.

Sample Lines

Only one sample line available. The number of points were doubled along the remaining line as recommended by EA MID 13284.

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 10 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDICES

CONTENTS

APPENDIX 1 - Monitoring Schedule, Calibration Checklist & Monitoring Team

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

APPENDIX 3 - Measurement Uncertainty Budget Calculations

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 11 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

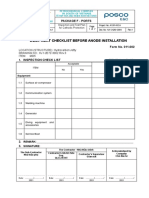

APPENDIX 1 - Monitoring Schedule, Calibration Checklist & Monitoring Team

MONITORING SCHEDULE

Method SOCOTEC UKAS Lab MCERTS

Number of

Species Standard Reference Method / Technical Number Accredited

Samples

Alternative Method Procedure Method

Total Particulate Matter SRM - BS EN 13284-1 AE 104 1015 MCERTS 1

Hydrogen Fluoride SRM - ISO 15713 AE 113 1015 MCERTS 1

Moisture SRM - BS EN 14790 AE 105 1015 MCERTS 1

Velocity SRM - EN ISO 16911-1 AE 154 1015 MCERTS 1

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 12 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 1 - Monitoring Schedule, Calibration Checklist & Monitoring Team

CALIBRATEABLE EQUIPMENT CHECKLIST

Extractive Sampling Instrumental Analyser/s Miscellaneous

Equipment Equipment I.D. Equipment Equipment I.D. Equipment Equipment I.D.

Control Box DGM LNO 13 - 23 Horiba PG-250 Analyser - Laboratory Balance LNO 00-12/00-13

Box Thermocouples LNO 03 - 23 FT-IR Gasmet - Tape Measure LNO 24 - MD

Meter In Thermocouple LNO 03 - 23 FT-IR Oven Box - Stopwatch LNO 17 - MD

Meter Out Thermocouple LNO 03 - 23 Bernath 3006 FID - Protractor -

Control Box Timer LNO 17 - 23 Signal 3030 FID - Barometer LNO 08 - MD

Oven Box LNO 09 - 11 Servomex - Digital Micromanometer LNO 01 - MD

Probe LNO 11 - 03 JCT Heated Head Filter - Digital Temperature Meter LNO 03 - MD

Probe Thermocouple LNO 10 - 03 Thermo FID - Stack Thermocouple LNO 01 - MD

Probe - Stackmaster - Mass Flow Controller -

Probe Thermocouple - FTIR Heater Box for Heated Line - MFC Display module -

S-Pitot LNO 06 - MD Anemometer - 1m Heated Line (1) -

L-Pitot - Ecophysics NOx Analyser - 1m Heated Line (2) -

Site Balance LNO 14 - MD Chiller (JCT/MAK 10) - 1m Heated Line (3) -

Last Impinger Arm - Heated Line Controller (1) - 5m Heated Line (1) -

Dioxins Cond. Thermocouple - Heated Line Controller (2) - 10m Heated Line (1) -

Callipers - Site temperature Logger - 10m Heated Line (2) -

Small DGM - 15m Heated Line (1) -

Heater Controller - 20m Heated Line (1) -

Inclinometer (Swirl Device) LNO 23-MD 20m Heated Line (2) -

NOTE: If the equipment I.D is represented by a dash (-), then this piece of equipment has not been used for this test.

CALIBRATION GASES

Cylinder I.D Analytical

Gas (traceable to ISO 17025) Supplier ppm %

Number Tolerance +/- %

- - - - - -

STACK EMISSIONS MONITORING TEAM

MONITORING TEAM

MCERTS MCERTS TE / H&S Qualifications and Expiry Date

Personnel

Number Level Expiry TE1 TE2 TE3 TE4 H&S

MCERTS Level

Mark Derbyshire MM 02 022 Nov-22 Nov-22 Dec-22 Nov-23 Dec-22 Apr-24

2

MCERTS Level

Joe Saxton MM 18 1501 Apr-24 - - - - Apr-24

1

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 13 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

TOTAL PARTICULATE MATTER SUMMARY

Parameter Sampling Times Concentration Uncertainty ELV Emission

mg/m³ mg/m³ mg/m³ Rate g/hr

10:35 - 14:35

Run 1 0.80 0.16 5 4.8

27 November 2020

Blank - 0.35 - - -

Reference conditions are 273K, 101.3kPa without correction for water vapour

Acetone Blank Value Acceptable Value

mg/l mg/l

0.3 10

FILTER INFORMATION

SAMPLES

Filter & Probe Filter Start Filter End Mass Gained Probe Rinse Probe Rinse Mass Gained on Combined Total

Test

Rinse Number Weight Weight on Filter Start Weight End Weight Probe Mass Gained

g g g g g g g

Run 1 Q1866 0.14072 0.14278 0.00206 61.16080 61.16160 0.00080 0.00286

If total mass gained is less than the LOD then the LOD is reported

BLANKS

Filter & Probe Filter Start Filter End Mass Gained Probe Start Probe End Mass Gained Combined Total

Test

Number Weight Weight Filter Weight Weight Probe Mass Gained

g g g g g g g

Run 1 Q1865 0.14456 0.14513 0.00057 71.58440 71.58510 0.00070 0.00127

If total mass gained is less than the LOD then the LOD is reported

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 14 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

ISOKINETIC SAMPLING EQUATIONS - RUN 1 TPM

Absolute pressure of stack gas, Ps Molecular weight of dry gas, Md

Barometric pressure, Pb Kpa 99.5 CO2 % 0.03

Stack static pressure, Pstatic pa -150.0 O2 % 21.00

Ps = Pb + Pstatic Kpa 99.4 Total % 21.03

N2 (100 -Total) % 78.97

Vol. of water vapour collected, Vwstd Md = 0.44(%CO2)+0.32(%O2)+0.28(%N2) 28.84

Moisture trap weight increase,Vlc g 16.0 Molecular weight of wet gas, Ms

Vwstd = (0.001246)(Vlc) m3 0.019936 Ms = Md(1 - Bwo) + 18(Bwo) g/gmol 28.78

Volume of gas metered dry, Vmstd Actual flow of stack gas, Qa

Volume of gas sample through gas meter, Vm m3 3.765 Area of stack, As m2 0.18

Gas meter correction factor, Yd 1.024 Qa = (60)(As)(Vs) m³/min 108.7

Mean dry gas meter temperature, Tm K 290 Total flow of stack gas, Q

Mean pressure drop across orifice, DH mmH 2O 30.199 Conversion factor (K/mm.Hg) 0.3592

Vmstd = (0.3592)(Vm)(Pb+(DH/13.6))(Yd) m3 3.573 Qstd = (Qa)Ps(0.3592)(1-Bwo) Dry 100.0

Tm (Ts)

Volume of gas metered wet, Vmstw QstdO2 = (Qa)Ps(0.3592)(1-Bwo)(O2REF) @O2ref No O2 Ref

Vmstw = Vmstd + Vwstd m3 3.5934 (Ts)

Qstw = (Qa)Ps(0.3592) Wet 100.59

Vol. of gas metered at O2 Ref. Cond., Vmstd@X%O2

(Ts)

Is the process burning hazardous waste? (If yes, no No Percent isokinetic, %I

favourable oxygen correction) Nozzle diameter, Dn mm 5.97

% oxygen measured in gas stream, act%O2 21.0 Nozzle area, An mm2 28.03

% oxygen reference condition 21 Total sampling time, q min 240

O2 Reference O2 Ref = 21.0 - act%O2 No O2 Ref %I = (4.6398E6)(Ts)(Vmstd) % 96.1

Factor 21.0 - ref%O2 (Ps)(Vs)(An)(q)(1-Bwo)

Vmstd@X%oxygen = (Vmstd) (O2 Ref) m3 No O2 Ref Acceptable isokinetic range 95% to 115% Yes

Moisture content, Bwo Particulate Concentration, C

Bwo = Vwstd 0.0055 Mass collected on filter, Mf g 0.00206

Vmstd + Vwstd % 0.55 Mass collected in probe, Mp g 0.00080

Moisture by FTIR % - Total mass collected, Mn g 0.00286

Velocity of stack gas, Vs Cwet = Mn mg/m³ 0.796

Velocity pressure coefficient, Cp 0.84 Vmstw

Mean of velocity heads, DPavg Pa 84.04 Cdry = Mn mg/m³ 0.800

Mean stack gas temperature, Ts K 289 Vmstd

Gas density (wet, ambient), p Cdry@X%O2 = Mn mg/m³ No O2 Ref

p=(Ms*Ps)/(8.314*Ts) kg/m3 1.190 Vmstd@X%oxygen

Stack Velocity, Vs ∆𝐷𝑃𝑎𝑣𝑔 Particulate Emission Rates, E

𝑉𝑠 = 𝐶𝑝

𝑝 m/s 10.01 E = [(Cwet)(Qstw)(60)] / 1000 4.80

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 15 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

TOTAL PARTICULATE MATTER QUALITY ASSURANCE CHECKLIST

LEAK RATE

Mean SamplingPre-sampling Post-sampling Maximum Acceptable Leak Tests

Run Rate Leak Rate Leak Rate Vacuum Leak Rate Acceptable?

litre/min litre/min litre/min mm Hg litre/min

Run 1 16.06 0.23 - -457.2 0.32 Yes

In BS EN 13284-1:2017 a post sampling leak check is not required.

ISOKINETICITY WEIGHING BALANCE UNCERTAINTY

Isokinetic Acceptable

Result 5% ELV LOD < 5% ELV

Run Variation Isokineticity Run

% mg/m³ mg/m³

Run 1 96.11 Yes Run 1 0.08 0.25 N/A - ELV <5 mg/m³

Acceptable isokinetic range 95% to 115% The above is based on both the Filter and rinse uncertainty

Where installations have ELVs of 5 mg/m³ or less, it may not be

practical to meet the 5% of ELV requirement. Under these

circumstances, a minimum one hour sample time shall used.

BLANK VALUE

Overall Blank Daily Emission Acceptable Overall Blank

Run Value Limit Value Blank Value Acceptable

mg/m3 mg/m3 mg/m3 mg/m3

Blank 1 0.35 5 1.0 Yes

*For ELVs of 5 mg/m3 and lower a blank value must be <20% of the ELV

FILTERS

Run Filter Material Filter Size Max Filtration Pre-use Filter Conditioning Post-use Filter Conditioning

Temperature Temperature Temperature

mm °C °C °C

Run 1 Quartz Fibre 47 150 180 160

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 16 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

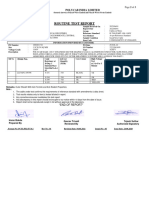

HYDROGEN FLUORIDE SUMMARY

Sampling Times Concentration LOD ELV Emission

Test

mg/m³ mg/m³ mg/m³ Rate g/hr

10:35 - 14:35

Run 1 0.11 0.001 0.5 0.64

27 November 2020

Field Blank - 0.005 - - -

Reference conditions are 273K, 101.3kPa without correction for water vapour

HYDROGEN FLUORIDE QUALITY ASSURANCE CHECKLIST

Leak Test Results Total Sample Mean Sampling Pre sampling Post sampling Acceptable leak Leak Tests

Volume @ ref Rate leak rate leak rate rate Acceptable?

Conditions

m³ l/min l/min l/min l/min

Run 1 3.6 16.1 0.23 0.23 0.32 Yes

Filter Material Filter Size Max. Filtration Temperature Type of Absorption Solutions

mm Temp. during storage Absorbers

°C / transit <25°C

Run 1 Quartz Fibre 47 150 N/A PTFE 0.1N Sodium Hydroxide

HYDROGEN FLUORIDE ABSORPTION EFFICIENCY

Parameter Total IMP C Absorption Acceptable Absorption Absorption Efficiency

ug ug Efficiency % Efficiency % Acceptable ?

Run 1 383.3 14.3 96 95 Yes

ND - None Detected

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 17 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

ISOKINETIC SAMPLING EQUATIONS 1 Hydrogen Fluoride

Absolute pressure of stack gas, Ps Velocity of stack gas, Vs

Barometric pressure, Pb kPa 100 Velocity pressure coefficient, Cp 0.842

Stack static pressure, Pstatic Pa -150 Mean of velocity heads, DPavg Pa 84.04

Ps = Pb + (Pstatic) kPa 99.35 Mean stack gas temperature, Ts K 289.17

Gas density (wet, ambient), p

Vol. of water vapour collected, Vwstd p=(Ms*Ps)/(8.314*Ts) kg/m3 1.190

Moisture trap weight increase,Vlc g - Stack Velocity, Vs ∆𝐷𝑃𝑎𝑣𝑔

𝑉𝑠 = 𝐶𝑝

Vwstd = (0.001246)(Vlc) m3 - 𝑝 m/s 10.01

Volume of gas metered dry, Vmstd Actual flow of stack gas, Qa

Volume of gas sample through gas meter, V m m3 3.7650 Area of stack, As m2 0.18

Gas meter correction factor, Yd 1.0237 Qa = (60)(As)(Vs) m³/min 109

Mean dry gas meter temperature, Tm K 289.98 Dry total flow of stack gas, Qstd

Mean pressure drop across orifice, DH mmH 2O 30.20 Conversion factor (K/mm.Hg) 0.3592

Vmstd = (0.3592)(Vm)(Pb+(DH/13.6))(Yd) m3 3.57 Qstd = (Qa)Ps(0.3592)(1-Bwo) m³/min 100

Tm (Ts)

Volume of gas metered wet, Vmstw Wet total flow of stack gas, Qstw

Vmstw = Vmstd + Vwstd m3 3.5934 Qstw = (Qa)Ps(0.3592) m³/min 101

(Ts)

Vol. of gas metered at O2 Ref. Cond., Vmstd@X%O2

Dry total flow of stack gas at X% O2, QstdO2

Is the process burning hazardous waste? (If yes, No

no favourable oxygen correction) QstdO2 = (Qa)Ps(0.3592)(1-Bwo)(O2REF) m³/min No O2 Ref

% oxygen measured in gas stream, act%O2 21.00 (Ts)

% oxygen reference condition 21 Percent isokinetic, %I

O2 Reference O2 Ref = 21.0 - act%O2 No O2 Ref Nozzle diameter, Dn mm 5.97

Factor 21.0 - ref%O2 Nozzle area, An mm2 28.03

Vmstd@X%oxygen = (Vmstd) (O2 Ref) m3 No O2 Ref Total sampling time, q min 240

Moisture content, Bwo %I = (4.6398E6)(Ts)(Vmstd) % 96

Bwo = Vwstd 0.0055 (Ps)(Vs)(An)(q)(1-Bwo)

Vmstd + Vwstd % 0.55 Acceptable isokinetic range 95% to 115% Yes

Moisture by FTIR % - Hydrogen Fluoride Concentration, C

Molecular weight of dry gas, Md Mass collected , M ug 383

CO2 0.03 Cwet = Mn mg/m³ 0.107

O2 21.00 Vmstw

Total 21.03 Cdry = Mn mg/m³ 0.107

N2 (100 -Total) 78.97 Vmstd

Cdry@X%O2 = Mn mg/m³ No O2 Ref

Md = 0.44(%CO2)+0.32(%O2)+0.28(%N2) 28.84 Vmstd@X%oxygen

Molecular weight of wet gas, Ms Hydrogen Fluoride Emission Rates, E

Ms = Md(1 - Bwo) + 18(Bwo) g/gmol 28.8 E = [(Cwet)(Qstw)(60)] / 1000 g/hr 0.64

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 18 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

MOISTURE CALCULATIONS

Moisture Determination - Isokinetic

Test Number Sampling Time and Date Start Weight End Weight Total gain Concentration LOD Uncertainty

kg kg kg % % %

10:35 - 14:35

Run 1 3.3495 3.3655 0.0160 0.55 0.003 3.4

27 November 2020

Moisture Quality Assurance

Sampling Total Volume Acceptable Leak Tests

Test Number Sampling Rate Start Leak Rate End Leak Rate

Duration Sampled Leak Rate Acceptable?

mins l l/min l/min l/min l/min

Run 1 240 3593 16.1 0.23 - 0.32 Yes

PRELIMINARY STACK SURVEY

Stack Characteristics

Stack Diameter / Depth, D 0.48 m

Stack Width, W - m

Stack Area, A 0.18 m2

o

Average stack gas temperature 15 C

Stack static pressure -1 kPa

Barometric Pressure 99.7 kPa

Stack Gas Composition & Molecular Weights

Component Molar Density Conc Dry Volume Dry Conc Conc Wet Volume Wet Conc

Mass kg/m3 Dry Fraction kg/m3 Wet Fraction kg/m3

M p % Vol r pi % Vol r pi

CO2 44 1.963059 0.028571 0.000286 0.000561 0.028413 0.000284 0.000558

O2 32 1.427679 21.000000 0.210000 0.299813 20.883492 0.208835 0.298149

N2 28 1.249219 78.971429 0.789714 0.986526 78.533296 0.785333 0.981053

H2 O 18 0.803070 - - - 0.554799 0.005548 0.004455

Where: p = M / 22.41 pi = r x p

Calculation of Stack Gas Densities

Determinand Result Units

Dry Density (STP), P STD 1.2869 kg/m3

Wet Density (STP), P STW 1.2842 kg/m3

Dry Density (Actual), P Actual 1.1886 kg/m3

Average Wet Density (Actual), P ActualW 1.186 kg/m3

Where:

P STD = sum of component concentrations, kg/m3 (not including water vapour) P Actual = P STD x (Ts / Ps) x (Pa / Ta)

P STW = (P STD + pi of H2O) / (1 + (pi of H2O / 0.8036)) P ActualW = P STW x (Ts / Ps) x (Pa / Ta)

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 19 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

PRELIMINARY STACK SURVEY

TRAVERSE 1

Date of Survey 27 November 2020

Time of Survey 10:10

Velocity Measurement Device: S-Type Pitot

Sampling Line A

Traverse Distance DP pt DP pt Temp Velocity Volumetric O2 Angle

o

Flow Rate

Point into Pa mmH2O C m/s % of Swirl

(actual)

(average of 3 (average of 3 o

duct (m) m³/s Vol

readings) readings)

1 0.05 83.0 8.5 15 10.0 1.8 - <15

2 0.12 84.3 8.6 15 10.0 1.8 - <15

3 0.36 86.9 8.9 15 10.2 1.8 - <15

4 0.43 82.3 8.4 15 9.9 1.8 - <15

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

Mean - 84.1 8.6 15 10.0 1.8 - -

Sampling Line B

Traverse Distance DP pt DP pt Temp Velocity Volumetric O2 Angle

o

Flow Rate

Point into Pa mmH2O C m/s % of Swirl

(actual)

(average of 3 (average of 3 o

duct (m) m³/s Vol

readings) readings)

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

- - - - - - - - -

Mean - - - - - - - -

PRELIMINARY STACK SURVEY QUALITY ASSURANCE CHECKLIST

PITOT LEAK CHECK

Pre Traverse Leak Rate Post Traverse Leak Rate

Run Start Value End Value Difference Outcome Start Value End Value Difference Outcome

mmH2O mmH2O % mmH2O mmH2O %

Run 1 145 143 1.4 Pass 150 149 0.7 Pass

To complete a compliant pitot leak check a pressure of over 80 mmH₂O (or 800 Pa) is applied and the pressure drop monitored over 5 mins. A drop of

less than 5% must be observed.

S-Type Pitot Stagnation Check

Outcome

Stagnation Reference Difference

Run (Permitted

(Pa) (Pa) (Pa)

+/- 10 Pa)

Run 1 -1000 -1000 0.0 Pass

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 20 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

PRELIMINARY STACK SURVEY (CONTINUED)

Sampling Plane Validation Criteria

EA Technical Guidance Note (Monitoring) M1 Result Units Requirement Compliant

Lowest Differential Pressure 82 Pa >= 5 Pa Yes

Lowest Gas Velocity 9.9 m/s - -

Highest Gas Velocity 10.2 m/s - -

Ratio of Gas Velocities 1.0 - <3:1 Yes

Maximum angle of flow with regard to duct axis <15 o

< 15o Yes

No local negative flow Yes - - Yes

Calculation of Stack Gas Velocity, V

Velocity at Traverse Point, V = Kpt x (1-e) * Ö(2 * DP pt / P ActualW)

Where:

Kpt = Pitot tube calibration coefficient

(1-e) = Compressibility correction factor, assumed at a constant 0.998

Average Stack Gas Velocity, Va 10.0 m/s

Calculation of Stack Gas Volumetric Flowrate, Q

Duct gas flow conditions Actual Reference Units

o

Temperature 15 0 C

Total Pressure 98.7 101.3 kPa

Oxygen 21.0 21 %

Moisture 0.55 0.55 %

Pitot tube calibration coefficient, K pt 0.84

Gas Volumetric Flowrate Result Units

Average Stack Gas Velocity (Va) 10.03 m/s

Stack Area (A) 0.18 m2

Gas Volumetric Flowrate (Actual), QActual 6532 m3/hr

Gas Volumetric Flowrate (STP, Wet), QSTP 6033 m3/hr

Gas Volumetric Flowrate (STP, Dry), QSTP,Dry 5999 m3/hr

Gas Volumetric Flowrate (REF), QRef 6033 m3/hr

Where:

QActual = Va x A x 3600

QSTP = Q (Actual) x (Ts / Ta) x (Pa / Ps) x 3600

QSTP,Dry = Q (STP) / (100 - (100 / Ma)) x 3600

QRef = Q (STP) x ((100 - Ma) / (100 - Ms)) x ((21 - O2a) / (21 - O2s))

Nomenclature:

Ts = Absolute Temperature, Standard Conditions, 273 K

Ps = Absolute Pressure, Standard Conditions, 101.3 kPa

Ta = Absolute Temperature, Actual Conditions, K

Pa = Absolute Pressure, Actual Conditions, kPa

Ma = Water vapour, Actual Conditions, % Vol

Ms = Water vapour, Reference Conditions, % Vol

O2a = Oxygen, Actual Conditions, % Vol

O2s = Oxygen, Reference Conditions, % Vol

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 21 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 2 - Summaries, Calculations, Raw Data and Charts

STACK DIAGRAM

Value Units Non-Isokinetic/Gases Sampling

Stack Depth 0.48 m Sampling Distance Distance into Units

Stack Width - m Point (% of Depth) Stack

Area 0.18 m2 - - - -

Isokinetic Sampling

Sampling Distance Distance into Swirl

o

Point (% of Depth) Stack (m)

4 1 10.4 0.05 < 15

2 25.0 0.12 < 15

3 3 75.0 0.36 < 15

4 89.6 0.43 < 15

- - - -

- - - -

- - - -

- - - -

- - - -

2

- - - -

- - - -

1

- - - -

- - - -

- - - -

Sampling Line A

- - - -

- - - -

Isokinetic sampling point - - - -

Isokinetic sampling points not used - - - -

Non Isokinetic/Gases sampling point - - - -

- - - -

SAMPLING LOCATION

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 22 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

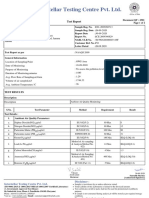

APPENDIX 3 - Measurement Uncertainty Budget Calculations

MEASUREMENT UNCERTAINTY BUDGET - TOTAL PARTICULATE MATTER

Run Sampled Sampled Gas Sampled Gas Sampled Gas Oxygen Limit of Leak Uncollected

Volume Temp Pressure Humidity Content Detection Mass

m³ K kPa % by volume % by volume % by mass % mg

MU required < 2% < 2% < 1% < 1% < 10% < 5% of ELV < 2% < 10% of ELV

Run 1 0.001 2.0 0.50 1.0 N/A 0.28 - -

as a % 0.03 0.69 0.50 1.0 N/A 1.56 1.43 0.025

compliant? Yes Yes Yes Yes N/A Yes Yes Yes

*Where installations have ELVs of 5 mg/m³ or less, it may not be practical to meet the 5% of ELV requirement. Under these circumstances, a minimum one hour sample

time shall used.

Run Volume (STP) Mass of O2 Correction Leak Uncollected Combined

particulate Mass uncertainty

m³ mg - mg/m³ mg

Run 1 3.31 2.8600 1.0 0.0066 0.0007 -

MU as mg/m3 0.01 0.0779 - 0.0066 0.0002 0.08

MU as % 1.32 9.7902 - 0.827 0.0256 -

R1 - Uncertainty expressed at a 95% confidence

0.16 mg/m³ 20 % Result 3.2 % ELV

level (where k = 2)

(k is a coverage factor which gives a 95% confidence in the quoted figures)

Reference – SOCOTEC Technical Procedure AE150 Estimation of Uncertainty of Measurement

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 23 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

APPENDIX 3 - Measurement Uncertainty Budget Calculations

MEASUREMENT UNCERTAINTY BUDGET - ISOKINETIC HYDROGEN FLUORIDE

Run Sampled Sampled Gas Sampled Gas Sampled Gas Oxygen Limit of Leak

Volume Temp Pressure Humidity Content Detection

m³ K kPa % by volume % by volume % by mass %

MU required <=2% <2.5 k <=1% <=1% <=5% < 5% of ELV <=2%

Run 1 3.593 290 98 1.0 - 0.66 -

as a % 0.03 0.69 0.51 1.0 - 0.23 1.43

compliant? Yes Yes Yes Yes N/A Yes Yes

Run Volume (STP) Mass of O2 Correction Leak Lab Combined

Hydrogen Uncertainty uncertainty

Fluoride

m³ mg - mg/m³ mg

Run 1 3.2728 0.6612 - 0.0009 - -

MU as mg/m3 0.0014 0.0012 - 0.0009 0.0065 0.0068

MU as % 1.3179 1.0911 - 0.8269 6.1 -

R1 - Uncertainty expressed at a 95% confidence

0.01 mg/m³ 13 % Result 2.7 % ELV

level (where k = 2)

(k is a coverage factor which gives a 95% confidence in the quoted figures)

Reference – SOCOTEC Technical Procedure AE150 Estimation of Uncertainty of Measurement

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 24 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

MEASUREMENT UNCERTAINTY BUDGET - VELOCITY & VOLUMETRIC FLOW RATE

Measured Velocity at Actual Conditions 10.0 m/s

Measured Volumetric Flow rate at Actual Conditions 6532 m³/hr

Performance Characteristics & Source of Value Units Values Requirement Compliant

Uncertainty of Local Gas Velocity Determination

Uncertainty of pitot tube coefficient - 0.010

Uncertainty of mean local dynamic pressures - 0.78

Factor loading, function of the number of measurements. 3 readings 0.591 minimum 3 Yes

Range of measurment device pa 1000

Resolution pa 1.00

<1% of Value or 20

Calibration uncertainty pa 14.08 Pa whichever is Yes

greater

Drift % range 0.10

Linearity % range 0.06 <2% of value Yes

Uncertainty of gas density determination

Uncertainty of molar mass determination kg/mol 0.00003

Uncertainty of temperature measurement K 1.47 <1% of value Yes

Uncertainty of absolute pressure in the duct pa 504

Uncertainty associated with the estimate of density - 0.007

Uncertainty associated with the measurement of local velocity - 0.0001

Uncertainty associated with the measurement of mean velocity - 0.0002

Measurement Uncertainty - Velocity m/s

Combined uncertainty 0.12

Expanded uncertainty at a 95% Confidence Interval 0.24

Note - The expanded uncertainty uses a coverage factor of k = 2.

Expanded Measurement Uncertainty of Velocity at a 95% Confidence Interval %

Expressed as a % of the Measured Velocity 1.2

Expanded uncertainty at a 95% Confidence Interval 2.4

Measurement Uncertainty Volumetric Flow Rate m³/hr

Combined uncertainty 171

Expanded uncertainty at a 95% Confidence Interval 336

Note - The expanded uncertainty uses a coverage factor of k = 2.

Expanded Measurement Uncertainty of Volumetric Flow Rate at a 95% Confidence Interval %

Expressed as a % of the Measured Volumetric Flow Rate 2.6

Expanded uncertainty at a 95% Confidence Interval 5.1

Reference – SOCOTEC Technical Procedure AE150 Estimation of Uncertainty of Measurement

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 25 of 26

EPR Permit: EPR/RP3233CZ/V002

SOCOTEC UK LTD

www.socotec.co.uk

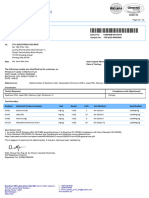

END OF REPORT

Thank you for choosing SOCOTEC for your environmental monitoring needs. We hope our services have met your requirements and that you are fully satisfied

with your experience of working with us, we really do value your custom and would welcome your feedback. We would appreciate it if you could take a moment

to complete a short online questionnaire so that we can improve our operations and address any areas that have not met with your expectations, by clicking on

the following

https://www.surveymonkey.co.uk/r/CAE_customer_feedback_weblink

Less Common Metals Ltd LNO 16148 / Version 1

Ellesmere Port 27th November 2020

Electrolysis Page 26 of 26

EPR Permit: EPR/RP3233CZ/V002

You might also like

- Stack Emissions Monitoring Report: Your Contact at ESGDocument26 pagesStack Emissions Monitoring Report: Your Contact at ESGMohamed Irfan Z H100% (1)

- Inspection and Test Plan For Anode T51-T60Document10 pagesInspection and Test Plan For Anode T51-T60congvt93No ratings yet

- 7650-8550-DS-500-6211 DoneDocument11 pages7650-8550-DS-500-6211 DoneKhan Akhtar HusainNo ratings yet

- Metrosil Test Report: Site Test Report Date: 29/07/2020 Customer: Sec-Eoa Name of SubstationDocument2 pagesMetrosil Test Report: Site Test Report Date: 29/07/2020 Customer: Sec-Eoa Name of Substationمحمد عادلNo ratings yet

- Inspection and Test Plan For Anode MD5Document7 pagesInspection and Test Plan For Anode MD5congvt93No ratings yet

- DB ChecklistDocument4 pagesDB ChecklistJabinNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Under Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Under Ground PipingBhavani PrasadNo ratings yet

- PC N 20151016001Document4 pagesPC N 20151016001Aaqib RasoolNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- U4-SY-109-L1000028 (Rev.L)Document14 pagesU4-SY-109-L1000028 (Rev.L)arbazNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingKheireddine AounallahNo ratings yet

- Acd Si 005Document13 pagesAcd Si 005Massimo FumarolaNo ratings yet

- RFMeter Safeand Sound Pro IIFrequency Response CurveDocument5 pagesRFMeter Safeand Sound Pro IIFrequency Response Curvebdmlw516No ratings yet

- PO SR - No.8, HEL REPORT 120004Document4 pagesPO SR - No.8, HEL REPORT 120004Agni DuttaNo ratings yet

- Test Report - Cable 111Document2 pagesTest Report - Cable 111vivek juthaniNo ratings yet

- Oman Tank Terminal Company (Ottco) : Project: Ras Markaz Crude Oil Park Project (Phase 1)Document13 pagesOman Tank Terminal Company (Ottco) : Project: Ras Markaz Crude Oil Park Project (Phase 1)ANIL PLAMOOTTILNo ratings yet

- Test Report: CTK Co., LTDDocument75 pagesTest Report: CTK Co., LTDRaja GuptaNo ratings yet

- ET032 Ed.5 (OPGW) .Es - enDocument56 pagesET032 Ed.5 (OPGW) .Es - enfixer_007722No ratings yet

- 38 Pcs LA4 M I FinalDocument5 pages38 Pcs LA4 M I FinalMinh NguyễnNo ratings yet

- CB CU Conveyor Belt Control Unit Safety CertificateDocument54 pagesCB CU Conveyor Belt Control Unit Safety CertificateBala Sasanka MadabhushiNo ratings yet

- 150 X3.5 C RTCDocument1 page150 X3.5 C RTCnitinNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- S Mir 001Document1 pageS Mir 001PRAVEENNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- T14166-4 Report 31.03.2021Document49 pagesT14166-4 Report 31.03.2021mayur dhandeNo ratings yet

- MWDS ATEX BulletinDocument4 pagesMWDS ATEX BulletinAna Paula Maia LimaNo ratings yet

- C1944526-01-WGS-EL00-ITP-0202 - 03 - Treated Water Filter - Material Test Certificate For Filter VesselDocument61 pagesC1944526-01-WGS-EL00-ITP-0202 - 03 - Treated Water Filter - Material Test Certificate For Filter VesselNishit KhuntNo ratings yet

- Interstellar Testing Centre Pvt. LTD.: Test ReportDocument2 pagesInterstellar Testing Centre Pvt. LTD.: Test ReportDemon barberNo ratings yet

- 2018-6032 HCT6 30mpa 02Document1 page2018-6032 HCT6 30mpa 02abrar4012No ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Cambridge Audio Azur 640c Service ManualDocument34 pagesCambridge Audio Azur 640c Service ManualMartin Szathmári100% (1)

- PLL Job No. PIIN-01 Project Dahej Vijaipur Pipeline: Quality Department Procedure For Concrete Weight CoatingDocument11 pagesPLL Job No. PIIN-01 Project Dahej Vijaipur Pipeline: Quality Department Procedure For Concrete Weight CoatingHariom GuptaNo ratings yet

- Kiem Tra Thiet Bi Truoc Khi Dong Dien (E-Ver RC2) - 2Document5 pagesKiem Tra Thiet Bi Truoc Khi Dong Dien (E-Ver RC2) - 2Thái TrầnNo ratings yet

- PDFDocument8 pagesPDFOnkar NaikNo ratings yet

- Hx8815-Qc-Pc-Misc-015 Rev. E2Document8 pagesHx8815-Qc-Pc-Misc-015 Rev. E2Selva SelvaaNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- Enkon PresentationDocument115 pagesEnkon PresentationSalimNo ratings yet

- 16a2093-L0003 - S03 - E Electr. - Eq. - in - Machine - DeliveryDocument31 pages16a2093-L0003 - S03 - E Electr. - Eq. - in - Machine - DeliverySebastian BenitezNo ratings yet

- Cems Rata Report PDFDocument264 pagesCems Rata Report PDFadhirga_moesNo ratings yet

- FTTH Webinar: Turn-Up TroubleshootingDocument51 pagesFTTH Webinar: Turn-Up TroubleshootingMuhammad Waqas AslamNo ratings yet

- EN61326 - 1 - Zugehörige EMV NormenDocument30 pagesEN61326 - 1 - Zugehörige EMV NormenHans U. LerchNo ratings yet

- Isq-O&G Ultrasonic Thickness and Corrosion Scanning ProtocolDocument13 pagesIsq-O&G Ultrasonic Thickness and Corrosion Scanning Protocolpon sharonNo ratings yet

- Stretch Film RoHS Test ReportDocument2 pagesStretch Film RoHS Test ReportAmirun AeimanzzNo ratings yet

- En 300 00Document28 pagesEn 300 00ShaunVermaakNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

- Method Statement: Erection of Concrete Pole ACO-9-3004-043-T7-4-0Document63 pagesMethod Statement: Erection of Concrete Pole ACO-9-3004-043-T7-4-0apollo castroNo ratings yet

- 2 Concrete Works MSDocument7 pages2 Concrete Works MSGaneshNo ratings yet

- Ffi RT: Details Test Osdllogram Photogmph DmwingsDocument14 pagesFfi RT: Details Test Osdllogram Photogmph DmwingsMeenakshiNo ratings yet

- Skyworth (Group) Co., LTD.: Engineering Evaluation Report (Components)Document42 pagesSkyworth (Group) Co., LTD.: Engineering Evaluation Report (Components)Abir AhmedNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Eqt 3Document10 pagesEqt 3santosh pasayatNo ratings yet

- 199 GST 0104 RevA - Power Control Center SpecificationDocument16 pages199 GST 0104 RevA - Power Control Center Specificationdhanny maNo ratings yet

- DCL Test Report - Size 15.24 MM - 18-2-2020Document2 pagesDCL Test Report - Size 15.24 MM - 18-2-2020docpt76No ratings yet

- Fault Detection Using OTDR: Ashwani Singh Salil Hegiste Arbaz MukriDocument95 pagesFault Detection Using OTDR: Ashwani Singh Salil Hegiste Arbaz MukriGhâdaAouiniNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- RRU ECM Report - E202203291840-01-1Document31 pagesRRU ECM Report - E202203291840-01-1Délsio CabáNo ratings yet

- Ict 1 Furan 17 5 23Document1 pageIct 1 Furan 17 5 23Boddu ThirupathiNo ratings yet

- Itp For Sampling Line (GFT Tank-48360)Document46 pagesItp For Sampling Line (GFT Tank-48360)Nithin GNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- 06 PressureDocument9 pages06 PressureTahmedul Hasan TanvirNo ratings yet

- Pressure Recovery in A Centrifugal Blower CasingDocument7 pagesPressure Recovery in A Centrifugal Blower CasingBensinghdhasNo ratings yet

- Series TD: Type TDL Type TDMDocument16 pagesSeries TD: Type TDL Type TDMAhmadNo ratings yet

- Non Reacting Mixtures PDFDocument6 pagesNon Reacting Mixtures PDFJerome MaldaNo ratings yet

- Rashtriya Chemicals and Fertilizers Limited Mini Ratna CompanyDocument20 pagesRashtriya Chemicals and Fertilizers Limited Mini Ratna CompanyRana KeyurNo ratings yet

- 09 Fluid Mechanics and Hydraulic Machineries - IDocument39 pages09 Fluid Mechanics and Hydraulic Machineries - IManoj PokharelNo ratings yet

- Sewage Air ValveDocument10 pagesSewage Air ValveAhmed TalaatNo ratings yet

- Scott Rit-Pak IiiDocument38 pagesScott Rit-Pak IiioquirogacNo ratings yet

- Now L23/30S and L28/32S As Dual FuelDocument2 pagesNow L23/30S and L28/32S As Dual FuelRichard RichardNo ratings yet

- Breathable Compressed Air BrochureDocument11 pagesBreathable Compressed Air BrochuremuppetscrapNo ratings yet

- Boiler-Steam Generator Protection PDFDocument12 pagesBoiler-Steam Generator Protection PDFأمير حارث100% (1)

- Zimmerman Et Al AIAA 2013-4045Document22 pagesZimmerman Et Al AIAA 2013-4045muttangi sushmaNo ratings yet

- Venturi Type Flow Meter: SubmittalDocument1 pageVenturi Type Flow Meter: SubmittalrajuNo ratings yet

- European Site #54 - Vacuum Distillation Unit (VDU) Vacuum Distillation Column CollapseDocument1 pageEuropean Site #54 - Vacuum Distillation Unit (VDU) Vacuum Distillation Column CollapsekrishnanshwetaNo ratings yet

- AIR COMPRESSOR SALES AND SERVICE - Gardner Denver Parts, Champion Parts, Champion Air Compressor PartsDocument10 pagesAIR COMPRESSOR SALES AND SERVICE - Gardner Denver Parts, Champion Parts, Champion Air Compressor PartsAndrés ChávezNo ratings yet

- 623-09 - Compressor Airflow ControlDocument36 pages623-09 - Compressor Airflow ControlA ENGENHARIA DAS COISASNo ratings yet

- Gas Compressor AvanceDocument36 pagesGas Compressor AvanceLina VargasNo ratings yet

- Modelling and Transient Simulation of Water Flow in Pipelines Using Wanda Transient SoftwareDocument10 pagesModelling and Transient Simulation of Water Flow in Pipelines Using Wanda Transient SoftwareEng Bagaragaza RomualdNo ratings yet

- ESA 368 Notes 03 - Isentropic FlowDocument15 pagesESA 368 Notes 03 - Isentropic FlowSiow Shung ChurnNo ratings yet

- Pulsation Design ReqsDocument2 pagesPulsation Design ReqsdigecaNo ratings yet

- Calorific Value (CV)Document3 pagesCalorific Value (CV)ShishirNo ratings yet

- Weekly Weld Repair AnalysisDocument1 pageWeekly Weld Repair AnalysisknocknocknockNo ratings yet

- Horizontal Centrifugal Pump - According To Iso 2858: Chemical Pumps Via Labirinto 159 - 25125 BRESCIA - ITALYDocument12 pagesHorizontal Centrifugal Pump - According To Iso 2858: Chemical Pumps Via Labirinto 159 - 25125 BRESCIA - ITALYPankaj RaneNo ratings yet

- Comparison Between NFPA 497 and API RP 505 FiguresDocument13 pagesComparison Between NFPA 497 and API RP 505 Figuresmagh042011100% (2)

- Turbine Meter Data SheetDocument24 pagesTurbine Meter Data SheetehsanelahimirzaNo ratings yet

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- Syllabus TurbomachinesDocument10 pagesSyllabus Turbomachinesdinu098No ratings yet

- Lesson 1 ThermodynamicsDocument40 pagesLesson 1 ThermodynamicsRex OabelNo ratings yet

- A5-A3 Service ManualDocument400 pagesA5-A3 Service ManualNguyễn Văn DuyNo ratings yet

- Petroleum Reservoirs Production From Petroleum ReservoirsDocument13 pagesPetroleum Reservoirs Production From Petroleum ReservoirsMahmoud Ahmed Ali AbdelrazikNo ratings yet