Professional Documents

Culture Documents

Qa Manual-9

Uploaded by

pitchapon janprasert0 ratings0% found this document useful (0 votes)

11 views1 pageThis document outlines PPAP retention and submission requirements for suppliers in 17 sections. It requires suppliers to submit certain documents to SRK-ER and retain copies, and to retain but not submit other documents. Documents like the design record, control plan, and part submission warrant must be submitted. Records like process flow diagrams, inspection results, and material test results must be submitted for some supplier groups but retained for others.

Original Description:

Original Title

qa_manual-9

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines PPAP retention and submission requirements for suppliers in 17 sections. It requires suppliers to submit certain documents to SRK-ER and retain copies, and to retain but not submit other documents. Documents like the design record, control plan, and part submission warrant must be submitted. Records like process flow diagrams, inspection results, and material test results must be submitted for some supplier groups but retained for others.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageQa Manual-9

Uploaded by

pitchapon janprasertThis document outlines PPAP retention and submission requirements for suppliers in 17 sections. It requires suppliers to submit certain documents to SRK-ER and retain copies, and to retain but not submit other documents. Documents like the design record, control plan, and part submission warrant must be submitted. Records like process flow diagrams, inspection results, and material test results must be submitted for some supplier groups but retained for others.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

1 1/6/2018 Company name change

0 1/9/2016 New Issue

Rev. Date History Record Issued by Staff Checked by Supv. Approved by Mgr.

Quality Supplier Manual

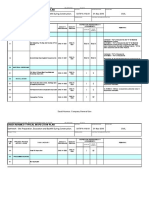

4.4.2 PPAP Retention/Submission Requirement for Supplier

Supplier shall submit document follow this requirement separate to supplier group or any required

by SRK-ER (supplier shall to use SRK-ER format some requirement at symbol is )

Production Matetial Submission Material

Rubber Com pound Fix SRK-ER

Requirement Metal part, Plas tic

Plas tic Material Other form at 1st SPTT 2nd SPTT 3rd SPTT

part, Rubber part

Chem ical

1 Design Record S - S

-For proprietary components/ details R - R

-For all other components/ details S - S

-Design Verf ication plan & Report (DVP&R) S - S

2 Engineering Change Documents S - S

-List of Engineering draw ing to supplier (a3) R - R

-Engineering draw ing recorder (a7) S - S

-Process change notice (a20) S S S

-Engineering change request (a28) S S S

-Change point management (a29) S S S

Customer Engineering Approval (Inspection std.)

3

(a26) S - S

4 Process Flow Diagrams (a8) S S S -

5 Process FMEA S - S -

6 Control Plan (a9) S S S -

7 Measurement System Analysis Studies (a5) S - - -

8 Dimensional Results S - S

-Full lay out Inspection Result (a10) S - S

-OFF TOOL sample data report (a30) S - S

9 Material test result (a11) S S S

-Supply chain database list (a12) S S S

-Component f low chart & Component part (a13) S S S

-Perf ormance test result (a14) S S S

10 Initial Process Studies S - - -

11 Qualif ied Laboratory Documentation S - S -

12 Initial Master Sample (a15) S - S -

13 Checking Aids R - - -

-

Records of Compliance w ith Customer-Specif ic

14

Requirements S - S

15 Part Submission Warrant (PSW) (a17) S S S

16 Environmental Substant S S S

-Supplier banned substance check sheet /SBSC

(a18) S S S

-Certif icate of non-use of the controlled

substances (a19) S S S

-Environment hazardous substance test report

(a22) S S S

-Material data sheet (a23) S S S

-Declaration of no use of PFOS (a24) S S S

-SVHC questionnaire (a25) S S S

17 Others - - - - - - -

- Project organization chart (a1) S S S

- Production Preparation Schedule (a2) S S S

- Tooling Schedule S S S - -

- SPTT audit result (a4) S S S

- Quality problem f ollow ing up sheet (a21) S S S

S = Supplier shall submit to SRK-ER and retain a copy of records or documentation items at appropriate locations.

R = Supplier shall retain at appropriate location and make available to SRK-ER upon request.

Page 7 of 47

You might also like

- Inspection and Test Plan Piping Prefabrication GAMA - CommentedDocument2 pagesInspection and Test Plan Piping Prefabrication GAMA - CommentedHaythem Ben ZidNo ratings yet

- Inspection and Test Plan For Line PipeDocument4 pagesInspection and Test Plan For Line PipeMohamed BencharifNo ratings yet

- SATIP-W-011-01 Note5Document14 pagesSATIP-W-011-01 Note5Deo MNo ratings yet

- ITP For Pressure Vessel PDFDocument4 pagesITP For Pressure Vessel PDFErica MartinNo ratings yet

- Inspection and Test Plan-Structural Steel C011Document2 pagesInspection and Test Plan-Structural Steel C011FurqanNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- Satip A 114 01 Earth WorkDocument11 pagesSatip A 114 01 Earth WorkZia ur RehmanNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument13 pagesSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289No ratings yet

- Komatsu Hd785-7 Rigid Dump TrucksDocument20 pagesKomatsu Hd785-7 Rigid Dump Truckswahyu100510No ratings yet

- 1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Document2 pages1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Anonymous S9qBDVkyNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanKhurram ShehzadNo ratings yet

- French Revolution Notes - IB Hist ExamDocument12 pagesFrench Revolution Notes - IB Hist ExamAshika I100% (52)

- Inspection and Test Plan Overhead CraneDocument5 pagesInspection and Test Plan Overhead CraneAdven Tius Surya SurbaktiNo ratings yet

- KSB RPHDocument22 pagesKSB RPHrayggzz_88482611No ratings yet

- PPAP Submission LevelsDocument1 pagePPAP Submission Levelsrgrao85No ratings yet

- Pressure Vessel Itp PDFDocument4 pagesPressure Vessel Itp PDFkorbelNo ratings yet

- Ppap Check List: Lear Automotive India Pvt. Ltd.,NasikDocument73 pagesPpap Check List: Lear Automotive India Pvt. Ltd.,Nasikrajesh sharma100% (1)

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- Drawing Seimens BRKRDocument14 pagesDrawing Seimens BRKRrajeshNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure Vesselbaskaran ayyapparajNo ratings yet

- Flight Ops Eng PDFDocument6 pagesFlight Ops Eng PDFIrfan Azmi0% (2)

- Inspection and Test Plan For Seel StructureDocument3 pagesInspection and Test Plan For Seel StructureChris McNairNo ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- Raw Material BurnabilityDocument12 pagesRaw Material Burnabilitym_verma21No ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- Inspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice BoomDocument4 pagesInspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice Boomrizal mubarokNo ratings yet

- Itp Vessel PDFDocument4 pagesItp Vessel PDFBUDAPESNo ratings yet

- NDT Map Itp Pressure VesselDocument4 pagesNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleAndika PusbiantoNo ratings yet

- Customer Name: Customer Part Number: Sercore Part Number: Drawing no./Level/Date: PPAP Number: PPAP Issue DateDocument9 pagesCustomer Name: Customer Part Number: Sercore Part Number: Drawing no./Level/Date: PPAP Number: PPAP Issue DateAdriana Martínez SorianoNo ratings yet

- RBCAPQPPPAPPackDocument60 pagesRBCAPQPPPAPPackAbdelilah KadriNo ratings yet

- Rbcapqpppappack JL 6718Document57 pagesRbcapqpppappack JL 6718Luis Marcio AnicezioNo ratings yet

- Ppap 50 50010996M - M2054Document55 pagesPpap 50 50010996M - M2054med seifiNo ratings yet

- Sample Ppap DocumentDocument132 pagesSample Ppap Documentఆనంద్ అవధానులNo ratings yet

- PPAP Workbook SupplierDocument25 pagesPPAP Workbook SupplierJuan VillaNo ratings yet

- PPAP Workbook 01 - 29 - 15Document48 pagesPPAP Workbook 01 - 29 - 15joy252No ratings yet

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleRanjan KumarNo ratings yet

- Pressure Vessel Inspection and Test Plan SampleDocument4 pagesPressure Vessel Inspection and Test Plan SampleTYO WIBOWONo ratings yet

- Catalogo Sellos Economos - SKFDocument6 pagesCatalogo Sellos Economos - SKFdani sanNo ratings yet

- Hani NassifDocument29 pagesHani NassifJulio LopesNo ratings yet

- PPAP RequirementsDocument2 pagesPPAP RequirementsMuthu KumarNo ratings yet

- Ppap - Q19-W240e 121Document32 pagesPpap - Q19-W240e 121Ragul0042No ratings yet

- ServiceManual - FB11 2 2 2Document56 pagesServiceManual - FB11 2 2 2solutronicNo ratings yet

- Inspection-and-Test-Plan-for-Fabrication and Erection of Structural SteelDocument4 pagesInspection-and-Test-Plan-for-Fabrication and Erection of Structural SteelVinayaga MoorthiNo ratings yet

- Onetrust Price List For SiemensDocument1 pageOnetrust Price List For SiemensAdolphus MashapaNo ratings yet

- ITP-Onshore-Pipeline PTMDocument2 pagesITP-Onshore-Pipeline PTMFerdie OSNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Machined Seals: Open To See The Full Range of Machined Seals, Wipers, Guide Rings and Back-Up RingsDocument2 pagesMachined Seals: Open To See The Full Range of Machined Seals, Wipers, Guide Rings and Back-Up Ringsg1763970No ratings yet

- Customized Machined SealsDocument6 pagesCustomized Machined Sealsgrupa2904No ratings yet

- V-SDK1-060 Rev. 2 PDFDocument77 pagesV-SDK1-060 Rev. 2 PDFDaniel Hernandez JimenezNo ratings yet

- Revised Pay Scale of Employees of AerbDocument2 pagesRevised Pay Scale of Employees of AerbnkswarunNo ratings yet

- List of Documents W/O STD Committee: Drilling & WorkoverDocument2 pagesList of Documents W/O STD Committee: Drilling & Workoverabdeslem mouloudjNo ratings yet

- Inspection and Test Plan Rotating Equipment:: LPG PumpDocument4 pagesInspection and Test Plan Rotating Equipment:: LPG PumpErico Haryanto LumbanrajaNo ratings yet

- STAAD Pro V8i SS4 AISC 14th Ed GuideDocument103 pagesSTAAD Pro V8i SS4 AISC 14th Ed Guideel.salumbidesNo ratings yet

- Satip e 007 01Document10 pagesSatip e 007 01Ansar Ali VemmullyNo ratings yet

- Appendix A7 Company Supplied Data and Design Dossier - Rev Final - 210908Document11 pagesAppendix A7 Company Supplied Data and Design Dossier - Rev Final - 210908Rianto FelissimoNo ratings yet

- Qap - Kongsberg - NabDocument4 pagesQap - Kongsberg - NabDeepak DasNo ratings yet

- SpaceQualifiedPartsList AD PDFDocument14 pagesSpaceQualifiedPartsList AD PDFguacher100% (1)

- De Thi Hoc Ky 2 Mon Tieng Anh Lop 10 Thi Diem So GD DT Binh PhuocDocument12 pagesDe Thi Hoc Ky 2 Mon Tieng Anh Lop 10 Thi Diem So GD DT Binh Phuoc17. Phạm Tuyết Nga 10HNo ratings yet

- Build LogDocument1 pageBuild LogdannywebseriesNo ratings yet

- CostcoDocument96 pagesCostcoChris DavidsonNo ratings yet

- Mpo - Compressor MotorDocument2 pagesMpo - Compressor MotorroelNo ratings yet

- Unit I CoaDocument59 pagesUnit I CoaRajitha ReddyNo ratings yet

- CA. AJAY JAIN, 9310167881: Time Allowed - 3 Hours Maximum Marks - 100Document14 pagesCA. AJAY JAIN, 9310167881: Time Allowed - 3 Hours Maximum Marks - 100RishabNo ratings yet

- Drug Study CaseDocument7 pagesDrug Study CaseKevin Sam AguirreNo ratings yet

- 5 Levers For GrowthDocument2 pages5 Levers For GrowthliusNo ratings yet

- Host To Host Communication in NetworkingDocument3 pagesHost To Host Communication in NetworkingAnmol ChitranshNo ratings yet

- Waiting Line Part I PDFDocument10 pagesWaiting Line Part I PDFJankiNo ratings yet

- Saeed Zaman CVDocument2 pagesSaeed Zaman CVSheeraz Ali khakiNo ratings yet

- Iso 21457-2010Document7 pagesIso 21457-2010empireamsyarNo ratings yet

- Hade KanDocument137 pagesHade KanasepramboNo ratings yet

- Campus Security AwarenessDocument19 pagesCampus Security AwarenessMiyangNo ratings yet

- VIP 32 Hybrid VentDocument8 pagesVIP 32 Hybrid VentsagarNo ratings yet

- First Page PDFDocument1 pageFirst Page PDFNebojsa RedzicNo ratings yet

- Record A FaceTime CallDocument3 pagesRecord A FaceTime Calltsultim bhutiaNo ratings yet

- RMC No. 124-2020Document6 pagesRMC No. 124-2020Raine Buenaventura-Eleazar100% (2)

- Jurnal Penelitian Tolak AnginDocument9 pagesJurnal Penelitian Tolak AnginAnton WahyudiNo ratings yet

- Electromagnetic and Electrostatic Transmission-Line Parameters by Digital ComputerDocument10 pagesElectromagnetic and Electrostatic Transmission-Line Parameters by Digital Computermrjack1No ratings yet

- Microstructure & Mechanical Characterization of Modified Aluminium 6061Document14 pagesMicrostructure & Mechanical Characterization of Modified Aluminium 6061Dinesh DhaipulleNo ratings yet

- Injection Pres Op GasDocument2 pagesInjection Pres Op GasSrWilson Z AriasNo ratings yet

- Mackenzie Marr Marketing ReportDocument13 pagesMackenzie Marr Marketing Reportapi-250686425100% (2)

- K-Means in Python - SolutionDocument6 pagesK-Means in Python - SolutionRodrigo ViolanteNo ratings yet

- Bmom5203 Assignment Part 1Document15 pagesBmom5203 Assignment Part 1ALBERT AK SIPAT STUDENTNo ratings yet