Professional Documents

Culture Documents

Fixture Jig

Uploaded by

vino pooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixture Jig

Uploaded by

vino pooCopyright:

Available Formats

301119614

Project 1 – Assembly

Description Grade Comment

1 Assy Drg – 3 views, + Exploded 4

2 Production part clearly shown 4

3 Sandwich jig submitted 4

4 Clearance above part 3 Insufficient – See Unit on drill bushings.

5 Clearance under part 3 Cannot use bullet nose round pins as rest buttons.

6 Jig plate clamped 3 Hook clamps require back up. See Car Lane catalogue

7 Jig plate located 4

8 Part clamped 3 Hook clamps require back up. See Car Lane catalogue

Wrong side – see production part dwg. And

9 Part located – Long ref. Side 1

Content/Extras/Tolerance and Location

Wrong side – see production part dwg. And

10 Part located – Short ref, side 1

Content/Extras/Tolerance and Location

11 Part error proofed 0 Cannot identify any error proofing.

12 Modular construction 4

13 Drill Bushings correctly defined 2 Drill bushings are purchased parts, see rules

14 B.O.M. Exists 4

15 B.O.M. All parts Ballooned 4

1. 17Cr3 is a foreign (European) standard special steel. CRS

would be fine here. I doubt if you could purchase European

special steels easily in North America. If you must specify the

steel for this project AISI 1018 or 1020 would be a much better

16 B.O.M. All Manuf. parts I.D. & Mat'l 2

choice.

2. Many years ago I specified EN31 (a British high strength

alloy steel) and found out no one locally had any idea what it

was.

17 B.O.M. All Purch parts I.D. 4

18 B.O.M. All Quantities shown 4

19 B.O.M. Format correct/notes 4

20 General formatting – title block 3 See rules

Project 1 – Parts

Description Grade Comment

1 Misc. Manuf parts drawn if reqd 4

2 Purchased parts NOT drawn 4

3 All parts Det#,Qty,Mat'l on dwg 4 Locator Blocks

No need to specify chamfer on holes. Just add a note to

4 Manuf misc parts dimns 4

remove all sharp edges unless otherwise specified.

5 Manuf misc parts tolerances 0 See rules

6 Top plate Det#,Qty,Matl on dwg 4

7 Top plate dimns from ref. 0 See Content/Extras/Tolerances and Location.

8 Top plate other dimns 3 See example for dimension notes when using two round pins.

9 Top plate ref tols 0

10 Top plate other tols 0 See rules

11 Base plate Det#,Qty,Matl on dwg 4

12 Extrusions NOT used 4

13 Base plate dimn from ref. 0 See Content/Extras/Tolerances and Location.

See example for dimension notes when using two round pins to

14 Base plate other dimns. 3

locate top plate.

15 Base plate ref tols 0

16 Base plate other tols 0 See rules

0, 10, 20 ,30, 40 or 50 Penalty %

Grading scheme Grade

Non-compliant 0

25% compliance 1

50% compliance 2

75% compliance 3

100% compliance 4

Page 1

You might also like

- Engineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandEngineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4.5 out of 5 stars4.5/5 (3)

- Do-It-Yourself Gun Repair: Gunsmithing at HomeFrom EverandDo-It-Yourself Gun Repair: Gunsmithing at HomeRating: 2 out of 5 stars2/5 (1)

- 1362-Mould Design Verification ChecklistDocument6 pages1362-Mould Design Verification Checklistrajesh100% (1)

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- 2022 CPM Group Silver YearbookDocument277 pages2022 CPM Group Silver YearbookAnthony FloresNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Carpentry and Framing Inspection Notes: Up to CodeFrom EverandCarpentry and Framing Inspection Notes: Up to CodeRating: 5 out of 5 stars5/5 (1)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- List of Saudi Business Delegation - 1021 현재 -Document13 pagesList of Saudi Business Delegation - 1021 현재 -Daniel Pandapotan Marpaung100% (1)

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingSun Rise100% (1)

- Gear Manufacturing Process With QuestionsDocument60 pagesGear Manufacturing Process With QuestionsUjwala Sonawane100% (1)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Macro & Weld Symbol CSWIPDocument54 pagesMacro & Weld Symbol CSWIPSuryaprakashNo ratings yet

- A Brief Synopsis ofDocument54 pagesA Brief Synopsis ofpatel ketan100% (2)

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFketanNo ratings yet

- Handbook for Clerks of Works: Greater London Council Department of Architecture and Civic DesignFrom EverandHandbook for Clerks of Works: Greater London Council Department of Architecture and Civic DesignNo ratings yet

- FTF Handrail Catalogue PDFDocument16 pagesFTF Handrail Catalogue PDFlopezmedgarNo ratings yet

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoFrom EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoNo ratings yet

- Welder Visual Inspection HandbookDocument77 pagesWelder Visual Inspection HandbookfaizalzolNo ratings yet

- Jigs and Fixture Locating PrinciplesDocument89 pagesJigs and Fixture Locating Principlesvino pooNo ratings yet

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Compressor Inspection Report PLQDocument15 pagesCompressor Inspection Report PLQkhairul muzamil khairuddinNo ratings yet

- Mumbai Company DataDocument96 pagesMumbai Company DataMuskan ThakurNo ratings yet

- Optimum Tu2506v ManualDocument132 pagesOptimum Tu2506v Manualga6ba5No ratings yet

- CommentsDocument1 pageCommentsvino pooNo ratings yet

- Drill JigDocument1 pageDrill Jigvino pooNo ratings yet

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- Incoming Nozzle F5 2nd GheshmDocument18 pagesIncoming Nozzle F5 2nd GheshmAli Ramezani KhoozestaniNo ratings yet

- Printed in GermanyDocument11 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Incoming F5 2nd Shroud Segment 1401-01Document18 pagesIncoming F5 2nd Shroud Segment 1401-01Ali Ramezani KhoozestaniNo ratings yet

- DownloadDocument47 pagesDownloadGajanVashishth100% (1)

- JBMMA F PE 38 01 - Static Check FormatsDocument13 pagesJBMMA F PE 38 01 - Static Check FormatsTarang ShandilyaNo ratings yet

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 pagesReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingLimar SetstraNo ratings yet

- U BOP Manual Rev BDocument32 pagesU BOP Manual Rev BKapil AgarwalNo ratings yet

- Indian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Document15 pagesIndian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Pratap Singh GangwarNo ratings yet

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocument36 pagesHouston Impact of J-STD-001F and IPC-A-610F Changes安靖No ratings yet

- Vendor ReportDocument3 pagesVendor ReportSalman TamboliNo ratings yet

- S&T - Purlins and Girts Design GuideDocument26 pagesS&T - Purlins and Girts Design GuideJoshua NicholasNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- Appendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Document17 pagesAppendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Dino Andrian100% (1)

- Manual Feeder KPI 48x16Document16 pagesManual Feeder KPI 48x16deiberrbNo ratings yet

- Smaw 9 Q3 W2-3Document8 pagesSmaw 9 Q3 W2-3Words Wero MascarinasNo ratings yet

- Unit 1. Pattern Making: Question Bank Manufacturing Processes - I F.Y. B. Tech (Tpe)Document5 pagesUnit 1. Pattern Making: Question Bank Manufacturing Processes - I F.Y. B. Tech (Tpe)Sanket chavanNo ratings yet

- Chapter 13Document19 pagesChapter 13Naved AlamNo ratings yet

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFquiron2014No ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهSwift WardNo ratings yet

- Data Sheet For Line StopDocument7 pagesData Sheet For Line StopMathi Vinoth PillaiNo ratings yet

- FTF Handrail CatalogueDocument16 pagesFTF Handrail Catalogueparag7676No ratings yet

- Recommended Details Galvanized Steel Structures PDFDocument24 pagesRecommended Details Galvanized Steel Structures PDFPättan DansNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarNo ratings yet

- Procedure For Welder QualificationDocument28 pagesProcedure For Welder Qualificationjagannath100% (1)

- Lecture 3: Parts of Weld Joints and Welding SymbolDocument41 pagesLecture 3: Parts of Weld Joints and Welding SymbolNavneet KumarNo ratings yet

- Part ListDocument203 pagesPart Listangela ruizNo ratings yet

- DrawingDocument1 pageDrawingvino pooNo ratings yet

- Top PlateDocument1 pageTop Platevino pooNo ratings yet

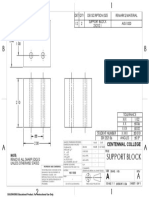

- Support BlockDocument1 pageSupport Blockvino pooNo ratings yet

- Tool DesignDocument8 pagesTool Designvino pooNo ratings yet

- Cutting Tool Part 1Document4 pagesCutting Tool Part 1vino pooNo ratings yet

- Cutting ToolDocument7 pagesCutting Toolvino pooNo ratings yet

- Tool EngineeringDocument5 pagesTool Engineeringvino pooNo ratings yet

- House SpecDocument6 pagesHouse SpecJuan CarlosNo ratings yet

- Bsen1011 3Document32 pagesBsen1011 3mohamed elmasryNo ratings yet

- Electrical and ElectronicDocument12 pagesElectrical and ElectronicAditya Shrivastava100% (1)

- MDF Hardboard Pinboard Standard MDF 2440mm X 1220mm X 9mm - N0705 - 856412 - TECH - 0Document13 pagesMDF Hardboard Pinboard Standard MDF 2440mm X 1220mm X 9mm - N0705 - 856412 - TECH - 0Adrian MartonNo ratings yet

- Precision Machine Tools QuizDocument3 pagesPrecision Machine Tools QuizkaluNo ratings yet

- Types of Lathe MachineDocument5 pagesTypes of Lathe MachineMD Mahmudul Hasan MasudNo ratings yet

- Methods of Test For Mortar For Masonry: BSI Standards PublicationDocument14 pagesMethods of Test For Mortar For Masonry: BSI Standards PublicationbihrajanNo ratings yet

- Material Data Sheet MDS - C21 Rev. 2Document3 pagesMaterial Data Sheet MDS - C21 Rev. 2Shakinah As SaadNo ratings yet

- 38CrSi DatasheetDocument3 pages38CrSi DatasheetKashif MohiuddinNo ratings yet

- May 2004 Board ExamDocument7 pagesMay 2004 Board ExamAndrei AlidoNo ratings yet

- Industrial Materials and Processes: Engr. Bingo B. Cueto, Msiem, Pie Industrial Engineering, LPULDocument31 pagesIndustrial Materials and Processes: Engr. Bingo B. Cueto, Msiem, Pie Industrial Engineering, LPUL湊崎エライザNo ratings yet

- GB-Mesutronic Fleischprospekt 20211126-WebDocument12 pagesGB-Mesutronic Fleischprospekt 20211126-Websuresh csNo ratings yet

- Brief Industrial Profile of Udaipur District: MSME - Development InstituteDocument25 pagesBrief Industrial Profile of Udaipur District: MSME - Development InstituteCarnival CooperationNo ratings yet

- Final YearprojectDocument63 pagesFinal Yearprojectjuber mullaNo ratings yet

- TENDER BOI VOL-2 - Nerul - 25-10-2012Document13 pagesTENDER BOI VOL-2 - Nerul - 25-10-2012Kareem SaberNo ratings yet

- l1 Section 1 Group eDocument12 pagesl1 Section 1 Group eNurul BalqishNo ratings yet

- Product Specification Sheet BELZONA 3412: General InformationDocument3 pagesProduct Specification Sheet BELZONA 3412: General InformationAjmi HmidaNo ratings yet

- Issued For Construction: Section A-A Anchor FlangeDocument1 pageIssued For Construction: Section A-A Anchor FlangeFahadNo ratings yet

- Environment Degradation of Materials - 1Document27 pagesEnvironment Degradation of Materials - 1NSHIMIYIMANA Jean d'AmourNo ratings yet

- 17-2 Material Types & FinishesDocument9 pages17-2 Material Types & FinishesZuberYousufNo ratings yet

- Scope of WorksDocument43 pagesScope of WorksbecpavanNo ratings yet

- Written TestDocument5 pagesWritten TestVanessa TuazonNo ratings yet

- SEC-I - Physics Workshop Skill Sample Questions With AnswersDocument20 pagesSEC-I - Physics Workshop Skill Sample Questions With AnswersMousam ChakraborttyNo ratings yet

- Oxidation and ReductionDocument21 pagesOxidation and ReductionKaroline UhlemannNo ratings yet

- SPECTRO Metal Database: ComprehensiveDocument2 pagesSPECTRO Metal Database: ComprehensivePeter GelburdNo ratings yet