Professional Documents

Culture Documents

Man Vs Sulzer All Differences

Uploaded by

Philic Rohit0 ratings0% found this document useful (0 votes)

135 views2 pagesMan and sulzer engine difference

Original Title

Man vs Sulzer all differences

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMan and sulzer engine difference

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

135 views2 pagesMan Vs Sulzer All Differences

Uploaded by

Philic RohitMan and sulzer engine difference

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

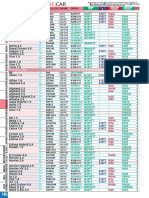

S.

No ITEM MAN B&W SULZER COMMON

Control air on top - Open

1 Starting Air valve Control air on top - Open Control Air on bottom - Close

(for +ve closing)

Both have NRV

2 Main Air Start Valve Ball Valve operated by Rack and Pinion Balancing Piston type

arrangement

3 Stating Air Manifold Bursting Disc Flame Trap

Negative cam. For overlap and not to

allow air while running . By retrival of

2 cams are mounted on the

piston. 1st method - Inner cam

4 AIR Distributor shaft. The shaft shifted

and outer cam combination 2nd

axially by pneumatic piston

method - ahd and astern cams axially

shited

Shifting Cam Follower. Follower will

move only when the engine is RD , RND - Rotating cam

rotating. During movement Puncture shaft (because Loop

valve is activated. Even if the follower Scavenging was there)

5 Fuel Cam Reversing did not move , Only indication will be RTA - Rotating cam

given in control room; The engine will alone by servo motor( 2

continue to start. High Exh temp cams rotated by 1 servo

deviation woukd activate but can run motor) Lost Motion Angle

for short time in emergency.

Only bottom shell is fitted(

Top and Bottom shells are employed. no grooves). Top crosshead

6 Cross head Bearing Shells have multiple wedges to assist bearing cover coated with

hydrodynamic lubrication white metal. No top shell

fitted.

Telescopic Pipe .

Cross head MC Engine - Tele. Pipe bolted to cross

7 Articulate Pipe

Lubrication head pin MCC Engine - Tele. Pipe

bolted to one of the guide Shoe

RTA - crosshead lub oil

pump fitted . 12 bar only.

Cross head same system pressure 4-5 Bar

8 (Hydrostatic Lubrication)

Lubrication (Hydrodynamic Lubrication )

RTFLEX - same system

pressure 5 bar

MC - 2 big tie rod per trasverse

RTFlex - 2 Big Tie Rods per

9 Tie Rod grider MCC - 4 small Tie rods( No

Transverse Grider

nut on bottom)

10 VIT fuel rack and VIT Rack Suction and spill valves

11 Cam shaft Coupling SKF Sleeve Coupling

12 servo oil pump ME - axial piston pump

ME C - CCU (cylinder control unit with

ELFI,ELVA & ALS)

13 Electronic Engine RTFLEX - ICU and VCU

ME B - HCU (hydralic Cyl Unit with

FIVA )

14 Exhasut valve seat W seat Plain seat

15 Fuel Injector NRV inside Injection No NRV in Sulzer

No Umberla seal in Suction

16 Fuel Pump Umberlla Seal.

Spill port design.

No Helix in Suction Spill port

17 Fuel Pump Double Helix

design.

Before this wet quil

RTFLEX- quill located below

ME- quill located below CW space. No was theres. It was

18 Lubricator Quil CW space. No need to drain

need to drain the CW for removal. going to liner through

the CW for removal.

CW space

19 Piston Crown Oros Design Conventional design

3 Rings. Top with S type

20 Piston ring 4 rings. Top with CPR and S type joint.

Joint. No CPR

PREPARED BY

VIGNESH KANAGARAJ

You might also like

- CVVT System CVVT SystemDocument15 pagesCVVT System CVVT SystemSubbu Kannappan SrinivasanNo ratings yet

- Hyd0029 DX Control Valve KVMG 270Document39 pagesHyd0029 DX Control Valve KVMG 270Abdelrahman SharafNo ratings yet

- Wartsila v/s MAN Marine Engines- Who’s is the bestDocument13 pagesWartsila v/s MAN Marine Engines- Who’s is the bestRachit SharmaNo ratings yet

- Turbine Presentation ForgetDocument97 pagesTurbine Presentation ForgetavtarsinghsandhuNo ratings yet

- Gas TurbineDocument76 pagesGas TurbineKaung Htet ChoNo ratings yet

- SY215C 9 ExcavatorDocument91 pagesSY215C 9 ExcavatorTalita Yasmin Talita100% (7)

- Presentasi VVT-i Unautorized - PpsDocument16 pagesPresentasi VVT-i Unautorized - PpssapikurkurNo ratings yet

- RDT Steering System Pressure ChartDocument118 pagesRDT Steering System Pressure ChartAnonymous 340A7vnwV1100% (2)

- Boiler Feed Pump: Basics & Its ConstructionDocument88 pagesBoiler Feed Pump: Basics & Its ConstructionVARCHAS MITTALNo ratings yet

- Steam Turbine Governing System 210mwDocument74 pagesSteam Turbine Governing System 210mwRajani Kanta MundaNo ratings yet

- Microsoft PowerPoint - ECM660 III Hyd Info Read-OnlyDocument32 pagesMicrosoft PowerPoint - ECM660 III Hyd Info Read-OnlyJannie van Staden100% (2)

- 660III HYD CircuitDocument32 pages660III HYD CircuitaugustoNo ratings yet

- Technical Training Guide v1.2 Key Systems OverviewDocument157 pagesTechnical Training Guide v1.2 Key Systems OverviewGogu Ilie0% (1)

- Stage1 TurbineDocument28 pagesStage1 TurbineNikhilNo ratings yet

- 6 - WDM2 Location PDFDocument83 pages6 - WDM2 Location PDFManohar GehlotNo ratings yet

- QYB Submersible Oil PumpDocument7 pagesQYB Submersible Oil PumpAnonymous Tj3ApePIrNo ratings yet

- 1 Trent 1000 - Pocket GuideDocument57 pages1 Trent 1000 - Pocket GuideJuan Lozano100% (3)

- ALgbDocument2 pagesALgbOlivier MontagueNo ratings yet

- 07 TransmissionDocument77 pages07 TransmissionRachmatulloh RamdaniNo ratings yet

- HTMT Power Generation SeminarDocument144 pagesHTMT Power Generation SeminarVhic Estefani100% (1)

- (Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)Document8 pages(Customer) 04 DX75-5B Control Valve (BCV-65) (To Print)AimHighNo ratings yet

- CAT th103-2Document2 pagesCAT th103-2adbernego montenegroNo ratings yet

- Stage 2 TDBFPDocument56 pagesStage 2 TDBFPvijaykrishnatenneti100% (2)

- Show PDF PDFDocument1 pageShow PDF PDFbelchiorNo ratings yet

- Section T Part 2 3l80 THM 400 t19 To t24-6044 PDFDocument47 pagesSection T Part 2 3l80 THM 400 t19 To t24-6044 PDFcampollano14No ratings yet

- Chapter 10 Rev 3 Rod ChangingDocument13 pagesChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1No ratings yet

- Starting Circuit & Radiator Fan Drive (ALCO)Document25 pagesStarting Circuit & Radiator Fan Drive (ALCO)S lenkaNo ratings yet

- Basic WHE and Pressure Control EqptDocument9 pagesBasic WHE and Pressure Control Eqptmohit narayanNo ratings yet

- KVMG 400 Control ValveDocument39 pagesKVMG 400 Control Valvevitor santosNo ratings yet

- LINDE R-02 Hydraulic Motors For Open and Closed OperationDocument44 pagesLINDE R-02 Hydraulic Motors For Open and Closed OperationRomanko100% (1)

- Porsche 928 1982 Service InformationDocument55 pagesPorsche 928 1982 Service InformationwaggcasNo ratings yet

- Himalayan 2 PDFDocument20 pagesHimalayan 2 PDFJulian GallegoNo ratings yet

- NOE F G 18 100 Manual 2860Document31 pagesNOE F G 18 100 Manual 2860sofyan_adekNo ratings yet

- RTTS Forced Circulation Valve and RTTS Positive Circulating ValveDocument14 pagesRTTS Forced Circulation Valve and RTTS Positive Circulating ValveMohamed ShafieNo ratings yet

- The CFM56Document4 pagesThe CFM56Okky Pangestoe WibowoNo ratings yet

- Section 11 Engine Fuel SystemDocument3 pagesSection 11 Engine Fuel SystemtechnicmerpatipilotschoolNo ratings yet

- Power Train For 9S W/Loaders: 2018/07/23 - 07/27 Medellin, ColombiaDocument36 pagesPower Train For 9S W/Loaders: 2018/07/23 - 07/27 Medellin, Colombialuis antonio vega parangueo100% (4)

- Training Tail Lift Technology Mod 4 Signs & Symbols enDocument19 pagesTraining Tail Lift Technology Mod 4 Signs & Symbols enArmin PatelNo ratings yet

- High Pressure Gear Pumps KP5 PDFDocument12 pagesHigh Pressure Gear Pumps KP5 PDFHau PhamNo ratings yet

- Bilge System in ERDocument34 pagesBilge System in ERCua TranNo ratings yet

- Oil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-InDocument2 pagesOil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-Inmochammad RezaNo ratings yet

- Hein Warner Series 14 SPM 9308131 Parts BookDocument8 pagesHein Warner Series 14 SPM 9308131 Parts Bookmichele100% (49)

- Cylinder Types:: Single Acting: Double Acting Piston: Work Is Done in Both DirectionsDocument29 pagesCylinder Types:: Single Acting: Double Acting Piston: Work Is Done in Both DirectionsTushar PatilNo ratings yet

- Beaker Installation.: Hydraulic Circuit For BreakerDocument7 pagesBeaker Installation.: Hydraulic Circuit For BreakerMasterrNo ratings yet

- Cessna 152 Systems OverviewDocument5 pagesCessna 152 Systems OverviewAŞKIN FIRATNo ratings yet

- Gec Em85a ManualDocument155 pagesGec Em85a ManualmmagdiNo ratings yet

- Jac HFC4GB1Document70 pagesJac HFC4GB1Jeifred Espitia AraujoNo ratings yet

- Nissan SD22-SD23-SD33Document68 pagesNissan SD22-SD23-SD33WILLY OSCAR YAURICASA VERGARAYNo ratings yet

- KWU Steam Turbine Governing System 210 X 4 MW HtpsDocument86 pagesKWU Steam Turbine Governing System 210 X 4 MW HtpsAneesh CR100% (1)

- OIL PUMP SPECIFICATION AND OPERATING PRINCIPLEDocument2 pagesOIL PUMP SPECIFICATION AND OPERATING PRINCIPLEPedroNo ratings yet

- Tyrone Gear Pump DiagnosisDocument20 pagesTyrone Gear Pump DiagnosisMohamad SaremyNo ratings yet

- ME Engine (Intelligent Engine)Document95 pagesME Engine (Intelligent Engine)Mahesh More100% (1)

- Burner ManualDocument28 pagesBurner ManualTesfaye ejetaNo ratings yet

- Repair PT-Tipping Valve Pressure Test InstructionsDocument6 pagesRepair PT-Tipping Valve Pressure Test InstructionsLuffy Albi FradanaNo ratings yet

- Hydraulic Mining Excavator CAT 6040: Matthias Aust - 2013Document11 pagesHydraulic Mining Excavator CAT 6040: Matthias Aust - 2013----No ratings yet

- Hydraulic SystemDocument14 pagesHydraulic SystemAndrei 26No ratings yet

- Doosan Retrofit ServiceDocument99 pagesDoosan Retrofit Servicestopless_dalian685No ratings yet

- REXROTH Data - SheetDocument24 pagesREXROTH Data - SheetRADHAKRISHNANNo ratings yet

- Turbine Auxiliaries Explained in DetailTITLEDocument72 pagesTurbine Auxiliaries Explained in DetailTITLESourav Saha100% (1)

- Engine BearingsDocument32 pagesEngine BearingsSwarg Vibha100% (1)

- RightShip Inspections Ship Questionaire RISQ 3.0Document207 pagesRightShip Inspections Ship Questionaire RISQ 3.0Philic Rohit100% (1)

- DNV TecRegNews No17 2023 MEPC 80 tcm8-245389 230713 192246Document5 pagesDNV TecRegNews No17 2023 MEPC 80 tcm8-245389 230713 192246GIASNo ratings yet

- Ever Given - Investigation ReportDocument68 pagesEver Given - Investigation ReportMaciej ReichelNo ratings yet

- Direction For Using ManualDocument146 pagesDirection For Using ManualSARAMQRNo ratings yet

- Denso Catalog PG 180Document1 pageDenso Catalog PG 180tongai100% (1)

- SeabulkDocument487 pagesSeabulkSUMYPORT SASNo ratings yet

- PTS Group periodic maintenance schedule and parts requirement for Sakai Roller SV520Document1 pagePTS Group periodic maintenance schedule and parts requirement for Sakai Roller SV520Arvin Macailing Arroyo100% (1)

- BT8380 Product Specification Sheet-02 PDFDocument2 pagesBT8380 Product Specification Sheet-02 PDFQNet SénégalNo ratings yet

- Medium Forklift Trucks 9 - 18 Tonnes: Technical Information Kalmar Dce90-180, DieselDocument12 pagesMedium Forklift Trucks 9 - 18 Tonnes: Technical Information Kalmar Dce90-180, DieselMichael AkhramovichNo ratings yet

- Case IH Self Propelled 1460 ReferenceDocument2 pagesCase IH Self Propelled 1460 ReferenceBalázs NémethNo ratings yet

- Datasheet R Temp Control Valves 0514 Rev1Document10 pagesDatasheet R Temp Control Valves 0514 Rev1Vipin SharmaNo ratings yet

- 2006 HD Touring Wiring DiagramsDocument12 pages2006 HD Touring Wiring DiagramsJames Szilard BartaNo ratings yet

- Kundendokumentation enDocument309 pagesKundendokumentation enHarri Mündel100% (1)

- Booklet Finisher SR3170Document93 pagesBooklet Finisher SR3170gkalman_2No ratings yet

- C2200 Forage Harvester Operator's ManualDocument70 pagesC2200 Forage Harvester Operator's ManualTesfa TsegayeNo ratings yet

- Volkswagen Golf MK7 ManualDocument840 pagesVolkswagen Golf MK7 ManualDmitry DimasNo ratings yet

- Tamiya Model Magazine July 2021Document68 pagesTamiya Model Magazine July 2021Ognjen MočevičNo ratings yet

- Jeep 2011Document182 pagesJeep 2011josecuellar6967% (3)

- Novi Enerji Makina Servis San Mail - Perkins Parts InvoiceDocument2 pagesNovi Enerji Makina Servis San Mail - Perkins Parts InvoiceFlorent A. d'Agoué CADETENo ratings yet

- 500MW Turbine O&M Manual Part#1of3Document170 pages500MW Turbine O&M Manual Part#1of3Lakshmi Narayan100% (1)

- GM 6T70/75 & Ford 6F50/55: 6 Speed FWD (Electronic Control)Document5 pagesGM 6T70/75 & Ford 6F50/55: 6 Speed FWD (Electronic Control)Hola ValdeNo ratings yet

- Fuel System: Section 5C - Fuel Injection Disassembly and RepairDocument10 pagesFuel System: Section 5C - Fuel Injection Disassembly and RepairsernafeNo ratings yet

- Bentley BrochureDocument9 pagesBentley BrochureRazvan Ionut CarametNo ratings yet

- Design of Below-the-Hook Lifting Devices: ASME BTH-1-2008Document3 pagesDesign of Below-the-Hook Lifting Devices: ASME BTH-1-2008arash0000No ratings yet

- Master Cylinder Repair GuideDocument13 pagesMaster Cylinder Repair GuideFOROTNo ratings yet

- Tesla Regen, Brakes and Sudden AccelerationDocument66 pagesTesla Regen, Brakes and Sudden AccelerationmartinvvNo ratings yet

- AFCompressors Brochure OPC OKDocument4 pagesAFCompressors Brochure OPC OKJD126No ratings yet

- Brochure Jimny SierraDocument8 pagesBrochure Jimny SierraΖαχος ΤσελιοςNo ratings yet

- Blazer 97 Electrical DiagramDocument46 pagesBlazer 97 Electrical DiagramMario Hernández83% (6)

- Company Profile GauravDocument12 pagesCompany Profile GauravGaurav_Kedare_6066No ratings yet

- WM Stock with Material DescriptionsDocument1 pageWM Stock with Material Descriptionsfitra ayuNo ratings yet

- Car Driveline LubricantsDocument5 pagesCar Driveline LubricantsAska QianNo ratings yet

- Xtreme XR Forward Reach Forklift Service ManualDocument20 pagesXtreme XR Forward Reach Forklift Service Manualtamara100% (46)