Professional Documents

Culture Documents

Inspection and Test Plan For Repair Procedure Patching Welded 42"-L-P1-1414A Line Tla Area

Inspection and Test Plan For Repair Procedure Patching Welded 42"-L-P1-1414A Line Tla Area

Uploaded by

Ferdie OSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Test Plan For Repair Procedure Patching Welded 42"-L-P1-1414A Line Tla Area

Inspection and Test Plan For Repair Procedure Patching Welded 42"-L-P1-1414A Line Tla Area

Uploaded by

Ferdie OSCopyright:

Available Formats

Legend :

Prepared By: Approved By: Verified By :

I - Information: Documents pertaining to the relevant task or stage must be transmitted to the

verifying party, solely for the purpose of information PTM PHM MIGAS

R-Review: Documents pertaining to the relevant specific task or stage must be transmitted to the

verifying party for review, before pursuing the execution process.

M-Monitoring: The verifying party attends the execution of the task, either continually or

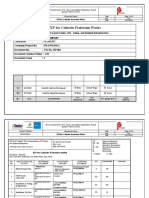

Document No. : ID-ALL-SNP-0102-520031 occasionally, as suitable for him/her

Client : PT PUTRA TUNGGAL MANDIRI W-Witness point: The verifying party must be notified in advance (to be defined beforehand) of the

Item No. : 7314668 execution of the relevant task or move on to the relevant stage. The absence of a verifying

Description : Repair Procedure Patching Welded 42"-L-P1-1404A TLA- authority does not suspend the continuation of the execution process.

Area - SENIPAH FIELD

H-Hold Point: The verifying party must be notified in advance (defined beforehand) of the execution

Date : 1 July 2023 of the task or move onto the relevant stage. The execution process is suspended (at a hold

Rev. : 0.0 point) in the event of absence of the verifying authority.

INSPECTION AND TEST PLAN FOR REPAIR PROCEDURE PATCHING WELDED 42"-L-P1-1414A LINE TLA AREA

NO. PROCESS DESCRIPTION INSPECTION ACTIVITIES CONTROL DOCUMENT CERTIFYING VERIFYING DOCUMENT DOCUMENT TO BE INCL, IN QA. DOSSIER

PTM SIGN PHM SIGN MIGAS SIGN

1.0 PRE-INSPECTION MEETING - Customer Specification - MOM - H H

2.0 PROCEDURE

2.1 Welding Procedures & Qualification WPS & PQR - WPS No. - WPS No : - WPS No : H R R

05/PTM/ASME/WPS/2013 05/PTM/ASME/WPS/2013 05/PTM/ASME/WPS/2013

- PQR No. : - PQR No. : - PQR No. :

05/PTM/ASME/PQR/2013 05/PTM/ASME/PQR/2013 05/PTM/ASME/PQR/2013

- ASME Section VIII Division I

- GS EP-PVV-211 Rev. 08 - WPQ - WPQ

- MHK-COMP-SPE-EP-PVV-0611 - Welding Map - Welding Map

2.2 Welder & Welding Operator Qualifications - WPQ ( Welder Performace qualification ) - WPQ ( Welder Performace qualification ) - WPQ ( Welder Performace qualification ) H R R

- Welder Certificate - Welder Certificate - Welder Certificate

2.3 Repair procedure - ASME Section IX - Welding Map - Welding Report H R

- ASME Section VIII Division I - Approved WPS - Approved WPS

- MHK-COMP-SPE-EP-PVV-0211 - Approved Drawing - Approved Drawing

- MHK-COMP-SPE-EP-PVV-0611

- MHK-COMP-SPE-EP-PVV-0171

2.4 Electrode handling procedure - Electrode Handling Procedure - ASME Section II Part A - Electrode Handling Report H W/R

- ASME Section II Part C - Electrode test certificate

- MHK-COMP-SPE-EP-PVV-0211 - Certificate Electrode

2.5 NDE procedure - ASME Section VIII Division I - ASME Section VIII Division I - NDE Report R R

- MHK-COMP-SPE-EP-PVV-611 - MHK-COMP-SPE-EP-PVV-0611

- ASME Section V - Welding & NDE Map - Welding & NDE Map

3.0 MATERIAL RECEIVING

3.1 Material Inspection & Verification - Welding Electrode Certificate - Material Test Report - Mill Certificate H W/R

- Material Certificates - MVR

Legend :

Prepared By: Approved By: Verified By :

I - Information: Documents pertaining to the relevant task or stage must be transmitted to the

verifying party, solely for the purpose of information PTM PHM MIGAS

R-Review: Documents pertaining to the relevant specific task or stage must be transmitted to the

verifying party for review, before pursuing the execution process.

M-Monitoring: The verifying party attends the execution of the task, either continually or

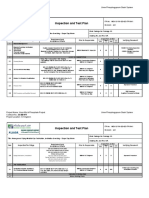

Document No. : ID-ALL-SNP-0102-520031 occasionally, as suitable for him/her

Client : PT PUTRA TUNGGAL MANDIRI W-Witness point: The verifying party must be notified in advance (to be defined beforehand) of the

Item No. : 7314668 execution of the relevant task or move on to the relevant stage. The absence of a verifying

Description : Repair Procedure Patching Welded 42"-L-P1-1404A TLA- authority does not suspend the continuation of the execution process.

Area - SENIPAH FIELD

H-Hold Point: The verifying party must be notified in advance (defined beforehand) of the execution

Date : 1 July 2023 of the task or move onto the relevant stage. The execution process is suspended (at a hold

Rev. : 0.0 point) in the event of absence of the verifying authority.

INSPECTION AND TEST PLAN FOR REPAIR PROCEDURE PATCHING WELDED 42"-L-P1-1414A LINE TLA AREA

NO. PROCESS DESCRIPTION INSPECTION ACTIVITIES CONTROL DOCUMENT CERTIFYING VERIFYING DOCUMENT DOCUMENT TO BE INCL, IN QA. DOSSIER

PTM SIGN PHM SIGN MIGAS SIGN

4.0 REPAIR PROCESS

4.1 Remove painting or coating by Wire brushes and grinding. Repair procedure patching welded 42"-L-P1-1414A line TLA area - Inspection Record - Inspection Record H R

After removed , surface shall be cleaned and free of the

4.2 Repair procedure patching welded 42"-L-P1-1414A line TLA area - Inspection Record - Inspection Record H W

scale, rust, oil, grease and other foreign matter.

Cutting pipe 42 ” Sch STD API 5L X65 with size Patching Type-

01 940x600x9 mm , Patching Type-02 3080x540x9 mm ,

Patching Type-03 600x180 mm , Patching Type-04 470x190

Repair procedure patching welded 42"-L-P1-1414A line TLA area Drawing

4.3 mm , Patching Type-05 1400x460x9 mm , Patching Type-06 - Inspection Record - Inspection Record H W

Approval

150x150x9 mm , Patching Type-07 300x170 mm , Patching

Type-08 350x470 mm , Patching Type-09 230x210 mm ,

Patching Type-10 1700x300 mm

After Cutting shall be checked measurement as per drawing

4.4 approved by CTR’s inspector and verified by CPY’s Repair procedure patching welded 42"-L-P1-1414A line TLA area - Inspection Record -I nspection Record H W

inspector.

Fit up and tack Weld Cut From Pipe 42 ” Sch STD API 5L X65

Repair procedure patching welded 42"-L-P1-1414A line TLA area Drawing

4.5 to Pipe 42”-L-P1-1404A as per drawing approved and - Inspection Record - Inspection Record H W

Approval

checked by CTR’s inspector and verified by CPY’s inspector.

Welding Cut from Cut From Pipe 42 ” Sch STD API 5L X65 to Repair procedure patching welded 42"-L-P1-1414A line TLA area WPS &

Pipe Existing 42”-L-P1-1404A by qualified welder , refer to PQR Welder

4.6 WPS No. 05/PTM/WPS/ASME/2013 & PQR No. Certificate - Inspection Record - Inspection Record H W

05/PTM/PQR/ASME/2013 and approved welding map and Drawing Approved

NDT Plan Welding Map and NDT Plan

After completion welding will be done cleaning and check

4.7 Repair procedure patching welded 42"-L-P1-1414A line TLA area - Inspection Record - Inspection Record H W

visual

Repair procedure patching welded 42"-L-P1-1414A line TLA area NDT

4.8 Final inspection with PT or MT - NDT Procedure - NDT Report H W/R

Procedure

5.0 TESTING & INSPECTION

- MHK-COMP-SPE-EP-PVV-0211 - MHK-COMP-SPE-EP-PVV-0211 visual Inspection Report

5.1 Visual & Final Dimension - MHK-COMP-SPE-EP-PVV-0611 - MHK-COMP-SPE-EP-PVV-0611 Dimension Inspection Report H W

- Drawing Approval - Drawing Approval

- Painting Procedure - Painting Procedure - Painting Inspection Report

5.2 Painting H W

- MHK-COMP-SPE-EP-COR-350 - Coating Application Report

6 REPORT AND RECORD

6.1 Final Documentation ( DOSSIER ) - Client Specification - MDR - MDR

Compile All Inpection Report / Record - Contract - All Relevant Dicipline Document - All Relevant Dicipline Document H M/R R

- Project Quality Plan - IRC - IRC

You might also like

- Dihr Gs 50 ManualDocument3 pagesDihr Gs 50 Manualfrancisco43% (7)

- ITP - Installation of Fiber Optic CablesDocument5 pagesITP - Installation of Fiber Optic CablesVasilica Barbarasa60% (5)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- EC145 FM - Refresher - POIDocument5 pagesEC145 FM - Refresher - POIHuda LestraNo ratings yet

- Site Inspection and Test Plan For Tie-In Works: Subcontrac TorDocument24 pagesSite Inspection and Test Plan For Tie-In Works: Subcontrac Torprabu palaniswamyNo ratings yet

- INFOSYS Quality Systems: Prepared byDocument22 pagesINFOSYS Quality Systems: Prepared byroshan_lizNo ratings yet

- KLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelDocument5 pagesKLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelRana AsifNo ratings yet

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDocument3 pagesInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNo ratings yet

- ITP For Pressure Vessel - Static EquipmentDocument8 pagesITP For Pressure Vessel - Static EquipmentReduddboyNo ratings yet

- Itp FGP 2Document21 pagesItp FGP 2fusionndtNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- ITP Modofication RF To RTJ BALL VALVE 6 INCH ID-BKP-SOME-2009-550318-P-BKP-19-001 - rev0.1-RSDocument2 pagesITP Modofication RF To RTJ BALL VALVE 6 INCH ID-BKP-SOME-2009-550318-P-BKP-19-001 - rev0.1-RSFerdie OSNo ratings yet

- Quality Assurance Plan - hd-99Document6 pagesQuality Assurance Plan - hd-99quality japtechNo ratings yet

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNo ratings yet

- 2005 S003 NBPG Rfi 04435Document1 page2005 S003 NBPG Rfi 04435RPDeshNo ratings yet

- QAP For FlangesDocument2 pagesQAP For FlangesGOPINATH KRISHNAN NAIRNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Inspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Document4 pagesInspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Delta akathehuskyNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- MD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFDocument11 pagesMD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFKarthikNo ratings yet

- 5 - PTJ-EL-ITP-005 Cathodic Protection Work Rev.c01Document3 pages5 - PTJ-EL-ITP-005 Cathodic Protection Work Rev.c01Ahmed NagyNo ratings yet

- ITP-3041 For PipeDocument8 pagesITP-3041 For PipeSkinhead TvNo ratings yet

- ITP - Erection Instalation and Testing of HDPE Piping - UGDocument10 pagesITP - Erection Instalation and Testing of HDPE Piping - UGVasilica BArbarasaNo ratings yet

- C1230D Intercooler SpecificationsDocument31 pagesC1230D Intercooler Specificationsprimeengineers444No ratings yet

- Inspection Test Plan For ElectricalDocument39 pagesInspection Test Plan For Electricalpire.resiNo ratings yet

- Itp Rotating ImipDocument2 pagesItp Rotating ImipHendra WidyantoroNo ratings yet

- H1006400MKF51 Sa12qt 01Document4 pagesH1006400MKF51 Sa12qt 01MarcoNo ratings yet

- Laporan Soil TestDocument11 pagesLaporan Soil TestMarvan Audy BurikoNo ratings yet

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Inspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice BoomDocument4 pagesInspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice Boomrizal mubarokNo ratings yet

- LREF-00-VDR-BBB-PR-20-0020-A4 Procedure For Process Piping Golden Joint Fabrication, Inspection, and Final AcceptanceDocument10 pagesLREF-00-VDR-BBB-PR-20-0020-A4 Procedure For Process Piping Golden Joint Fabrication, Inspection, and Final AcceptanceNauval Labiby Noor MohammadNo ratings yet

- Itp Piping WorksDocument7 pagesItp Piping WorksRudi EriantoNo ratings yet

- STFFD P1 004003 P05 0001 Rev C FAT Procedure For Complete Skid PDFDocument50 pagesSTFFD P1 004003 P05 0001 Rev C FAT Procedure For Complete Skid PDFSugeng WahyudiNo ratings yet

- Quality Assurance Plan For Api Pump (Qap)Document3 pagesQuality Assurance Plan For Api Pump (Qap)sanjay joshiNo ratings yet

- Inspection of Test Plan: Rotating EquipmentDocument7 pagesInspection of Test Plan: Rotating Equipmentzvlcar nainNo ratings yet

- NS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CDocument8 pagesNS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CAnh VàngNo ratings yet

- Mnt-Qa Qc-Itp-001 Inspection and Test PlanDocument3 pagesMnt-Qa Qc-Itp-001 Inspection and Test Plansivagnanam sNo ratings yet

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For ElectricalkhoerulNo ratings yet

- SATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFDocument2 pagesSATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFSabheeh AliNo ratings yet

- Inspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)Document2 pagesInspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)iwan NugrohoNo ratings yet

- Hot Tap Welding Procedure SpecificationDocument33 pagesHot Tap Welding Procedure SpecificationNeil JavierNo ratings yet

- PSP-ITP For Vibrating Screens ExciterDocument37 pagesPSP-ITP For Vibrating Screens ExciterMohammad AdilNo ratings yet

- ITP-ForkliftDocument30 pagesITP-Forkliftdafit herikson mNo ratings yet

- Inspection of Test Plan: Electrical EquipmentDocument7 pagesInspection of Test Plan: Electrical Equipmentzvlcar nainNo ratings yet

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- 474 ElbwDocument1 page474 ElbwMohammad MushtaqNo ratings yet

- DPK Filtration Skid 9com # One Time Approval: Inspection & Testing RequirementsDocument2 pagesDPK Filtration Skid 9com # One Time Approval: Inspection & Testing RequirementsVijay BhaleraoNo ratings yet

- Date & Time of Print: 22/02/2018 10:30:32 - Time Zone: Pakistan Time Buyer Organisation: Pakistan Petroleum LimitedDocument3 pagesDate & Time of Print: 22/02/2018 10:30:32 - Time Zone: Pakistan Time Buyer Organisation: Pakistan Petroleum LimitedShahbaz KhanNo ratings yet

- Duqm Refinery Project EPC Package OneDocument22 pagesDuqm Refinery Project EPC Package OnePrashant KumarNo ratings yet

- Inspection and Testing Plan (Itp) Item: Instruments Air PipingDocument9 pagesInspection and Testing Plan (Itp) Item: Instruments Air PipingNguyen DienNo ratings yet

- CEL-18663-UK-003-ITP01 - Rev-A1Document10 pagesCEL-18663-UK-003-ITP01 - Rev-A1TASNEEMNo ratings yet

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- 2.ITP Knuckle Boom-DikonversiDocument3 pages2.ITP Knuckle Boom-Dikonversidafit herikson mNo ratings yet

- Itp Page Copy-3.1Document1 pageItp Page Copy-3.1Deepu CNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For ElectricalTao BaoNo ratings yet

- Outotec: Danem Engineering Works WLL Doha - QatarDocument4 pagesOutotec: Danem Engineering Works WLL Doha - QatarRejoy babyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Aircraft Dispatcher Practical Test Standards (2024): FAA-S-8081-10EFrom EverandAircraft Dispatcher Practical Test Standards (2024): FAA-S-8081-10ENo ratings yet

- ITP Repair Patching Welded 20-DH-B1-2250A TLA AREA - SENIPAH FIELDDocument8 pagesITP Repair Patching Welded 20-DH-B1-2250A TLA AREA - SENIPAH FIELDArung IdNo ratings yet

- Daily Painting Report System P 01ndDocument49 pagesDaily Painting Report System P 01ndArung IdNo ratings yet

- Minutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Document13 pagesMinutes of Meeting: Bekapai-3 Surface Facilities Modification and Dogleg Installation (Epcic)Arung IdNo ratings yet

- Bend Test AceptenDocument1 pageBend Test AceptenArung IdNo ratings yet

- ID BKP SOME 2009 509035 P BKP 19 001 - Rev0.1 RSDocument3 pagesID BKP SOME 2009 509035 P BKP 19 001 - Rev0.1 RSArung IdNo ratings yet

- PIR-sensor-based Electronic Device Control With Ultra-Low Standby Power ConsumptionDocument6 pagesPIR-sensor-based Electronic Device Control With Ultra-Low Standby Power ConsumptionKeerthi KumarNo ratings yet

- Akamai Technologies: Group 13 A Arjun P Kottana B10013 Rana Md. Jamal B10043 Mayank Gupta B10028 Vibhu Mangla B10059Document24 pagesAkamai Technologies: Group 13 A Arjun P Kottana B10013 Rana Md. Jamal B10043 Mayank Gupta B10028 Vibhu Mangla B10059Rajat Goyal100% (2)

- Straight Prohibited or No EntryDocument12 pagesStraight Prohibited or No EntryKavi KumarNo ratings yet

- The Impact of Industry 4.0 On Supply Chains in Engineer-to-Order Industries - An Exploratory Case StudyDocument7 pagesThe Impact of Industry 4.0 On Supply Chains in Engineer-to-Order Industries - An Exploratory Case StudySidhi SoodNo ratings yet

- EMP Human IVD ProductsDocument10 pagesEMP Human IVD ProductsUrantuul dashNo ratings yet

- Computer Network Lesson PlanDocument3 pagesComputer Network Lesson PlansenthilvlNo ratings yet

- Maiwand Aslami, PMP: Work Experience SkillsDocument1 pageMaiwand Aslami, PMP: Work Experience SkillsFirdaus PanthakyNo ratings yet

- Nitish Kumar ResumeDocument1 pageNitish Kumar ResumebacardiblastwineNo ratings yet

- David James Ignacio - Label The MicroscopeDocument3 pagesDavid James Ignacio - Label The MicroscopeDavid James IgnacioNo ratings yet

- ECP 11-0008 LV Cable Testing ProcedureDocument9 pagesECP 11-0008 LV Cable Testing Procedurerobertovm2002No ratings yet

- Siemens Wire Harness Desing PDFDocument145 pagesSiemens Wire Harness Desing PDFYogessh PatiilNo ratings yet

- A Cloudy Crystal Ball - Visions of The FutureDocument5 pagesA Cloudy Crystal Ball - Visions of The FuturemercutNo ratings yet

- Optone 1100ASeriesDocument3 pagesOptone 1100ASeriesiman wahyudinNo ratings yet

- Test Bank Management System Applying Rasch Model and Data Encryption Standard (DES) AlgorithmDocument9 pagesTest Bank Management System Applying Rasch Model and Data Encryption Standard (DES) AlgorithmClarita MelisNo ratings yet

- SMC™ Dialog Plus Specifications: Additional ResourcesDocument14 pagesSMC™ Dialog Plus Specifications: Additional ResourcessimbamikeNo ratings yet

- SoftwareTutorial ZXT58Document17 pagesSoftwareTutorial ZXT58Luis Oscar Quispe ValeroNo ratings yet

- The Effectiveness of Online Marketing Strategies Such As Use of Social Media Applied On Food Microbusinesses in TaytayDocument9 pagesThe Effectiveness of Online Marketing Strategies Such As Use of Social Media Applied On Food Microbusinesses in TaytayEarl De LeonNo ratings yet

- GS112 2 PDFDocument25 pagesGS112 2 PDFGabriel Patruno100% (1)

- 4 Seminar Report After Index PDFDocument24 pages4 Seminar Report After Index PDFM. Sadiq. A. PachapuriNo ratings yet

- Hydraulic Elevators Basic ComponentsDocument16 pagesHydraulic Elevators Basic ComponentsIkhwan Nasir100% (2)

- Introduction To API 6A SpecificationDocument21 pagesIntroduction To API 6A SpecificationYovaraj KarunakaranNo ratings yet

- Do Not Print Digital Electronics PDFDocument122 pagesDo Not Print Digital Electronics PDFAngelicaNo ratings yet

- Came Corsa Install ManualDocument24 pagesCame Corsa Install ManualRyad Rajack0% (1)

- Va2016w 20 LCD MonitorDocument79 pagesVa2016w 20 LCD MonitorFABRI311No ratings yet

- Component List, Switches: Service InformationDocument4 pagesComponent List, Switches: Service InformationJozefNo ratings yet

- NCP Exam - Free Actual Q&as, Page 13 - ExamTopicsDocument3 pagesNCP Exam - Free Actual Q&as, Page 13 - ExamTopicsluckyNo ratings yet

- Command Pattern SlidesDocument11 pagesCommand Pattern SlidesAnca StoicaNo ratings yet