Professional Documents

Culture Documents

Steam Turbine Pedestal Installation Alignment

Uploaded by

Sh.nasirpurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Turbine Pedestal Installation Alignment

Uploaded by

Sh.nasirpurCopyright:

Available Formats

Steam Turbine Pedestal Installation Alignment

Introduction

This is an example of the ACQUIP process of applying laser tracker technology and

3D CAD software to a steam turbine installation.

Challenge

Steam Turbines are required to be positioned in tight tolerances. The expected time

to complete the installation is getting shorter while locating personnel with the skill

set to complete the process is more difficult than ever.

Benefits

ACQUIP Procedures and Experience combined with laser tracker technology and 3D

CAD software increases the accuracy and speed of the pedestal location. The quality

of the installation is improved by assuring each soul plate is level and in the exact

location, thus reducing the chance of rework during the installation process. Less

time is required to locate the components which creates the opportunity for the

project to finish early. Documentation and reports can be created in the CAD

program that are used to locate the pedestals to the drawing. This produces a paper

trail that can be used as records of the job that was performed. The alignment

portion of the installation is delegated to the alignment engineers, thus allowing the

project manager to focus on other tasks.

Overview

The pictures, graphics and data below are an example of the pedestal alignment

installation process. The pictures show the pedestal bores and reference locations.

The graphics are created in the 3D software from the actual measurements taken on

the components. The data is an example of the output from the 3D CAD software

used to align the pedestals.

Call or email ACQUIP today to see how we can provide this technology and

procedure for your steam turbine and pedestal installation and alignment.

info@acquip.com +1 (305) 538 7101

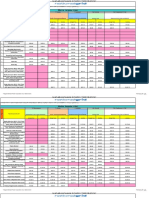

Pedestal Bore and Elevation Measurements

In Process Data Analysis

You might also like

- ABAP RESTful Programming Model EN PDFDocument824 pagesABAP RESTful Programming Model EN PDFprabhu100% (4)

- 1.1.3.11 Lab - Draw A Process DiagramDocument4 pages1.1.3.11 Lab - Draw A Process DiagramJoshua ManalotoNo ratings yet

- Peek - Long-Term Mechanical PropertiesDocument5 pagesPeek - Long-Term Mechanical PropertiesSh.nasirpurNo ratings yet

- Big Data AnalyticsDocument5 pagesBig Data AnalyticshadiNo ratings yet

- SmallgroupresultsreportDocument1 pageSmallgroupresultsreportapi-392364749No ratings yet

- Investigative ProcessDocument20 pagesInvestigative ProcessJaneth LwenaNo ratings yet

- BPMN 2.0 - Business Process Model and Notation Innovator For Business AnalystsDocument1 pageBPMN 2.0 - Business Process Model and Notation Innovator For Business AnalystsinigomNo ratings yet

- BPMN-Poster2019 FINAL en PDFDocument1 pageBPMN-Poster2019 FINAL en PDFsimdowNo ratings yet

- DIDIN - Design For Six Sigma - 3Document30 pagesDIDIN - Design For Six Sigma - 3Mas OlisNo ratings yet

- Oracle Database In-Memory: Powering The Real-Time EnterpriseDocument9 pagesOracle Database In-Memory: Powering The Real-Time EnterpriseJawaharJasNo ratings yet

- Sccurriculumresultsreport 2Document1 pageSccurriculumresultsreport 2api-392364749No ratings yet

- Career Cert Paths Poster PDFDocument1 pageCareer Cert Paths Poster PDFI_ggizNo ratings yet

- Metrics That Impact Bank Business Results: Introducing Human Capital Financial StatementsDocument31 pagesMetrics That Impact Bank Business Results: Introducing Human Capital Financial StatementsAlexander RuizNo ratings yet

- BizTalk Server 2010 Runtime Architecture PosterDocument1 pageBizTalk Server 2010 Runtime Architecture PosterascsaNo ratings yet

- AWS Periodic TableDocument1 pageAWS Periodic Tabledouglas.dvferreiraNo ratings yet

- Modification Method For Predicting Relative Permeability: M.SC in Petroleum EngineeringDocument11 pagesModification Method For Predicting Relative Permeability: M.SC in Petroleum Engineeringmohamed ameenNo ratings yet

- Sejal Divekar Resume1Document2 pagesSejal Divekar Resume1Jason StanleyNo ratings yet

- Srinivasa Rao 2016Document4 pagesSrinivasa Rao 2016Shashi KantNo ratings yet

- Good Process / Good Part: QRQC For Non Manufacturing ProcessesDocument1 pageGood Process / Good Part: QRQC For Non Manufacturing ProcessesHugo Ramírez ReyesNo ratings yet

- Embedded Project WorksheetDocument4 pagesEmbedded Project WorksheetcammanderNo ratings yet

- Order Cash 1Document14 pagesOrder Cash 1Alecia ChenNo ratings yet

- SessionsDocument260 pagesSessionsAhmed RamadanNo ratings yet

- Jacquiskweli CV 3998480248 Professional-Resume189Document2 pagesJacquiskweli CV 3998480248 Professional-Resume189Himalayan MerchantsNo ratings yet

- MEC 601 Final Year Project 1 Presentation: 23 December 2013 Faculty of Mechanical Engineering Universiti Teknologi MaraDocument25 pagesMEC 601 Final Year Project 1 Presentation: 23 December 2013 Faculty of Mechanical Engineering Universiti Teknologi MaraMohamad ZackuanNo ratings yet

- Rapid Object Detection Using A Boosted Cascade of Simple FeaturesDocument9 pagesRapid Object Detection Using A Boosted Cascade of Simple FeaturesYuvraj NegiNo ratings yet

- Arcgis Spatial Analyst Key FeaturesDocument9 pagesArcgis Spatial Analyst Key Featuresakeramos7gmail.comNo ratings yet

- BPMN Poster A4 Ver 1.0.10 PDFDocument1 pageBPMN Poster A4 Ver 1.0.10 PDFSatrio N. W. NotoamidjojoNo ratings yet

- Z Option and KPS For Download PDFDocument23 pagesZ Option and KPS For Download PDFanusha ikkkurthiNo ratings yet

- Environmental Aspects and Impacts Evaluation REV-003Document12 pagesEnvironmental Aspects and Impacts Evaluation REV-003sunthu100% (1)

- DataBase Jobs To Be MonitoredDocument28 pagesDataBase Jobs To Be MonitoredSurendraNo ratings yet

- BPMN Poster v1.0.10 (A2)Document1 pageBPMN Poster v1.0.10 (A2)calypso342No ratings yet

- PRS Overview Poster PDFDocument1 pagePRS Overview Poster PDFOlivier KNNo ratings yet

- Appendix B: Sample Project Plan Outline and Role ResponsibilitiesDocument7 pagesAppendix B: Sample Project Plan Outline and Role ResponsibilitiesMinwiyelet FisehaNo ratings yet

- Epc Epcm ChartDocument1 pageEpc Epcm ChartjcerignaleNo ratings yet

- QRQC Problem Solving TechniquesDocument1 pageQRQC Problem Solving TechniquesjaninaNo ratings yet

- Good Process / Good Part: QRQC For Non Manufacturing ProcessesDocument1 pageGood Process / Good Part: QRQC For Non Manufacturing ProcessesVeung SingkhekNo ratings yet

- Autos PoolDocument8 pagesAutos PoolPARASCADD Private LimitedNo ratings yet

- EXP-8 Experiment TitleDocument7 pagesEXP-8 Experiment TitleManan SharmaNo ratings yet

- 3 - PROCESS CONTROL - 2010 - Chemical Process EquipmentDocument21 pages3 - PROCESS CONTROL - 2010 - Chemical Process Equipmentalbertol_bilaNo ratings yet

- Az 900Document1 pageAz 900olivier larocheNo ratings yet

- MSL CertificationPathways Commercial 2015 FinalDocument1 pageMSL CertificationPathways Commercial 2015 FinalAhmed yaoNo ratings yet

- MSL Commercial Certification Roadmap 2015 03 04Document1 pageMSL Commercial Certification Roadmap 2015 03 04linakat441No ratings yet

- Global Solutions SharePoint 2013Document1 pageGlobal Solutions SharePoint 2013ညီ ထွေးNo ratings yet

- Deep Learning-Based Semantic Segmentation in Autonomous DrivingDocument7 pagesDeep Learning-Based Semantic Segmentation in Autonomous Drivingprajna acharyaNo ratings yet

- DBMSDocument4 pagesDBMSMo EmadNo ratings yet

- DBMSDocument3 pagesDBMSMo EmadNo ratings yet

- Performance Manage MenDocument1 pagePerformance Manage MenmariaaltammamNo ratings yet

- Operations and Maintenance Responsibility MatrixDocument22 pagesOperations and Maintenance Responsibility MatrixmelieneideaNo ratings yet

- SWOT-Analyse ISO /TS 16949:2009Document1 pageSWOT-Analyse ISO /TS 16949:2009Nedra DebbechNo ratings yet

- App x86 ServerDocument11 pagesApp x86 ServerOnur FilizoğluNo ratings yet

- Breanna Lee Fall 2023Document1 pageBreanna Lee Fall 2023api-355877355No ratings yet

- Awp Practicals2Document73 pagesAwp Practicals2Pratik PrajapatiNo ratings yet

- Aval Aase 2324 FinalDocument1 pageAval Aase 2324 Finalguihermatador45No ratings yet

- Digium Failover Appliances Application BriefDocument3 pagesDigium Failover Appliances Application Briefmaple4VOIPNo ratings yet

- Dmaic 12873122766122 Phpapp01Document1 pageDmaic 12873122766122 Phpapp01quycoctuNo ratings yet

- Ayushi Patel Resume 1Document2 pagesAyushi Patel Resume 1api-710831774No ratings yet

- Research Methods - Chapter 6-8 - ShortDocument17 pagesResearch Methods - Chapter 6-8 - ShortHailemariam FeteneNo ratings yet

- 22 11 03-Assignmen (EC7502)Document1 page22 11 03-Assignmen (EC7502)ashu singhNo ratings yet

- Real-Time Ray Tracing - Unreal Engine DocumentationDocument9 pagesReal-Time Ray Tracing - Unreal Engine DocumentationFrancisco Javier Andrade CorreaNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- Meco4000 WebDocument1 pageMeco4000 WebSh.nasirpurNo ratings yet

- M 6141 PisDocument2 pagesM 6141 PisSh.nasirpurNo ratings yet

- Steam Turbines en InteractiveDocument1 pageSteam Turbines en InteractiveSh.nasirpurNo ratings yet

- Sealring Flyer ISO WEBDocument2 pagesSealring Flyer ISO WEBSh.nasirpurNo ratings yet

- MaterialsDocument4 pagesMaterialsSh.nasirpurNo ratings yet

- Single Stage Steam Turbine Overhauls E10679Document2 pagesSingle Stage Steam Turbine Overhauls E10679Sh.nasirpurNo ratings yet

- Topless AlignmentDocument2 pagesTopless AlignmentSh.nasirpurNo ratings yet

- 1999RIGAUD EffectsGearboxDesignParametersDocument6 pages1999RIGAUD EffectsGearboxDesignParametersSh.nasirpurNo ratings yet

- Rotational Speed Adjustment Due To Shaft FitDocument3 pagesRotational Speed Adjustment Due To Shaft FitSh.nasirpurNo ratings yet

- HCH BearingDocument2 pagesHCH BearingSh.nasirpurNo ratings yet

- Peek Design PrinciplesDocument15 pagesPeek Design PrinciplesSh.nasirpurNo ratings yet

- Mitsubishi Steam Turbine Tops On Tops Off Internal Laser AlignmentDocument1 pageMitsubishi Steam Turbine Tops On Tops Off Internal Laser AlignmentSh.nasirpurNo ratings yet

- Vertical HighThrust MotorsDocument1 pageVertical HighThrust MotorsSh.nasirpurNo ratings yet

- Tensile PropertiesDocument2 pagesTensile PropertiesSh.nasirpurNo ratings yet

- Rating Life of BearingsDocument5 pagesRating Life of BearingsSh.nasirpurNo ratings yet

- Peek Short-Term Mechanical PropertiesDocument15 pagesPeek Short-Term Mechanical PropertiesSh.nasirpurNo ratings yet

- Flexural PropertiesDocument2 pagesFlexural PropertiesSh.nasirpurNo ratings yet

- MN1603 - 0222 (W)Document16 pagesMN1603 - 0222 (W)Sh.nasirpurNo ratings yet

- Shear PropertiesDocument1 pageShear PropertiesSh.nasirpurNo ratings yet

- Peek Environmental and Chemical ResistanceDocument13 pagesPeek Environmental and Chemical ResistanceSh.nasirpurNo ratings yet

- Compressive PropertiesDocument3 pagesCompressive PropertiesSh.nasirpurNo ratings yet

- Impact Properties of PeekDocument2 pagesImpact Properties of PeekSh.nasirpurNo ratings yet

- Wire and Cable Extrusion (Peek)Document3 pagesWire and Cable Extrusion (Peek)Sh.nasirpurNo ratings yet

- Dresser Rand CompressorsDocument2 pagesDresser Rand CompressorsSh.nasirpurNo ratings yet

- Peek Electrical PropertiesDocument4 pagesPeek Electrical PropertiesSh.nasirpurNo ratings yet

- Problem Example of Pneumatic Conveying SystemDocument9 pagesProblem Example of Pneumatic Conveying SystemSh.nasirpurNo ratings yet

- Painting and Marking-PeekDocument3 pagesPainting and Marking-PeekSh.nasirpurNo ratings yet

- Processing PeekDocument12 pagesProcessing PeekSh.nasirpurNo ratings yet

- Ketaspire-Secondary OperationsDocument3 pagesKetaspire-Secondary OperationsSh.nasirpurNo ratings yet

- How To Cancel Your Premium Membership - Scribd Help CenterDocument1 pageHow To Cancel Your Premium Membership - Scribd Help Centeraminjamal17% (18)

- MOSA 4491: User ManualDocument62 pagesMOSA 4491: User ManualItalo RochaNo ratings yet

- Critical Ops Circuit - Season 3 RulesDocument10 pagesCritical Ops Circuit - Season 3 RulesThiên Hà 4 ChiềuNo ratings yet

- AVA - A Video Dataset of Spatio-Temporally Localized Atomic Visual ActionsDocument15 pagesAVA - A Video Dataset of Spatio-Temporally Localized Atomic Visual ActionsmareNo ratings yet

- Lecture-11 Dynamic Scheduling ADocument18 pagesLecture-11 Dynamic Scheduling AYumna ShahzadNo ratings yet

- Advanced Workshop On Qualitative Research Methodology: Approved by ATAL AICTEDocument7 pagesAdvanced Workshop On Qualitative Research Methodology: Approved by ATAL AICTEjayveeNo ratings yet

- Third Party Distribution Pole Attachment Make-Ready Work Rate Summary Sheet (Dollars)Document6 pagesThird Party Distribution Pole Attachment Make-Ready Work Rate Summary Sheet (Dollars)PeterLiangNo ratings yet

- Decision Log TemplateDocument6 pagesDecision Log TemplateIrshad AliNo ratings yet

- Revpi Do: Technical DataDocument2 pagesRevpi Do: Technical DatasebadansNo ratings yet

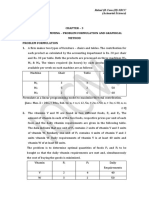

- Chapter - 3 Linear Programming - Problem Formulation and Graphical Method Problem Formulation 1. A Firm Makes Two Types of Furniture - Chairs and Tables. The Contribution ForDocument11 pagesChapter - 3 Linear Programming - Problem Formulation and Graphical Method Problem Formulation 1. A Firm Makes Two Types of Furniture - Chairs and Tables. The Contribution ForYamica ChopraNo ratings yet

- JournalDocument117 pagesJournalsagaru_idNo ratings yet

- k-309 SCADA SYSTEMDocument58 pagesk-309 SCADA SYSTEMELPIDIO LUCERONo ratings yet

- IEC 60050-151-2001 Amd2-2014Document8 pagesIEC 60050-151-2001 Amd2-2014mameri malekNo ratings yet

- Salma VeraDocument1 pageSalma VeraSalma VeraNo ratings yet

- Data Migration AssistantDocument3 pagesData Migration AssistantarrelNo ratings yet

- AuthorizationDocument9 pagesAuthorizationRuth VirtudazoNo ratings yet

- About Triboform®: Market-Leading Expertise High-Value Innovations Trustworthy PartnershipDocument6 pagesAbout Triboform®: Market-Leading Expertise High-Value Innovations Trustworthy PartnershiptuấnNo ratings yet

- CIS Controls v8 Mapping To CSA Cloud Controls MatrixDocument132 pagesCIS Controls v8 Mapping To CSA Cloud Controls MatrixANAMORALES100% (1)

- Starter Kit ManualDocument175 pagesStarter Kit Manualanne smithNo ratings yet

- Atellica NEPH 630 System BrochureDocument2 pagesAtellica NEPH 630 System BrochureAhmed MostafaNo ratings yet

- SAP Service CloudDocument2 pagesSAP Service CloudLucía MartínezNo ratings yet

- Prepare A Professional CV With A Cover Letter.Document7 pagesPrepare A Professional CV With A Cover Letter.Master MindNo ratings yet

- Illustration 101: - Is A Drawing, Painting orDocument9 pagesIllustration 101: - Is A Drawing, Painting orRomz BajzNo ratings yet

- Sip Module 12Document5 pagesSip Module 12timothy limNo ratings yet

- Current Transducer Test FormDocument8 pagesCurrent Transducer Test FormArun Kumar ShahNo ratings yet

- U010C-Lost Communication With Turbocharger/Supercharger Control ModuleDocument11 pagesU010C-Lost Communication With Turbocharger/Supercharger Control ModuleAshley GymanNo ratings yet

- Essentials (4 Day) Agenda BL-9am StartDocument7 pagesEssentials (4 Day) Agenda BL-9am StartKarl WeedNo ratings yet