Professional Documents

Culture Documents

Roxas A2

Uploaded by

Luis Manuel RoxasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roxas A2

Uploaded by

Luis Manuel RoxasCopyright:

Available Formats

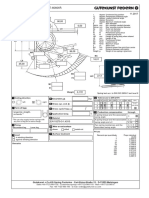

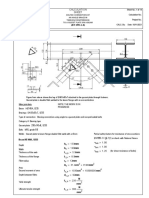

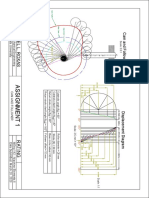

Problem:

Design a gear drive using spur gears to reduce the speed of a shaft from 1800 rpm to 1200 rpm. The entire assembly should fit within a 20 cm by 15 cm enclosure.

Common Tangent

Pressure Line

Pressure Angle

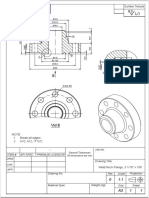

Ø90 mm, 36 Teeth

20°

Dedendum Circle 1200 RPM

Clearance Circle

Ø60 mm, 24 Teeth

Base Circle 1800 RPM

Involute Tooth Profile

Pitch Circle

Base Circle Addendum Circle Pitch Point

Pressure Angle = 20 Diametral Pitch = 0.4 Whole Depth = 5.39

Addendum = 2.5 Circular Pitch = 7.85398 Pinion Diameter = 60 Tooth Profile Dedendum = 2.89

Backlash = 0.10

Dedendum = 2.89 Tooth Thickness = 3.877 Gear Diameter = 90

Addendum = 2.50

Clearance = 0.3925 Tooth Space = 3.977 Fillet Radius = 0.59 Tooth Space = 3.98 Tooth Thickness = 3.87

Pinion Base Circle Ø = 56.382 Backlash = 0.10 Working Depth = 5.01

Base Circle

Gear Base Circle Ø = 84.572

Scale 1:2 Working Depth = 5.01

Whole Depth = 5.39

DWG NO.

MENG 142 - MACHINE ELEMENTS II

DEPARTMENT OF MECHANICAL ENGINEERING

VISAYAS STATE UNIVERSITY - MAIN CAMPUS

A-2

TITLE

SPUR GEAR DESIGN

DRAWN BY DATE SUBMITTED

LUIS MANUEL L. ROXAS APRIL 11, 2023

CHECKED RATING SCALE 1:1

SHEET 1 / 2

You might also like

- Servis Manual Eloblock6-28K13EN Vaill 280910 SmallDocument105 pagesServis Manual Eloblock6-28K13EN Vaill 280910 SmallBOREBGK33% (6)

- Basics of Well Completion-EPDocument41 pagesBasics of Well Completion-EPHamdan Hamzah92% (12)

- Thread Engagement Length CalculationDocument2 pagesThread Engagement Length CalculationVenkateswaran venkateswaran100% (1)

- Boilers RLADocument60 pagesBoilers RLAGanesh100% (1)

- H84ACM Coursework GuidelinesDocument6 pagesH84ACM Coursework GuidelinesYeeXuan TenNo ratings yet

- Dimensions: Bellows CouplingDocument1 pageDimensions: Bellows CouplingEric MontesNo ratings yet

- SJ71-00055D (08Q) Cylinder CAN Process Inspection Check Sheet (SE)Document6 pagesSJ71-00055D (08Q) Cylinder CAN Process Inspection Check Sheet (SE)segar PalanisamyNo ratings yet

- Chapter 4Document26 pagesChapter 4Tan Mei QianNo ratings yet

- FlipCUT Brochure 06-24-16 PDFDocument16 pagesFlipCUT Brochure 06-24-16 PDFAlexandre SouzaNo ratings yet

- Connection Steel DesignDocument9 pagesConnection Steel DesignFaiz JaafarNo ratings yet

- Planetary Gearhead GP 32 BZ 32 MM, 0.75-4.5 NM: Low BacklashDocument1 pagePlanetary Gearhead GP 32 BZ 32 MM, 0.75-4.5 NM: Low BacklashMonori BenceNo ratings yet

- Gear CorrectionDocument17 pagesGear CorrectionMurugesanNo ratings yet

- Drw. Surface Texture: 1. Break All Edges. 2Document1 pageDrw. Surface Texture: 1. Break All Edges. 2Ruslan BayramovNo ratings yet

- DWG 002Document1 pageDWG 002Deepak KumarNo ratings yet

- Form M Date 10/15/82 Time 16:41 Pinion Gear: Appendix BDocument3 pagesForm M Date 10/15/82 Time 16:41 Pinion Gear: Appendix BCarlos GonzalesNo ratings yet

- Involute Spur Gear Geometry Calculations: Input DataDocument11 pagesInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVNo ratings yet

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- Maxon GP 22 LDocument1 pageMaxon GP 22 LElectromateNo ratings yet

- DWG 001Document1 pageDWG 001Deepak KumarNo ratings yet

- Thread Engagement Length CalculationDocument2 pagesThread Engagement Length CalculationVenkateswaran venkateswaranNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- Bevel Gear Formula - MasterDocument191 pagesBevel Gear Formula - Masterer_winwibowo100% (1)

- O-Ring CalculatorDocument1 pageO-Ring CalculatorMatyas TakacsNo ratings yet

- PJU H 9mtr Tunggal PDFDocument1 pagePJU H 9mtr Tunggal PDFbgan29No ratings yet

- Armature Skew Angle Calculation Description Result: Le Tapped Hole Le ScrewDocument2 pagesArmature Skew Angle Calculation Description Result: Le Tapped Hole Le ScrewVenkateswaran venkateswaranNo ratings yet

- Rotary O-Ring Seal GlandsDocument5 pagesRotary O-Ring Seal Glandsdinesh panchalNo ratings yet

- Doubly Reinforcement Beam Design MVT (Working)Document38 pagesDoubly Reinforcement Beam Design MVT (Working)abdullah rahmanNo ratings yet

- 90 Vs R - V-Ring Seals, Globally Valid - SKFDocument2 pages90 Vs R - V-Ring Seals, Globally Valid - SKFWildan PriatnaNo ratings yet

- Angrenaj MelcatDocument4 pagesAngrenaj MelcatDiana Maria CozmaNo ratings yet

- Sprockets: Iso Chain Sprockets Asa Chain Sprockets Stainless Steel Chain SprocketsDocument53 pagesSprockets: Iso Chain Sprockets Asa Chain Sprockets Stainless Steel Chain SprocketsAnonymous lswzqloNo ratings yet

- Catalogo General de Fresado (MKT11 ED01 REV01 - 11) PDFDocument96 pagesCatalogo General de Fresado (MKT11 ED01 REV01 - 11) PDFLeonardo OlivaresNo ratings yet

- B7006-C-T-P4S-UL: Spindle BearingDocument2 pagesB7006-C-T-P4S-UL: Spindle BearingRamesh RamNo ratings yet

- 06) UB254x146x43TOUB356x171x51 Beam To Beam End PlateDocument117 pages06) UB254x146x43TOUB356x171x51 Beam To Beam End PlateCivil StructureNo ratings yet

- BC-LP-001 2021-22Document2 pagesBC-LP-001 2021-22Ravikant YadavNo ratings yet

- 18) UC203x203x46toUC254x254x73-B2CF - MCDocument125 pages18) UC203x203x46toUC254x254x73-B2CF - MCAsaru DeenNo ratings yet

- Input Data MijaDocument3 pagesInput Data MijaMijael Tarqui PortilloNo ratings yet

- Maxon GS 16 ADocument1 pageMaxon GS 16 AElectromateNo ratings yet

- Datasheet Mola de Torção 16161RDocument1 pageDatasheet Mola de Torção 16161RBruno SantosNo ratings yet

- Design Calculation For Anchor Chair API 650Document1 pageDesign Calculation For Anchor Chair API 650Mohammed Faizal Nv100% (2)

- Mathcad - Angle Bracing Connected To A Gusset Plate On BeamDocument14 pagesMathcad - Angle Bracing Connected To A Gusset Plate On BeamValentinNo ratings yet

- Characteristics: Ø 12 ÷ 100 MM - Short Stroke Cylinders Tube New DesignDocument1 pageCharacteristics: Ø 12 ÷ 100 MM - Short Stroke Cylinders Tube New Designjitendra shahNo ratings yet

- Design of Base RingDocument1 pageDesign of Base RingMohammed Faizal Nv100% (1)

- Sprocket PT Petrodrill Manufacture IndonesiaDocument1 pageSprocket PT Petrodrill Manufacture Indonesiaer_winwibowoNo ratings yet

- 4.design Specification 2Document1 page4.design Specification 2Soe Soe MonNo ratings yet

- Props PDFDocument13 pagesProps PDFxyzhynNo ratings yet

- Thread Cutting Acme ThreadformsDocument3 pagesThread Cutting Acme ThreadformsHMPGNo ratings yet

- External Involute Spline Data: 12/24 Pitch, 30 Degree Pressure Angle, Fillet Root Side Fit, Class 2, ANSI B92.1-1970Document1 pageExternal Involute Spline Data: 12/24 Pitch, 30 Degree Pressure Angle, Fillet Root Side Fit, Class 2, ANSI B92.1-1970ratnakarNo ratings yet

- 90 VA V - V-Ring Seals, Globally Valid - SKFDocument2 pages90 VA V - V-Ring Seals, Globally Valid - SKFMohamed AliNo ratings yet

- John Crane Type 32 SealDocument4 pagesJohn Crane Type 32 SealhichamNo ratings yet

- X B BC y F FC Z B C y W WC Z C BC: Designed By: Sheet No: Date: Rev No: Checked By: Revised By: Date: DateDocument123 pagesX B BC y F FC Z B C y W WC Z C BC: Designed By: Sheet No: Date: Rev No: Checked By: Revised By: Date: DateAsaru DeenNo ratings yet

- Kalkulasi HEDocument4 pagesKalkulasi HEagusnnnNo ratings yet

- Maj51br101a1 01Document1 pageMaj51br101a1 01Kamil FornalNo ratings yet

- Spur Gear PDFDocument1 pageSpur Gear PDFJayaprakashNo ratings yet

- OL-388.8-Hitachi 20211203184635.614 XDocument1 pageOL-388.8-Hitachi 20211203184635.614 XWilson AlvesNo ratings yet

- Maxon GP 32 BZDocument1 pageMaxon GP 32 BZElectromateNo ratings yet

- Simora As Staked Adv PDFDocument29 pagesSimora As Staked Adv PDFVictor DlreyesNo ratings yet

- Test PDFDocument1 pageTest PDFMichael FelixrajNo ratings yet

- PistonDocument1 pagePistongeronimojuarez179No ratings yet

- Details of Beams: Restrained Beam - 6Document1 pageDetails of Beams: Restrained Beam - 6Janea Ree ManzalaNo ratings yet

- Criminology Student Intern Data SheetDocument1 pageCriminology Student Intern Data SheetLuis Manuel RoxasNo ratings yet

- Final Shear Cutting Machine Rehabilitation ProjectDocument21 pagesFinal Shear Cutting Machine Rehabilitation ProjectLuis Manuel RoxasNo ratings yet

- All ToltablesDocument6 pagesAll ToltablesLuis Manuel RoxasNo ratings yet

- Learning Task 4 (1) - Roxas Luis Manuel (W 2-4pm)Document1 pageLearning Task 4 (1) - Roxas Luis Manuel (W 2-4pm)Luis Manuel RoxasNo ratings yet

- TablesDocument5 pagesTablesLuis Manuel RoxasNo ratings yet

- Final Case StudyDocument8 pagesFinal Case StudyLuis Manuel RoxasNo ratings yet

- Roxas A2 SolutionsDocument2 pagesRoxas A2 SolutionsLuis Manuel RoxasNo ratings yet

- Learningtaskno3 - RoxasLuisManuel (W 2-4pm)Document2 pagesLearningtaskno3 - RoxasLuisManuel (W 2-4pm)Luis Manuel RoxasNo ratings yet

- Learning Task 5 - Roxas Luis Manuel (W 2-4pm)Document1 pageLearning Task 5 - Roxas Luis Manuel (W 2-4pm)Luis Manuel RoxasNo ratings yet

- Roxas Activity3 COM11Document3 pagesRoxas Activity3 COM11Luis Manuel RoxasNo ratings yet

- Roxas - MEng142 - Assignment Sheet 1Document1 pageRoxas - MEng142 - Assignment Sheet 1Luis Manuel RoxasNo ratings yet

- Assessment3.2 RoxasLuisManuelDocument2 pagesAssessment3.2 RoxasLuisManuelLuis Manuel RoxasNo ratings yet

- Assessment3.3 RoxasLuisManuelDocument2 pagesAssessment3.3 RoxasLuisManuelLuis Manuel RoxasNo ratings yet

- Assessment 1.3 Esci 110-N028Document1 pageAssessment 1.3 Esci 110-N028Luis Manuel RoxasNo ratings yet

- 2.2 LT and ASSESSMENTDocument7 pages2.2 LT and ASSESSMENTLuis Manuel RoxasNo ratings yet

- Module 2Document14 pagesModule 2Luis Manuel RoxasNo ratings yet

- Assessment 1.1 (B) Esci 110-N028Document1 pageAssessment 1.1 (B) Esci 110-N028Luis Manuel RoxasNo ratings yet

- Assessment 1.2 (B, C) Esci 110-N028Document1 pageAssessment 1.2 (B, C) Esci 110-N028Luis Manuel RoxasNo ratings yet

- Assessment 1.1 (A) Esci 110-N028Document1 pageAssessment 1.1 (A) Esci 110-N028Luis Manuel RoxasNo ratings yet

- CNG Bush DrawingDocument1 pageCNG Bush DrawingAnkur Agarwal Vedic AstrologerNo ratings yet

- D 6693 - 03 Tensile Properties PDFDocument4 pagesD 6693 - 03 Tensile Properties PDFHussein BeqaiNo ratings yet

- Modeling and Simulation of BLDC Motor Using Soft Computing TechniquesDocument5 pagesModeling and Simulation of BLDC Motor Using Soft Computing TechniquesJulián Peláez RestrepoNo ratings yet

- Arcoaire Amfk Series Electric HeatersDocument5 pagesArcoaire Amfk Series Electric HeatersdwilhNo ratings yet

- ATA 32 Landing Gear (1) - Páginas-194-195Document2 pagesATA 32 Landing Gear (1) - Páginas-194-195Maria Fernanda Nuñez RuizNo ratings yet

- CE 212 Mechanics of Solids Sessional: Department of Civil EngineeringDocument54 pagesCE 212 Mechanics of Solids Sessional: Department of Civil EngineeringjulesNo ratings yet

- PRV e 50b 4kg1kolDocument2 pagesPRV e 50b 4kg1kolmoh. rusli bahtiarNo ratings yet

- 3 The Basics of An Injection Molding MachineDocument2 pages3 The Basics of An Injection Molding MachineGerardo ArroyoNo ratings yet

- Wood Group Kenny-Development of ABAQUS User Subroutine For Advance Pipe Soil Modelling-Fuming YangDocument6 pagesWood Group Kenny-Development of ABAQUS User Subroutine For Advance Pipe Soil Modelling-Fuming YangWalid MghazliNo ratings yet

- Dimensionless Numbers in Fluid MechanicsDocument7 pagesDimensionless Numbers in Fluid MechanicsEduardoNo ratings yet

- Compressive Strength Testing of PlasticsDocument2 pagesCompressive Strength Testing of Plasticsmohammad norooziNo ratings yet

- Machine Systems Torsional Vibration of Ronald L. Eshleman PDFDocument10 pagesMachine Systems Torsional Vibration of Ronald L. Eshleman PDFtylerdurdaneNo ratings yet

- Temperature, Prestrain & SupportDocument8 pagesTemperature, Prestrain & SupportSarah SullivanNo ratings yet

- SECTION 15190 Fuel Piping Rev 0Document34 pagesSECTION 15190 Fuel Piping Rev 0mohamad damerlyNo ratings yet

- F400 Brochure PDFDocument5 pagesF400 Brochure PDFJuan Guereca ContrerasNo ratings yet

- Part-2-July21a P P E N D I X 9 Welding Procedure Qualification Tests of Steels For Hull Construction and Marine Structures (1 July 2014)Document27 pagesPart-2-July21a P P E N D I X 9 Welding Procedure Qualification Tests of Steels For Hull Construction and Marine Structures (1 July 2014)Sergio AlejandroNo ratings yet

- Pocket Book Material - HKI 2020Document43 pagesPocket Book Material - HKI 2020Yuan PermanaNo ratings yet

- Problems&SolutionsDocument3 pagesProblems&SolutionsRandeep Iyyad N CNo ratings yet

- Cam Design and ManufacDocument140 pagesCam Design and ManufacJoseph H Finigan100% (4)

- STP 1010Document26 pagesSTP 1010waleedyehiaNo ratings yet

- Automatic Filter Type 6.18 en BOLLFILTERDocument7 pagesAutomatic Filter Type 6.18 en BOLLFILTERИван ПарлапановNo ratings yet

- Automobile Lab ManualDocument35 pagesAutomobile Lab ManualKeshav AsopaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- Rules of Thumb - Fluid FlowDocument14 pagesRules of Thumb - Fluid FlowAlex Kramer100% (2)

- MD-217-7000-EG-ME-SPC-0002 - Fuel Tanks and PumpsDocument11 pagesMD-217-7000-EG-ME-SPC-0002 - Fuel Tanks and PumpsUmair RazaNo ratings yet

- CM YSM Air Handling Unit Catalogue Part11Document1 pageCM YSM Air Handling Unit Catalogue Part11JosephRusselVizmanosNo ratings yet