Professional Documents

Culture Documents

NBR 70.10-02

Uploaded by

titi suryaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NBR 70.10-02

Uploaded by

titi suryaniCopyright:

Available Formats

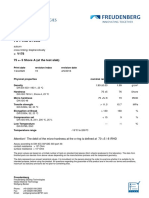

HITEC® NBR 70.

10-02

Sealing technology

Technical Data Sheet

Material name, short description NBR

Material name, based on technical standards Acrylic-Butadiene-Rubber

Material description / intended use Elastomer with good resistance to mineral and vegetable

oils/greases, alkalis, alcohols, gas, water

Color black

Compound code NBR 70.10-02

Old, but still valid compound code NBR 70.5/P5F

Crosslinking/curing agent sulfur

Manufacturing process moulded parts

Remarks ACN content 33%

ASTM code: ASTM D2000 SAEJ200-M2 BG714 A14 B14 EA14

EF11 EF21 EO14 EO34

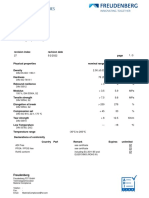

Mechanical properties Thermal properties

Hardness nominal 70 ±5 Shore A Operating temperature min.* -20 °C

Density nominal 1.3 ±0.03 g/cm³ Operating temperature max.* 125 °C

Tensile strength 14 N/mm² TR 10 value -20 °C

ASTM D 412-C ASTM D 1329

Elongation at break 270 % Brittleness point -20 °C

ASTM D 412-C

* Approximate value, dependent on the application

Compression set 18 %

ASTM D 395-B

22 h, 125 °C

23 %

ASTM D 395-B

70 h, 100 °C

Tear resistance 40 N/mm

ASTM D 624-B

Storage in medium 1 Storage in medium 2

Medium IRM 901 Oil (ASTM 1) Medium IRM 903 Oil (ASTM 3)

Test parameter 70 h, 100 °C Test parameter 70 h, 100 °C

Test standard ASTM D 471 Test standard ASTM D 471

Value change Hardness: 0 Points Value change Hardness: -9

Tensile strength: -24 % Tensile strength: -20 %

Elongation at break: -29 % Elongation at break: -18 %

Volume: -3 % Volume: +15 %

Air aging 2

Test parameter 70 h, 110 °C

Test standard ASTM D 573

Value change Hardness: +7 Points

Tensile strength: +5 %

Elongation at break: -34 %

In compliance with RoHS and REACH directives.

This information is based on our available data. These values are measured on standard test specimens and are within the normal tolerance range of material properties

and do not represent guaranteed property values. Therefore they shall not be used for specification purposes. The customer is solely responsible for quality and suitability of

material for his application. He has to test usage and processing prior to use. Angst+Pfister makes no guarantees for the suitability of the material for any given application

and assumes no obligation or liability in connection with the information provided above.

15.11.2021 / Status: Released www.angst-pfister.com Page 1 of 3

HITEC® NBR 70.10-02

Sealing technology

Technical Data Sheet

Storage in medium 3

Medium Water ASTM

Test parameter 70 h, 100 °C

Test standard ASTM D 471

Value change Hardness: -6 Points

Tensile strength: -9 %

Elongation at break: -10 %

Volume: +8 %

Air aging 1

Test parameter 70 h, 100 °C

Test standard ASTM D 573

Value change Hardness: +5 Points

Tensile strength: 0 %

Elongation at break: -20 %

In compliance with RoHS and REACH directives.

This information is based on our available data. These values are measured on standard test specimens and are within the normal tolerance range of material properties

and do not represent guaranteed property values. Therefore they shall not be used for specification purposes. The customer is solely responsible for quality and suitability of

material for his application. He has to test usage and processing prior to use. Angst+Pfister makes no guarantees for the suitability of the material for any given application

and assumes no obligation or liability in connection with the information provided above.

15.11.2021 / Status: Released www.angst-pfister.com Page 2 of 3

HITEC® NBR 70.10-02

Sealing technology

Technical Data Sheet

Approvals / Compliance

Drinking water NSF 61 for drinking water cold and warm up to 85°C

ACS (DGS/VS4 n° 99/217 dated 12/04/1999 and DGS/VS4 n° 2000/232 dated 27/04/2000

CLP (DGS/VS4 n°99/217 dated 12/04/1999 and DGS/VS4 n°2000/232 dated 27/04/2000

D.M. 06/04/04 n° 174

DVGW W270 for drinking water

ÖNORM (B 5014-1) for drinking water cold and warm up to 85°C

UBA Elastomer-Guideline cold 23°C and hot water up to 85°C

WRAS (BS 6920) for drinking water cold water 23 °C

Food & Bevarage FDA CFR 21 - 177.2600 a) - f)

D.M. 21/03/1973 (Migration test)

Dlgs. 25.01.1992 n.108 Art.2 (ex. DPR 777/82 art 2) - Complies with Arsenic content limits

EC 1935/2004 (excl. article 15, based on FDA) and EC Regulation 2023/2006 (GMP)

GB 4806.11-2016 (Migration test)

Oil & Gas DVGW EN 549 B1 / H3

Others PAH Category 2 (AfPS GS 2019:01)

ADI free (free of Animal Derived Ingredients) resp. TSE/BSE related substances

DEHP, free of Phthalates

In compliance with RoHS and REACH directives.

This information is based on our available data. These values are measured on standard test specimens and are within the normal tolerance range of material properties

and do not represent guaranteed property values. Therefore they shall not be used for specification purposes. The customer is solely responsible for quality and suitability of

material for his application. He has to test usage and processing prior to use. Angst+Pfister makes no guarantees for the suitability of the material for any given application

and assumes no obligation or liability in connection with the information provided above.

15.11.2021 / Status: Released www.angst-pfister.com Page 3 of 3

You might also like

- NBR 60.10-01Document1 pageNBR 60.10-01UcokNo ratings yet

- Material NBR NB807101: Technical Data Sheet in Accordance With ASTMDocument2 pagesMaterial NBR NB807101: Technical Data Sheet in Accordance With ASTMDacetIronForceNo ratings yet

- EPDM - Test by Romac Inc PDFDocument2 pagesEPDM - Test by Romac Inc PDFRajendra Kumar SharmaNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- 80 NBR 186349-En - 1Document2 pages80 NBR 186349-En - 1leonNo ratings yet

- LLDPE-218BJ_edit (1)Document3 pagesLLDPE-218BJ_edit (1)Chu ChuNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Desmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Document2 pagesDesmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Johnny SyluanciaNo ratings yet

- ERIKS Fluor Elastomer 90 - Compound 514530 - Technical DatasheetDocument1 pageERIKS Fluor Elastomer 90 - Compound 514530 - Technical DatasheetDarkedgeNo ratings yet

- Chloroprene (Neoprene) 70 Sha: Astm D2000 M2 Bc714 A14 B14 Eo14 Eo34 F17Document1 pageChloroprene (Neoprene) 70 Sha: Astm D2000 M2 Bc714 A14 B14 Eo14 Eo34 F17clarenceNo ratings yet

- Material: Natural Rubber (NR) : Max Spare Code: NR 70Document1 pageMaterial: Natural Rubber (NR) : Max Spare Code: NR 70Bagus OktiNo ratings yet

- 72 NBR 902-En - 1Document3 pages72 NBR 902-En - 1Pierre PescayNo ratings yet

- ERIKS Fluor Elastomer Compound 514532 DatasheetDocument1 pageERIKS Fluor Elastomer Compound 514532 DatasheetDarkedgeNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Desmopan 6064A - en - 81165785 05123103 20014072Document2 pagesDesmopan 6064A - en - 81165785 05123103 20014072shahin_723No ratings yet

- Material 72 NBR 872: Black Cross Linking: SulfurDocument3 pagesMaterial 72 NBR 872: Black Cross Linking: SulfurPhong DuongNo ratings yet

- Carlisle Epdm 60 MIL MTC - IIIDocument1 pageCarlisle Epdm 60 MIL MTC - IIIHimanshu ChaudharyNo ratings yet

- 80 FKM B1OR81FK-en - 1Document2 pages80 FKM B1OR81FK-en - 1Joabe MartinsNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- (AdvanSix) (TDS) Aegis H135ZPDocument3 pages(AdvanSix) (TDS) Aegis H135ZPMarcos KodairaNo ratings yet

- Material NBR NB902803: Technical Data Sheet in Accordance With ASTMDocument3 pagesMaterial NBR NB902803: Technical Data Sheet in Accordance With ASTMDacetIronForceNo ratings yet

- Material FKM FP801801: Technical Data Sheet in Accordance With ASTMDocument3 pagesMaterial FKM FP801801: Technical Data Sheet in Accordance With ASTMElőd JobbNo ratings yet

- Material Spec Sheets PolyurethaneDocument21 pagesMaterial Spec Sheets PolyurethaneVũ GiangNo ratings yet

- Materialdatasheet 80 NBR 186349Document2 pagesMaterialdatasheet 80 NBR 186349loloNo ratings yet

- FKM 37508 Material PropertiesDocument2 pagesFKM 37508 Material PropertiesXavierNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- FFKM Material SheetDocument1 pageFFKM Material Sheetmarco SimonelliNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- 9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMDocument2 pages9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMqcsupNo ratings yet

- Halene - P: Technical Data Sheet F103Document1 pageHalene - P: Technical Data Sheet F103Dharmendrasinh ZalaNo ratings yet

- 70 EPDM 291-En - 1Document4 pages70 EPDM 291-En - 1ashfaq shaikhNo ratings yet

- FKM 595 elastomer properties and testing resultsDocument3 pagesFKM 595 elastomer properties and testing resultsPillar ManufacturingNo ratings yet

- Marco Material Datasheet V1005Document2 pagesMarco Material Datasheet V1005Bib GmzNo ratings yet

- SCGC LSP L2420J Technical Datasheet ProvisionalDocument3 pagesSCGC LSP L2420J Technical Datasheet Provisionalakankshas06No ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- TPU 95A Technical Data SheetDocument3 pagesTPU 95A Technical Data SheetSteven DonosoNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Cycoloy Resin C1200 Americas: COMMERCIAL: PropertyDocument2 pagesCycoloy Resin C1200 Americas: COMMERCIAL: PropertymarceloNo ratings yet

- LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetDocument1 pageLNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetWang MbaoNo ratings yet

- Golden Power ATF DEX III TDSDocument1 pageGolden Power ATF DEX III TDSsimon.clove034No ratings yet

- SABIC_Cycolac_MG47FDocument3 pagesSABIC_Cycolac_MG47FChu ChuNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Document2 pagesUltraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Phuoc Thinh TruongNo ratings yet

- TECAPEEK_natural_polyetheretherketone_14Document2 pagesTECAPEEK_natural_polyetheretherketone_14e.montgomeryNo ratings yet

- S1005 TairiproDocument1 pageS1005 TairiproJacquelin DelgadoNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- 1 en H ECOPUR Material DatasheetDocument1 page1 en H ECOPUR Material DatasheetCarlos FiorilloNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- White NBR PDFDocument1 pageWhite NBR PDFNik Danial Aiman Nik HassanNo ratings yet

- Amistco - KO Drum Demister Options (Mist Eliminator Spacing What To Do For Liquid Carryover)Document6 pagesAmistco - KO Drum Demister Options (Mist Eliminator Spacing What To Do For Liquid Carryover)Mubarik AliNo ratings yet

- Technical Data Sheet: 4 January 2010Document3 pagesTechnical Data Sheet: 4 January 2010TinasheNo ratings yet

- Trommel Frame 4500 Diax5200 LGDocument3 pagesTrommel Frame 4500 Diax5200 LGFelipe IgnacioNo ratings yet

- Wet Adhesion of Latex Paints To A Gloss Alkyd Enamel SubstrateDocument4 pagesWet Adhesion of Latex Paints To A Gloss Alkyd Enamel Substrateasma hamzaNo ratings yet

- What Is Hazardous Waste DisposalDocument4 pagesWhat Is Hazardous Waste DisposalOnelNo ratings yet

- Finite Element Analysis of CFRP-externally Strengthened Reinforced Concrete Beams Subjected To Three-Point BendingDocument20 pagesFinite Element Analysis of CFRP-externally Strengthened Reinforced Concrete Beams Subjected To Three-Point BendingHùngNo ratings yet

- J-DMS: Typical Floor ConnectionDocument1 pageJ-DMS: Typical Floor ConnectionMary DenizeNo ratings yet

- Calculating Steam Requirements for Concentrating Apple JuiceDocument5 pagesCalculating Steam Requirements for Concentrating Apple JuiceHasnaNo ratings yet

- Chitin, Chitosan, and Co-Products: Chemistry, Production, Applications, and Health EffectsDocument43 pagesChitin, Chitosan, and Co-Products: Chemistry, Production, Applications, and Health EffectsMartin Raynaldi SimanjuntakNo ratings yet

- Phetrofigisg Pages 113 140Document28 pagesPhetrofigisg Pages 113 140UncabresNo ratings yet

- DEP T13376797RevL - F001Document13 pagesDEP T13376797RevL - F001Kalyankumar KumarNo ratings yet

- Uk 506 - Fita GuiaDocument5 pagesUk 506 - Fita GuiaAlessandro OliveiraNo ratings yet

- Compression Test and Analysis of Tpu Material Using Utm & FeaDocument7 pagesCompression Test and Analysis of Tpu Material Using Utm & Feaci_balaNo ratings yet

- T-Top Waterleak Manual PDFDocument50 pagesT-Top Waterleak Manual PDFBjörn RydholmNo ratings yet

- Chrome TailingsDocument5 pagesChrome Tailingsnickie2611No ratings yet

- Science 7 First QuarterDocument5 pagesScience 7 First QuarterWillyn Grace Sacasac PacanosNo ratings yet

- MDB Lecture Simple StrainDocument9 pagesMDB Lecture Simple StrainAura Paige Montecastro-RevillaNo ratings yet

- Ceramics Pore-Free FutureDocument2 pagesCeramics Pore-Free FutureGustavo MarquesNo ratings yet

- Improvement of Thermal Insulation and Compressive Performance ofDocument10 pagesImprovement of Thermal Insulation and Compressive Performance ofLin YangNo ratings yet

- Bapolene Hdpe 3257u PDFDocument1 pageBapolene Hdpe 3257u PDFGabs GabrielaNo ratings yet

- Bap - Bwro SystemDocument55 pagesBap - Bwro SystemGloria HamiltonNo ratings yet

- DAXXXDocument11 pagesDAXXXMichael WoodNo ratings yet

- Shear Plate ConnectionDocument18 pagesShear Plate ConnectionSangkhayanon PhuNo ratings yet

- Elastic Buckling of Plates With HoleDocument16 pagesElastic Buckling of Plates With Hole201087No ratings yet

- ASTM D2564-12 Solvent Cements For Poly (Vinyl Chloride) (PVC) Plastic Piping Systems-4-5Document2 pagesASTM D2564-12 Solvent Cements For Poly (Vinyl Chloride) (PVC) Plastic Piping Systems-4-5roy tambunanNo ratings yet

- Test Bank, G 10Document48 pagesTest Bank, G 10abdullah.1723006No ratings yet

- Section 4 - HLDDocument13 pagesSection 4 - HLDfaizal_7138No ratings yet

- ProjectReport On Expressway (Divyanshu Shukla)Document30 pagesProjectReport On Expressway (Divyanshu Shukla)Divyanshu ShuklaNo ratings yet

- Use of Alternative Materials and Technology For Roads PDFDocument10 pagesUse of Alternative Materials and Technology For Roads PDFDwijendra ChanumoluNo ratings yet