Professional Documents

Culture Documents

General Notes: Nashville BMW

Uploaded by

Ali KhalafOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes: Nashville BMW

Uploaded by

Ali KhalafCopyright:

Available Formats

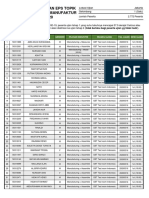

GENERAL NOTES STRUCTURAL STEEL STRENGTHS

STEEL SHAPE ASTM Fy (ksi) Fu (ksi) REFERENCE CODES

DESIGN NOTES

CONCRETE NOTES COLD-FORMED STEEL NOTES REPAIR, PROTECT, AND STRENGTHENING NOTES ANGLES,PLATES, S SHAPE, INTERNATIONAL BUILDING CODE IBC 2012

REINFORCING STEEL FOR ALL MEMBERS SHALL HAVE A YIELD STRENGTH OF 60,000 PSI MINIMUM, THE BELOW PRODUCTS ARE THE DESIGN BASIS FOR THIS PROJECT. CONTRACTOR SHALL FOLLOW AND MISC. MINIMUM DESIGN LOADS ASCE 7-10

ALL EXTERIOR METAL STUDS ARE TO BE C.S.J. (U.N.O.)

EXCEPT FOR STIRRUPS, TIES AND HOOPS, WHICH SHALL HAVE A YIELD. STRENGTH OF 40,000 PSI MANUFACTURER'S INSTALLATION INSTRUCTIONS AND CONTACT MANUFACTURER'S REPRESENTATIVE CHANNELS MC15 AND

MINIMUM. ALL EXTERIOR METAL STUDS SHALL BE DESIGNED FOR LATERAL WIND PRESSURE BASED UPON MASONRY STRUCTURES ACI 530-11

(800-999-5099) WITH PRODUCT RELATED QUESTIONS. SUBSTITUTION REQUESTS FOR PRODUCTS SMALLER, AND A36 36 58 100 Peachtree St, NW

ULTIMATE DESIGN WIND SPEED AS SHOWN ON DESIGN NOTES AND SHOULD BE LIMITED TO CHANNELS C8 AND STRUCTURAL CONCRETE ACI 318-11

UNLESS SHOWN OTHERWISE, FRAMED CONCRETE SLABS SHALL BE 4" THICK REINFORCED WITH #4 OTHER THAN THOSE LISTED BELOW MAY BE SUBMITTED BY THE CONTRACTOR TO THE ENGINEER-OF- Suite 1450

@ 8" o.c. EACH WAY. LATERAL DEFLECTION OF L/600 WHEN BACKING MASONRY, AND L/360 WHEN BACKING E.I.F.S., AND RECORD (EOR) FOR REVIEW AND APPROVAL. SUBSTITUTIONS WILL ONLY BE CONSIDERED FOR SMALLER STRUCTURAL STEEL AISC 360-10

METAL PANELS PRODUCTS HAVING INDEPENDENT TEST RESULTS OR OTHER DOCUMENTATION INDICATING THE Atlanta, GA 30303

WHERE MAIN REINFORCING IN A SOLID SLAB IS ONE DIRECTION, PROVIDE #3 BARS AT 12" o.c. IN THE PRODUCT IS APPROPRIATE FOR THE INTENDED APPLICATION. W SHAPES, MISC CHANNELS A992 50 65 LIVE LOADS

OTHER DIRECTION, UNLESS SHOWN OTHERWISE. ALL EXTERIOR FLANGES OF STUD WALLS SHALL BE BRACED BY SHEATHING PROPERLY ATTACHED

MC18 AND LARGER,

TO THEM.

CHANNELS C10 AND LARGER UNIFORM CONC. UNIFORM CONC. 404-875-4500 tel

BACKFILL SHALL NOT BE PLACED AGAINST BASEMENT WALLS UNTIL THE BASEMENT FLOOR SLAB AND A. REBAR PRIMER: REBAR PRIMER SHALL BE USED TO PROTECT EXISTING STEEL REINFORCING OCCUPANCY OR USE OCCUPANCY OR USE

THAT PORTION OF THE FIRST SLAB OVER THE BASEMENT ARE IN PLACE. CONTRACTOR SHALL FURNISH DETAILED DESIGN CALCULATIONS INCLUDING CONNECTION AND GAUGE

AND ENCOURAGE POSITIVE BOND FROM EXISTING STEEL REINFORCING TO NEW REPAIR

(PSF) (LBS) (PSF) (LBS) 404-876-8884 fax

OF ALL EXTERIOR METAL STUDS, METAL STUD TRUSSES AND METAL STUD TRUSS GIRDERS SEALED BY HSS RECTANGULAR AND

MATERIAL. PRE-APPROVED PRODUCTS INCLUDE: A500 GRADE B 46 58 ROOF 20 300 OFFICES & CORRIDORS 80 2,000

UNLESS SHOWN OTHERWISE, CONCRETE WALLS 8" THICK OR LESS SHALL BE REINFORCED WITH #4 A REGISTERED ENGINEER IN THE STATE IN WHICH THE PROJECT IS BUILT. SQUARE

@ 8" o.c. EACH WAY. WALLS OVER 8" THICK SHALL BE REINFORCED WITH #4 @ 12" o.c. EACH WAY, I. SIMPSON STRONG TIE "FX-406" LIGHT STORAGE 125 HANDRAILS AND GUARDS 200 www.praxis3.com

THE TOP COMPRESSION FLANGES OF JOISTS & TRUSSES ARE TO BE LATERALLY BRACED BY PROPER STAIRS AND EXIT WAYS 100 300 GRAB BARS 250

EACH FACE. HSS ROUND A500 GRADE B 42 58

ATTACHMENT OF THE DECKING.

WHERE THE LENGTH OF A BAR IS GIVEN, AND IT IS TO BE HOOKED, THE HOOK SHALL BE IN ADDITION TO B. BONDING AGENTS: BONDING AGENTS SHALL BE USED TO ENCOURAGE POSITIVE BOND OF

THE TOP FLANGES OF BOTTOM CHORDS OF TRUSSES, SHALL BE BRACED LATERALLY AT INTERVALS NOT NEW REPAIR MATERIAL TO EXISTING CONCRETE. PRE-APPROVED PRODUCTS INCLUDE: SHEAR STUDS A108 65 ROOF SNOW LOAD

THE LENGTH GIVEN.

EXCEEDING 3'-0" o.c. BY CONTINUOUS C STUDS WELDED TO TOP FLANGES OR BY SHEATHING ATTACHED

WHERE OPENINGS OCCUR IN SLABS, PLACE THE REINFORCING THAT WOULD OCCUR IN LINE WITH THE DIRECTLY TO BOTTOM FLANGE. I. SIMPSON STRONG TIE "FX-762" ANCHOR RODS (A.BOLTS) F1554 36 58 FLAT-ROOF SNOW LOAD (Pf ) : ?? PSF SNOW IMPORTANCE FACTOR (I s ) : 1.0

OPENING EQUALLY TO EITHER SIDE OF THE OPENING. CUT NO STEEL IN THE FIELD. TOP FLANGE OF CEILING STUD SHALL BE BRACED LATERALLY BY CONTINUOUS C STUDS WELDED TO SNOW EXPOSURE FACTOR (Ce) : 0.9 THERMAL FACTOR (Ct ) : 1.0

C. REPAIR MORTARS: REPAIR MATERIAL SHALL BE USED TO REPAIR AREAS OF DAMAGED HIGH STRENGTH BOLTS

REINFORCING BARS THAT ARE TO BE WELDED SHALL BE OF A WELDABLE GRADE AND WELDED IN EACH JOIST. EACH BRACE SHALL BE CAPABLE OF TRANSMITTING A MINIMUM OF 200 POUNDS IN TENSION 3/4" TO 1" DIAM. INCLUSIVE A325 120

CONCRETE. PRE-APPROVED PRODUCTS INCLUDE: DESIGN FROST DEPTH 12"

ACCORDANCE WITH A.W.S. RECOMMENDATIONS. OR COMPRESSION. BOTTOM FLANGE OF CEILING SHALL BE BRACED BY SHEATHING PROPERLY ATTACHED 1-1/8" TO 1-1/2" DIAM. INCL. A325 105

TO BOTTOM FLANGE. I. SIMPSON STRONG TIE "FX-263" (FOR USE IN OVERHEAD AND VERTICAL APPLICATIONS)

PROTECTIVE COVERING OF REINFORCEMENT (SEE DETAILS) SHALL BE AS FOLLOWS : FOOTINGS AND 1-1/8" TO 1-1/2" DIAM. INCL. A490 150 WIND DESIGN CRITERIA

GRADE BEAMS 3" CLEAR BOTTOM AND SIDES, 1 1/2" CLEAR SIDES. BEAMS 1 1/2" CLEAR TO STIRRUPS. ALL INTERIOR FLANGES OF STUD WALLS SHALL BE BRACED EITHER BY SHEATHING OR BY CONTINUOUS II. SIMPSON STRONG TIE "FX-261" (FOR USE IN HORIZONTAL AND FORM & POUR APPLICATIONS)

CHANNELS WELDED TO FLANGE AT INTERVALS NOT EXCEEDING 2'-0" o.c. OR AS DETERMINED BY DETAIL WELDED WIRE FABRIC A185 INTERNAL PRESSURE COEFFICIENT ±0.18

CONCRETE COLUMNS AND PIERS 1 1/2" CLEAR TO TIES. 3/4" CLEAR FOR CONCRETE JOIST TOP BARS DESIGN WIND SPEED

DESIGN DOCUMENTS FURNISHED BY A REGISTERED ENGINEER IN THE STATE IN WHICH THE PROJECT IS D. CRACK REPAIR SYSTEM: CRACK REPAIR SYSTEM SHALL CONSIST OF CRACK INJECTION 6x6-W.9xW2.9

ALL CONCRETE FOR TOPPING SLAB SHALL BE REGULAR WEIGHT CONCRETE. ULTIMATE (Vult ) : 115 MPH

BUILT. MATERIAL AND PASTE OVER ADHESIVE AND SHALL BE USED TO PRESSURE INJECT CRACKS. A615 60 NOMINAL (Vasd ) : 90 MPH

REINFORCING STEEL

ALL NON-LOAD-BEARING METAL STUD WALLS (INTERIOR AND EXTERIOR) SHALL BE CONNECTED TO PRE-APPROVED SYSTEMS INCLUDE: .

CONTRACTOR'S NOTES ALLOW FOR 3/4" VERTICAL MOVEMENT BETWEEN STUD WALL AND STRUCTURE.

I. SIMPSON STRONG TIE "FX-751 LV" INJECTION MATERIAL WITH "FX-763" PASTE OVER ADHESIVE RISK CATEGORY : 2 Copyright (c) 2015 Praxis3, LLC

ALL OTHER INTERIOR METAL STUD PARTITIONS, BULKHEADS, CEILING STUDS AND ECT. SHALL BE MINIMUM REINFORCED CONCRETE STRENGTHS COMPONENTS AND CLADDING WIND

SEE ARCHITECTURAL, MECHANICAL, PLUMBING AND ELECTRICAL DRAWING. AND SPECIFICATIONS WIND EXPOSURE (X-X) : C All reports, plans, specifications, computer files, field data, notes and

PRESSURES: SEE TABLES, THIS SHEET

FOR SIZE AND LOCATION OF DRIPS, CHAMFERS, SLEEVES, ANCHORS, INSERTS AND OPENINGS FURNISHED UNDER THE DIRECTION OF THE ARCHITECTURAL DOCUMENTS . ANY ADDITIONAL STUD E. NON-SHRINK GROUT MATERIAL: NON-SHRINK GROUT MATERIAL SHALL BE USED TO GROUT f 'c AT 28 DAYS (U.N.O. ON SCHEDULES) other documents and instruments prepared by Praxis3 shall retain all

common law, statutory and other reserved rights, including copyright

REQUIRED. THE LOCATION AND SIZE OF SLEEVES OR OPENINGS NOT SHOWN ON THE DRAWINGS IN DESIGN REQUIREMENTS SHALL BE PROVIDED BY THE GENERAL CONTRACTOR'S METAL STUD BENEATH BASEPLATES, BEARING PLATES AND EQUIPMENT BASES. PRE-APPROVED (TYPE 1 CEMENT ONLY. DO NOT SUBSTITUTE FLYASH OR WIND EXPOSURE (Y-Y) : C thereto.

STRUCTURAL MEMBERS SHALL BE SUBJECT TO THE APPROVAL OF THE ARCHITECT. ANY CONFLICT DESIGN ENGINEER. PRODUCTS INCLUDE: SLAG FOR CEMENT) This drawing may not be reproduced in whole or in part without written

SHALL BE BROUGHT TO THE ATTENTION OF THE ARCHITECT BEFORE PROCEEDING WITH THE WORK

AFFECTED. PRINCIPAL OPENINGS IN THE STRUCTURE ARE INDICATED ON THE CONTRACT

METAL STUD WALLS SHALL NOT BE ERECTED UNTIL AFTER DEAD LOADS AND ALL CONCRETE

I. SIMPSON STRONG TIE "FX-228" LOCATION DENSITY STRENGTH SEISMIC DESIGN CRITERIA permission of Praxis3. It is to be returned upon request. Scales as

stated are valid on the original drawings which are 30" x 42".

FLOORS ON FRAMING ABOVE ABOVE ARE IN PLACE.

DRAWINGS. ANY SUBSTITUTIONS RESULTING IN REVISIONS TO THE STRUCTURE SHALL BE THE

RESPONSIBILITY OF THE CONTRACTOR TO COORDINATE WITH THE ARCHITECT. 145 P.C.F. 3000 PSI RISK CATEGORY : 2

SLAB SUPPORTED ON GRADE

CONCRETE MASONRY NOTES SUBMITTAL NOTES Rev Date Comments

THE CONTRACTOR SHALL NOT SCALE THE CONTRACT DRAWINGS FOR THE PURPOSE OF ESTABLISHING SEISMIC IMPORTANCE FACTOR (Is ) : Is = 1.0

CORRECT DIMENSIONS. MORTAR SHALL COMPLY WITH ASTM C 270, TYPE S, UNLESS GREATER STRENGTH IS SPECIFIED THE GENERAL CONTRACTOR SHALL SUBMIT A SCHEDULE OF SUBMITTALS PRIOR TO CONSTRUCTION FOOTINGS SUPPORTING WOOD,

145 P.C.F. 3000 PSI

05/20/16 Permit Set

BEGINNING ON THE PROJECT. THE SCHEDULE SHOULD DESCRIBE WHAT EACH SUBMITTAL IS, MASONRY, AND STEEL STRUCTURES

U.N.O. DENOTES: "UNLESS NOTED OTHERWISE". ELSEWHERE. MAPPED SPECTRAL RESPONSE ACCELERATIONS : Ss = 0.337 g

WHETHER IT IS THE ENTIRE PACKAGE, OR BROKEN INTO PHASES FOR REVIEW.

GENERAL CONTRACTOR SHALL FIELD VERIFY EXISTING SIZES, DIMENSIONS, NOTES OR CONDITIONS MASONRY GROUT SHALL BE COMPLYING WITH ASTM C 476, MINIMUM REQUIRED GROUT CONCRETE PIERS SUPPORTING S1 = 0.130 g

COMPRESSIVE STRENGTH f'm = 1900 PSI, U.N.O. THE GENERAL CONTRACTOR SHALL ALLOW FOR 10 BUSINESS DAYS OF ALL STRUCTURAL 145 P.C.F. 3000 PSI

PRIOR TO ANY DETAILING, OR FABRICATION OF MATERIALS. SUBMITTALS. IF THE CONTRACTOR WISHES TO EXPEDITE OR REDUCE THE REVIEW TIME, IT SHALL STEEL OR MASONRY COLUMNS

SITE CLASS: C

REQUIRED MASONRY NET AREA COMPRESSIVE STRENGTH f'm=1500 PSI, U.N.O. BE DONE FOR AN ADDITIONAL CHARGE AND MUST BE NEGOTIATED WITH THE ARCHITECT AND

ENGINEER PRIOR TO THE SUBMISSION OF THE PACKAGE. SLAB ON GRADE AT BIN- MAPPED SPECTRAL RESPONSE ACCELERATIONS : Sds = 0.269 g

DECKING NOTES CONCRETE GROUT, CONFORMING TO ASTM C476, NOT MORTAR, SHALL BE USED AT CELLS AND BOND 145 P.C.F. 5000 PSI

BEAMS CONTAINING REINFORCING BARS. DO NOT FILL CELLS NOT CONTAINING REINFORCING BARS, SUPPORTED MEZZANINE Sd1 = 0.145 g

NO PIPING, DUCTWORK, OR CONDUIT LARGER THAN 3/4" DIAMETER OR STUD WALLS SHALL BE IN THE EVENT THE CONTRACTOR ATTEMPTS TO SUBMIT THE ENTIRE PROJECT AT THE SAME TIME

EXCEPT BELOW GRADE, UNLESS SO INDICATED. FOR SUBMISSION, ADDITIONAL TIME WILL BE REQUIRED BEYOND THE STANDARD 10 DAY REVIEW SEISMIC DESIGN CATEGORY : C

SUPPORTED DIRECTLY FROM METAL DECK OR PERMANENT METAL FORM. FRAMED SLABS IN COMPOSITE

UNLESS NOTED OTHERWISE , MAXIMUM CONTROL JOINT SPACING SHALL BE 32'-0", 16'-0" FROM TIME. 115 P.C.F. 4000 PSI

ALL METAL ROOF DECKS SHALL BE WIDE RIB AND GALVANIZED TYPE "B" DECKS UNLESS NOTED STEEL CONSTRUCTION BASIC SEISMIC-FORCE-RESISTING SYSTEM(S) : STEEL SYSTEMS NOT SPECIFICALLY

CORNERS, COORDINATE WITH ARCHITECTURAL. ALL HORIZONTAL REINFORCING SHALL BE WHERE GLASS REQUIRES ADDITIONAL DESIGN OF MISCELLANEOUS STEEL AND MULLIONS, DETAILED FOR SEISMIC RESISTANCE

OTHERWISE. DISCONTINUED AT WALL CONTROL JOINTS. VERTICAL WALL CONTROL JOINTS SHALL BE LOCATED AT CONTRACTOR SHALL FURNISH DETAILED DESIGN CALCULATIONS SEALED BY A REGISTERED ENGINEER

EACH FLOOR JOINT, MINIMUM. IN THE STATE IN WHICH THE PROJECT IS BUILT.

DESIGN BASE SHEAR : Fx =Fy = 242 k

FOUNDATION NOTES LOAD BEARING MASONRY WALLS SHALL BE LATERALLY BRACED UNTIL ALL FLOOR / ROOF DIAPHRAGM IS STRUCTURAL STEEL SUPPLIER SHALL PROVIDE COMPLETE SHOP DRAWINGS INCLUDING AN ANCHOR

IN PLACE. SETTING PLAN, ERECTION DRAWINGS WITH ALL PIECE MARKS, AND ASSOCIATED FABRICATION DRAWINGS STAIR TREADS AND LANDINGS 145 P.C.F. 3000 PSI RESPONSE MODIFICATION FACTOR(S) : R= 3

BUILDING FOOTINGS ARE DESIGNED TO BEAR ON ORIGINAL EARTH OR LABORATORY CONTROLLED

COMPACTED FILL WITH AN ALLOWABLE BEARING CAPACITY OF 2,500 PSF. ALLOWABLE BEARING AT ALL NON-LOAD BEARING MASONRY WALLS (INTERIOR AND EXTERIOR), PROVIDE A 3/4" CAULKED JOINT SHOWING ALL MATERIAL AND CONNECTIONS. CONNECTIONS SHALL BE DESIGNED BASED UPON THE END ANALYSIS PROCEDURE: EQUIVALENT LATERAL FORCE

CAPACITY AT CONTINUOUS WALL FOOTINGS SHALL BE 2,500 PSF. SOIL BEARING CAPACITY SHALL BE BETWEEN UNDERSIDE OF BEAM, JOIST, DECK, OR STRUCTURE AND TOP OF MASONRY WALL. SHEAR TABLES PROVIDED IN THE AISC UNLESS NOTED OTHERWISE. BASEMENT, TIEBACK, AND

145 P.C.F. 3000 PSI

VERIFIED BY A REGISTERED GEOTECHNICAL ENGINEER AT THE TIME OF EXCAVATION. ELEVATIONS REBAR SUPPLIER SHALL PROVIDE COMPLETE SHOP DRAWINGS INCLUDING PLAN VIEWS WITH MARKS RETAINING WALLS

GIVEN ARE FOR PURPOSES OF CONTRACT AND SHALL BE ADJUSTED AT THE TIME OF EXCAVATION TO PROVIDE MASONRY HORIZONTAL JOINT REINFORCEMENT 16" o.c. VERTICAL IN ALL CONCRETE

ILLUSTRATING BAR SIZES AND BAR BENDING DETAILS. INCLUDE ALL LOCATION OF STEPS NOTED IN THE

MEET SOILS CONDITIONS. SITE SHALL BE PREPARED IN ACCORDANCE TO THE GEOTECHNICAL BLOCK WALLS. REINFORCEMENT SHALL BE FOR TOTAL WIDTH OF CAVITY WALLS. NON-SHRINK GROUT AT STEEL

GENERAL NOTES FOR PLUMBING AND CIVIL LINES WHERE APPLICABLE. WHERE CONCRETE PIER AND 145 P.C.F. 5000 PSI

REPORT PREPARED BY "TERRACON CONSULTANTS, INC." DATED 17 FEBRUARY 2016. PROJECT NO . PROVIDE A 2 SQUARE INCH INSPECTION HOLE AT THE BOTTOM CELL FOR EACH LIFT TO ALLOW STEM WALLS OCCUR PROVIDE SECTION CUTS, AND ELEVATIONS ILLUSTRATING THE MATERIAL SPECIFIED COLUMN BASEPLATES

18135053. VISUAL INSPECTION AND TO REMOVE MORTAR DROPPING PRIOR TO GROUTING.

REBAR SUPPLIER SHALL PROVIDE COMPLETE SHOP DRAWINGS FOR LOAD BEARING MASONRY.

WALL FOOTINGS, UNLESS SHOWN OTHERWISE, SHALL BE 12" THICK WITH A 6" SPREAD EACH SIDE OF ALL MASONRY SHALL BE RUNNING BOND UNLESS NOTED OTHERWISE. PROVIDE ALL WALLS INCLUDING NON LOAD BEARING PARTITIONS IN ELEVATIONS DEPICTING THE

MASONRY WALL, REINFORCED WITH 2 #6 CONTINUOUS. (UNLESS NOTED OTHERWISE)

SLEEVE ALL PLUMBING OR FIRE PROTECTION PIPING THROUGH CMU WALL.

VERTICAL WALL REINFORCEMENT/ LAPS, ALL LINTELS AT OPENINGS , REINFORCING AND BOND MINIMUM LAP SPLICE LENGTH SCHEDULE

THE MAXIMUM WALL FOOTING STEP-OFF SHALL BE 2'-0" VERTICAL SPACED NOT LESS THAN: 4'-0"o.c. BEAMS AS DESCRIBED IN TYPICAL DETAILS AND WALL SECTIONS INCLUDING MASONRY CONTROL

FOOTING STEP-OFFS ARE INDICATED BY THE SYMBOL: SEE ARCHITECT DRAWINGS AND SPECIFICATIONS FOR MASONRY FINISHES. JOINT LOCATIONS. 3000 PSI CONC.

BAR TYPE

WHERE PIPES OR CONDUITS RUN PERPENDICULAR TO A FOOTING, STEP TOP OF FOOTING DOWN TO AT LOAD-BEARING MASONRY WHERE JOISTS OR BEAMS BEAR ON MASONRY WALLS, GROUT JOIST AND DECK SUPPLIER SHALL PROVIDE COMPLETE SHOP DRAWINGS INCLUDING ERECTION #3 #4 #5 #6 #7 #8 #9 #10 #11

ALLOW PIPES OR CONDUIT TO RUN OVER TOP OF FOOTINGS. POCKET SOLID WITH GROUT TO THE SAME FINISH FACE AS MASONRY ABOVE AND BELOW. DO THIS DRAWINGS, SECTIONS INCLUDING MATERIALS PROVIDED, ALL ASSOCIATED CONNECTIONS AS OUTLINED

WHERE PIPES OR CONDUIT RUN PARALLEL TO A FOOTING, STEP DOWN BOTTOM OF FOOTING SO ONLY AFTER JOIST SEAT CONNECTION HAS BEEN INSPECTED. IN THE CONTRACT DOCUMENTS AND SPECIFICATIONS. SHOP DRAWINGS SHALL INCLUDE ALL EDGE OF TOP BARS 29" 38" 47" 56" 82" 94" 105" 118" 131"

THAT A LINE DRAWN BETWEEN INVERT OF PIPE AND BOTTOM OF FOOTING SHALL NOT EXCEED 30 DECK DIMENSIONS, EDGE OF JOIST DIMENSIONS .

DEGREES, SEE "TRENCHES NEAR FOOTINGS" DETAIL. OTHER BARS 22" 29" 36" 43" 62" 72" 81" 91" 101"

POST-INSTALLED ANCHOR NOTES SEE DISCIPLINE SPECIFIC NOTES AND SPECIFICATIONS FOR ALL ADDITIONAL SUBMITTAL REQUIREMENTS.

NO PIPES OR CONDUIT SHALL BE PLACED IN THE FOOTINGS, OR SLAB ON GRADE. THE BELOW PRODUCTS ARE THE DESIGN BASIS FOR THIS PROJECT. PRODUCT DIAMETER AND FOR THIRD-PARTY DESIGN SUBMITTALS INCLUDING, BUT NOT LIMITED TO, PRECAST, HOLLOW CORE 4000 PSI CONC.

EMBEDMENT SHALL BE AS SHOWN IN THE DETAILS. INSTALL PRODUCTS IN ACCORDANCE WITH SLABS, METAL STUDS, STAIRS & HANDRAILS, GLASS DESIGN, AND WOOD TRUSSES, PLEASE SUBMIT BAR TYPE

#3 #4 #5 #6 #7 #8 #9 #10 #11

SLAB-ON-GRADE NOTES MANUFACTURER'S PRINTED INSTALLATION INSTRUCTIONS (MPII). SUBSTITUTION REQUESTS FOR MANUFACTURER'S DRAWINGS WITH ACCOMPANYING CALCULATIONS SEALED BY A REGISTERED

PRODUCTS OTHER THAN THOSE LISTED BELOW MAY BE SUBMITTED BY THE CONTRACTOR TO THE ENGINEER IN THE STATE IN WHICH THE PROJECT IS BUILT.

TOP BARS 25" 33" 40" 48" 70" 81" 91" 103" 113"

WHERE SLABS REST ON FILL, FILL SHALL BE COMPACTED IN ACCORDANCE WITH THE SPECIFICATIONS. ENGINEER-OF-RECORD (EOR) FOR REVIEW. SUBSTITUTIONS WILL ONLY BE CONSIDERED FOR

SLABS ON GROUND MAY BE PLACED IN LANE FASHION USING GALVANIZED STEEL, PREFORMED KEYED PRODUCTS HAVING A CODE REPORT RECOGNIZING THE PRODUCT FOR THE APPROPRIATE OTHER BARS 20" 25" 31" 38" 55" 62" 70" 79" 87" = ZONE 1

FORMS AT FLOOR JOINT LOCATION INDICATED. REINFORCING SHALL NOT CROSS CONSTRUCTION OR APPLICATION. SUBSTITUTION REQUESTS SHALL INCLUDE CALCULATIONS THAT DEMONSTRATE THE

KEYED JOINTS. SUBSTITUTED PRODUCT IS CAPABLE OF ACHIEVING THE EQUIVALENT PERFORMANCE VALUES OF THE = ZONE 2

DESIGN BASIS PRODUCT. CONTRACTOR SHALL CONTACT MANUFACTURER'S REPRESENTATIVE

SEE CIVIL AND ARCH. DRAWINGS AND SPECIFICATIONS FOR EXTERIOR SLAB WORK AND JOINTING. = ZONE 3

(800-999-5099) FOR PRODUCT INSTALLATION TRAINING AND A LETTER SHALL BE SUBMITTED TO THE MINIMUM PRETENSION OF BOLTS (KIPS)

'2a'

HORIZONTAL RUNS OF CONDUIT AND PIPE SHALL NOT BE PLACED IN SLABS ON GROUND, PLACE IN SUB- EOR INDICATING TRAINING HAS TAKEN PLACE. SPECIAL INSPECTIONS ARE REQUIRED PER THE IBC AND

'a'

GRADE. ICC-ES REPORTS. BOLT DIAMETER A325 BOLTS A490 BOLTS

STEEL BAR JOIST NOTES A. FOR ANCHORING INTO CONCRETE 3/4" DIAMETER ROOF PLAN

28 35

JOIST BRIDGING SHALL NOT BE USED TO SUPPORT CONDUIT, PIPING, DUCTWORK, ETC. I. MECHANICAL ANCHORS SHALL HAVE BEEN TESTED AND QUALIFIED FOR USE IN ACCORDANCE

WITH ACI 355.2 AND ICC-ES AC193 FOR CRACKED CONCRETE AND SEISMIC APPLICATIONS. 7/8" DIAMETER 39 49 COMPONENTS AND CLADDING ROOF (ENCLOSED) 115 MPH

JOISTS SHALL NOT BE FIELD MODIFIED EXCEPT AS SHOWN. PRE-APPROVED ANCHORS INCLUDE: EXP. "C" 'ULT' EXTERNAL PRESSURES (PSF)

1" DIAMETER 51 64

WHERE JOISTS CANNOT ACHIEVE THE REQUIRED BEARING ON STEEL BEAMS, STAGGER JOISTS TO (1) SIMPSON STRONG TIE "STRONG-BOLT 2" (IAPMO-UES ESR ER-240)

PROVIDE ADEQUATE BEARING. A e (EFFECTIVE AREA) ZONE 1 ZONE 2 ZONE 3

STEEL JOISTS SHALL BE OPEN WEB STEEL JOISTS OF THE SIZES AND SERIES

II. ADHESIVE FOR REBAR AND ANCHORS SHALL HAVE BEEN TESTED AND QUALIFIED FOR USE IN

ACCORDANCE WITH ACI 355.4 AND ICC-ES AC308 FOR CRACKED CONCRETE AND SEISMIC A e = 10 SQ. FT. +16.0, -32.5 +16.0, -54.6 +16.0, -82.2

Walid. Nannis, P.E., F. ASCE

SHOWN ON THE DRAWINGS. JOISTS, BRIDGING AND SPACING OF BRIDGING SHALL MEET THE APPLICATIONS. ADHESIVE ANCHORS SHALL BE INSTALLED BY A CERTIFIED ADHESIVE ANCHOR A e = 20 SQ. FT. +16.0, -31.7 +16.0, -48.8 +16.0, -68.1

Structural Engineer

REQUIREMENTS OF THE LATEST EDITION OF THE "STANDARD INSTALLER PER ACI 318-11 D.9.2.2 WHERE INDICATED ON THE CONTRACT DOCUMENTS.

SPECIFICATIONS" OF THE STEEL JOIST INSTITUTE, EXCEPT WHERE OTHERWISE INSTALLATIONS REQUIRING CERTIFIED INSTALLERS SHALL BE INSPECTED PER ACI 318-11 A e = 50 SQ. FT. +16.0, -30.6 +16.0, -41.1 +16.0, -49.4 5608 Battle Ridge Drive

INDICATED BY THE DRAWINGS OR SPECIFICATIONS. D.9.2.4. PRE-APPROVED ANCHORS INCLUDE:

WHERE ANGLE BRACES ARE SHOWN ON STRUCTURAL SECTIONS, JOIST MANUFACTURER SHALL A e = 100 SQ. FT. +16.0, -29.8 +16.0, -35.3 +16.0, -35.3 Flowery Branch, GA 30542

(1) SIMPSON STRONG TIE "SET-XP" (ICC-ES ESR-2508)

RESOLVE AN AXIAL LOAD OF 2000 POUNDS FROM THE BRACE INTO THE JOIST - TYPICAL UNLESS (2) SIMPSON STRONG TIE "AT-XP" (IAPMO-UES ESR-263)

NOTED OTHERWISE. 770-614-6114 tel

III. POWER-ACTUATED FASTENERS SHALL HAVE BEEN TESTED IN ACCORDANCE WITH ICC-ES COMPONENTS AND CLADDING ROOF (ENCLOSED) 90 MPH

IN ADDITION TO WHAT IS CALLED FOR ON PLAN, BAR JOISTS SHALL BE DESIGNED TO SUPPORT AN

AC70. PRE-APPROVED ANCHORS INCLUDE: EXP. "C" 'ASD' EXTERNAL PRESSURES (PSF) 678-765-7966 fax

ADDITIONAL CONCENTRATED LOAD OF 300 POUNDS AT TOP OR BOTTOM CHORD AT ANY ONE

LOCATION ALONG THE SPAN. (1) SIMPSON STRONG TIE "GAS ACTUATED PINS" (ICC-ES ESR-2811) All drawings, specifications, and other work product of

(2) SIMPSON STRONG TIE "POWDER ACTUATED PINS" (ICC-ES ESR-2138) A e (EFFECTIVE AREA) ZONE 1 ZONE 2 ZONE 3 Walid A. Nannis for this project are instruments of

AT THE END OF EACH ROOF JOIST, PROVIDE A CONTINUOUS ROW OF BRIDGING AT THE LAST BOTTOM

service for this project only and shall remain the

CHORD PANEL POINT FOR UPLIFT. TYPICAL AT EACH END OF JOIST. A e = 10 SQ. FT. +10.0, -19.9 +10.0, -33.4 +10.0, -50.3 property of Walid A. Nannis whether the project is

B. FOR ANCHORING INTO MASONRY complete or not. Reuse of any of the instruments of

A e = 20 SQ. FT. +10.0, -19.4 +10.0, -29.9 +10.0, -41.7 service of Walid A. Nannis by the owner or extensions

STRUCTURAL STEEL NOTES I. ANCHORAGE TO SOLID-GROUTED CONCRETE MASONRY of this project without the written permission of Walid

A e = 50 SQ. FT. +10.0, -18.7 +10.0, -25.2 +10.0, -30.3 A. Nannis shall be at the owner's risk and the owner

FABRICATION AND ERECTION OF ALL STEEL SHALL BE IN ACCORDANCE WITH THE AISC (1) MECHANICAL ANCHORS SHALL HAVE BEEN TESTED AND QUALIFIED FOR USE IN agrees to defend, indemnify, and hold harmless Walid

SPECIFICATIONS. ACCORDANCE WITH ICC ES AC01 OR ICC-ES AC106 PRE-APPROVED ANCHORS INCLUDE: A e = 100 SQ. FT. +10.0, -18.2 +10.0, -21.6 +10.0, -21.6 A. Nannis from all claims, damages, and expenses

ALL BOLTS SHALL BE ASTM A-325 HIGH STRENGTH BOLTS U.N.O. (T.C. BOLTS) including attorney's fees arising out of such

WHERE BEAMS REST ON MASONRY OR CONCRETE WALLS THEY SHALL BEAR A MINIMUM OF 8" AND (A) SIMPSON STRONG TIE "TITEN-HD" (ICC-ES ESR-1056) unauthorized reuse of Walid A. Nannis' instruments of

SHALL HAVE BEARING PLATES AND ANCHORS. (B) SIMPSON STRONG TIE "STRONG-BOLT 2" (IAPMO-ES ER-240) service by the owner or others acting through the

owner. ©2015

WHERE NOT SHOWN OTHERWISE, ALL COLUMNS SHALL HAVE BASE PLATES AND (4) 3/4" DIAMETER

x 1'-2" LONG+HOOK ANCHOR BOLTS. (2) ADHESIVE FOR REBAR AND ANCHORS SHALL HAVE BEEN TESTED AND QUALIFIED FOR USE IN

ACCORDANCE WITH ICC-ES AC58. PRE-APPROVED ANCHORS INCLUDE: "a"

UNLESS SHOWN OTHERWISE, PROVIDE 5/8"x12"x7-1/2" BEARING PLATES ON 1" GROUT WITH (2) 3/4"

DIAMETER ANCHOR BOLTS UNDER ALL STEEL BEAMS THAT BEAR ON MASONRY WALLS. (A) SIMPSON STRONG TIE "AT-XP" (IAPMO-UES ER-281) Client:

COLUMN BASES ARE DESIGNED AS UNRESTRAINED, THEREFORE COLUMNS MUST BE BRACED (B) SIMPSON STRONG TIE "SET-XP" (IAPMO-UES ER-265) 5 4 5

DURING ERECTION.

AS ERECTION PROGRESSES, FRAMING SHALL BE ADEQUATELY GUYED AND BRACED AND

CONNECTIONS SHALL BE SECURELY BOLTED OR WELDED.

(3) POWER-ACTUATED FASTENERS SHALL HAVE BEEN TESTED IN ACCORDANCE WITH ICC-ES

AC70. PRE-APPROVED ANCHORS INCLUDE:

Sonic Automotive,

NO SHOP SPLICE OR OTHER CONNECTION WILL BE PERMITTED UNLESS THIS SPLICE OR DETAIL IS

SHOWN ON SHOP DRAWINGS AND REVIEWED BY THE ENGINEERS.

(A) SIMPSON STRONG TIE "GAS ACTUATED PINS" (ICC-ES ESR-2811)

WALL ELEVATION INC

(B) SIMPSON STRONG TIE "POWDER ACTUATED PINS" (ICC-ES ESR-2138)

ALL STEEL SHALL CONFORM TO ASTM A992, 50 KSI STEEL UNLESS SHOWN OTHERWISE. TUBE

STEEL SHALL CONFORM TO ASTM A-500, GRADE B (Fy = 46 KSI MINIMUM) ALL MISC. PLATES,

CONNECTION PLATES AND ANGLES SHALL BE 36 KSI STEEL. II. ANCHORAGE TO HOLLOW CONCRETE MASONRY COMPONENTS AND CLADDING WALL (ENCLOSED) 115 MPH

ALL FASTENERS SHALL CONSIST OF ONE NUT, ONE BOLT, AND ONE WASHER. EXP. "C" 'ULT' EXTERNAL PRESSURES (PSF)

ALL BEAM SHOP CONNECTIONS SHALL BE WELDED. BEAM SHOP CONNECTIONS MAY BE BOLTED IN (1) MECHANICAL ANCHORS SHALL HAVE BEEN TESTED AND QUALIFIED FOR USE IN

LIEU OF WELDING PROVIDED THAT THE CONTRACTOR ASKS AND RECEIVES AN AFFIRMATIVE ACCORDANCE WITH ICC-ES AC106 PRE-APPROVED ANCHORS INCLUDE: A e (EFFECTIVE AREA) ZONE 4 ZONE 5

ANSWER BY THE ENGINEER OF RECORD IN WRITING. FURTHERMORE, ACCEPTANCE OF A BOLTED Project:

(A) SIMPSON STRONG TIE "TITEN-HD" A e = 10 SQ. FT. +29.8, -32.3 +29.8, -39.7

CONNECTION WILL ONLY OCCUR IF THE FABRICATOR FOLLOWS THE ECCENTRIC LOAD TABLES

PROVIDED ON PAGES 7-30 THROUGH 7-53 OF THE AISC MANUAL. (2) ADHESIVE FOR REBAR AND ANCHORS WITH SCREEN TUBES SHALL HAVE BEEN TESTED

FACE OF

FRAMING

e

e = ECCENTRICITY

(SEE 7-30 - 7-53, AISC

AND QUALIFIED FOR USE IN ACCORDANCE WITH ICC-ES AC58. THE APPROPRIATE SCREEN

TUBE SHALL BE USED AS RECOMMENDED BY THE ADHESIVE MANUFACTURER. PRE-

APPROVED ANCHORS WITH SCREEN TUBES INCLUDE:

A e = 20 SQ. FT.

A e = 50 SQ. FT.

+28.5, -30.9

+26.7, -29.2

+28.5, -37.1

+26.7, -33.6

Nashville

MEMBER FOURTEENTH EDITION)

ALL WELDING SHALL CONFORM TO THE "STRUCTURAL WELDING CODE - AMERICAN WELDING

(A) SIMPSON STRONG TIE "SET" (ICC-ES ESR-1772)

(3) POWER-ACTUATED FASTENERS SHALL HAVE BEEN TESTED IN ACCORDANCE WITH ICC-ES

A e = 100 SQ. FT. +25.4, -27.9 +25.4, -30.9

BMW

AC70. PRE-APPROVED ANCHORS INCLUDE: COMPONENTS AND CLADDING WALL (ENCLOSED) 90 MPH

SOCIETY." FOR WELD TESTING REQUIREMENTS, SEE SPECIFICATIONS.

ALL ANCHOR BOLTS SHALL BE ASTM F-1554. (A) SIMPSON STRONG TIE "GAS ACTUATED PINS" (ICC-ES ESR-2811) EXP. "C" 'ASD' EXTERNAL PRESSURES (PSF)

NO SLOTTED HOLES ARE PERMITTED UNLESS SPECIFICALLY DETAILED BY THE ENGINEER OF RECORD. (B) SIMPSON STRONG TIE "POWDER ACTUATED PINS" (ICC-ES ESR-2138)

IT SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR TO SECURE STEEL AGAINST DISPLACEMENT A e (EFFECTIVE AREA) ZONE 4 ZONE 5 Brentwood, TN 37027

DURING ERECTION AND TO MAINTAIN IT AGAINST DISPLACEMENT UNTIL THE ERECTION OF ALL STEEL C. FOR ANCHORING INTO STEEL POWER-ACTUATED FASTENERS SHALL HAVE BEEN TESTED IN A e = 10 SQ. FT. +18.2, -19.8 +18.2, -24.3

IS COMPLETED, ALL FLOOR AND ROOF DECKS ARE IN PLACE, AND ALL EXTERIOR MASONRY IS ACCORDANCE WITH ICC-ES AC70. PRE-APPROVED ANCHORS INCLUDE:

COMPLETED. ALL STRUCTURAL METAL WORK SHALL HAVE TEMPORARY GUYS, BRACES AND STAYS A e = 20 SQ. FT. +17.4, -19.0 +17.4, -22.7

TO HOLD IT IN POSITION UNTIL IT IS PERMANENTLY SECURE. I. SIMPSON STRONG TIE "GAS ACTUATED PINS" (ICC-ES ESR-2811) Project Number: 15240

ALL GROUT UNDER BASE PLATES AND BEAM BEARING PLATES SHALL BE NON SHRINK GROUT. (5,000 II. SIMPSON STRONG TIE "POWDER ACTUATED PINS" (ICC-ES ESR-2138) A e = 50 SQ. FT. +16.4, -17.9 +16.4, -20.6

PSI)

WHERE ROOF DECKS FRAME ONTO A ROOF MEMBER, AND DECK IS IN A DIFFERENT PLANE THAN THE A e = 100 SQ. FT. +15.6, -17.1 +15.6, -19.0 Site Key Plan:

ROOF MEMBER, PROVIDE A 3/16" CONTINUOUS BENT PLATE WELDED ACROSS THE TOP OF THE ROOF

STEEL STAIR AND ALL RAILING NOTES

MEMBER SLOPED TO MATCH PLANE OF ROOF DECK. NOTES:

SUBMIT COMPLETE ERECTION, FABRICATION DRAWINGS AND CALCULATIONS SIGNED AND SEALED

FILL ALL CMU CELLS WITH GROUT WHERE REINFORCING AND/OR ANCHORS OCCUR. 1. INTERPOLATION MAY BE UTILIZED FOR EFFECTIVE AREAS THAT

BY A PROFESSIONAL ENGINEER LICENSED IN THE STATE IN WHICH THIS PROJECT IS BUILT WHICH

HEADED CONCRETE ANCHORS SHALL BE NELSON OR K.S.M. HEADED CONCRETE ANCHORS (OR OCCUR BETWEEN VALUES SHOWN ON THE TABLE.

ADDRESSES THE DESIGN FOR ALL STEEL STAIRS, GUARD RAILS AND HANDRAILS. DETAILS SHALL BE

APPROVED EQUAL), AND SHALL CONFORM TO ASTM A-108. 2. PLUS AND MINUS SIGN INDICATES THE PRESSURE ACTING

FURNISHED OF ALL STEEL STAIRS. STAIRS SHALL MEET THE SPECIFICATIONS FOR

ANCHORS SHALL BE AUTOMATICALLY END WELDED WITH SUITABLE STUD WELDING EQUIPMENT IN TOWARD AND AWAY FROM THE SURFACES, RESPECTIVELY.

ARCHITECTURALLY EXPOSED STRUCTURAL STEEL (AESS) OF THE AISC CODE OF STANDARD

ACCORDANCE WITH THE RECOMMENDATIONS OF THE MANUFACTURER. 3. FORCES AND DIAGRAMS ARE BASED ON IBC / ASCE 7.

PRACTICE. ALLOW TEN (10) BUSINESS DAYS FOR REVIEW OF SUBMITTED STRUCTURAL DRAWINGS.

WHERE A ROOF FRAMING MEMBER DOES NOT FRAME OVER A COLUMN, PROVIDE A 1/2" THICK CAP End zone width, a = 10' - 8"

PLATE (i.e. TUBES AND PIPES) TREADS AND RISERS SHALL BE PREFORMED OF 14 GAUGE METAL. LANDING PAN SHALL BE 12

FABRICATOR SHALL SUBMIT COMPLETE CALCULATIONS OF ALL CONNECTIONS, STRUCTURAL STEEL, GAUGE MINIMUM.

RELEASED FOR CONSTRUCTION AND PERMIT

AND JOIST SEALED BY THE REGISTERED DESIGN ENGINEER STRINGERS, LANDING BEAMS, CLOSURE PLATES, STIFFENERS AND CONNECTION ANGLES SHALL BE OF

WHERE HSS OUTLOOKERS OCCUR PROVIDE 1/4" CAP PLATE AT END SIZES DESIGNED BY THE STAIR PROVIDER AND SHALL RESIST A MINIMUM OF SELF WEIGHT OF STEEL,

CONCRETE, ARCHITECTURAL FINISHES AND 100 PSF LIVE LOAD.

COMPOSITE FLOOR NOTES AT LOWEST LEVEL, STAIRS MAY BE SUPPORTED FROM POST BEARING ON A FOOTING, THICKENED SLAB,

OR CONCRETE WALL PROVIDED SUPPORT BASE PLATE CAN REMAIN CONCEALED WITHIN ARCHITECTURAL

ALL SHEAR STUDS SHALL BE 3/4" DIAMETER x 3-1/2" LONG. SHEAR STUDS SHALL BE FIELD WELDED TO ELEMENTS WITHOUT BEING EXPOSED.

TOP FLANGE OF BEAMS AND TESTED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS.

WHERE STAIR LANDINGS ARE SUSPENDED FROM FLOORS ABOVE, USE A MINIMUM OF DOUBLE ANGLE

NO CONDUIT SHALL BE PLACED OR RUN IN THE CONCRETE SLAB. ALL CONDUIT SHALL BE SUPPORTED 3x3x1/4" HANGERS. HANG CONCENTRICALLY FROM FLOOR BEAM. CONTRACTOR SHALL COORDINATE

FROM BELOW THE SLAB. WITH THE ARCHITECTURAL PARTITION SCHEDULE TO ENSURE HANGERS ARE CONCEALED WITHIN Sheet Title:

PARTITIONS. DO NOT USE ROD HANGERS.

ALL DECK SIDE LAPS SHALL BE EITHER WELDED OR FASTENED WITH A SELF TAPPING FASTENER.

BUTTON PUNCHING, OR CRIMPING IS NOT PERMITTED. SEE SPECIFICATIONS FOR SPACING. INTERMEDIATE LANDINGS SHALL BE COMPRISED OF CHANNELS SPANNING BETWEEN SUPPORT

STRINGERS SPACED AT A MAXIMUM OF 2'-0" o.c. MAX. General Notes

METAL STUD WALLS SHALL NOT BE ERECTED UNTIL AFTER DEAD LOADS AND ALL CONCRETE FLOORS

5/23/2016 10:06:38 AM

ON FRAMING ABOVE ARE IN PLACE. AT ORNAMENTAL STAIRS, STRINGERS SHALL BE COMPRISED OF TUBE STEEL OR CHANNELS WITH

CONTINUOUS COVER PLATES TO FORM A TUBE. IN THIS CASE WELDS SHALL BE CONTINUOUS AND

GROUND SMOOTH.

SEE ARCHITECTURAL DRAWINGS FOR ALL STAIR LAYOUTS, DIMENSIONS AND SECTIONS.

Sheet Number:

S001

You might also like

- Line Item Renovation Budget: Cost As % of Total Accepted Bid or Cost Change OrdersDocument4 pagesLine Item Renovation Budget: Cost As % of Total Accepted Bid or Cost Change OrdersAswad TonTong100% (1)

- E18189 Full Set - BATCHED PDFDocument13 pagesE18189 Full Set - BATCHED PDFchristineNo ratings yet

- Auto Service and Repair - Martin W. StockelDocument224 pagesAuto Service and Repair - Martin W. StockelAlexis Rodríguez71% (14)

- Details - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End DetailsDocument1 pageDetails - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End Detailsacurvz2005No ratings yet

- Define Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author CheckerDocument2 pagesDefine Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author Checkerdnl_vicarsNo ratings yet

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- Woodcraft 08.09 2022Document68 pagesWoodcraft 08.09 2022Tibor KovácsNo ratings yet

- New Fulcrum Canopies - Structural Drawings - PermitDocument6 pagesNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezNo ratings yet

- Design Criteria For BridgesDocument1 pageDesign Criteria For BridgesEarl Justin Enrique100% (1)

- AISC - American Institute of Steel Construction, Inc.: Popular StandardsDocument6 pagesAISC - American Institute of Steel Construction, Inc.: Popular StandardsMagdy Ismail0% (1)

- Diy Ferestrau Vertical at HomeDocument104 pagesDiy Ferestrau Vertical at HomeFlorinNo ratings yet

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- 4 Analysis and Design of Steel Deck - Concrete Composite SlabsDocument112 pages4 Analysis and Design of Steel Deck - Concrete Composite SlabsLê Ngọc-Hà100% (2)

- TWAS-Tender Addendum - StructuralDocument116 pagesTWAS-Tender Addendum - StructuralnvnagarajuNo ratings yet

- Bracing Connections To Rectangular Hss Columns: N. Kosteski and J.A. PackerDocument10 pagesBracing Connections To Rectangular Hss Columns: N. Kosteski and J.A. PackerJordy VertizNo ratings yet

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- BCM Block BoardDocument34 pagesBCM Block BoardNidhi JoshiNo ratings yet

- Key structural notes and legend for general building projectDocument1 pageKey structural notes and legend for general building projectMazen Ismail0% (1)

- Wooden Sliding Folding Door: MMBC-6Document1 pageWooden Sliding Folding Door: MMBC-6SNEHA DEVARAJU100% (1)

- Beginner Woodworking Tools ChecklistDocument10 pagesBeginner Woodworking Tools ChecklistpaikiaNo ratings yet

- Partition BB - PPTXPPPPPDocument33 pagesPartition BB - PPTXPPPPPSimran DeepNo ratings yet

- Bamboo Joints and Joinery Techniques - Guadua BambooDocument13 pagesBamboo Joints and Joinery Techniques - Guadua Bambooupendar reddy Mallu50% (2)

- Governing SpecificationsDocument1 pageGoverning SpecificationsAshley JeyahNo ratings yet

- Interior DesignDocument53 pagesInterior DesignJorim Oliver Pornelosa Sumangid100% (1)

- 01 StructuralDocument39 pages01 StructuralSaifullahNo ratings yet

- General Notes: General Design and Detailing Criteria For Suppliers Structural SteelDocument2 pagesGeneral Notes: General Design and Detailing Criteria For Suppliers Structural SteelNguyen SonNo ratings yet

- Structural notes for cold-formed steel framingDocument2 pagesStructural notes for cold-formed steel framingCivix VarixNo ratings yet

- Structural Design Criteria Abbreviations:: S1.00 Raemulan Land IncorporatedDocument1 pageStructural Design Criteria Abbreviations:: S1.00 Raemulan Land Incorporateddaveglai24No ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- General Structural Notes: Wall Intersection DetailDocument1 pageGeneral Structural Notes: Wall Intersection DetailAndrea Mae SanchezNo ratings yet

- General Notes 1Document1 pageGeneral Notes 1Wee RenNo ratings yet

- HSK Lot4312 Fall Restraint Steel Bracket Comment 11august2023Document2 pagesHSK Lot4312 Fall Restraint Steel Bracket Comment 11august2023rickysw 7No ratings yet

- Weight by Drawing Sheet: RevisionDocument1 pageWeight by Drawing Sheet: RevisionOseni MomoduNo ratings yet

- For Construction Drawing - FCD: General Structural Notes & SpecificationsDocument1 pageFor Construction Drawing - FCD: General Structural Notes & SpecificationsJossell De AlaNo ratings yet

- All Plans & Details - 06-05-2020 (1) - S-0.0Document1 pageAll Plans & Details - 06-05-2020 (1) - S-0.0Altaf husainNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- S 1 Structural NotesDocument1 pageS 1 Structural NotesJBFPNo ratings yet

- Niagara Frontier Transportation Authority Serving The Niagara RegionDocument1 pageNiagara Frontier Transportation Authority Serving The Niagara RegionHamid EhsanNo ratings yet

- Construction notes for reinforced concrete detailingDocument1 pageConstruction notes for reinforced concrete detailingShariah MelonNo ratings yet

- S0-03 - General NotesDocument1 pageS0-03 - General NotesJason toraldeNo ratings yet

- General notes and reinforcement detailsDocument1 pageGeneral notes and reinforcement detailsFarhan DanishNo ratings yet

- Design Drawing: Baladna Farm 2 Tse Polishing PlantDocument12 pagesDesign Drawing: Baladna Farm 2 Tse Polishing PlantWasim OfficialNo ratings yet

- S025-F.F Roof.-A3Document1 pageS025-F.F Roof.-A3Ashraf MNo ratings yet

- This Site: Going TO Digos City ProperDocument14 pagesThis Site: Going TO Digos City ProperJude Darwin EmanoNo ratings yet

- S0-04 - General NotesDocument1 pageS0-04 - General NotesJason toraldeNo ratings yet

- Richmond LG Structural SheetsDocument31 pagesRichmond LG Structural SheetsSantiago VALLEJONo ratings yet

- 5 Integration Supersky PDFDocument4 pages5 Integration Supersky PDFnabaeisNo ratings yet

- Proposed Retaining Wall at CHR - Gen NotesDocument1 pageProposed Retaining Wall at CHR - Gen NotesErica PaciaNo ratings yet

- Cantilever Beam DrawingDocument1 pageCantilever Beam DrawingROHIT PANDEYNo ratings yet

- STRUCTURAL NOTES FOR SOLAR PROJECTDocument3 pagesSTRUCTURAL NOTES FOR SOLAR PROJECTKoti Veera Bhadram TammaNo ratings yet

- Structural Notes Guide for Building ProjectsDocument1 pageStructural Notes Guide for Building Projectssua749No ratings yet

- General Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerDocument14 pagesGeneral Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerMark JangadNo ratings yet

- STRUCDocument5 pagesSTRUCEdward D. SarcoNo ratings yet

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Document1 pageDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelNo ratings yet

- BY PASS BRIDGES (1 - 4) - ModelDocument1 pageBY PASS BRIDGES (1 - 4) - ModelHelen Joy AdvientoNo ratings yet

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrNo ratings yet

- Ni Aisi 9024 PipingsystemsDocument27 pagesNi Aisi 9024 PipingsystemsNofrizal HasanNo ratings yet

- Steelwork Steelwork Continuation... Legend Metal Stud Walls: NHQC2 - CF - ST - DWG-00 - S01.03Document1 pageSteelwork Steelwork Continuation... Legend Metal Stud Walls: NHQC2 - CF - ST - DWG-00 - S01.03Ma'arif Nuzul Addib100% (1)

- Structural Notes & Specifications: 3 FormworksDocument1 pageStructural Notes & Specifications: 3 FormworksRonnie Buico Conejos CENo ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- STRUCTURAL RESIDENCEDocument4 pagesSTRUCTURAL RESIDENCE2226558No ratings yet

- General Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersDocument1 pageGeneral Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersByen VillanuevaNo ratings yet

- Project Title: Project Location: Prepared By: Sheet Content: Sheet # Raymar R. Bartolome Carlo C. Cairel SB - 1 6 Submitted ToDocument1 pageProject Title: Project Location: Prepared By: Sheet Content: Sheet # Raymar R. Bartolome Carlo C. Cairel SB - 1 6 Submitted ToRaymar BartolomeNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- BeamDocument1 pageBeamPaschal MazikuNo ratings yet

- Beam PDFDocument1 pageBeam PDFPaschal MazikuNo ratings yet

- General Construction Notes: Typical Connection Detail of Masonry WallDocument1 pageGeneral Construction Notes: Typical Connection Detail of Masonry WallMItchNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- SFSDFDocument1 pageSFSDFbillNo ratings yet

- السقفDocument1 pageالسقفafk.oxfordNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Design SteelStructHeavyLoadDocument6 pagesDesign SteelStructHeavyLoadElqofa BerivanelNo ratings yet

- Fire Resistance of SteelDocument136 pagesFire Resistance of Steeltopnoch5454No ratings yet

- Analysis of Blast Resistant RCC Structure PDFDocument7 pagesAnalysis of Blast Resistant RCC Structure PDFNikhila KanchiNo ratings yet

- TV 19 2012 3 643 652 PDFDocument10 pagesTV 19 2012 3 643 652 PDFsaharuiNo ratings yet

- Steel Beams With Large Web Openings of Various Shapes and Sizes: An Empirical Design Method Using A Generalised Moment-Shear Interaction CurveDocument24 pagesSteel Beams With Large Web Openings of Various Shapes and Sizes: An Empirical Design Method Using A Generalised Moment-Shear Interaction Curvejuan carlosNo ratings yet

- Structural Reliability Analysis of Steel Portal FramesDocument6 pagesStructural Reliability Analysis of Steel Portal FramesAli KhalafNo ratings yet

- Is BN 9512260980Document198 pagesIs BN 9512260980amirgholami1No ratings yet

- Cyclic Response and Design Recommendations of RBS Moment Connections With Deep ColumnDocument10 pagesCyclic Response and Design Recommendations of RBS Moment Connections With Deep ColumnMuhammad irfan javaidNo ratings yet

- Twilt 2001 PDFDocument14 pagesTwilt 2001 PDFMarcelo Zapata MuñozNo ratings yet

- Gusset PlatesDocument11 pagesGusset PlatesJoseph Cristhian Lipa FloresNo ratings yet

- Cyclic BehaviorDocument11 pagesCyclic BehaviorMaria PopNo ratings yet

- Design of Haunched Composite Connections For Long-Span Beam ConstructionDocument10 pagesDesign of Haunched Composite Connections For Long-Span Beam ConstructioncasanovavnNo ratings yet

- Column Web Compression Strength AT END PLATE CON PDFDocument9 pagesColumn Web Compression Strength AT END PLATE CON PDFAli KhalafNo ratings yet

- Design For A Cold-Formed Steel Framed Manufactured HomeDocument36 pagesDesign For A Cold-Formed Steel Framed Manufactured HomeJohn Paulsy100% (1)

- Concrete Encased Composite Column ACI - AISCDocument14 pagesConcrete Encased Composite Column ACI - AISCAli KhalafNo ratings yet

- A Simplified Look at Partially Restrained Beams - GESCHWINDNER - 1991Document6 pagesA Simplified Look at Partially Restrained Beams - GESCHWINDNER - 1991mariovalentiNo ratings yet

- Cost Based EngineeringDocument9 pagesCost Based EngineeringAli KhalafNo ratings yet

- Cyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsDocument11 pagesCyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsAli KhalafNo ratings yet

- Blind Moment ConnDocument9 pagesBlind Moment ConnJim SpsNo ratings yet

- Column Web Compression Strength AT END PLATE CON PDFDocument9 pagesColumn Web Compression Strength AT END PLATE CON PDFAli KhalafNo ratings yet

- Effective Length of T-Stub of Rhs Column Base PlatesDocument10 pagesEffective Length of T-Stub of Rhs Column Base PlatesMelenciuc SilviuNo ratings yet

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDocument25 pagesAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyNo ratings yet

- A Fresh Look at Bolted End-Plate Behavior and Design - Krishnamurthy1978q2Document11 pagesA Fresh Look at Bolted End-Plate Behavior and Design - Krishnamurthy1978q2mert_atasoyNo ratings yet

- Welded Connections in High Strength SteelsDocument11 pagesWelded Connections in High Strength SteelsAli KhalafNo ratings yet

- Beam To SHS ColumnDocument8 pagesBeam To SHS ColumnAli KhalafNo ratings yet

- Theoretical Analysis of The Structural Performance of Space Trusses Commonly Used in BrazilDocument24 pagesTheoretical Analysis of The Structural Performance of Space Trusses Commonly Used in BrazilCarlos RodriguesNo ratings yet

- Tests of Cold-Formed Lipped C-Section Members Subject to CompressionDocument6 pagesTests of Cold-Formed Lipped C-Section Members Subject to CompressionAli KhalafNo ratings yet

- Cyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsDocument11 pagesCyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsAli KhalafNo ratings yet

- Loft Materials ListDocument19 pagesLoft Materials ListJose Rafael Rodriguez MonteroNo ratings yet

- Ledged, Bracedandbattened'Timber Doorshutters-Specification (Document12 pagesLedged, Bracedandbattened'Timber Doorshutters-Specification (Pramukh Test houseNo ratings yet

- Notice: Antidumping: Persulfates From— CanadaDocument9 pagesNotice: Antidumping: Persulfates From— CanadaJustia.comNo ratings yet

- Groove Boards by Jaali in PDFDocument44 pagesGroove Boards by Jaali in PDFGunjan ShahNo ratings yet

- Homemade Drill Press ViceDocument15 pagesHomemade Drill Press ViceEricsNo ratings yet

- Anutone Ekcel Tufbloc HDFR AcousticsDocument4 pagesAnutone Ekcel Tufbloc HDFR AcousticsInterior ProjectsNo ratings yet

- Architectural Patterns - Tudor Revival (PDF) - 201505211539364731Document10 pagesArchitectural Patterns - Tudor Revival (PDF) - 201505211539364731Leo196No ratings yet

- Stair Notes FunctionsDocument7 pagesStair Notes Functionsweston chegeNo ratings yet

- Types of WindowsDocument16 pagesTypes of WindowsShivamNo ratings yet

- Try Square PDFDocument7 pagesTry Square PDFzlaja_25No ratings yet

- Workshop Practice-I ES - ME - 292 Manual MainDocument55 pagesWorkshop Practice-I ES - ME - 292 Manual MainKunal KumarNo ratings yet

- 06 4113 Wood-Veneer-Faced Architectural CabinetsDocument8 pages06 4113 Wood-Veneer-Faced Architectural CabinetsEva MarquezNo ratings yet

- Accessories and Attachments of Lathe MachineDocument6 pagesAccessories and Attachments of Lathe MachinejadeNo ratings yet

- Building Science and Environment Services Lab Report SoundDocument14 pagesBuilding Science and Environment Services Lab Report SoundMUN SIM SOHNo ratings yet

- FI - PK.FIT.001 - BASE 1: Fitting Guide Base CabinetDocument1 pageFI - PK.FIT.001 - BASE 1: Fitting Guide Base CabinetChris MilnerNo ratings yet

- Quotation for Marvens & Co renovationDocument11 pagesQuotation for Marvens & Co renovationArsalan YaqoobNo ratings yet

- Liyuan Library and Prostheo Museum: A Comparison of Site, Culture, Grid and MaterialDocument35 pagesLiyuan Library and Prostheo Museum: A Comparison of Site, Culture, Grid and MaterialJohn AdrianNo ratings yet

- Data 13-03-2020 Jadwal Ujian CBT Umum Sektor Manufaktur Tahun 2020 Gelombang 1 Jakarta PDFDocument72 pagesData 13-03-2020 Jadwal Ujian CBT Umum Sektor Manufaktur Tahun 2020 Gelombang 1 Jakarta PDFJauhar MaknunNo ratings yet

- Nari GandhiDocument16 pagesNari GandhiChandrahas ChandrahasNo ratings yet

- Cashflow and Bar ChartDocument7 pagesCashflow and Bar ChartAries Villegas MontabonNo ratings yet