Professional Documents

Culture Documents

Bundle Extractor Clip

Uploaded by

Su Kil Sung0 ratings0% found this document useful (0 votes)

17 views1 pageThis document provides calculations to verify the design of a bundle pulling bracket. It calculates stresses at different points, including:

1. Shear stress at the extractor, which is below the allowable shear stress.

2. Bending stress at the extractor, which is below the allowable bending stress.

3. Combined weld stresses from tension, bending, and shear during pulling, which are below the allowable weld stress.

The design of the bundle pulling bracket is determined to meet allowable stress requirements.

Original Description:

Original Title

Bundle extractor clip

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides calculations to verify the design of a bundle pulling bracket. It calculates stresses at different points, including:

1. Shear stress at the extractor, which is below the allowable shear stress.

2. Bending stress at the extractor, which is below the allowable bending stress.

3. Combined weld stresses from tension, bending, and shear during pulling, which are below the allowable weld stress.

The design of the bundle pulling bracket is determined to meet allowable stress requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageBundle Extractor Clip

Uploaded by

Su Kil SungThis document provides calculations to verify the design of a bundle pulling bracket. It calculates stresses at different points, including:

1. Shear stress at the extractor, which is below the allowable shear stress.

2. Bending stress at the extractor, which is below the allowable bending stress.

3. Combined weld stresses from tension, bending, and shear during pulling, which are below the allowable weld stress.

The design of the bundle pulling bracket is determined to meet allowable stress requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

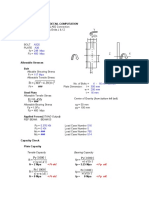

CALCULATION OF BUNDLE PULLING BRACKET

ITEM NO.: E-101419A/B/C/D

ATTACHED AT SHELL FLANGE.

"A" **** DIMENSION ****

tg L2 L1 = 100 mm

45˚

tw L2 = 200 mm

t1 = 56 mm

L1 t1 F tw = 5 mm

L1/2 tg = 24 mm

N = 2 EA

VIEW "A"

SHELL FLANGE

STRESS MATERIAL & LOAD

MATERIAL = SA-516 70N

Sy(Min. Yield Strength) = 260.000 MPa BUNDLE WEIGHT, W = 29300 kg

SLb = 0.66Sy = 171.600 MPa = 287433 N

SLs = 0.4Sy = 104.000 MPa BUNDLE PULLING FORCE, Fp

τ a = 0.4Sy = 104.000 MPa Fp = 1.5 x W x μ = 215575 N

F= Fp / N = 107787 N

Friction Factor (μ) = 0.5 Fv = 0 N

1 . SHEAR STRESS AT EXTRACTOR : S1

S1 = F / ( L2 x t1 ) = 107787.375 / ( 200 X 56 ) = 9.624 < SLs = 104.000 O.K !!

2 . BENDING STRESS AT EXTRACTOR : S2

S2 = ( 6 × F × (L1 / 2 )) / ( L2 x t1^2 ) = ( 6 × 107787.375 × (100 / 2)) / (200 × 3136) = 51.556 < SLb = 171.600 O.K !!

3 . WELD STRESS, TENSILE, BENDING AND SHEAR DURING PULLING:

Aweld = 0.707 × (tw + tg) × 2 × (L2 + t1) = 0.707 × (5 + 24) × 2 × (200+56) = 10497 mm2

τt = Fv / Aweld = 0 / 10497 = 0.000 MPa

τb = 3 (F x (L1 / 2)) / (0.707×(tw + tg) × t1 × (3×L2 + t1))

= 3 ( 107787.375× ( 100/ 2 ) / (0.707 × (5 + 24) ×56 × ( 3 ×200+56) = 21.466 MPa

τs = F / Aweld = 107787.375 / 10497 = 10.268 MPa

τ ratio = Sqr ((τt + τb)2 + ts2) / τa = Sqr ((0.0+21.5)^2+10.3^2 ) / 104.0

= 0.229 ≤ 1.0 O.K !!

※ NOTE SLs : ALLOWABLE SHEAR STRESS.

BASED SLb : ALLOWABLE BENDING STRESS.

ON τ a : ALLOWABLE STRESS OF WELDMENT.

"AISC"

You might also like

- 148841505-Verificare-StalpDocument50 pages148841505-Verificare-StalpkrmeenNo ratings yet

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- Calculation Sheet Connection New Column To ExistingDocument4 pagesCalculation Sheet Connection New Column To ExistingDamar BudiNo ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- Section Properties: Left Beam Member MC 400: Major MinorDocument12 pagesSection Properties: Left Beam Member MC 400: Major MinorshaimenneNo ratings yet

- D. Disain Tumpuan Base Plate Dan Angkur: Gaya Dalam Maksimum, Nu 171.39 KN, Vu 7.94 KN, Mu 1.753 KNM X MDocument2 pagesD. Disain Tumpuan Base Plate Dan Angkur: Gaya Dalam Maksimum, Nu 171.39 KN, Vu 7.94 KN, Mu 1.753 KNM X MMudiyaNo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Example Forging Problem: Solution: K 530 Mpa N .26Document2 pagesExample Forging Problem: Solution: K 530 Mpa N .26sameeringateNo ratings yet

- Lifting/Tailing Lug Calculation: Design DataDocument3 pagesLifting/Tailing Lug Calculation: Design DataMr IncognitoNo ratings yet

- Fastener-Stiffness - Huth - MethodDocument4 pagesFastener-Stiffness - Huth - MethodHesham Abd El-azizNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Design of Replaceent Scheme of Inadequate GussetDocument9 pagesDesign of Replaceent Scheme of Inadequate GussetPartha GangopadhyayNo ratings yet

- Designing of Slabs One Way FinalDocument2 pagesDesigning of Slabs One Way FinalZyril BestoNo ratings yet

- Calculo de AlçaDocument4 pagesCalculo de AlçaMarcio GentaNo ratings yet

- Cantilever Beam Design - I BeamDocument1 pageCantilever Beam Design - I Beamberylqz5878No ratings yet

- Calculation Note Pondasi Tower Crosing NusakambanganDocument49 pagesCalculation Note Pondasi Tower Crosing Nusakambanganolis.uikNo ratings yet

- Girder DesignDocument3 pagesGirder DesignDhimas Surya NegaraNo ratings yet

- Machine DesignDocument6 pagesMachine DesignRen RenNo ratings yet

- StairDocument1 pageStairAek JanNo ratings yet

- Design Data: Design For Base Plate (Fixed)Document4 pagesDesign Data: Design For Base Plate (Fixed)Wibawa WorksNo ratings yet

- 4F Design-2Document12 pages4F Design-2Jake CortezNo ratings yet

- Slab DesignDocument12 pagesSlab DesignPAOLO AGORILLANo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal Vesselmiteshpatel191100% (2)

- Davit Design Calculation: L 1 D V H V H V DDocument2 pagesDavit Design Calculation: L 1 D V H V H V DSiva baalanNo ratings yet

- Cantilever Beam Design - PFCDocument1 pageCantilever Beam Design - PFCberylqz5878No ratings yet

- Loads:: Donnees de Calcul ChargesDocument6 pagesLoads:: Donnees de Calcul ChargesAdekimi EmmanuelNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting Lug Calculations KodDocument2 pagesLifting Lug Calculations Kodanu radhaNo ratings yet

- NSCP Code: Specificatio N ScoreDocument17 pagesNSCP Code: Specificatio N ScoreMarco SatomeraNo ratings yet

- Screw Jack - Steps - Sample-1Document4 pagesScrew Jack - Steps - Sample-1unimech_enggNo ratings yet

- Boardwork No.1 and 2Document9 pagesBoardwork No.1 and 2John Nalog100% (1)

- Over Head Tank Circular Flat SlabDocument14 pagesOver Head Tank Circular Flat SlabPruthviraj JuniNo ratings yet

- 1Document2 pages1thaierNo ratings yet

- ANALYSISDocument4 pagesANALYSISfrancis sebastian lagamayoNo ratings yet

- Davit CalculationDocument2 pagesDavit CalculationpiziyuNo ratings yet

- A Keyed Sprocket Delivers A Torque of 778Document2 pagesA Keyed Sprocket Delivers A Torque of 778arcelio emiyaNo ratings yet

- Keys Coupling With SampleDocument9 pagesKeys Coupling With SampleGen ReyesNo ratings yet

- Lifting - Lug (Modification)Document11 pagesLifting - Lug (Modification)Sam LowNo ratings yet

- Duct Design As Per RoarksDocument2 pagesDuct Design As Per Roarksbubalan SundaramNo ratings yet

- BEAM Bending LTBDocument16 pagesBEAM Bending LTBcretz2No ratings yet

- Beams: (Frame 2)Document54 pagesBeams: (Frame 2)John Rafael R. CanoosNo ratings yet

- AISC Connection-2nd Edition - (3+3) Anchor Rod-FixedDocument14 pagesAISC Connection-2nd Edition - (3+3) Anchor Rod-FixedTuấnThanhNo ratings yet

- Metal Deck 2 WayDocument3 pagesMetal Deck 2 Waymjfprgc0% (1)

- StairDocument1 pageStairAek JanNo ratings yet

- Member Dimensions: D 850 MM B 850 MM L 3.657 M DDocument6 pagesMember Dimensions: D 850 MM B 850 MM L 3.657 M DOfficial 074BCEGHNo ratings yet

- AISC Connection-2nd Edition - (2+2) Anchor Rod-FixedDocument16 pagesAISC Connection-2nd Edition - (2+2) Anchor Rod-FixedTuấnThanhNo ratings yet

- Receiver Design StepsDocument3 pagesReceiver Design StepsSureshkannan VNo ratings yet

- Design of Baseplate With Large EccentricityDocument4 pagesDesign of Baseplate With Large EccentricityLeah Ann ManuelNo ratings yet

- Sample ConnectionDocument10 pagesSample ConnectionMarielle Bias MercadoNo ratings yet

- FFB2Document8 pagesFFB2prajjwal patidarNo ratings yet

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Design of Long Pier Lp3, Rp3 & Rp2-116Document1 pageDesign of Long Pier Lp3, Rp3 & Rp2-116VISHALNo ratings yet

- Rolled - MomentDocument5 pagesRolled - MomentAdekimi EmmanuelNo ratings yet

- Splice Connection CHSDocument180 pagesSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Zapata Conectada PrincipalDocument10 pagesZapata Conectada PrincipalGALLEGOS PARRANo ratings yet

- Zapata Conectada PrincipalDocument10 pagesZapata Conectada PrincipalJulio Sergio Cauti ChocceNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- KDS 41 17 00 건축물 내진설계기준 - 2019Document131 pagesKDS 41 17 00 건축물 내진설계기준 - 2019Su Kil SungNo ratings yet

- API Valve Inspection and Test SummaryDocument4 pagesAPI Valve Inspection and Test SummarySu Kil SungNo ratings yet

- Pipe Size Outside Diameter Nominal Wall ThicknessDocument1 pagePipe Size Outside Diameter Nominal Wall ThicknessSu Kil SungNo ratings yet

- Malaysia Fifth Schedule - Rev.1Document1 pageMalaysia Fifth Schedule - Rev.1Su Kil SungNo ratings yet

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNo ratings yet

- Garlok GasketDocument60 pagesGarlok GasketSu Kil SungNo ratings yet

- Metallic Gasket: One Source For Sealing Solution Provider To Every of Your Specific ApplicationDocument12 pagesMetallic Gasket: One Source For Sealing Solution Provider To Every of Your Specific ApplicationSu Kil SungNo ratings yet

- Ebook Chemistry The Molecular Nature of Matter 7Th Edition Jespersen Solutions Manual Full Chapter PDFDocument43 pagesEbook Chemistry The Molecular Nature of Matter 7Th Edition Jespersen Solutions Manual Full Chapter PDFformatbalanoidyxl100% (12)

- Schedule of ERBA-2018 Tuesday, 3 July DAY of HALE and Solar AircraftDocument5 pagesSchedule of ERBA-2018 Tuesday, 3 July DAY of HALE and Solar AircraftHardeep ZintaNo ratings yet

- TOPIC 1 Physical ChemistryDocument65 pagesTOPIC 1 Physical ChemistrySurendra Louis DupuisNo ratings yet

- Silo - Tips - Macroscopic Balances For Nonisothermal SystemsDocument18 pagesSilo - Tips - Macroscopic Balances For Nonisothermal Systemsmarlenys cuevasNo ratings yet

- HVACPow Den 08 ADocument64 pagesHVACPow Den 08 AEric MagnayeNo ratings yet

- Plastic CollapseDocument10 pagesPlastic CollapseVijaya Kumar Manikandan100% (1)

- Thermodynamics - Steam TurbineDocument8 pagesThermodynamics - Steam TurbineSaiful ZakwanNo ratings yet

- CH31001 Mass Transfer I MA 2016Document1 pageCH31001 Mass Transfer I MA 2016praween kNo ratings yet

- Thermodynamic Analysis of A 2-Stage Cascade VCR CycleDocument27 pagesThermodynamic Analysis of A 2-Stage Cascade VCR CycleAkshat RNo ratings yet

- MF-03 Modular Valve, Presssure Flow Control ValveDocument4 pagesMF-03 Modular Valve, Presssure Flow Control ValveYus BewokNo ratings yet

- 21 Me 435,435,435,435Document40 pages21 Me 435,435,435,435Faisal MehrbanNo ratings yet

- Archimedes PrincipleDocument10 pagesArchimedes PrincipleWilliam OkongoNo ratings yet

- The Critical Radius of Insulation PDFDocument2 pagesThe Critical Radius of Insulation PDFAlejandro100% (1)

- 1968-Turbulent Boundary Layer Separation PDFDocument13 pages1968-Turbulent Boundary Layer Separation PDFManu ChakkingalNo ratings yet

- ENCH-633: Chemical Thermodynamics: Sathish Ponnurangam Fall 2018 Week - 5: Fugacities in Gas MixtureDocument28 pagesENCH-633: Chemical Thermodynamics: Sathish Ponnurangam Fall 2018 Week - 5: Fugacities in Gas Mixtureraja.mtNo ratings yet

- 5.1 Cone Penetrometer Test - GeneralDocument43 pages5.1 Cone Penetrometer Test - GeneralJAVIER ADRIANNo ratings yet

- EM 1110-1-1905 c-3 PDFDocument13 pagesEM 1110-1-1905 c-3 PDFAlex RotsNo ratings yet

- External Pressure Calculation For Pressure Vessel - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesExternal Pressure Calculation For Pressure Vessel - Boiler and Pressure Vessel Engineering - Eng-TipsHaseeb KazmiNo ratings yet

- Presentation On Heat EXchanger1Document51 pagesPresentation On Heat EXchanger1BaqirMuhammadNo ratings yet

- System Curves - Goulds Pump.Document3 pagesSystem Curves - Goulds Pump.sgrsthNo ratings yet

- Pa6 GF30 - Basf Ultramid B3WG6Document2 pagesPa6 GF30 - Basf Ultramid B3WG6armandoNo ratings yet

- Air Cooled Condenser Design SpreadsheetDocument8 pagesAir Cooled Condenser Design Spreadsheetjamil100% (2)

- DSN Ver PDFDocument576 pagesDSN Ver PDFRamakrishnan SakthivelNo ratings yet

- Design For Reinforcement in Pier: Slenderness RatioDocument2 pagesDesign For Reinforcement in Pier: Slenderness RatioPreetam SundarayNo ratings yet

- Duct IlityDocument14 pagesDuct IlityMehman NasibovNo ratings yet

- SCIENCE 10 4th TMTDocument3 pagesSCIENCE 10 4th TMTkaycin Duzon100% (1)

- Grafico CS2Document2 pagesGrafico CS2Rones JuniorNo ratings yet

- Lecture 2 Properties of Pure Substances PDFDocument46 pagesLecture 2 Properties of Pure Substances PDFMZNo ratings yet

- Lom Quiz by Ruchir AroraDocument4 pagesLom Quiz by Ruchir Arorachaitanya goyalNo ratings yet