Professional Documents

Culture Documents

Issued For Construction: ZAIT Engineering Solutions Pty LTD

Uploaded by

AhmedBoutlyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Issued For Construction: ZAIT Engineering Solutions Pty LTD

Uploaded by

AhmedBoutlyCopyright:

Available Formats

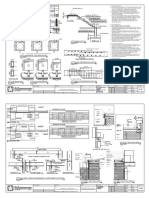

15.0 MASONRY 16.0 STRUCTURAL STEEL 16.0 STRUCTURAL STEEL (CONTINUED) 19.

0 CONSTRUCTION TOLERANCES

Regulated Design Record

16.19. WHERE MASONRY ANCHORS ARE SHOWN, THE SIZE REFERS TO THE STUD THREAD DIAMETER.

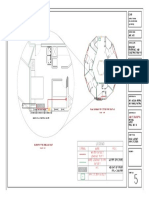

Project Address: 175-177 SHAFTSBURY ROAD, EASTWOOD, NSW 15.1. ALL WORKMANSHIP AND MATERIALS SHALL COMPLY WITH AS3700, AS2699, AS4773.1 and AS4773.2 AND 16.1. ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS 4100, AS 1554.1, AS 1554.2, AS AS 19.1. ALL STRUCTURAL ELEMENTS SHALL BE CONSTRUCTED IN ACCORDANCE WITH THE AUSTRALIAN

16.20. WHERE THE FABRICATOR PROVIDES A SPLICE FOR AN APPROVED REASON (EG. TRANSPORTATION) THE

OTHER RELEVANT AUSTRALIAN STANDARDS. 1554.3, AS 1554.4, AS 1554.6 AS 1554.7 EXCEPT WHERE VARIED BY THE CONTRACT DOCUMENTS. STANDARD TOLERANCES. (TIGHTER TOLERANCES MAY BE REQUIRED FOR SERVICEABILITY OR

Project Title: RESIDENTIAL DEVELOPMENT SPLICE SHALL BE COMPLETE PENETRATION BUTT WELDED (CATEGORY SP) AND TESTED AS SPECIFIED. AESTHETICS)

15.2. MINIMUM DURABILITY REQUIREMENTS: 16.2. UNLESS NOTED OTHERWISE, ALL STEEL COMPONENTS SHALL BE IN ACCORDANCE WITH THE FOLLOWING 16.21. WELDING IS TO BE EXAMINED BY AN INDEPENDENT TESTING AUTHORITY. TEST RESULTS ARE TO BE

Consent No: Body Corporate Reg No: TABLE: SUBMITTED FOR APPROVAL. 19.2. TOLERANCES SCHEDULE

GENERAL NOTES DURABILITY

Drawing Title: SHEET 4 Drawing No: S104 SALT ATTACK

CLASS OF WALL PILING

RESISTANCE COMPONENT AS GRADE EXTENT (% OF

LOCATION MORTAR CLASS TIES AND TYPE OF WELD EXAMINATION

Rev Date Description DP Full Name Reg No GRADE OF TOTAL LENGTH OF

BUILT-IN AND CATEGORY METHOD CRITERIA MAX PERMISSIBLE DEVIATION

dd.mm.yy MASONRY UNIT WELD TYPE)

COMPONENTS HOT ROLLED SECTIONS 3679 300

C 11.08.2021 ISSUED FOR C.C. DAVID ZAITER DEP0000078 FILLET VISUAL 100 POSITION IN PLAN 75mm ANY DIRECTION

GENERAL WELDED BEAMS & COLUMNS 3679 300

01 26.04.2023 ISSUED FOR CONSTRUCTION DAVID ZAITER DEP0000078 INTERIOR MASONRY M3 R3

PURPOSE VISUAL 100 VERTICALITY 1.0 PERCENT (%) OF HEIGHT OF THE PILE

CHS 1074.1 250

BUTT FULL

EXTERIOR MASONRY ABOVE GENERAL CHS 1163 C350 PENETRATION ULTRASONIC OR CUT-OFF LEVEL +10mm, -25mm

M3 R3 50

DAMP PROOF COURSE PURPOSE RADIOGRAPHIC

RHS & SHS 1163 C350

BELOW DAMP PROOF OR IN FLAT BARS & RODS 3679 300 SITE FILLET VISUAL 100

EXPOSURE M4 R4 CONCRETE MEMBERS

CONTACT WITH GROUND VISUAL 100

PLATE 3678 250

SITE BUTT FULL CRITERIA MAX PERMISSIBLE DEVIATION

PURLINS & GIRTS AS BELOW ULTRASONIC OR

SEVERE MARINE EXPOSURE M4 R4 PENETRATION 50

1.0 mm BMT G550 RADIOGRAPHIC POSITION IN PLAN +/- 15mm

1397

FACADE DESIGNER SHALL CONFIRM DURABILITY CLASS AND CORROSIVITY CATEGORY 1.2 mm BMT & 4600 G550 POSITION IN ELEVATION +/- 10mm

16.22. FIRE PROTECTION TO ALL STEEL ELEMENTS SHALL BE IN ACCORDANCE WITH THE BCA AND FIRE

1.5, 1.9, 2,4, AND 3.0 mm BMT G450 ENGINEER ’ S REQUIREMENTS FOR THE NECESSARY FIRE RESISTANCE PERIOD FOR STRUCTURAL STOREY PLUMBNESS MAXIMUM OF +/- 10mm AND HEIGHT/200

15.3. PROVIDE TEMPORARY PROPPING TO WALLS AS REQUIRED TO MAINTAIN STABILITY DURING ADEQUACY.

CONSTRUCTION, INCLUDING THE DESIGN OF NEEDLING WHERE REQUIRED. 16.23. ALLOWANCE SHALL BE MADE FOR PRECAMBER OF TYPICAL FLOOR BEAMS. MAGNITUDE OF PRECAMBER DIMENSION MAXIMUM OF +/- 5mm AND HEIGHT/200

16.3. TWO (2) COPIES OF WORKSHOP FABRICATION DRAWINGS SHALL BE SUBMITTED TO THE ENGINEER FOR

15.4. OBTAIN ENGINEER'S APPROVAL BEFORE COMMENCING MASONRY WALLS ON SUSPENDED SLABS. TO BE CONFIRMED IN DETAILED DESIGN. SURFACE ALIGNMENT LENGTH / 250

REVIEW AT LEAST 7 DAYS PRIOR TO COMMENCEMENT OF FABRICATION. FABRICATION IS NOT TO

MASONRY WALLS MUST NOT BE BUILT ON PROPPED SLABS. COMMENCE WITHOUT ENGINEER'S APPROVAL OF WORKSHOP DRAWINGS. ALL DIMENSIONS AND SETOUTS

15.5. NO STACKED OR MASONRY IN PALLETS TO BE PLACED ON SUSPENDED FLOORS WITHOUT PROPPING TO TO BE OBTAINED FROM ARCHITECTURAL DRAWINGS WHERE NOT INDICATED ON STRUCTURAL DRAWINGS. 17.0 PURLINS:

FORMWORK ENGINEER'S APPROVAL. 17.1. ALL PURLINS, GIRTS AND BRIDGING SHALL BE EITHER LYSAGHT OR STRAMIT. MASONRY MEMBERS

16.4. BOLT CATEGORIES AS SHOWN ON THE DRAWINGS:

15.6. CUTTING AND CHASING OF MASONRY WALLS IN NOT PERMITTED WITHOUT PRIOR APPROVAL OF THE 17.2. ALL SECTIONS SHALL BE PRODUCED FROM GALVANISED STEEL TO AS1397 AND DESIGNED IN CRITERIA MAX PERMISSIBLE DEVIATION

ENGINEER. BOLT ACCORDANCE WITH AS4600.

DESCRIPTION POSITION IN PLAN +/- 15mm

CATEGORIES 17.3. THE PURLINS AND GIRTS SHALL HAVE A MINIMUM ZINC COATING MASS OF 350 g/sqm (Z350)UNLESS NOTED

15.7. IN PARTICULAR HORIZONTAL CUTTING AND CHASING OF LOAD BEARING EXTRUDED BRICKS IS NOT

PERMITTED. OTHERWISE, THE FIXING OF PURLINS, GIRTS, BRIDGING, SHEETING AND ANY OTHER COMPONENT SHALL POSITION IN ELEVATION +/- 10mm

4.6/S COMMERCIAL BOLTS OF GRADE 4.6 TO AS 1111 SNUG TIGHTENED. BE IN ACCORDANCE WITH THE MANUFACTURER'S SPECIFICATION AND RECOMMENDATIONS.

15.8. PROVIDE WATERPROOFING AND DRAINAGE TO BACK OF WALLS AS REQUIRED IN ACCORDANCE WITH MINIMUM OF +/- 10MM / 3M AND 5

17.4. BRIDGING TO ALL PURLINS SHALL BE DESIGNED AND ERECTED IN ACCORDANCE WITH THE STOREY PLUMBNESS PERCENT (%) OF THE WALL THICKNESS

ARCHITECT'S SPECIFICATION. BACKFILL RETAINING WALLS AFTER OBTAINING ENGINEER'S APPROVAL,

WITH CLEAN GRANULAR FILL, FREE FROM CLAY AND OTHER ORGANIC MATTER. MANUFACTURER'S REQUIREMENTS. ROD BRIDGING SHALL NOT BE USED UNLESS APPROVED BY THE

8.8/S HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS 1252 SNUG TIGHTENED. BUILDING PLUMBNESS +/- 25mm

ENGINEER IN WRITING.

15.9. ALL OPENINGS IN MASONRY ARE TO BE ADEQUATELY SUPPORTED BY EITHER REINFORCED MASONRY OR 17.5. SHEETING / CLADDING SHALL BE SCREW FIXED TO THE PURLINS / GIRTS TO PROVIDE LATERAL RESTRAINT

STEEL LINTELS. HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS 1252 FULLY TENSIONED TO THE PURLIN / GIRTS IN ACCORDANCE WITH THE MANUFACTURER'S REQUIREMENTS.

8.8/TB

15.10. MINIMUM STRENGTH REQUIREMENTS:

TO AS 4100 AS BEARING TYPE JOINT. 17.6. PROVIDE DOUBLE PURLINS AT EXPANSION JOINTS IN ROOF SHEETING. 20.0 TIMBER FRAMING NOTES

17.7. FOR BRIDGING MEMBERS TO PURLINS AT CURVED ROOF AREAS, PROVIDE BRIDGING SUITABLE FOR

HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS 1252 FULLY TENSIONED CURVED ROOFS IN ACCORDANCE WITH THE MANUFACTURER'S REQUIREMENTS. 20.1. ALL DESIGN, WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH THE FOLLOWING

STRENGTH OF 8.8/TF

WALL TYPE MORTAR CLASS # TO AS 4100 AS A FRICTION TYPE JOINT WITH FACING SURFACES LEFT UNCOATED. AUSTRALIAN STANDARDS AS APPLICABLE AS1748, AS2858, AS2082, AS1720, AS1684, AS1604 AND IN

MASONRY UNIT

17.8. PURLINS / GIRT SIZES SHOWN ARE BASED ON: ADDITION COMPLY WITH THE 'TIMBER MARKETING ACT 1977 NSW'. AS 1684 SHALL BE APPLIED TO

CLAY BRICKWORK f'uc = 20 MPa M3 17.8.1. THE CURRENT STRAMIT PURLINS AND GIRTS DESIGN DATA, OR DOMESTIC CONSTRUCTION (CLASS 1).

16.5. UNLESS NOTED OTHERWISE: 17.8.2. THE CURRENT BLUESCOPE LYSAGHT DESIGN DATA, INCLUDING RESTRAINT FROM ROOF

CONCRETE BLOCKWORK (UNREINF) f'uc = 15 MPa M3 20.2. ALL STRUCTURAL TIMBER SHALL BE OF STRESS GRADE AS INDICATED ON THE DRAWINGS.

ALL PLATES TO BE 10 mm THICK MINIMUM, WELDED ALL ROUND. SHEETING AND BRIDGING

CONCRETE BLOCKWORK (REINF) f'uc = 15 MPa M4 ALL BOLTS SHALL BE M20 CATEGORY 8.8/S. 17.9. PURLIN CLEATS SHALL BE IN ACCORDANCE WITH THE MANUFACTURER'S DETAILS. WHERE THE DISTANCE 20.3. ALL TIMBER USED SHALL HAVE BEEN STRESS GRADED BY VISUAL OR MECHANICAL MEANS IN

ALL HOLDING DOWN BOLTS SHALL BE M20 CATEGORY 4.6/S. BETWEEN THE BOTTOM FLANGE OF THE PURLIN AND THE RAFTERS IS GREATER THAN 100mm, USE ACCORDANCE WITH THE APPROPRIATE AUSTRALIAN STANDARDS.

# UNLESS A HIGHER CLASSIFICATION IS REQUIRED FOR DURABILITY. ALL BOLTS, NUTS AND WASHERS SHALL BE HOT DIPPED GALVANISED.

75x75x8.0 EA CLEATS. 20.4. ALL VISIBLE STRUCTURAL TIMBER SPECIFIED SHALL BE COATED WITH CLEAR OR TRANSPARENT STAIN

ALL CONNECTIONS SHALL HAVE A MINIMUM OF 2 BOLTS.

15.11. PROVIDE VERTICAL CONTROL JOINTS IN MASONRY WALLS AS FOLLOWS: 17.10. PROVIDE 75x75x3.0 GALVANISED ANGLE TRIMMERS TO SUPPORT ROOF SHEETING EDGES AT ALL HIPS, FINISH AND SHALL COMPLY WITH THE APPEARANCE GRADE SPECIFIED IN THE RELEVANT AUSTRALIAN

16.6. /TB AND /TF BOLTS TO BE INSTALLED IN ACCORDANCE WITH SECTION 15 OF AS 4100, USING EITHER THE VALLEYS AND ANGLED SHEET EDGES. FIX TO EACH PURLIN WITH ONE No. 14 TEK SCREW. STANDARD OR SHALL BE PAINTED AS SPECIFIED FOR THE PROJECT.

PART-TURN METHOD OR THE DIRECT-TENSION INDICATOR METHOD. FOR TYPE /TF BOLTS, ALL CONTACT

MAX JOINT 17.11. PURLINS SHALL BE LAPPED IN ACCORDANCE WITH MANUFACTURER'S RECOMMENDATIONS.

WALL TYPE JOINT WIDTH SURFACES ARE TO REMAIN UNPAINTED. 20.5. ALL SOFTWOOD SHALL BE SEASONED TIMBER HAVING A MOISTURE CONTENT RANGE 10% < M.C. < 15% IF

SPACING REQUIRED BY THE SUPERINTENDENT, EVIDENCE OF THE TIMBERS MOISTURE CONTENT SHALL BE

17.12. ALL PURLINS AND GIRTS SHALL BE MANUFACTURED FROM GRADE 450 STEEL OR HIGHER AND

16.7. ALL FABRICATION SHALL COMPLY WITH AS 4100, SECTION 14. GALVANISED PROVIDED BY THE SUPPLIER.

CLAY BRICKWORK 15 mm 8m

TO A MINIMUM AVERAGE THICKNESS OF 350g/m² UNLESS NOTED OTHERWISE.

CONCRETE BLOCKWORK (UNREINF) 10 mm 8m 16.8. ALL ERECTION SHALL COMPLY WITH AS 4100, SECTION 15. 20.6. ALL TIMBERS EXPOSED TO VIEW EXTERNALLY SHALL BE DRESSED UNLESS SPECIFIED OTHERWISE. WHEN

17.13. THE PURLIN SETOUT SHOWN ON DESIGN DOCUMENTS IS INDICATIVE ONLY. SHOP DRAWINGS ARE TO

SPECIFIED TO BE SAWN FINISHED ALL EXPOSED CORNERS SHALL BE ARRISSED.

AT CORNERS, CONTROL JOINTS SHALL BE WITHIN HALF THE SPECIFIED JOINT 16.9. UNLESS NOTED OTHERWISE, WELDS SHALL BE: CONFIRM THE ACTUAL NUMBER OF PURLINS REQUIRED. REFER TO THE ARCHITECTURAL DOCUMENTATION

SPACING FROM THE CORNER. JOINTS SHALL BE SEALED WITH AN APPROVED FOR ADDITIONAL PURLINS/GIRTS REQUIRED TO SUPPORT FLASHING, GUTTERS AND OTHER 20.7. TIMBER SHALL BE HANDLED AND STORED SO AS NOT TO OVERSTRESS THE MEMBERS AT ANY TIME.

FLEXIBLE SEALANT. TESTING NON-STRUCTURAL ITEMS. TIMBER DELIVERED TO THE SITE SHALL BE STORED AT A LEVEL NOT LESS THAN 150mm OFF THE GROUND,

PROVIDE JOINTS TO MATCH JOINTS IN SUPPORTING SLABS. WELD DESCRIPTION CATEGORY ELECTRODE EVENLY SUPPORTED, WELL VENTILATED AND PROTECTED FROM THE ELEMENTS.

TO AS1554.1 17.14. UNLESS NOTED OTHERWISE OR REQUIRED BY THE MANUFACTURER, LAPS SHOWN ON DRAWINGS SHALL

FOR RESIDENTIAL SLABS ON GRADE PROVIDE ARTICULATION JOINTS. BE IN ACCORDANCE WITH THE FOLLOWING TABLE:

20.8. ALL HARDWOODS SHALL HAVE A MINIMUM STRESS GRADING F14 UNLESS NOTED OTHERWISE. ALL

FILLET ALL FILLET WELDS SHALL BE 6mm CONTINUOUS SP E43XX SOFTWOODS SHALL HAVE A MINIMUM STRESS GRADING OF F7 UNLESS NOTED OTHERWISE.

15.12. PROVIDE BED JOINT REINFORCEMENT AT 500 mm MAX VERTICAL SPACING, AND 2 BED JOINTS ABOVE AND PURLIN DEPTH MINIMUM LAP

BELOW OPENINGS. (mm) (mm) 20.9. ALL JOINT GROUPS IN SOFTWOOD TIMBER SHALL BE JD4 UNO. ALL JOINT GROUPS IN HARDWOOD TIMBER

ALL BUTT WELDS SHALL BE COMPLETE SHALL BE J2 UNO.

15.13. PROVIDE SLIP JOINTS BETWEEN THE TOP OF LOADBEARING MASONRY WALLS AND THE UNDERSIDE OF BUTT SP E43XX 100 900

CONCRETE SLABS. SLIP JOINTS SHALL BE 2 LAYERS OF ALCOR OR GRANOR GRAFTON SJJ-100-50 / WALL PENETRATION BUTT WELDS 20.10. ALL TIMBER SUBJECT TO WEATHER EXPOSURE SHALL BE DURABILITY CLASS 1 IN ACCORDANCE WITH THE

WIDTH OR APPROVED EQUIVALENT UNLESS NOTED OTHERWISE. ENSURE TOP OF WALLS ARE FINISHED 180-250 1500 NSW TIMBER MARKETING ACT (1977) OR HAZARD LEVEL H3 FOR TREATED TIMBERS IN ACCORDANCE WITH

LEVEL AND SMOOTH. ALL PURLIN CLEAT WELDS SHALL BE 6mm AS1604.

CLEAT GP E43XX 300-350 1800

CONTINUOUS

15.14. NON-LOADBEARING WALLS SHALL BE KEPT 30 mm CLEAR OF STRUCTURE OVER. FIX TOP OF WALLS TO 20.11. ALL TIMBER SET IN THE GROUND SHALL BE DURABILITY CLASS 1 & TREATMENT CLASS H5 UNO.

STRUCTURE OVER WITH MET 4-3 TIES, OR APPROVED EQUIVALENT, AT MAXIMUM 480 mm CENTRES FOR 17.15. UNLESS NOTED OTHERWISE, BRIDGING SHALL BE LOCATED AT THE LESSER OF 18 X THE PURLIN DEPTH

BRICKWORK, 400 mm CENTRES FOR BLOCKWORK CAPABLE OF VERTICAL BUT NOT HORIZONTAL 16.10. STEELWORK INTENDED TO BE CONCRETE ENCASED SHALL BE UNPAINTED. OS 20.12. TIMBER TRUSSES SHALL BE PRECAMBERED AN AMOUNT EQUAL TO DEAD LOAD DEFLECTION. THREE (3)

MOVEMENT. 3600mm. COPIES OF SHOP DRAWINGS ARE TO BE SUBMITTED TO THE ENGINEER FOR APPROVAL CLEARLY

16.11. PROVIDE SEAL PLATES TO THE ENDS OF ALL HOLLOW SECTIONS, WITH 'BREATHER' HOLES IF MEMBERS 17.16. ITEMS SUCH AS CEILING AND SERVICES, ETC THAT ARE SUSPENDED FROM THE PURLINS SHALL BE FIXED SHOWING THE DESIGN LOADS ON THE ROOF AND CEILING AND TRUSS NODE POINT LOADS AND

15.15. CONCRETE BLOCKS SHALL BE BORAL 'CORE FILL BLOCK', DOUBLE-U TYPE, OR SIMILAR APPROVED. ARE TO BE HOT DIP GALVANISED. THROUGH THE WEB ONLY. NO LOADS SHAL BE SUSPENDED, OR HOLES SHALL BE DRILLED THROUGH THE PRECAMBER. DRAWINGS SHALL BE SUBMITTED MINIMUM 14 DAYS PRIOR TO COMMENCEMENT OF

PURLIN FLANGES. FABRICATION. FABRICATION SHALL NOT COMMENCE UNLESS PERMISSION TO DO SO HAS BEEN GIVEN.

15.16. LAY BOTTOM COURSE OF BLOCKS ON FULL MORTAR BED. ALL PERPENDS SHALL BE FILLED WITH MORTAR, 16.12. ALL STEELWORK SHALL BE SECURELY TEMPORARILY BRACED BY THE ERECTOR AS NECESSARY TO

DESIGN OF TRUSSES SHALL ONLY BE DONE BY A QUALIFIED STRUCTURAL ENGINEER EXPERIENCED IN

EXCEPT WEEPHOLES. STABILISE THE STRUCTURE DURING ERECTION. 17.17. LOADS SHALL NOT BE SUSPENDED FROM THE PURLIN BRIDGING. TIMBER DESIGN.

15.17. ALL CORES SHALL BE GROUTED UNLESS NOTED OTHERWISE. 16.13. CORROSION PROTECTION AND PAINTING SPECIFICATION TO BE IN ACCORDANCE WITH STRUCTURAL AND 17.18. LAPPED PURLINS AND GIRTS USE M12 4.6/S PURLIN BOLTS AND FOR UNLAPPED PURLINS AND GIRTS USE

20.13. ALL BOLTS IN TIMBER CONSTRUCTION SHALL BE MINIMUM M16 UNLESS NOTED OTHERWISE. BOLT HOLES

ARCHITECTURAL SPECIFICATIONS. M12 4.6/S SHOULDERED PURLIN BOLTS. SHOULDERED PURLIN BOLT HEAD TO BE AGAINST COLD FORMED

15.18. GROUT FOR CORE FILLING SHALL BE IN ACCORDANCE WITH AS3600, WITH THE FOLLOWING PROPERTIES: TO BE DRILLED EXACT SIZE. WASHERS UNDER HEADS AND NUTS TO BE AT LEAST 2.5 TIMES THE BOLT

STRENGTH GRADE S20, 16.14. STRUCTURAL STEELWORK NOT ENCASED IN CONCRETE SHALL HAVE THE FOLLOWING SURFACE SECTION. ALL PURLIN AND GIRT BOLTS SHALL HAVE INTEGRAL WASHERS. DIAMETER. EDGE DISTANCES FOR FASTENERS IN TIMBER (FROM ENDS AND SIDES) SHALL BE IN

MAX AGGREGATE SIZE 10 mm, TREATMENT IN ACCORDANCE WITH THE SPECIFICATION UNLESS NOTED OTHERWISE. 17.19. USE M12 4.6/S GALVANISED FASCIA PURLIN BOLTS FOR ALL BARGE AND FASCIA PURLINS. ACCORDANCE WITH AS 1720. SHANK AND THREAD OF BOLTS SHALL BE THOROUGHLY COATED WITH A

SLUMP 230 mm ± 25mm, HEAVY WATERPROOF GREASE BEFORE INSERTING INTO THE TIMBER.

17.20. THE DISTANCE FROM THE EDGE BEAM/FASCIA/PURLIN SHALL BE NO MORE THAN 400 mm. THE DISTANCE

MIN CEMENT CONTENT 300 kg/m3 ELEMENT

SURFACE

PRIME COAT 2nd COAT 3rd COAT

PREPARATION TO THE NEXT PURLIN SHAL BE NO MORE THAN 600mm. 20.14. SPECIALISED TIMBER FASTENERS SUCH AS GANG-NAIL PLATES, TRIP-L-GRIP ETC. SHALL BE OF PROVEN

15.19. PROVIDE CLEANOUT OPENINGS AT THE BASE OF ALL REINFORCED CORES AND REMOVE ALL MORTAR TYPE AND SHALL HAVE HAD WORKING LOADS DETERMINED IN ACCORDANCE WITH THE PROCEDURE

PROTRUSIONS BEFORE GROUTING. 2 COATS ROZP (MIN. DRY SPECIFIED IN AS 1849.

ADDITIONAL CLEANOUT OPENINGS SHALL BE PROVIDED ABOVE EACH HORIZONTAL POUR BREAK. ALL

ABRASIVE

BLAST CLASS FILM THICKNESS TO 75

REFER REFER 18.0 SECONDARY STEELWORK:

ARCHITECT ARCHITECT 20.15. ALL TIMBER JOINTS AND NOTCHES SHALL BE 100MM MINIMUM AWAY FROM LOOSE KNOTS, SEVERE

2.5 MICRONS) 18.1. SECONDARY STEELWORK IS ALL STEELWORK THAT IS NOT REQUIRED TO SUPPORT THE MAIN BUILDING

15.20. MAXIMUM HEIGHT OF POUR FOR GROUTING SHALL NOT EXCEED 3.6m FOR 190 BLOCKWORK, AND 1.6m FOR SLOPING GRAIN, GUM VEINS OR OTHER MINOR DEFECTS.

STRUCTURE. SECONDARY STEELWORK SHALL INCLUDE BUT IS NOT LIMITED TO STEELWORK ASSOCIATED

140 BLOCKWORK. STOP POURING 50 mm BELOW TOP OF BLOCK TO PROVIDE KEY FOR SUBSEQUENT POUR.

20.16. ALL BOLTS, NUTS, WASHERS & OTHER FITMENTS IN THE TIMBER TO BE HOT DIP GALVANISED. ALL STEEL

ON COMPLETION OF THE LAST LIFT IN A STOREY, THE GROUT SHALL BE TOPPED UP AFTER 30 MINUTES ALL EXTERNAL ABRASIVE WITH: CEILING SYSTEMS, CLADDING SYSTEMS, INTERNAL PARTITIONS, DOORS AND GLAZING SYSTEMS,

STRAPPING, NAIL PLATES & FRAMING ANCHORS TO BE MANUFACTURERED FROM GALVANIZED STEEL

AND THE TOPPING VIBRATED OR RODDED TO MERGE WITH THE PREVIOUS POUR. STEELWORK BLAST CLASS HOT DIP GALVANISED - -

SUPPORTS FOR FURNITURE, FIXTURES AND EQUIPMENT, SIGNAGE, HANDRAILS, BARRIERS, LIGHTING SHEET.

(UNPAINTED) 2.5

15.21. GROUT SHALL BE THOROUGHLY COMPACTED IN THE CORES BY RODDING OR MECHANICAL VIBRATION.

SUPPORT, FALL ARREST/ACCESS SYSTEMS AND PROPRIETARY PRODUCTS. 20.17. IF TIMBER MEMBERS HAVE A NATURAL CAMBER WITHIN THE STRAIGHTNESS TOLERANCE, ERECT THEM

15.22. REINFORCEMENT SHALL BE SECURELY TIED IN POSITION. WHERE REINFORCEMENT IS NOT NOTED INTERZINC 52 ZINC RICH WITH THE CAMBER UP.

CENTRAL IN THE WALL, PROVIDE CLEAR COVER TO THE FACE OF THE SHELL AS NOMINATED ON THE ALL EXTERNAL ABRASIVE EPOXY PRIMER (MIN. DRY 18.2. SECONDARY STEELWORK IS NOT INCLUDED IN THE STRUCTURAL DOCUMENTATION.

REFER REFER 20.18. ALL BRACING WALLS TO BE CONSTRUCTED IN ACCORDANCE WITH AS1684, RELEVANT MANUFACTURERS

DRAWINGS. STEELWORK BLAST CLASS FILM THICKNESS TO 75

ARCHITECT ARCHITECT 18.3. THE CONTRACTOR SHALL ENGAGE OTHER CONSULTANTS TO DESIGN ALL SECONDARY STEELWORK. THE DETAILS AND SPECIFICATIONS. REFER TO DRAWINGS FOR BRACING DETAILS.

(PAINTED) 2.5 MICRON). TO ARCHITECT'S

15.23. WEEPHOLES SHALL BE PROVIDED IN THE MASONRY COURSE IMMEDIATELY ABOVE ALL FLASHING AT DETAILS. CONTRACTOR SHALL ALLOW IN THEIR PRICES, THE DESIGN, SUPPLY, INSTALLATION AND CERTIFICATION 20.19. TIMBER SIZES, WALL BRACING AND CONNECTION DETAILS WHERE NOT SHOWN ON DRAWINGS SHALL BE

CENTRES NOT EXCEEDING 1200mm.

IN ACCORDANCE WITH AS 1684.

OF THE SECONDARY STEELWORK. ALL WORK REQUESTED TO ZAIT REGARDING SECONDARY SHALL BE

15.24. WALL TIES SHALL BE OF TYPE A HEAVY DUTY, EMBEDDED 50mm MINIMUM INTO THE MORTAR JOINT, HAVE

16.15. THE BUILDER SHALL PROVIDE ALL CLEATS AND DRILL ALL HOLES NECESSARY FOR FIXING STEEL TO 20.20. ROOF BRACING AND ANCHOR DETAILS WHERE NOT SHOWN ON DRAWINGS SHALL BE IN ACCORDANCE

20mm COVER FROM ANY EXPOSED SURFACE OF THE JOINT, AND ATTACHED BY SCREW FIXING TO THE CHARGED TO THE CONTRACTOR AT TIME AND EXPENSE.

STEEL AND TIMBER TO STEEL WHETHER OR NOT DETAILED IN THE DRAWINGS. WITH AS 1684.

STUDS, UNO.

18.4. THE DESIGN, SUPPLY AND INSTALLATION OF THE SECONDARY STEELWORK SHALL BE IN ACCORDANCE 20.21. TIMBER ROOF TRUSSES, FIXING DETAILS AND LATERAL STABILITY OF ROOF SHALL BE DESIGNED BY THE

16.16. FREE ALL MEMBERS FROM TWISTS AND DISTORTIONS BEFORE AND AFTER WELDING.

15.25. WALL TIES SSHALL BE SPACED NO GREATER THAN 600mm VERTICALLY AND HORIZONTALLY, WITH THE

TRUSS MANUFACTURER. TRUSS MANUFACTURER TO SUBMIT TWO (2) COPIES OF SHOP DRAWINGS

FIRST ROW OF WALL TIES LOCATED WITHIN 300mm FROM THE LINE OF THE LATERAL SUPPORTS, CONTROL WITH AUSTRALIAN STANDARDS AND NASH. (NATIONAL ASSOCIATION OF STEEL HOUSING)

16.17. ALL MEMBERS TO BE IN ONE LENGTH, UNLESS OTHERWISE APPROVED. DETAILING ALL TRUSSES, NAILING PLATES AND FIXINGS, TOGETHER WITH ONE (1) COPY OF ALL

JOINTS OR OPENINGS.

SUPPORTING CALCULATIONS TO 'ZAIT ENGINEERING' FOR APPROVAL PRIOR TO FABRICATION OF THE

16.18. CAMBERS TO BE AS NOTED ON THE DRAWINGS. NATURAL CAMBERS TO BE UPWARDS. TRUSSES. TRUSS MANUFACTURER TO ALSO SUPPLY ALL NECESSARY DESIGN CERTIFICATION PRIOR TO

INSTALLATION OF TRUSSES.

20.22. AT THE PRACTICAL COMPLETION OF THE CONTRACT, AND AGAIN AT THE END OF THE MAINTENANCE

PERIOD AND IF NECESSARY DURING THAT PERIOD, THE CONTRACTOR SHALL RE-TIGHTEN ALL BOLTS TO

APPROVAL. BOLTS THAT WILL BE INACCESSIBLE AFTER COMPLETION OF THE PROJECT, SHALL BE

RE-TIGHTENED, IMMEDIATELY PRIOR TO BEING BUILT IN.

ISSUED FOR CONSTRUCTION

ZAIT Engineering Solutions Pty Ltd DATE ISSUED REVISION: PROJECT: ARCHITECT: DRAWING TITLE: ISSUE: 01 NORTH:

30-11-19 A ISSUED FOR DRAFT AND COORDINATION RESIDENTIAL DEVELOPMENT

Suite 5, 5-7 Villiers Street, GENERAL NOTES DRAWING

07-04-20 B ISSUED FOR C.C. S104

Parramatta, NSW 2150 175-177 SHAFTSBURY ROAD, GHAZI AL ALI NUMBER:

11-08-21 C ISSUED FOR C.C. SHEET 4

Phone: 02 9630 3087 26-04-23 01 ISSUED FOR CONSTRUCTION EASTWOOD, NSW ARCHITECTS JOB

NUMBER: 19DZ2093

PTY LTD

Email: info@zait.com.au CLIENT:

NSW reg. no. 7542

Engineering Solutions Pty Ltd ABN 40 608 862 899 Southern Star Property Holding Pty Ltd T, +612 9744 7035 E. office@ghazia.com DESIGNED: DRAWN: CHECKED: DATE: SCALE: APPROVED:

ACN: 67167131848

ACN 608 862 899

BUILDER: LEVEL 2 UNIT 2, 14 RAILWAY PARADE

Copyright BURWOOD NSW 2134 J.T. T.K. D.Z. NOV-19 1:100 DAVID ZAITER

BEng (Hons), MIEAust, CPEng NER RPEQ

You might also like

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- FORM No.: PCM-8.9.1 Consultant'S Review Form For Contractor'S Submittals Fahim, Nanji & Desouza (PVT.) LTDDocument4 pagesFORM No.: PCM-8.9.1 Consultant'S Review Form For Contractor'S Submittals Fahim, Nanji & Desouza (PVT.) LTDFahad NaveedNo ratings yet

- BCP5ASDocument1 pageBCP5ASAnkit SenguptaNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- Construction Notes: CASE-1Document1 pageConstruction Notes: CASE-1Cyril AleaNo ratings yet

- Garage Master Bed: Section A-A Scale: 1:100Document1 pageGarage Master Bed: Section A-A Scale: 1:100rao_vinay8296No ratings yet

- MVC1 - CP - C200 20230816Document1 pageMVC1 - CP - C200 20230816Margarita VitoNo ratings yet

- 400KV Beam Type G1 VT473 Sheet 1Document1 page400KV Beam Type G1 VT473 Sheet 1aviral mishraNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- BILL OF MATERIALS LISTDocument1 pageBILL OF MATERIALS LISTNanang SujanaNo ratings yet

- General Notes: Nashville BMWDocument1 pageGeneral Notes: Nashville BMWAli KhalafNo ratings yet

- ARC01016-Building Data SheetDocument12 pagesARC01016-Building Data SheetCamilo CastilloNo ratings yet

- p92-4441 Harness - Chassis Load CNTR MXDocument4 pagesp92-4441 Harness - Chassis Load CNTR MXDiego Lira100% (1)

- Front Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Document1 pageFront Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Habibulla BavajiNo ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Hindu College of Design, Architecture & Planning, Industrial Area, SONEPAT-131001Document1 pageHindu College of Design, Architecture & Planning, Industrial Area, SONEPAT-131001charuNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- 01 StructuralDocument39 pages01 StructuralSaifullahNo ratings yet

- Governing SpecificationsDocument1 pageGoverning SpecificationsAshley JeyahNo ratings yet

- Mansilingan Structural PDFDocument6 pagesMansilingan Structural PDFSyre Yan Moscoso Tubale100% (1)

- 400KV Beam Type G2 VT473 Sheet 1Document1 page400KV Beam Type G2 VT473 Sheet 1aviral mishraNo ratings yet

- STD Vessel 1C3 1134B FosterDocument67 pagesSTD Vessel 1C3 1134B FosterSebastien SchlesserNo ratings yet

- Course Objectives: Design of RCC Structures CIVL-3102 BY D.CDocument4 pagesCourse Objectives: Design of RCC Structures CIVL-3102 BY D.CSuraj PandeyNo ratings yet

- 9X15 G Bound 1Document1 page9X15 G Bound 1rabbani bagwanNo ratings yet

- Bajaj PEB Brochure-July-2022Document12 pagesBajaj PEB Brochure-July-2022Sukrito Kumar MittraNo ratings yet

- BD1620Document1 pageBD1620SeyedAli TabatabaeeNo ratings yet

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Fore End ConstructionDocument33 pagesFore End ConstructionWEN HANNo ratings yet

- Structural notes for cold-formed steel framingDocument2 pagesStructural notes for cold-formed steel framingCivix VarixNo ratings yet

- Strip Seal-BcDocument1 pageStrip Seal-BcC.S. MishraNo ratings yet

- Ad 036821 001Document1 pageAd 036821 001hai sunNo ratings yet

- Original-Approved-Building-Plan 2 PDFDocument23 pagesOriginal-Approved-Building-Plan 2 PDFAndrew EllisonNo ratings yet

- Drawing3-Layout1Document1 pageDrawing3-Layout1mohamedsshNo ratings yet

- Beaver ST Apt Make-Up Air Addition AppendicesDocument134 pagesBeaver ST Apt Make-Up Air Addition AppendicesJay MarkNo ratings yet

- Material Take-Off List: Saudi Aramco 6228-ENG (11/2010)Document1 pageMaterial Take-Off List: Saudi Aramco 6228-ENG (11/2010)FahadNo ratings yet

- Rambabu SHED PLANDocument1 pageRambabu SHED PLANsmplanners47No ratings yet

- S-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesDocument1 pageS-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesTAIQ MASROORNo ratings yet

- ARAMCO DrawingDocument1 pageARAMCO DrawingLainhatanhNo ratings yet

- Starbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendDocument56 pagesStarbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendMmr Pré MoldadosNo ratings yet

- Ramp SectionDocument1 pageRamp SectionBhavya PatelNo ratings yet

- STRUCTURAL NOTES FOR SOLAR PROJECTDocument3 pagesSTRUCTURAL NOTES FOR SOLAR PROJECTKoti Veera Bhadram TammaNo ratings yet

- Acp Cladding Option 3Document1 pageAcp Cladding Option 3SACHIDANANDA SNo ratings yet

- General Submittal FormDocument1 pageGeneral Submittal FormSadi GürsoyNo ratings yet

- SACTR-W-2006 Rev 2Document1 pageSACTR-W-2006 Rev 2husnain aliNo ratings yet

- Amief-2693 0Document1 pageAmief-2693 0wangkai01.sneiNo ratings yet

- General notes and details for substation constructionDocument1 pageGeneral notes and details for substation constructionA.K.M Shafiq MondolNo ratings yet

- Scheda Tecnica Console 30cm 6elementiDocument3 pagesScheda Tecnica Console 30cm 6elementikinkywoodesignNo ratings yet

- CW4 00Document1 pageCW4 00daveglai24No ratings yet

- Archiplan 123Document1 pageArchiplan 123Jom AsagraNo ratings yet

- VRV 4A AC INSTALLATION NOTESDocument7 pagesVRV 4A AC INSTALLATION NOTESJerry MaratasNo ratings yet

- General Notes: Philippine Charity Sweepstakes OfficeDocument15 pagesGeneral Notes: Philippine Charity Sweepstakes OfficeNelson OrejudosNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- Schedule of Material Submittals Submittal Register: No. of Copies Required Before Constr After ConstrDocument2 pagesSchedule of Material Submittals Submittal Register: No. of Copies Required Before Constr After ConstrWissam AhmedNo ratings yet

- Ram Telescopica AlluminioDocument3 pagesRam Telescopica AlluminioNicola MisciaNo ratings yet

- MECHANICAL PLAN RAWIS 2 STOREY Model2Document1 pageMECHANICAL PLAN RAWIS 2 STOREY Model2Catherine ZamudioNo ratings yet

- Submittal ScheduleDocument6 pagesSubmittal ScheduleWalidNo ratings yet

- Saudi Aramco noise data sheetDocument1 pageSaudi Aramco noise data sheetAnonymous X3PnFL6No ratings yet

- Arch Plans v2 (Approved)Document12 pagesArch Plans v2 (Approved)rabbetmrNo ratings yet

- For Approval: P.O.Box 46551, Fahaheel-64016, KuwaitDocument2 pagesFor Approval: P.O.Box 46551, Fahaheel-64016, KuwaitEr Md AamirNo ratings yet

- Causative SentencesDocument2 pagesCausative SentencesElePra23No ratings yet

- Application Procedure - Phoscast 60Document2 pagesApplication Procedure - Phoscast 60RAJKUMARNo ratings yet

- Rebar Drawing Check ListDocument1 pageRebar Drawing Check Listalok100% (1)

- Hadley Group Steel Framing BrochureDocument27 pagesHadley Group Steel Framing BrochureVengatesh HariNo ratings yet

- Architecture During AkbarDocument2 pagesArchitecture During AkbarShruti ParikhNo ratings yet

- C-Sgroup - Expansion Joint CatalogueDocument23 pagesC-Sgroup - Expansion Joint CatalogueAnweshNo ratings yet

- Title 27 / Subchapter 19Document12 pagesTitle 27 / Subchapter 19GreenockNo ratings yet

- Ea 0042Document1 pageEa 0042fereetNo ratings yet

- TRADITIONAL BUILDING MATERIALS - DocumentDocument5 pagesTRADITIONAL BUILDING MATERIALS - DocumentAnja M.No ratings yet

- Catalog Atlas FormDocument196 pagesCatalog Atlas FormrobertofortNo ratings yet

- Project Execution PlanDocument7 pagesProject Execution PlanJOHNK100% (12)

- Coldstorage Price Quote 3x4x3mDocument1 pageColdstorage Price Quote 3x4x3mChannel ArifNo ratings yet

- Eco Furniture Manufacturers- FabulivDocument4 pagesEco Furniture Manufacturers- Fabulivsonal guptaNo ratings yet

- 0621 SIKA Waterproofing - Wet AreasDocument12 pages0621 SIKA Waterproofing - Wet AreasstarykltNo ratings yet

- (WRIGHT) A Home in A Prairie TownDocument1 page(WRIGHT) A Home in A Prairie TownGabriel MadrugaNo ratings yet

- Bricks Messonary Work Job Hazard AnalysisDocument2 pagesBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- Carpet Production Process: S - GTM B.S - (T &)Document17 pagesCarpet Production Process: S - GTM B.S - (T &)abverma91No ratings yet

- QS Report Example 5Document18 pagesQS Report Example 5Hedi ZarkounaNo ratings yet

- Donggwang Clark ConcominiumDocument15 pagesDonggwang Clark ConcominiumJay-Ar Chris CariagaNo ratings yet

- 7-17-0473 Rev. 1 FABSIGHT DOOR 120x220Document9 pages7-17-0473 Rev. 1 FABSIGHT DOOR 120x220chandu chandrababuNo ratings yet

- Lesson 1 Arts q1Document7 pagesLesson 1 Arts q1Reenacris AtienzaNo ratings yet

- Yale Push Button User GuideDocument2 pagesYale Push Button User GuideHussnain razaNo ratings yet

- Retaining Walls and Road PavementDocument14 pagesRetaining Walls and Road PavementPraise SamuelNo ratings yet

- Brochure - AJIYA Roofing SheetDocument2 pagesBrochure - AJIYA Roofing SheetAnonymous fE2l3DzlNo ratings yet

- Doctor Who Rose by Davies Russell T.Document118 pagesDoctor Who Rose by Davies Russell T.Antonio Michele Calia100% (4)

- Ruta Del Modernisme - Guide - Capilla, Antoni, 1964 - Huertas, Josep M. 1939-2007 - 1997 - Barcelona Mediterrània - 9788489622616 - Anna's ArchiveDocument92 pagesRuta Del Modernisme - Guide - Capilla, Antoni, 1964 - Huertas, Josep M. 1939-2007 - 1997 - Barcelona Mediterrània - 9788489622616 - Anna's Archivesofia di fabioNo ratings yet

- Ituplus Ituplus: B B G 4200 G 4200Document4 pagesItuplus Ituplus: B B G 4200 G 4200Engr KamalNo ratings yet

- Floor Systems ComparisonDocument7 pagesFloor Systems ComparisonJohn Michael JanorasNo ratings yet

- Ahsp 2020Document91 pagesAhsp 2020februari telaumbanuaNo ratings yet

- Minova MAI SDA Self-Drilling Anchor Design GuideDocument54 pagesMinova MAI SDA Self-Drilling Anchor Design GuideaparsapaNo ratings yet