Professional Documents

Culture Documents

Issued For Construction: ZAIT Engineering Solutions Pty LTD

Uploaded by

AhmedBoutlyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Issued For Construction: ZAIT Engineering Solutions Pty LTD

Uploaded by

AhmedBoutlyCopyright:

Available Formats

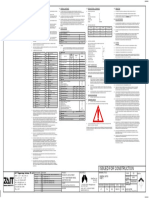

Regulated Design Record

12.0 CONCRETE 12.0 CONCRETE (CONTINUED) 13.0 REINFORCEMENT (CONTINUED) 14.0 POST TENSIONING

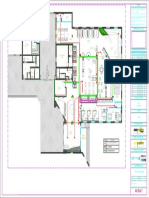

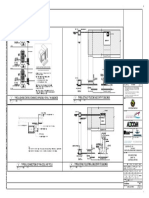

Project Address: 175-177 SHAFTSBURY ROAD, EASTWOOD, NSW

Project Title: RESIDENTIAL DEVELOPMENT 12.1. ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS 3600 CURRENT EDITION WITH 12.16. CONSTRUCTION SUPPORT PROPPING IS TO BE LEFT IN PLACE WHERE NEEDED TO AVOID OVERSTRESSING 14.1. THE PRESTRESS CONTRACTOR SHALL BE RESPONSIBLE FOR THE DESIGN, PREPARATION OF

AMENDMENTS, EXCEPT WHERE VARIED BY THE CONTRACT DOCUMENTS. THE STRUCTURE DUE TO CONSTRUCTION LOADING. NO MASONRY OR PARTITION WALLS ARE TO BE SINGLE BAR STRAIGHT LENGTH CONSTRUCTION DRAWINGS, SITE INSPECTIONS AND CERTIFICATION OF ALL ASPECTS OF THE WORKS.

Consent No: Body Corporate Reg No: CONSTRUCTED ON SUSPENDED LEVELS UNTIL ALL PROPPING IS REMOVED AND THE SLAB HAS ABSORBED BLOCKWALL - LAP LENGTH PAST END OF BEND FITMENTS

12.2. PRE-MIXED CONCRETE SUPPLY SHALL COMPLY WITH AS 1379 ITS DEAD LOAD DEFLECTION. 14.2. THE PRESTRESS CONTRACTOR SHALL PROVIDE THE FOLLOWING CERTIFICATES STATING COMPLIANCE

GENERAL NOTES

Drawing Title: SHEET 3 Drawing No: S103 HORIZONTAL 135° OR WITH THESE DOCUMENTS AND STRUCTURAL ADEQUACY TO ZAIT FOR:

12.3. NO ADMIXTURES SHALL BE USED IN CONCRETE UNLESS APPROVED IN WRITING. VERTICAL LAP BAR 90° COG

12.17. THE ENGINEER SHALL BE GIVEN 48 HOURS NOTICE FOR REINFORCEMENT INSPECTION AND CONCRETE LAP LENGTH 180° COG - DESIGN

Rev Date Description DP Full Name Reg No BAR LENGTH (mm)

SHALL NOT BE DELIVERED UNTIL FINAL APPROVAL OBTAINED. (mm) - CONSTRUCTION.

12.4. CONCRETE MIX DESIGNS TO BE SUBMITTED FOR REVIEW PRIOR TO USE OF CONCRETE.

dd.mm.yy N12 170 70

12.18. CONDUITS, PIPES, ETC. SHALL ONLY BE LOCATED IN THE MIDDLE THIRD OF THE SLAB DEPTH. PIPES OR 20 MPa 20 MPa 14.3. ALL WORKS SHALL BE IN ACCORDANCE WITH THE BUILDING CODE OF AS3600, THE DESIGN LOADS

C 11.08.2021 ISSUED FOR C.C. DAVID ZAITER DEP0000078 12.5. ENSURE CLEAR COVER TO REINFORCEMENT IS AS FOLLOWS UNLESS NOTED OTHERWISE. N16 200 70

CONDUITS SHALL NOT BE PLACED WITHIN THE COVER TO REINFORCEMENT. N12 625 675 SPECIFIED IN THESE DRAWINGS, THE FIRE RATINGS AND THE PROJECT SPECIFICATION. IF

01 26.04.2023 ISSUED FOR CONSTRUCTION DAVID ZAITER DEP0000078 COVER (mm) N20 250 80 CONTRADICTIONS EXIST THE MORE ONEROUS WILL GOVERN.

12.19. SLABS AND BEAMS SHALL BE CONSTRUCTED TO BEAR ONLY ON THE BEAMS, WALLS, COLUMNS, ETC. N16 925 1050

FORMED - NOT EXPOSED FORMED - EXPOSED TO NOT FORMED - CAST SHOWN ON THE DRAWINGS. ALL OTHER BUILDING ELEMENTS SHALL BE KEPT 30 mm MINIMUM CLEARANCE N24 300 100 14.4. THE PRESTRESS CONTRACTOR SHALL SUBMIT THE CONSTRUCTION DRAWINGS TO ZAIT FOR REVIEW AND

TO THE WEATHER THE WEATHER AGAINST THE GROUND FROM SOFFITS OF STRUCTURE. N20 1250 1450 COMMENT PRIOR TO CONSTRUCTION.

ELEMENT N28 350 120

B1 B2 WITHOUT NOTE:

WITH DAMP 12.20. TESTING OF CONCRETE SPECIMENS SHALL BE CARRIED OUT IN ACCORDANCE WITH AS1012, AS1379 AND 14.5. ANCHORAGE AND TENDON DESIGNATION:

(32 MPa (40 MPa DAMP THESE LAP LENGTHS ARE BASED ON THE N32 400 130

A1 A2 PROOF THE PROJECT SPECIFICATIONS.

MIN) MIN.) PROOF FOLLOWING MINIMUM CONCRETE COVER TO 14.5.1. ALL STRANDS SHALL BE 12.7mm OR 15.2mm NOMINAL DIAMETER SEVEN WIRE SUPER GRADE,

MEMBRANE N36 450 150

MEMBRANE 13.0 REINFORCEMENT REINFORCEMENT: STRESS RELIEVED, LOW RELAXATION TO AS4672.

PILES (mild) - - - - - 70 25 mm VERTICAL & 37 mm HORIZONTAL

13.1. REINFORCEMENT SYMBOLS: 14.5.2. MINIMUM BREAKING LOADS:

FOOTING - - - - 50 75 -184kN FOR 12.7mm TENDONS

SINGLE BAR -250kN FOR 15.2mm TENDONS

40 BOTTOM

SLAB ON GROUND 20 TOP 25 TOP 40 EXP 45 EXP

& SIDES

- TYPE DESCRIPTION STANDARD GRADE BEAM / BAND / SLAB / STAIR - DEVELOPMENT LENGTH (mm)

14.6. PLACING:

20 TOP N HOT ROLLED DEFORMED BAR AS 4671 D500N LESS THAN 300 mm CONCRETE CAST MORE THAN 300 mm CONCRETE CAST

40 BOTTOM 14.6.1. DIMENSIONS INDICATED ARE TO THE UNDERSIDE OF THE DUCT FROM THE SOFFIT OF THE SLAB

SUSPENDED SLAB 25 BOTTOM 25 40 45 - BELOW BAR BELOW BAR

& SIDES R HOT ROLLED PLAIN ROUND BAR AS 4671 R250N BAR EXCEPT AT THE ANCHORAGE, WHERE DIMENSIONS ARE TO THE CENTRELINE OF THE DUCT.

& SIDES

30 TOP 32 MPa 40 MPa 50 MPa 65 MPa 80 MPa 32 MPa 40 MPa 50 MPa 65 MPa 80 MPa DUCTS SHALL BE SUPPORTED AT 1000 mm MAXIMUM CENTRES TO A VERTICAL TOLERANCE OF ±

BAND & BEAM 40 BOTTOM 65 BOTTOM V HOT ROLLED PLAIN ROUND BAR AS 4671 R750N

2525 BOTTOM 40 45 5mm.

≥ 600 WIDTH & SIDES & SIDES S DEFORMED BAR (POOLS ONLY) AS 4671 D250N N12 375 350 350 350 350 475 475 475 475 475

& SIDES 14.6.2. THE DUCTS ARE TO BE GALVANIZED AND RIGID ENOUGH TO RETAIN THEIR SHAPE. JOINTS

25 TOP 30 TOP SL SQUARE MESH AS 4671 D500L N16 550 475 475 475 475 700 625 625 625 625 SHALL BE SECURELY TAPED TO PREVENT ENTRY OF SLURRY INTO DUCTS.

BEAMS 230 - 600 40 BOTTOM 65 BOTTOM

35 BOTTOM 35 BOTTOM 40 45

WIDTH & SIDES & SIDES RL RECTANGULAR MESH AS 4671 D500L N20 725 650 600 600 600 925 825 775 775 775 14.6.3. WHEREVER THERE IS A CONFLICT BETWEEN A TENDON AND ANY KIND OF CONDUIT OR

& SIDES & SIDES

L_TM TRENCH MESH AS 4671 D500L N24 900 800 700 700 700 1150 1025 925 925 925 REINFORCEMENT, THE TENDON PROFILE SHALL GOVERN. THE STATED TENDON SPACING IS

WALL 30 30 30 45 - - INDICATIVE ONLY, IN THE EVENT OF ANY CONSTRAINT TO THE POST-TENSIONING WORK, THE

COLUMN 40 40 40 45 - - RW COLD ROLLED RIBBED WIRE AS 4671 D500L N28 1075 975 850 825 825 1400 1250 1100 1075 1075 SPACING MAY BE ADJUSTED ACCORDINGLY TO SUIT THE SITE CONDITION. SUBJECT TO THE

W COLD DRAWN ROUND WIRE AS 4671 D500L N32 1275 1150 1000 950 950 1650 1475 1300 1225 1225 APPROVAL OF THE ENGINEER.

NOTES:

a. THE ABOVE COVERS ARE BASED ON: A 3RD PARTY PROCESSOR CERTIFICATION (ACRS OR EQUIVALENT) SHALL BE SUPPLIED N36 1500 1350 1175 1050 1050 1950 1725 1525 1375 1375 14.6.4. THE PRESTRESS CONTRACTOR SHALL BE RESPONSIBLE FOR THE PERFORMANCE OF THE

f'c = 32 MPa MIN TYPICAL WITH ALL STEEL REINFORCEMENT AT PROCUREMENT, BEFORE ANY CONCRETE IS PLACED ANCHORAGES AND SHALL SUPPLY ANY ADDITIONAL REINFORCEMENT CONSIDERED

PILE DURABILITY SEVERE NOTE:

NECESSARY.

FIRE RATING LEVEL 90/90/90 MIN THESE DEVELOPMENT LENGTHS ARE BASED ON THE FOLLOWING MINIMUM COVER TO

b. FOR SINGLE SPAN ONE WAY SLABS WITH EXPOSURE CLASSIFICATIONS A1 & A2, BOTTOM COVER 13.2. REINFORCEMENT NOTATION: REINFORCEMENT: SLABS AND STAIRS - GREATER OF 20 mm OR DIA OF BAR 14.6.5. FOLLOWING COMPLETED INSTALLATION OF ANCHORAGES AND TENDONS, CARE MUST BE

IS TO BE INCREASED TO 30 mm. 13.8. LAPPED SPLICES FOR BUNDLED BARS: TAKEN TO PREVENT DAMAGE OR MOVEMENT OF ANY OF THE COMPONENTS. PARTICULAR CARE

NUMBER OF BARS BAR DIAMETER (mm)

c. FOR FOOTING DESIGNS TO AS 2870 RESIDENTIAL SLABS AND FOOTINGS CONSTRUCTION, 3 - BAR BUNDLE, INCREASE THE ABOVE VALUES BY 20% (= *1.20) SHALL BE TAKEN DURING PLACING AND COMPACTING OF CONCRETE AROUND ANCHORAGES TO

THE COVER SHALL BE 40 mm FOR SURFACES CAST AGAINST GROUND, WITH OR WITHOUT DAMP 4 - BAR BUNDLE, INCREASE THE ABOVE VALUES BY 33% (= *1.33) ENSURE THAT FULL COMPACTION IS ACHIEVED AND THAT NO PART OF THE ANCHORAGE OR

PROOF MEMBRANE. 17N20-250 INDIVIDUAL BAR SPLICES WITHIN A GROUP SHALL NOT OVERLAP. TENDON OR THEIR ANCILLARIES ARE MOVED FROM ITS CORRECT POSITION.

d. SOME ELEMENTS MAY HAVE COVER WHICH VARIES FROM THE ABOVE TO AVOID CLASHES etc.

BAR GRADE BAR SPACING (mm) 14.7. STRESSING:

REFER DRAWINGS.

COVER SHOWN IS THE MINIMUM COVER TO ALL GROOVES AND CHAMFERS. MESH SHALL BE LAPPED SUCH THAT THE TWO OUTERMOST WIRES OF ONE SHEET OVERLAP THE TWO

THE FIGURES FOLLOWING THE FABRIC SYMBOL SL, RL AND TM IS THE REFERENCE NUMBER FOR FABRIC 14.7.1. THE END OF ALL STRANDS SHALL BE SPRAY-PAINTED (OR SIMILAR) 100 mm FROM THE

TO AS 4671. OUTERMOST WIRES OF THE OTHER SHEET BY 25mm MINIMUM. ANCHORAGE SO THAT THE EXTENSION CAN BE CLEARLY SEEN BY THE ENGINEER.

25 MIN

12.6. CONCRETE MIXES SHALL CONFORM TO THE FOLLOWING PERFORMANCE CRITERIA 13.3. REINFORCEMENT LAYERS ARE AS FOLLOWS: 14.7.2. JACKING LOADS:

LAYER (4) LAYER (3) 14.7.2.1. ALL 12.7mm STRANDS = 156kN (85% BREAKING LOAD)

CONCRETE MIX PERFORMANCE CRITERIA TABLE OVERLAP

LENGTH 14.7.2.2. ALL 15.2mm STRANDS = 212kN (85% BREAKING LOAD)

STRENGTH (MPa) TARGET SLUMP MAXIMUM A MAXIMUM OF THREE SHEETS OF MESH SHALL BE LAPPED AT ANY POINT. 14.7.3. STRESSING CYCLE AND CONCRETE STRENGTHS UNO:

U.N.O (mm) SHRINKAGE

MAXIMUM

CEMENT AT 56 DAYS

ELEMENT LOCATION AGGREGATE

TYPE (mm/mmx10 -6) DEVELOPMENT AGE OF CONCRETE STRENGTH STRESS PER

f'c AT f'c AT SIZE (mm) 13.9. BEND RADII: CYCLE

f'c AT 28 PRIOR TO (AS 1012 part LAYER (1) LAYER (2)

56 4 INITIAL LENGTH MIN. NUMBER CONCRETE (MPa) STRAND

DAYS PLACEMENT 12)

DAYS DAYS

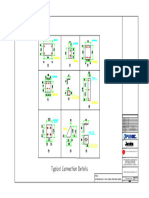

13.4. ALL REINFORCEMENT SHALL BE FIRMLY SUPPORTED ON MILD STEEL PLASTIC TIPPED CHAIRS, PLASTIC BEND AROUND

10x 1 24 HOURS f'cp = 7 25% TOTAL

PILES ALL 50 40 - - 150 SR 10 - CHAIRS OR CONCRETE CHAIRS AT NO GREATER THAN 1m CENTRES IN BOTH DIRECTIONS. BARS SHALL BE db 10db MANDREL,

TIED AT ALTERNATE INTERSECTIONS. IN EXPOSURE CONDITIONS GREATER THAN B1 USE ONLY PLASTIC TYPICAL 10x

FOOTING ALL 50 40 - - 80 GP 20 - db AT STRESSING

CHAIRS. 2 f'cp = 22 REMAINDER

(MIN 4 DAYS)

SLAB ON

ALL 40 32 - - 80 SL 20 650 13.5. REINFORCEMENT IS REPRESENTED DIAGRAMMATICALLY AND NOT NECESSARILY IN TRUE PROJECTION.

GROUND HAIRPINS Z BARS REFER FLOOR GENERAL

3 28 DAYS

SUSPENDED 13.6. SLAB REINFORCEMENT SHALL EXTEND AT LEAST 75mm ONTO SUPPORT WALLS AND 50 PERCENT OF ARRANGEMENT

SLAB AND ALL 50 40 22 - 80 SL 20 650 BOTTOM REINFORCEMENT SHALL BE COGGED TO ACHIEVE ANCHORAGE AT SIMPLY SUPPORTED ENDS.

R2

BEAM 5

N5 0-3x 14.7.4. STRANDS SHALL NOT BE CUT OFF OR TENDONS GROUTED UNTIL ZAIT APPROVES TENDON

13.7. SPLICES IN REINFORCEMENT SHALL BE MADE ONLY IN POSITIONS SHOWN OR OTHERWISE APPROVED IN 0 d

REFER V7 0-4xd b MA DEVELOPMENT

50- ELONGATIONS.

COLUMN ALL - DWG - - 120 SL 20 650 WRITING BY THE ENGINEER. LAPS SHALL BE IN ACCORDANCE WITH THE FOLLOWING: 7xd MA NDRE

b LENGTH MIN.

b M ND L

AN REL 14.8. GROUTING:

CORE AND REFER DR

ALL - - - 120 SL 20 650 EL

STAIR WALL DWG SINGLE BAR 10x

db 14.8.1. ANCHORAGE RECESSES ARE TO BE FILLED WITH APPROVED SAND EPOXY MORTAR AND

NOTES: BEAM / BAND / SLAB / STAIR - LAP LENGTH (mm) FITMENTS STARTER BARS FINISHED TO ARCHITECTS SPECIFICATION.

a. THE ABOVE COVERS ARE BASED ON:

f'c = 32 MPa MIN TYPICAL LESS THAN 300 mm CONCRETE CAST MORE THAN 300 mm CONCRETE CAST 14.8.2. TENDONS THAT ARE COUPLED TO ARE NOT TO BE GROUTED UNTIL THE SECOND TENDON HAS

BE BE BE

PILE DURABILITY SEVERE BELOW BAR BELOW BAR 5xd ND AR 5xd ND AR 5xd ND AR HAD ITS FINAL STRESS APPLIED.

FIRE RATING LEVEL 90/-/- MIN BAR b M OU b M OU b M OU

AN ND AN ND AN ND 14.8.3. ALL STRESSING DUCTS TO BE GROUTED. REFER PROJECT SPECIFICATION FOR GROUTING

b. FOR SINGLE SPAN ONE WAY SLABS WITH EXPOSURE CLASSIFICATIONS A1 & A2, BOTTOM 32 MPa 40 MPa 50 MPa 65 MPa 80 MPa 32 MPa 40 MPa 50 MPa 65 MPa 80 MPa DR DR DR

EL EL EL REQUIREMENTS.

COVER IS TO BE INCREASED TO 30 mm.

c. FOR FOOTING DESIGNS TO AS 2870 RESIDENTIAL SLABS AND FOOTINGS CONSTRUCTION N12 525 475 475 475 475 675 625 600 600 600

14.9. EXPOSED SLABS SHALL BE DESIGNED AS WATERTIGHT.

THE COVER SHALL BE 40 mm FOR SURFACES CAST AGAINST GROUND, WITH OR WITHOUT N16 775 700 625 625 625 1000 900 800 800 800

DAMP PROOF MEMBRANE. 180 DEG HOOKS 135 HOOKS COGS 14.10. TO LIMIT THE AMOUNT OF MOMENT TRANSFERRED TO COLUMN, THE FRAME ANALYSIS IS TO BE BASED ON

d. SOME ELEMENTS MAY HAVE COVER WHICH VARIES FROM THE ABOVE TO AVOID CLASHES etc. N20 1025 925 825 775 775 1325 1175 1075 975 975 25% OF COLUMN STIFFNESS FOR INTERNAL COLUMNS AND 0% OF COLUMN STIFFNESS FOR EXTERNAL

REFER DRAWINGS. 13.10. WELDING OF REINFORCEMENT SHALL NOT BE PERMITTED UNLESS SHOWN ON THE STRUCTURAL COLUMNS.

N24 1275 1125 1025 900 900 1625 1475 1325 1175 1175

COVER SHOWN IS THE MINIMUM COVER TO ALL GROOVES AND CHAMFERS. DRAWINGS OR APPROVED BY THE ENGINEER. WELDING SHALL BE IN ACCORDANCE WITH AS 1554.3

N28 1525 1375 1225 1075 1050 1975 1775 1575 1400 1350 14.11. PUNCHING SHEAR ANALYSIS SHALL BE BASED ON 100% OF COLUMN STIFFNESS.

13.11. JOGGLES TO BARS SHALL BE 1 BAR DIAMETER OVER A LENGTH OF 12 BAR DIAMETERS.

12.7. CONCRETE SIZES SHOWN DO NOT INCLUDE THICKNESSES OF APPLIED FINISHES. N32 1800 1625 1450 1275 1200 2325 2100 1875 1650 1550 14.12. TENDON LAYOUT IS TO BE CO-ORDINATED WITH THE FOLLOWING:

N36 2100 1900 1700 1500 1350 2725 2450 2200 1925 1750 13.12. WHERE TRANSVERSE TIE BARS ARE NOT SHOWN PROVIDE N12-300 SPLICED WHERE NECESSARY AND LAP

12.8. DEPTHS OF BEAMS ARE GIVEN FIRST AND INCLUDE SLAB THICKNESS. 14.12.1. THE CONSTRAINTS OF BALUSTRADE STANCHION POCKET LOCATIONS.

WITH MAIN BARS U.N.O.

NOTE:

12.9. FOR CHAMFERS, DRIP GROOVES, REGLETS, ETC., REFER TO ARCHITECTURAL DETAILS. MAINTAIN COVER 14.12.2. SERVICE PENETRATIONS AND PENETRATION COLLARS AS SHOWN ON SERVICES DRAWINGS.

THESE LAP LENGTHS ARE BASED ON THE FOLLOWING MINIMUM COVER TO REINFORCEMENT: 13.13. FOR CHEMICALLY ANCHORED REINFORCEMENT:

TO REINFORCEMENT AT THESE DETAILS.

SLABS AND STAIRS - GREATER OF 20 mm OR DIA OF BAR 14.12.3. EMBEDDED BALCONY DRAINAGE PIPEWORK.

13.13.1. REINFORCEMENT BARS SHALL BE 2-PART EPOXY ANCHORED INTO EXISTING CONCRETE WHERE

12.10. NO HOLES, CHASES OR EMBEDMENT OF PIPES OTHER THAN THOSE SHOWN ON THE STRUCTURAL

SHOWN ON DRAWING. 14.12.4. DRIP GROOVES.

DRAWINGS SHALL BE MADE IN CONCRETE MEMBERS WITHOUT THE PRIOR WRITTEN APPROVAL OF THE

ENGINEER. SINGLE BAR 13.13.2. SUITABLE EPOXY MORTAR SYSTEM SHALL BE ONE OF:

WALLS / COLUMNS - LAP LENGTH RAMSET CHEMSET 800 SERIES,

12.11. CONSTRUCTION JOINTS WHERE NOT SHOWN SHALL BE LOCATED TO THE APPROVAL OF THE ENGINEER.

CHEMSET REO502 OR

CONSTRUCTION JOINT SHALL BE PROPERLY FORMED AND USED ONLY WHERE SHOWN OR SPECIFICALLY

HILTI HIT RE-500.

APPROVED BY THE ENGINEER. ALL CONSTRUCTION JOINTS SHALL BE THOROUGHLY SCABBLED. VERTICAL LAP LENGTH (mm) HORIZONTAL LAP LENGTH (mm)

BAR 13.13.3. THE FOLLOWING HOLE DIAMETERS AND EMBEDMENT DEPTHS SHALL BE USED UNLESS NOTED

12.12. THE FINISHED CONCRETE SHALL BE A DENSE HOMOGENEOUS MASS, COMPLETELY FILLING THE

32 MPa 40 MPa 50 MPa 65 MPa 80 MPa 32 MPa 40 MPa 50 MPa 65 MPa 80 MPa ON THE DRAWINGS.

FORMWORK THOROUGHLY EMBEDDING THE REINFORCEMENT AND FREE OF STONE POCKETS. ALL

CONCRETE INCLUDING SLABS ON GROUND AND FOOTINGS SHALL BE COMPACTED WITH MECHANICAL BAR SIZE HOLE DIA HOLE DEPTH

VIBRATORS. N12 525 475 475 475 475 725 725 725 725 725

(N) (mm) (mm)

N16 775 700 625 625 625 950 950 950 950 950

12.13. THE MAXIMUM HEIGHT OF POUR FOR CONCRETE ELEMENTS SHALL BE 3.0m UNLESS METHOD OF

12 16

PLACEMENT HAS BEEN APPROVED BY THE ENGINEER. COLUMNS AND WALLS SHALL NOT BE POURED WITH N20 1025 925 825 775 775 1325 1200 1175 1175 1175

THE SLAB OVER. 16 22

N24 1275 1125 1025 900 900 1750 1550 1400 1400 1400 REFER DWGS

12.14. WHEN THE SHADE TEMPERATURE EXCEEDS 35°C, THE EXPOSED SURFACE OF CONCRETE SHALL BE 20 28

N28 1525 1375 1225 1075 1050 2175 1950 1750 1625 1625

SPRAYED WITH A FINE FILM OF APPROVED ALIPHATIC ALCOHOL DURING CONCRETE PLACEMENT AND 24 32

FINISHING IN ACCORDANCE WITH THE MANUFACTURER'S RECOMMENDATIONS. ENSURE ADEQUATE N32 1800 1625 1450 1275 1200 2675 2400 2150 1875 1850

SUPPLY OF ALIPHATIC ALCOHOL ON SITE BEFORE COMMENCING CONCRETE WORK. N36 2100 1900 1700 1500 1350 3200 2850 2550 2250 2075

13.13.4. EPOXY MORTAR GROUT SHALL BE MIXED AND THE BARS PLACED AND CURED STRICTLY IN

12.15. CURING OF CONCRETE SHALL COMMENCE WITHIN 2 HOURS OF FINISHING OPERATIONS AND SHALL BE NOTE: ACCORDANCE WITH THE MANUFACTURER'S SPECIFICATIONS.

MAINTAINED FOR A MINIMUM OF 7 DAYS USING AN APPROVED PROPRIETARY CURING COMPOUND IN THESE LAP LENGTHS ARE BASED ON THE FOLLOWING MINIMUM COVER TO REINFORCEMENT:

ACCORDANCE WITH AS3799 AND COMPATIBLE WITH THE PROPOSED FINISH OR CONTINUOUS PONDING WALLS - 30 + 12mm 13.13.5. ANCHOR TO BE INSTALLED AND TESTED TO AS 5216

WITH POTABLE WATER. THE CONTRACTOR TO SUBMIT PROPOSED CURING PROCEDURE FOR APPROVAL

OF THE ENGINEER.

ISSUED FOR CONSTRUCTION

ZAIT Engineering Solutions Pty Ltd DATE ISSUED REVISION: PROJECT: ARCHITECT: DRAWING TITLE: ISSUE: 01 NORTH:

30-11-19 A ISSUED FOR DRAFT AND COORDINATION RESIDENTIAL DEVELOPMENT

Suite 5, 5-7 Villiers Street, GENERAL NOTES DRAWING

07-04-20 B ISSUED FOR C.C. S103

Parramatta, NSW 2150 11-08-21 C ISSUED FOR C.C.

175-177 SHAFTSBURY ROAD, GHAZI AL ALI SHEET 3 NUMBER:

Phone: 02 9630 3087 26-04-23 01 ISSUED FOR CONSTRUCTION EASTWOOD, NSW ARCHITECTS JOB

NUMBER: 19DZ2093

PTY LTD

Email: info@zait.com.au CLIENT:

NSW reg. no. 7542

Engineering Solutions Pty Ltd ABN 40 608 862 899 Southern Star Property Holding Pty Ltd T, +612 9744 7035 E. office@ghazia.com DESIGNED: DRAWN: CHECKED: DATE: SCALE: APPROVED:

ACN: 67167131848

ACN 608 862 899

BUILDER: LEVEL 2 UNIT 2, 14 RAILWAY PARADE

Copyright BURWOOD NSW 2134 J.T. T.K. D.Z. NOV-19 1:100 DAVID ZAITER

BEng (Hons), MIEAust, CPEng NER RPEQ

You might also like

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- FORM No.: PCM-8.9.1 Consultant'S Review Form For Contractor'S Submittals Fahim, Nanji & Desouza (PVT.) LTDDocument4 pagesFORM No.: PCM-8.9.1 Consultant'S Review Form For Contractor'S Submittals Fahim, Nanji & Desouza (PVT.) LTDFahad NaveedNo ratings yet

- Warehouse 11,12,13Document26 pagesWarehouse 11,12,13Ibrahim FarhanNo ratings yet

- General Notes For RoadDocument2 pagesGeneral Notes For RoadEngr Sayyar Ahmad100% (1)

- DE008 of - Mechanical Yard Pier Reinforcement - Shop Drawings - Datum ReviewedDocument3 pagesDE008 of - Mechanical Yard Pier Reinforcement - Shop Drawings - Datum ReviewedAzeemuddin Gulam MohammedNo ratings yet

- 1tb01005-005c17-Hah-Xx-Xx-Sdw-Me-05005-C0-Projected Floor LoadingDocument2 pages1tb01005-005c17-Hah-Xx-Xx-Sdw-Me-05005-C0-Projected Floor LoadingMAZHAR ALINo ratings yet

- 04 Structural DrawingsDocument10 pages04 Structural DrawingszeipoibjasNo ratings yet

- Short BridgeDocument306 pagesShort BridgeChowdhury PriodeepNo ratings yet

- UAE045-801-IBD-HR3-H24A-GFL-SE-SDW-0424-02 - S SabuDocument1 pageUAE045-801-IBD-HR3-H24A-GFL-SE-SDW-0424-02 - S SabuMahmoud ElsmahyNo ratings yet

- Tunis MallDocument16 pagesTunis Mallعبدالمجيد اشرف عادل مجيدNo ratings yet

- Description S.NO.: Produced by An Autodesk Educational ProductDocument1 pageDescription S.NO.: Produced by An Autodesk Educational ProductAshar HassanNo ratings yet

- S020-General Notes (Sheet 1 of 3)Document1 pageS020-General Notes (Sheet 1 of 3)WNo ratings yet

- Final Construction PlansDocument12 pagesFinal Construction Plansapi-597427971No ratings yet

- Abs Tamm Ald Ab It 03Document1 pageAbs Tamm Ald Ab It 03fairoos aliNo ratings yet

- Proposed Residence at Panamanna Ground Floor Plan: Common Toilet 138 X 210Document1 pageProposed Residence at Panamanna Ground Floor Plan: Common Toilet 138 X 210NaufalMuhammedNo ratings yet

- Kamar MandiDocument4 pagesKamar MandiRafi RahmandaNo ratings yet

- Tyagi-Drainage and Ac LayoutDocument6 pagesTyagi-Drainage and Ac LayoutIbrahim FarhanNo ratings yet

- Plumbing and SanitaryDocument13 pagesPlumbing and SanitaryEllixerxes Channel100% (1)

- BAND 675 North RD - Mechanical IFC - 2023-11-15Document162 pagesBAND 675 North RD - Mechanical IFC - 2023-11-15Hakar Qadir GardiNo ratings yet

- 564SHJ22 01 Gym Av 101 3Document1 page564SHJ22 01 Gym Av 101 3IbrahimUnesNo ratings yet

- Pub TWRPPL C4 So-2Document1 pagePub TWRPPL C4 So-2Zhiqin LeeNo ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Manhole Cove 800Document1 pageManhole Cove 800Yosi AyuNo ratings yet

- Request For Proposals For Design-Build Services For Construction Package 4 Book I, Part C.5 Scope of Work-Scope Elements MatrixDocument7 pagesRequest For Proposals For Design-Build Services For Construction Package 4 Book I, Part C.5 Scope of Work-Scope Elements Matrixjackson michaelNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- AASHTO Standard Details - Folded Steel Plate Girder System - 2014Document20 pagesAASHTO Standard Details - Folded Steel Plate Girder System - 2014houstonhimselfNo ratings yet

- Legend: Proposed Addition To Existing Building TBC Client: DR Winsome RussellDocument17 pagesLegend: Proposed Addition To Existing Building TBC Client: DR Winsome RussellA.B. CbmNo ratings yet

- Arch Plans v2 (Approved)Document12 pagesArch Plans v2 (Approved)rabbetmrNo ratings yet

- D000-EL-701 Rev 4Document19 pagesD000-EL-701 Rev 4Sardar PerdawoodNo ratings yet

- Binder Latest GA 2020.01.13 PDFDocument30 pagesBinder Latest GA 2020.01.13 PDFABHINAY MUVVALANo ratings yet

- Emergency Rescue Plan Cgc082c07Document17 pagesEmergency Rescue Plan Cgc082c07sawkariqbal75% (4)

- Gen All e 0113 - 0Document1 pageGen All e 0113 - 0MadhankumarNo ratings yet

- Staircase Handrail Design Using StaadDocument20 pagesStaircase Handrail Design Using StaadSukhbir SinghNo ratings yet

- Nameplate Abbreviations Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-A Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-BDocument1 pageNameplate Abbreviations Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-A Nameplate Schedule 2 DWG. DD-950025 DETAIL 031-BBachir GeageaNo ratings yet

- MSCL-SEC-CIV-LAY-016 - Rev.0Document1 pageMSCL-SEC-CIV-LAY-016 - Rev.0Mohd Sami UddinNo ratings yet

- Equipment Schedule: A R Balce AssociatesDocument1 pageEquipment Schedule: A R Balce Associatestechnocyclesale1 engineerNo ratings yet

- MAT AC 004 Vibration IsolatorsDocument5 pagesMAT AC 004 Vibration IsolatorsSyed SalmanNo ratings yet

- 1 PDFDocument1 page1 PDFHayman AhmedNo ratings yet

- Column Layout Ground Floor: Container Roof-AtrushDocument1 pageColumn Layout Ground Floor: Container Roof-AtrushHayman AhmedNo ratings yet

- 1 PDFDocument1 page1 PDFHayman AhmedNo ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Original-Approved-Building-Plan 2 PDFDocument23 pagesOriginal-Approved-Building-Plan 2 PDFAndrew EllisonNo ratings yet

- Method - of - Statement - For Epoxy Painting Works For Wall and Soffits Rev-00Document34 pagesMethod - of - Statement - For Epoxy Painting Works For Wall and Soffits Rev-00Sher DilNo ratings yet

- 564SHJ22 01 Gym TC 101 1Document1 page564SHJ22 01 Gym TC 101 1IbrahimUnesNo ratings yet

- Material Requisition Approval Sheet: LG2-A5-MR-0093Document1 pageMaterial Requisition Approval Sheet: LG2-A5-MR-0093engmaar201037No ratings yet

- S0-04 - General NotesDocument1 pageS0-04 - General NotesJason toraldeNo ratings yet

- Ge200d0005 PDFDocument1 pageGe200d0005 PDFEdson HuertaNo ratings yet

- General Notes: Legends: Abbreviations:: Reference DrawingsDocument1 pageGeneral Notes: Legends: Abbreviations:: Reference DrawingsmuthuvelaaNo ratings yet

- BAST Jasa Curug MekarDocument41 pagesBAST Jasa Curug Mekarsurijanti447No ratings yet

- Drawing Index Vicinity Map General Construction Notes: Jobsite LocationDocument8 pagesDrawing Index Vicinity Map General Construction Notes: Jobsite LocationAndrew EllisonNo ratings yet

- PLUMBINGDocument5 pagesPLUMBINGKhalil AlluhaybiNo ratings yet

- DSI PS HDAR-GR 200 25nov19 092724Document19 pagesDSI PS HDAR-GR 200 25nov19 092724kobay101No ratings yet

- Daimler Trucks North AmericaDocument2 pagesDaimler Trucks North AmericaMiguel CardenasNo ratings yet

- Comments Resolution Sheet (CRS)Document27 pagesComments Resolution Sheet (CRS)Cyril J PadiyathNo ratings yet

- 3839 18-P1216po005-0073 0001 50Document3 pages3839 18-P1216po005-0073 0001 50avivekprasathNo ratings yet

- SOK0902357-0506087-AB04-B00-CS-CL-0004 - 0 - BH CommentsDocument17 pagesSOK0902357-0506087-AB04-B00-CS-CL-0004 - 0 - BH CommentsrohitNo ratings yet

- RCP LayoutDocument1 pageRCP LayoutAkosh AchuNo ratings yet

- Comparsion Sheet GROUTDocument1 pageComparsion Sheet GROUTmohammed rinshinNo ratings yet

- Causeway Stoving Zinc Phosphate Primer: Technical Data SheetDocument1 pageCauseway Stoving Zinc Phosphate Primer: Technical Data SheetYogan KilakshanNo ratings yet

- Unit 5Document42 pagesUnit 5ashok Pradhan0% (1)

- Installation Instructions Insulating Refractory Materials Revision 2 15-12-2010Document2 pagesInstallation Instructions Insulating Refractory Materials Revision 2 15-12-2010konstantasNo ratings yet

- Superheated Steam Drying Powerpoint FileDocument49 pagesSuperheated Steam Drying Powerpoint FileKevin YaptencoNo ratings yet

- Thermal CrackingDocument24 pagesThermal Crackingzubi0585No ratings yet

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Technical Data 2013: Description SafetyDocument1 pageTechnical Data 2013: Description SafetyGregorio Mata MartínezNo ratings yet

- Materials Today: Proceedings: N.H. Sabri, N.H.A. Rani, N.F. Mohamad, N.A.S. Mohd Muhsen, M.S. MD ZainiDocument8 pagesMaterials Today: Proceedings: N.H. Sabri, N.H.A. Rani, N.F. Mohamad, N.A.S. Mohd Muhsen, M.S. MD ZainiMuchammad AdriyanNo ratings yet

- M S D S - Caustic Soda PDFDocument5 pagesM S D S - Caustic Soda PDFHeru PrasetyoNo ratings yet

- Lecture 7.3 - SolidsDocument33 pagesLecture 7.3 - SolidsAdamNo ratings yet

- What Is Hydrocarbons?Document6 pagesWhat Is Hydrocarbons?Kathelyn Ruiz-SumandoNo ratings yet

- Chemistry Unit 4 NotesDocument16 pagesChemistry Unit 4 NotesBrandon TorcasioNo ratings yet

- Standard Specification For: Designation: B 6 - 06Document4 pagesStandard Specification For: Designation: B 6 - 06Thaiminh VoNo ratings yet

- 1) LSM Pavement LayersThickness DesignDocument1 page1) LSM Pavement LayersThickness DesignMahar Qasim LaliNo ratings yet

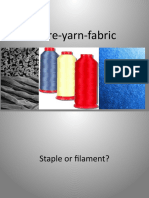

- Staple or Filament1Document29 pagesStaple or Filament1Vachan Abhilekh ThakurNo ratings yet

- About ReFlex™ Closed-Circuit Reverse Osmosis Tech FactDocument1 pageAbout ReFlex™ Closed-Circuit Reverse Osmosis Tech Factsamsu.hid2023No ratings yet

- Manual Injection MoldingDocument5 pagesManual Injection MoldingM. AhmadNo ratings yet

- Characterization of MaterialsDocument1 pageCharacterization of MaterialsSalem GarrabNo ratings yet

- 27 - 1 - Engineering Ceramics For ApplicationsDocument9 pages27 - 1 - Engineering Ceramics For ApplicationsMd. Rafiqul IslamNo ratings yet

- HERITAGE WORKS Canal and River TrustDocument60 pagesHERITAGE WORKS Canal and River TruststevemwilliamsNo ratings yet

- Introduction To Strain GaugesDocument32 pagesIntroduction To Strain GaugesManjunatha Babu N.s100% (1)

- HG ASTM ThermometersDocument4 pagesHG ASTM ThermometersmegacobNo ratings yet

- ESR 1056 Titen HeadDocument6 pagesESR 1056 Titen HeadSandeepNo ratings yet

- Tabel Berat 1Document22 pagesTabel Berat 1Mamat SubekanNo ratings yet

- Laundry Soap PDFDocument4 pagesLaundry Soap PDFAjay Prajapati100% (1)

- MetalsDocument16 pagesMetalsmhataNo ratings yet

- Chapter 1 Electric Charges and FieldsDocument22 pagesChapter 1 Electric Charges and FieldsSajjan BalasubramanyanNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- Top Civil Engineering Interview QuestionsDocument6 pagesTop Civil Engineering Interview QuestionsSaddaqatNo ratings yet

- Analysis and Design of SlabsDocument6 pagesAnalysis and Design of SlabsricardoNo ratings yet