Professional Documents

Culture Documents

Woven Fabric DefectsDefects in The Weft Direction

Woven Fabric DefectsDefects in The Weft Direction

Uploaded by

Arunachalam AnbusezhiyanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Woven Fabric DefectsDefects in The Weft Direction

Woven Fabric DefectsDefects in The Weft Direction

Uploaded by

Arunachalam AnbusezhiyanCopyright:

Available Formats

Best Quality of India Textiles Group WhatsApp & Telegram

Join in +91-9360634126 Only Message

Woven Fabric Defects/Defects in the Weft Direction

Short Definition and Consequences

Broken Pick/Cut Pick/ Filling Run out/Missing Pick

A broken yarn is partly picked and partly broken. This is where the

Best Quality of India Textiles Group WhatsApp & Telegram Join in +91-9360634126 Only Message

pick is missing for a porti- on of the width of the fabric and present

for only a part of the fabric width.

Double Pick

A disruption of the wave pattern similar in appearance to a thick pick

but where two yarns are in the same shed. This defect is

characterized by the presence of two picks in the same shed in a

plain weave fabric.

Dragged-in Weft/Jerked-in Weft/Lashed-in Weft/ Pulled-in Filling

An extra length of weft yarn has been inserted for a part of the fabric

width, usually starting from the selvedge. Extra weft yarn is tucked

into the selvedge of the fabric. Fabric woven with fly shuttle loom is

Best Quality of India Textiles Group WhatsApp & Telegram Join in +91-9360634126 Only Message

more likely to have this problem. Piece of weft yarn that has been

pulled into the shed from a subsequent pick.

Kinky Weft/Looped Yarn/ Weft Kinks

Exposed loops of weft yarn. Weft loop is protruding out from the

cloth surface. The yarn length in the loop is not sufficient to perform

snarling. These loops may protrude out from both sides of the fabric.

Weft loops are essentially caused by entanglements of threads in the

warp sheet between the reed and the fell of the cloth.

Mispick/Missing Pick/ Missing Weft Yarns

A bar across the fabric where no weft has been inserted.

Best Quality of India Textiles Group WhatsApp & Telegram

Best Quality of India Textiles Group WhatsApp & Telegram

Join in +91-9360634126 Only Message

Set Mark/Starting Place/ Starting Mark

A prominent band of greater or lower weft density that has a clearly

defined beginning and which gradually merges away to normal

fabric. This defect happens weftwise, it can also defined as “an

Best Quality of India Textiles Group WhatsApp & Telegram Join in +91-9360634126 Only Message

unevenness during beating-up of the weft”. This defect is difficult to

detect even counting the picks under the counting glass. The best

way to detect this fault is to view the fabric from as many angles as

possible

Slack Filling/Slack Pick/ Slack Weft

A weft yarn that appears slightly puckered in relation to the adjacent

weft yarns

Sloughed-off Weft

Several thicknesses of weft yarn appearing in the position intended

for one weft yarn for a limited width.

Tight filling/Tight Pick/ Tight Weft

A weft yarn which is under greater tension, or exhibits less crimp,

than the adjacent weft yarns. A single pick that is woven under

excessive tension.

Possible causes:

• This defect is often caused by a weft yarn breaking, running

Best Quality of India Textiles Group WhatsApp & Telegram Join in +91-9360634126 Only Message

out, or being prematurely released during insertion.

• Breaking or running out of a weft yarn.

• Weft yarn being prematurely released during insertion

• This defect is often caused by the insertion of two weft yarns

Best Quality of India Textiles Group WhatsApp & Telegram

Best Quality of India Textiles Group WhatsApp & Telegram

Join in +91-9360634126 Only Message

in the same shed when only one was intended.

Best Quality of India Textiles Group WhatsApp & Telegram Join in +91-9360634126 Only Message

• Starting loom is placed on incorrect pick after pick-out and

the loom is turned backward before starting

Best Quality of India Textiles Group WhatsApp & Telegram

You might also like

- Vineland Social Maturity Scale PDFDocument10 pagesVineland Social Maturity Scale PDFAmeera Chauhan100% (4)

- OnboardingDocument19 pagesOnboardingWilliamAllanGibson100% (4)

- Best Practice For Fabric InspectionDocument3 pagesBest Practice For Fabric InspectionvinayakasisNo ratings yet

- Landmark Group Company ProfileDocument2 pagesLandmark Group Company ProfileLeela JenniferNo ratings yet

- 12 Angry Men Study GuideDocument11 pages12 Angry Men Study GuideMatthew SuricoNo ratings yet

- Woven Fabric DefectsDefects in The Warp DirectionDocument3 pagesWoven Fabric DefectsDefects in The Warp DirectionArunachalam AnbusezhiyanNo ratings yet

- Fab DefectsDocument15 pagesFab DefectshirenNo ratings yet

- Fabric DefectsDocument27 pagesFabric Defectsniftchennai9067% (3)

- Fabric Quality Assessment Assignment - 1: National Institute of Fashion TechnologyDocument19 pagesFabric Quality Assessment Assignment - 1: National Institute of Fashion TechnologyAyushi ThakurNo ratings yet

- DefectsDocument31 pagesDefectsKawsar HamidNo ratings yet

- Fabric DefectsDocument25 pagesFabric DefectsNikhil SinghNo ratings yet

- ..Knitting Defects and Remedies..: Made By: Raisa GuptaDocument39 pages..Knitting Defects and Remedies..: Made By: Raisa Guptalovelife_gupta83% (6)

- Seam Puckering - Session1Document22 pagesSeam Puckering - Session1Mritunjay BhartiNo ratings yet

- 5 Categorization of Fabric Defects As Major, MinorDocument62 pages5 Categorization of Fabric Defects As Major, MinorAnkur Makhija100% (1)

- Seam PuckeringDocument16 pagesSeam PuckeringIshika100% (2)

- Shanto-Mariam University of Creative TechnologyDocument17 pagesShanto-Mariam University of Creative TechnologyMd JubayerNo ratings yet

- Common Faults in Weaving and Their Analysis and RemediesDocument8 pagesCommon Faults in Weaving and Their Analysis and RemediesManish KumarNo ratings yet

- Case Study On Weave Designs and Fabric Mechanical PropertiesDocument7 pagesCase Study On Weave Designs and Fabric Mechanical PropertiesSwati Sharma100% (1)

- 1) Count Variation: 2) Unevenness or Irregularity: 3) Frequently Occurring FaultsDocument40 pages1) Count Variation: 2) Unevenness or Irregularity: 3) Frequently Occurring FaultsshaifaliNo ratings yet

- Major Defects Found in Woven FabricDocument15 pagesMajor Defects Found in Woven FabricTuan Nguyen MinhNo ratings yet

- Fault ClassificationDocument1 pageFault ClassificationMd Rejaur RahmanNo ratings yet

- Faults in The Knitted FabricsDocument11 pagesFaults in The Knitted FabricsShwetaLoonkarPitliya100% (2)

- Fabric Inspection GuidelinesDocument18 pagesFabric Inspection GuidelinesMohammed Atiqul Hoque Chowdhury100% (2)

- Tezera Kassa Import and Export Company: Study OnDocument6 pagesTezera Kassa Import and Export Company: Study Onwubishet beleteNo ratings yet

- Broken EndsDocument2 pagesBroken EndsMuhammad AhmadNo ratings yet

- Home AssignmentDocument6 pagesHome Assignmentshero indiaNo ratings yet

- Fiber Article Part 2 May 07Document2 pagesFiber Article Part 2 May 07Charanu BabuNo ratings yet

- Seam PuckeringDocument4 pagesSeam PuckeringRavi Jain100% (1)

- WF Lecture 29 Quality ControlDocument3 pagesWF Lecture 29 Quality ControlAhmad SamerNo ratings yet

- ABUJEDIDDocument5 pagesABUJEDIDyenesew mulluNo ratings yet

- Ashraf Sir 2Document11 pagesAshraf Sir 2Moklesur RahmanNo ratings yet

- Defects in The Knitted Fabrics (Project)Document23 pagesDefects in The Knitted Fabrics (Project)Rana AhmedNo ratings yet

- Sewing Needles Used in Sewing MachineDocument6 pagesSewing Needles Used in Sewing MachineKhandaker Sakib Farhad100% (1)

- Defect Source 1Document16 pagesDefect Source 1Ramasubramaniam PalaniswamyNo ratings yet

- Knitting Defects and RemediesDocument13 pagesKnitting Defects and RemediesKomal ChauhanNo ratings yet

- WeaveDocument170 pagesWeavejyotiyugalNo ratings yet

- Types of Stitch Used in Garments SewingDocument10 pagesTypes of Stitch Used in Garments SewingMasudur RahmanNo ratings yet

- Selecting The Correct Sewing ThreadDocument5 pagesSelecting The Correct Sewing ThreaddieselakiasNo ratings yet

- Effect of Weaves On The Fabric PropertyDocument7 pagesEffect of Weaves On The Fabric Propertypuja_14100% (2)

- 4 225 WoolDocument2 pages4 225 Woolagga1111No ratings yet

- SelvedgeDocument16 pagesSelvedgejony_nsu022No ratings yet

- General Purpose ThreadDocument33 pagesGeneral Purpose ThreadShweta upariNo ratings yet

- Fabric DefectsDocument30 pagesFabric Defectsaparna_ftNo ratings yet

- Woven FabricDocument64 pagesWoven FabricSanghamitra Kalita100% (1)

- Chap 3Document17 pagesChap 3amanatbuttNo ratings yet

- Textile Material Knowledge SeriesDocument9 pagesTextile Material Knowledge SeriesSamy DagneNo ratings yet

- The Hole Problem in Knit GoodsDocument13 pagesThe Hole Problem in Knit GoodsKathirrveluSubramainanNo ratings yet

- Sewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerFrom EverandSewing Knits from Fit to Finish: Proven Methods for Conventional Machine and SergerRating: 4 out of 5 stars4/5 (3)

- Common Defects of FabricsDocument4 pagesCommon Defects of FabricsDeepika SandeepNo ratings yet

- Defects in The Knitted Fabrics (SGS Project)Document35 pagesDefects in The Knitted Fabrics (SGS Project)Manisha RaniNo ratings yet

- Preparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricDocument13 pagesPreparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricNaasonNo ratings yet

- WeaveDocument88 pagesWeavejyotiyugalNo ratings yet

- Type of WeavesDocument5 pagesType of WeavesSanket PatilNo ratings yet

- KnittingDocument50 pagesKnittingSanghamitra KalitaNo ratings yet

- Knitting TechnologyDocument31 pagesKnitting Technologyagga1111No ratings yet

- Fibre & FabricsDocument6 pagesFibre & FabricsVarun GuptaNo ratings yet

- Know Your Battings: Carry-along Reference Guide for Quilters and SewersFrom EverandKnow Your Battings: Carry-along Reference Guide for Quilters and SewersNo ratings yet

- Beginner's Guide to Crewelwork Embroidery: 33 Stitches and Techniques for CrewelworkFrom EverandBeginner's Guide to Crewelwork Embroidery: 33 Stitches and Techniques for CrewelworkRating: 5 out of 5 stars5/5 (3)

- Beginner's Guide to Goldwork Embroidery: Essential Stitches and Techniques for GoldworkFrom EverandBeginner's Guide to Goldwork Embroidery: Essential Stitches and Techniques for GoldworkRating: 4 out of 5 stars4/5 (1)

- Learning Decorative Stitches: the Art of Shirring and SmockingFrom EverandLearning Decorative Stitches: the Art of Shirring and SmockingRating: 2.5 out of 5 stars2.5/5 (2)

- Beginner's Guide to Hardanger Embroidery: 28 stitches and techniques for hardangerFrom EverandBeginner's Guide to Hardanger Embroidery: 28 stitches and techniques for hardangerNo ratings yet

- BATADocument11 pagesBATARamya BalanNo ratings yet

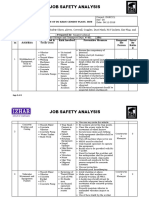

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- 5firefighter Personal Protective EquipmentDocument72 pages5firefighter Personal Protective Equipmentkk sNo ratings yet

- Packing Internal1 PDFDocument40 pagesPacking Internal1 PDFLamdNo ratings yet

- Hydrocolloid Recipe Collection v2.2 Screen ResDocument89 pagesHydrocolloid Recipe Collection v2.2 Screen ResJoão MartinsNo ratings yet

- Module 1 Engineering EconomyDocument13 pagesModule 1 Engineering EconomyZarah Astraea Longcob100% (3)

- Packaging of Fruits and VegetablesDocument2 pagesPackaging of Fruits and VegetablesDr.Eswara Reddy SiddareddyNo ratings yet

- Cake Mixing and BakingDocument4 pagesCake Mixing and BakingSenthil KumarNo ratings yet

- A. Match The Words With The Pictures:-: Learnenglish Kids Print and DoDocument1 pageA. Match The Words With The Pictures:-: Learnenglish Kids Print and DoOky DaysNo ratings yet

- Ap AmmanDocument2 pagesAp AmmanMircea HavaNo ratings yet

- ProfileDocument5 pagesProfileZhengXianLimNo ratings yet

- Toshiba Washing Machiane Aw8570sm PDFDocument20 pagesToshiba Washing Machiane Aw8570sm PDFtidchong prakoonmongkoneNo ratings yet

- Asian Paints PDFDocument36 pagesAsian Paints PDFPreeti AroraNo ratings yet

- Textile HistoryDocument23 pagesTextile Historyajabrao75% (4)

- Food and Beverage Service: Convention Management and Service Eighth Edition (478TXT or 478CIN)Document28 pagesFood and Beverage Service: Convention Management and Service Eighth Edition (478TXT or 478CIN)Jaiveer YadavNo ratings yet

- VOA Special English 5Document2 pagesVOA Special English 5halloweeNo ratings yet

- Let S Talk 1 2nd Edition Teacher S ManualDocument186 pagesLet S Talk 1 2nd Edition Teacher S ManualCao Thu HàNo ratings yet

- Western Electric No. 2 Sewing Machine Instruction ManualDocument44 pagesWestern Electric No. 2 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Upstream c1 Engl 11 16 PDFDocument14 pagesUpstream c1 Engl 11 16 PDFAdriana IliescuNo ratings yet

- Project A03 - ICPNADocument2 pagesProject A03 - ICPNACarlos Castañeda OkamuraNo ratings yet

- 6 - Bahasa Inggris - AbsDocument4 pages6 - Bahasa Inggris - Absguswahyu72No ratings yet

- Aeg Fav40750Document40 pagesAeg Fav40750gabi chisNo ratings yet

- Perfect HeartDocument4 pagesPerfect HeartRahaf AhmedNo ratings yet

- Kiosk Design CriteriaDocument11 pagesKiosk Design CriteriaTezinNo ratings yet

- Hazard Types Sprinklers and Pipe SizingDocument4 pagesHazard Types Sprinklers and Pipe SizingJayNo ratings yet

- Advise Given To Sahaj MothersDocument4 pagesAdvise Given To Sahaj MothersRita Dulanyi100% (1)