Professional Documents

Culture Documents

Procedure For Hot Punching

Uploaded by

parshuram malvekar0 ratings0% found this document useful (0 votes)

6 views2 pagesThis document outlines the procedure for hot punching stickers at Siddhivinayak Industries. It describes cleaning and preparing the machine, taking the inspection report and materials, setting sizes on the machine, punching samples, conducting inspections, completing the punching process, handling scrap and finished materials, and safety specifications. The operator is responsible for following the procedure and inspection reports are used to record the process.

Original Description:

Original Title

Procedure for Hot Punching

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the procedure for hot punching stickers at Siddhivinayak Industries. It describes cleaning and preparing the machine, taking the inspection report and materials, setting sizes on the machine, punching samples, conducting inspections, completing the punching process, handling scrap and finished materials, and safety specifications. The operator is responsible for following the procedure and inspection reports are used to record the process.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesProcedure For Hot Punching

Uploaded by

parshuram malvekarThis document outlines the procedure for hot punching stickers at Siddhivinayak Industries. It describes cleaning and preparing the machine, taking the inspection report and materials, setting sizes on the machine, punching samples, conducting inspections, completing the punching process, handling scrap and finished materials, and safety specifications. The operator is responsible for following the procedure and inspection reports are used to record the process.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

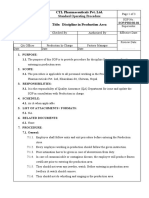

SIDDHIVINAYAK INDUSTRIES

Doc.: Procedure for Hot punching Doc. No. SPI/8.5.1/SOP-01 Page 1 of 2

Issue No: 00 Issue Date: 13.06.2019 Rev. No: 0 Rev. Date: --

PROCEDURE FOR STICKER HOT PUNCHING

1. PURPOSE: To do the hot punching of the material as per the Inspection report and the

specification chart.

2. SCOPE: This procedure as applicable to the functions of die punching machine operator.

3. RESPONSIBILITY: It is the responsibility of the Hot punching machine operator to do work as

per the Inspection report and specification sheet.

4. REFEENCE: Inspection report, Supervisor

5. PROCEDURE:

5.1 Do Machine & Screen Zig cleaning by using dry cloth.

5.2 Clean all Sticker with help of thinner

5.3 Do oiling and greasing to the moving parts.

5.4 Take Inspection report from the supervisor. (Inspection report no. SPI/8.5.1/F-01)

5.5 Take material from the store and check for its size.

5.6 Set size on the cutting machine by referring customer drawings.

a. Set machine for proper Zig

b. Check alignment of press bed and the tool

c. Ensure the punch plate matched properly

d. Punch for the required measurement.

e. Check sample for the proper finish, like bur, damage etc.

5.7 Do inspection for the first piece as per the specifications.

5.8 If Visually & Fitment is ok then start the further punching process and record on the

inspection report

5.9 Do in-process inspection and record after every 4 hours per lot on the Inspection report on

daily basis.

5.10 Check for the cut, damage, bend, dent & surface finish of the jobs. If Jobs is not up to the

mark then reject it and record accordingly.

REVIEWED BY : PRATIK TRIVADI APPROVED BY: PRASAD DALAL

SIDDHIVINAYAK INDUSTRIES

Doc.: Procedure for Hot punching Doc. No. SPI/8.5.1/SOP-01 Page 2 of 2

Issue No: 00 Issue Date: 13.06.2019 Rev. No: 0 Rev. Date: --

PROCEDURE FOR STICKER HOT PUNCHING

5.11 After completion of job handover material to next department. Segregate scrap as well as

produced material, put identification label and keep in the designated area.

5.12 If any problem then contact supervisor.

5.13 SAFETY SPECIFICATION S

a. Ensure surrounding area is clean and free from trip hazards.

b. Make process with safety requirements.

c. Safety precautions should be taken before performing the operation.

d. Refer Job specification for the job operation.

e. Job taken for the process must be properly inspected.

f. Remove wire connections or switch off the mains during any maintenance.

g. Do not put hand or any object in moving parts of machine.

h. Switch of the machine, if any abnormal sound appears

i. Always use safety equipments where ever necessary.

6.0 RECORD:

Sr. Document/ Record Name Doc./ Record No.

1. In-process Inspection Form SPI/8.5.1/F-01

Inspection report Cum In-process Inspection

2. SPI/8.5.1/R-01

Record File

REVIEWED BY : PRATIK TRIVADI APPROVED BY: PRASAD DALAL

You might also like

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- ESCL-SOP-016, Work Instruction For WorkShop OperatorsDocument5 pagesESCL-SOP-016, Work Instruction For WorkShop OperatorsadiqualityconsultNo ratings yet

- SQ Mark & 100ppm ChecklistDocument14 pagesSQ Mark & 100ppm Checklistkarpags100% (2)

- Pipe Bend Procedure SA-4200-70621Document7 pagesPipe Bend Procedure SA-4200-70621mohd as shahiddin jafri100% (1)

- All Work InstructionsDocument7 pagesAll Work InstructionsAmine Chahi100% (1)

- 16 - Procedure For Control of Production Provisions (Machine Shop I &II)Document6 pages16 - Procedure For Control of Production Provisions (Machine Shop I &II)rockyNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- Work Instruction FormatDocument17 pagesWork Instruction Formatdevaraj100% (1)

- Ooredoo: Method Statement For Fiber Optic Cable WorkDocument5 pagesOoredoo: Method Statement For Fiber Optic Cable WorkYousaf RichuNo ratings yet

- Method Statement For Internal Rotary Inspection System: Document No: D-P5-BV-MS-011Document4 pagesMethod Statement For Internal Rotary Inspection System: Document No: D-P5-BV-MS-011Thinh NguyenNo ratings yet

- Sop For Operating Dry GranulatorDocument3 pagesSop For Operating Dry GranulatorsaimaNo ratings yet

- What Is Fibonacci Trading - A Complete Guide by Xena ExchangeDocument6 pagesWhat Is Fibonacci Trading - A Complete Guide by Xena Exchangejose58No ratings yet

- SOP For Cleaning of Packing AreaDocument2 pagesSOP For Cleaning of Packing AreaBejoy Karim100% (4)

- Hydrotest Ansi b31.3 2017Document13 pagesHydrotest Ansi b31.3 2017Bangkit SusiloNo ratings yet

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDocument7 pagesProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistnasirNo ratings yet

- Night AuditDocument16 pagesNight AuditKumarasamy Vijayarajan100% (1)

- OQ Protocol Capsulating MachineDocument11 pagesOQ Protocol Capsulating MachineNadine LilleNo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Sop For Operation of Sachet Filling MachineDocument3 pagesSop For Operation of Sachet Filling Machinesaima56% (9)

- Project Work InstructionDocument5 pagesProject Work InstructionRAJU RAJPUTNo ratings yet

- Sop For Bag FilterDocument5 pagesSop For Bag FiltervinodsnNo ratings yet

- 5-Operation & Cleaning of Ropp Sealing MachineDocument3 pages5-Operation & Cleaning of Ropp Sealing MachineananthNo ratings yet

- House Keeping (Shazoo)Document3 pagesHouse Keeping (Shazoo)usman javaid100% (1)

- Saudi Aircon Method StatementDocument12 pagesSaudi Aircon Method StatementSavad AlwyeNo ratings yet

- Method of Statement Scafollding WorksDocument6 pagesMethod of Statement Scafollding WorksAhmed saberNo ratings yet

- Sop For Operating Tray DryerDocument3 pagesSop For Operating Tray Dryersaima0% (1)

- 44-O&C Blister Packing MachineDocument7 pages44-O&C Blister Packing MachineananthNo ratings yet

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- Visual Inspection Procedure 0222 160 P PT PTJ 0008Document7 pagesVisual Inspection Procedure 0222 160 P PT PTJ 0008Yassine Koot100% (1)

- Process & Product Audit Check SheetDocument6 pagesProcess & Product Audit Check SheetPrakashRai100% (7)

- BSC Unit 2 AssignmentDocument17 pagesBSC Unit 2 AssignmentJamshar Kt89% (9)

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- MS Concrete Crack RepairDocument5 pagesMS Concrete Crack Repairjoseph guiyab100% (1)

- Fco Sib Rizal PDFDocument2 pagesFco Sib Rizal PDFJulian NicoNo ratings yet

- PS 7 - Chapter 9 - An Analysis of Conflict (Solutions)Document31 pagesPS 7 - Chapter 9 - An Analysis of Conflict (Solutions)Matteo Vidotto0% (1)

- Dust Extractor - IQOQPQDocument13 pagesDust Extractor - IQOQPQAtul Sharma0% (1)

- STD-InSP-0005 (Plate Inspection Procedure)Document3 pagesSTD-InSP-0005 (Plate Inspection Procedure)airbroomNo ratings yet

- SOP For Change OverDocument6 pagesSOP For Change OverJayesh Meharwal100% (3)

- Preventive MaintenanceDocument2 pagesPreventive Maintenancedoctor_mumairkNo ratings yet

- Ppap 02080 - A01Document66 pagesPpap 02080 - A01shiromaxs100% (1)

- DPWH Structural 01Document9 pagesDPWH Structural 01AndengBaduriaNo ratings yet

- D-p5-Bv-pd-016 - FT, Issue 01, Rev 00 - Ferrite TestDocument12 pagesD-p5-Bv-pd-016 - FT, Issue 01, Rev 00 - Ferrite TestThinh NguyenNo ratings yet

- PPEPL-SOP-03 Procedure For Control of NCDocument7 pagesPPEPL-SOP-03 Procedure For Control of NCRaja RehaNo ratings yet

- GPE-16 Refractory Concrete Installation Procedure R. 1pdfDocument12 pagesGPE-16 Refractory Concrete Installation Procedure R. 1pdfmaupatas100% (1)

- Procedure For AssemblyDocument2 pagesProcedure For Assemblyparshuram malvekarNo ratings yet

- Project Work Instruction BackupDocument4 pagesProject Work Instruction BackupRAJU RAJPUTNo ratings yet

- MAPP OTP 001 Rev1.2 PDFDocument11 pagesMAPP OTP 001 Rev1.2 PDFTee Klong RungNo ratings yet

- Production SOPDocument26 pagesProduction SOPSales Creative EngineeringNo ratings yet

- Regent Garment - IED-SOP 020 Scan & PackDocument3 pagesRegent Garment - IED-SOP 020 Scan & Packie.madeups.ktml1No ratings yet

- 6 Inspection Report - LP Heater 7 - PMT 4004 - MIOV 2019Document4 pages6 Inspection Report - LP Heater 7 - PMT 4004 - MIOV 2019zaihasrenNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Ingress Protection-IP66-IEC60529Document12 pagesIngress Protection-IP66-IEC60529tushar2.khandelwalNo ratings yet

- Method Statement For VESSEL 1180-E: Expertise Contracting CompanyDocument6 pagesMethod Statement For VESSEL 1180-E: Expertise Contracting CompanyFaraz AhmedNo ratings yet

- Sop of Octangonal BlenderDocument3 pagesSop of Octangonal BlenderHamidNo ratings yet

- SOP On Discipline in Production AreaDocument3 pagesSOP On Discipline in Production AreaRakesh Rauniyar100% (1)

- 01 - 04.00 Sop For Cleaning CorridorsDocument3 pages01 - 04.00 Sop For Cleaning CorridorsYashNo ratings yet

- Scope of Test and Inspection For Insulating WorkDocument5 pagesScope of Test and Inspection For Insulating WorkDineshNo ratings yet

- D p5 BV Ms 013 Msra For ViDocument4 pagesD p5 BV Ms 013 Msra For ViThinh NguyenNo ratings yet

- 0705 Die ApprovelDocument4 pages0705 Die ApprovelSundara Rajan RamakrishnanNo ratings yet

- 190724005SHF-001 Drum Peel Strength PDFDocument5 pages190724005SHF-001 Drum Peel Strength PDFaziz hNo ratings yet

- D.Y.Patil. College of Pharmacy, Pune: Instrument DetailsDocument3 pagesD.Y.Patil. College of Pharmacy, Pune: Instrument DetailsNavdeep ChaudharyNo ratings yet

- 50 IC30 GEN 004 A IC Offline ProgrammingDocument8 pages50 IC30 GEN 004 A IC Offline ProgrammingnguyencaohuygmailNo ratings yet

- Lkt-Prc-Qaqc-Pip-0019 Insulation ProcedureDocument6 pagesLkt-Prc-Qaqc-Pip-0019 Insulation ProcedureHerman Syah100% (1)

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- Business School ADA University ECON 6100 Economics For Managers Instructor: Dr. Jeyhun Mammadov Student: Exam Duration: 18:45-21:30Document5 pagesBusiness School ADA University ECON 6100 Economics For Managers Instructor: Dr. Jeyhun Mammadov Student: Exam Duration: 18:45-21:30Ramil AliyevNo ratings yet

- Unitile Raised Access FlooringDocument23 pagesUnitile Raised Access Flooringsaloni patilNo ratings yet

- Operations ManagementDocument50 pagesOperations ManagementasprillaNo ratings yet

- Foundations of Financial Management 16th Edition Block Test BankDocument35 pagesFoundations of Financial Management 16th Edition Block Test Bankwinifredholmesl39o6z100% (25)

- Nor Cal IsolationPoppetValvesDocument26 pagesNor Cal IsolationPoppetValvesinfoNo ratings yet

- Large bore size Filter Specifications・How to order・Dimensions (0.6MB)Document12 pagesLarge bore size Filter Specifications・How to order・Dimensions (0.6MB)Adrian SetyadharmaNo ratings yet

- Blinder-Is There A Core of Practical Macro We Should BelieveDocument7 pagesBlinder-Is There A Core of Practical Macro We Should BelieveSantiagoNo ratings yet

- Liebherr LTC 1045-3-1 Part CatalogueDocument3 pagesLiebherr LTC 1045-3-1 Part Catalogueelisa100% (60)

- SRC SEC (1008)Document28 pagesSRC SEC (1008)Muhammad DanialNo ratings yet

- Financial Analyst or Senior Economist or Senior Risk AnalystDocument3 pagesFinancial Analyst or Senior Economist or Senior Risk Analystapi-77399063No ratings yet

- RFL Lined Ball ValveDocument4 pagesRFL Lined Ball ValveRasaii Flow Lines Pvt. LtdNo ratings yet

- Valpra Wash Basin E-Catalogue 13 Juni 2023Document14 pagesValpra Wash Basin E-Catalogue 13 Juni 2023Aska JanakiNo ratings yet

- Testing Linear Restriction: DR Hédi EssidDocument19 pagesTesting Linear Restriction: DR Hédi Essidcyrine chahbaniNo ratings yet

- FLC Application FormDocument10 pagesFLC Application FormMuhammad Zaheer NaivasalNo ratings yet

- Hazel Bumanglag Salomon: Employment HistoryDocument1 pageHazel Bumanglag Salomon: Employment HistoryJOEFRAN ENRIQUEZNo ratings yet

- Footplate Inspection Conducted By: Divisional Telecom Engineer Sukkur, at Roh-Kpr Section On.15.12.2020Document3 pagesFootplate Inspection Conducted By: Divisional Telecom Engineer Sukkur, at Roh-Kpr Section On.15.12.2020Ahmed NoumanNo ratings yet

- Office Address Ro BangaloreDocument3 pagesOffice Address Ro Bangaloresandeep naikNo ratings yet

- BWN TicketDocument3 pagesBWN TicketSOUMMYA KARMAKARNo ratings yet

- MSL 19 0003Document1 pageMSL 19 0003Sovanna HangNo ratings yet

- Rolando Pacana vs. Atty. Maricel Pascual-Lopez-Case DigestDocument2 pagesRolando Pacana vs. Atty. Maricel Pascual-Lopez-Case Digestrejine mondragonNo ratings yet

- Acc Statement 1120566636663 2023-10-01 2023-10-31 20231215111413Document1 pageAcc Statement 1120566636663 2023-10-01 2023-10-31 20231215111413Agung MaharNo ratings yet

- Chapter - 5 Capital BudgetingDocument9 pagesChapter - 5 Capital BudgetingShuvro RahmanNo ratings yet

- Real Estate Economics in PakistanDocument3 pagesReal Estate Economics in PakistanAli AkhtarNo ratings yet

- Regional Integration in Africa PDFDocument6 pagesRegional Integration in Africa PDFSean JoshuaNo ratings yet

- Introduction in Construction IndustryDocument16 pagesIntroduction in Construction IndustryGerald KhoNo ratings yet