TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

1 of 8 Effective Date: [EffectiveDate]

Revision History Details

Re Date Modification History Prepared by Reviewed by Approved by

v

A 03-12-2020 Initial Release( WMI-P2-PRO-HR-023 Mallikarjunachari V N Veerabhadra S M Senthilkumar I

Rev B obsoleted and released in

common folder)

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

2 of 8 Effective Date: [EffectiveDate]

Table of Contents

1.0 Purpose:...........................................................................................................................3

2.0 Scope:..............................................................................................................................3

3.0 Abbreviation:....................................................................................................................3

4.0 Roles & Responsibility:....................................................................................................3

5.0 Related Documents:.........................................................................................................3

6.0 Process flow & Description:.............................................................................................4

6.1 Work Permit Process Flow:..........................................................................................4

6.2 Work Permit Process description:.................................................................................5

7.0 Check/Verification:...........................................................................................................8

8.0 Reference documents:.....................................................................................................8

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

3 of 8 Effective Date: [EffectiveDate]

1.0 Purpose:

This Operational Control Procedure is to ensure work permit is provided to contractors/Vendors working in the

premises of Wistron India Bengaluru for working at heights, Hot Work, Confined space work, Electrical work and

General work carrying out hazardous process,

2.0 Scope:

This procedure is applicable for control of documents to the within all Construction sites and Operations of

WMI1.1, Bengaluru and WMI2, Narasapura.

3.0 Abbreviation:

PPE : Personal Protective Equipment

LOTO : Lock out Tag Out

JSA : Job Safety Analysis

WMS : Work Method Statement

HIRA : Hazard Identification and Risk Assessment

4.0 Roles & Responsibility:

Roles Responsibility

Security Person Inform to EHS team and to the in-charge of the vendor through phone call.

Allow the vendor to workplace after receiving the signed copy of work permit

Issuer Initiating and completing all applicable section of the permit to work. ... Supervising

the work prescribe in the permit to work to ensure it is conducted in the most efficient

manner. Notifying the issuer of work progress and completion, and ensuring that the site is

return to a safe and operational state.

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

4 of 8 Effective Date: [EffectiveDate]

To ensure that required PPE’s are used by the vendor before starting the work.

To ensure that LOTO system is followed wherever applicable.

To communicate to area in-charge in advance / before starting the work and get the

signature done.

Area In-charge To ensure workplace safe for carrying out the work allocated to the vendor.

To ensure multiple works not carried out simultaneously.

To read and sign the work permit before starting the work.

Safety Officer / EHS: Authorizes and ensure the work permit, proper PPE used.

Cross checking of filled work permit and ensure if any addition and deletion

Rights to reject the work permit if not meet the requirements.

To check the legal compliance if applicable to the activity.

To ensure that work permit filled by the issuer is meeting the safety requirements.

Vendor/Contractor To Ensure Safety measure while working

To understand and follow the company safety police and procedures.

Vendor or Contract supervisor should be closing of work permit and return to EHS team for

documentation.

To carry the necessary certificates or licence which has applicable for the work related tools

and tackles

Only competent person should carry out the work.

Vendor should thoroughly read the work permit, sign the permit and follow same in the

workplace.

5.0 Related Documents:

Document Number Description

WMI-GLO-PRO-HRD-006 Lockout Tag out Procedure

WMI-P2-GEN-REC-011 HIRA Register (WMI 2)

WMI-P1.1-GEN-REC-003 HIRA – Register (WMI 1.1)

WMI-GLO-FOM-HRD-016 Work Permit Form

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

5 of 8 Effective Date: [EffectiveDate]

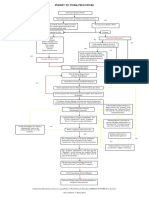

6.0 Process flow & Description:

6.1 Work Permit Process Flow:

Facility Officer / Admin Executive Area In-charge Safety Officer /EHS Officer

Vendor / Contractor / Work In-charge DRI

Start

Work plan for Non-routine,

Critical

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

Work accepted by Assign the work to

Vendor / Contractor approved vendor

� Filling of Work permit

confirming the same to

Form

Client

TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

[VersionNo]

Area in-charge will beVersion: Safety Officer Check

approve for6work the safety

Approach for LOTO to of 8 to Effective Date: [EffectiveDate]

concern Person No carry with signature on requirements based

Work permit form on the Nature of work

being carry out

Yes

Authorized person

should be ensure

LOTO and Certify

Work permit receive

Receiving of Work

from Safety officer Approve the Work and

permit and Start the

after approval and handover to Issuer

work

handover to Vendor

Cross checking of Work

Close the Work permit Remove the LOTO To Ensure Worked Permit and close

after completion of and Close the Work area, close the Work

Work and Checkout permit permit

from worked area

Security Officer will retain

work permit signed copy of

record

End

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

7 of 8 Effective Date: [EffectiveDate]

6.2 Work Permit Process description:

a) Work Permit Form issuing and authorization procedure

Work permit must be required for Non-routine / Critical works therefore Facility Officer / Admin Executive /

Work In-charge DRI should be propose to work with management approval to authorized vendors or

contractors

Authorized contractors or vendors want accept and plan for job and send feedback to client with necessary

safety precautions

Before entry of any vendors or contractors should be obtain work permit form so Work In-charge should be fill

the work permit, which has available at security gate.

Work in-charge shall be issue the Work permit to the contractor for work involving working at heights, carrying

out hazardous process, working with processes involving heat and doing electrical works

The contractor/Vendor first signs the ‘application for taking up contract work which provides the name &

address of the contractor, type of work assigned to him, safety instructions the contractor has to abide while

carrying out the work.

Work In-charge should be take work authorization from area in-charge, Any area in-charge’s positions has

been Engineer and above

The work permit contains the date of issue of permit, permit validity, location of work, nature of work involved,

No. of contractors, LOTO for applicable electrical and mechanical works , safety instructions adhered by

vendor types of hazards & risks and required PPE to be worn by the contractor while carrying out the work

assigned to him,/her Instructions to be given to the contractor with regard to environmental and occupational

health & safety requirements involved in his work, declaration by contractor and permit authorization by

competent personnel.

Work In-charge instructs the contractor on the hazards and risks involved while carrying out the work

assigned to him, the type of PPE to be used by him while carrying out the work, emergency preparedness

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

8 of 8 Effective Date: [EffectiveDate]

and response requirements, environmental and occupational health & safety requirements to be met by the

organization, location of fire extinguishers, first aid facility available.

The contractor/Vendor and duly signs the work permit for having understood the environmental and

occupational health & safety requirements to be meet by the organization.

Safety Officer Check the safety requirements based on the Nature of work and approve the same.

Applicable PPE’s mentioned/ticked by the vendor shall be use and worn during work.

Contractor or Vendor should be clear the work and remove the unwanted material from the work place and

close the work permit and inform to work in-charge for further process

Follow of energize the LOTO for applicable electrical, hydraulic, thermal equipment

Work in-charge and area in-charge should check the worked area and close the work permit and submit to

security department

Work permit filing by the security in charges and maintain up to 5 years from the issuing date.

b) All employees/vendor who work in an area where energy are utilized need to be instructed in the purpose and

use of the energy especially prohibition against attempting to restart or reenergize machines or other

equipment that are locked or tagged out.

c) All relevant machines/equipment shall be lock out to protect against accidental or inadvertent operation when

such operation could cause injury to personnel. Lockout will also apply when working on or near exposed De-

energized electrical circuits / parts

d) No employee/vendor shall attempt to operate any switch, valve, or other energy -isolating device, which is

lock out.

e) Each lockout device shall only be removed by the Maintenance supervisor/maintenance technician who

applied the device

f) Before tagging Stop machine, unplug cord, and install clamshell, lock, and tag.

g) Verify the attempt to start machine, visually confirm it will not start.

h) Once after the completion of the work, the work permit shall be close for the day by signing off by

contractor/vendor and Maintenance/Responsible person.

i) The permit closure shall be verified by the security and Safety officer signs off

Note: ONLY the authorized individual who placed the lock and tag onto the system is the one who is permitted to

remove them. This procedure helps make sure the system cannot be start up without the authorized individual’s

knowledge.

A. Dangers can arise in confined spaces because of:

Fire or explosion, e.g. from flammable vapors, excess oxygen, etc.

Presence of dust in high concentrations, e.g. in flour silos.

Hot conditions leading to a dangerous increase in body temperature.

A lack of oxygen.

B. Basic principles of safety precautions

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

9 of 8 Effective Date: [EffectiveDate]

Avoid entering confined spaces, e.g. by doing the work from outside;

If entry to a confined space is unavoidable, develop and implement a safe system of work; and

Devise an appropriate emergency plan before the work starts.

C. Isolation

Disconnect and properly lock off the power supply of all the machinery and equipment that could cause hazards

in a confined space; blank off pipelines and service pipes with contents that could cause hazards; take effective

steps to prevent an ingress or in-rush to the confined space of hazardous gas, vapor, dust, fume or free flowing

solid and liquid.

D. Cleaning and cooling before entry

a) Check the size of the entrance

The entrance should be big enough to allow workers wearing all the necessary equipment to get in and out

easily, and provide safe access and egress in an emergency.

b) Provision of ventilation

c) Testing the air

d) Provision of special tools and lighting.

e) Provision of personal protective equipment

Provide and keep readily available in a satisfactory condition a sufficient supply of:

Approved breathing apparatus

Suitable reviving apparatus

Vessels containing oxygen or air

Safety harness and ropes

An audio and visual alarm for alerting others outside the confined space.

Oxygen level monitor

f) Issuance of Confined Work permit

g) Emergency plan

h) Communications

i) Emergency services

E. Dangers can arise in hot work because of:

Fire or explosion, e.g. from flammable vapors, etc.

Burn Injury and Fumes

Non – lionizing radiations

Sparks

Gas cylinders falling, rolling

Work wise PPE’s Matrix:

List of Personal Protective Equipment’s for carrying out the specified works

Personal protective Equipment’s General work Hot work Height Work Confined Space Electrical Work

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A

� TITLE: Work Permit Procedure

Management

Doc. No: [DocNo]

System

DEPARTMEN: HR CLASSIFICATION: Procedure PAGE

Version: [VersionNo]

10 of 8 Effective Date: [EffectiveDate]

Hard Hat

Nose Mask

Respirators

Ear muff/plug

Safety Goggles

Hand gloves

Face shield

Safety Harness

Full body suit

Safety Shoes

Correction and Corrective Actions:

In case of any deviations as per this procedure, the Maintenance and Administration raise non-conformance report.

Maintenance and Administration in charges ensures corrections & corrective actions are taken without undue delay.

Retention:

All the above-mentioned records are retained for 5 years for analysis and to identify opportunities for continual

improvements.

All work permit form (WMI-GL0-FOM-HRD-016) to be fill by authorized issuer.

7.0 Check/Verification:

a) The results of measurements are checked by in order to ensure that they meet the statutory & regulatory

requirements.

b) The Administration -in charge also verifies with the service provider that the measuring instruments used by

the external agency do have valid calibration.

c) The test records of the water report will maintained

8.0 Reference documents:

Document Number Description

ISO 9001:2015 Quality Management System [Clause 8.1]

ISO 14001:2015 Environmental Management System [Clause 8.1]

ISO 45001:2018 Occupational Health and Safety Management System [Clause 8.1 ]

Note: "Document has been electronically reviewed & approved through DCC System"

Format Number: WMI-GLO-GEN-TEM-003 Rev A