Professional Documents

Culture Documents

Thread Engagement Length Calculation

Uploaded by

Venkateswaran venkateswaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thread Engagement Length Calculation

Uploaded by

Venkateswaran venkateswaranCopyright:

Available Formats

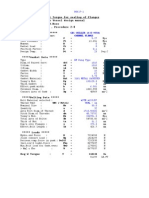

THREAD ENGEMENT LENGTH CALCULATION

DESCRIPTION RESULT

28.7

Minimum thread engagement length required Le min

Tapped Hole 14.14

Le

Screw Le 28.666183

Utilmate tensile strength of screw 800

Rm

Yield strength of screw 640

Re

Utilmate tensile strength of cast material (Tapped Hole) 435

Rm

Yield strength of cast material (Tapped Hole) 290

Re

Stress area cross section 156.7

A

Pitch 2

P

Screw diameter d 16

Pitch diameter d2 14.701

Le tapped hole

Equation

Le screw

Le = Minimum Length engagement in mm

Rm = Ultimate tensile strength in Mpa

Re = Yield strength in Mpa (80% of UTS is Yield stren

A = Stress area cross section in mm^2

P= Pitch in mm

d2 = Pitch diameter = d - (0.6495*P)

ATION

Unit Detail Input cell

mm Maximum length from Tapped Result output cell

hole or screw hole to be

mm captured

mm

Mpa

Mpa

Mpa

Mpa

mm^2

mm

mm

mm

=(Rm Screw / Re tapped Hole) * ( 2* A / 0.6*p*d )

=(Rm Screw / Re Screw)* ( 2 A / 0.6*p*d2 )

Le min > maximum value

Minimum Length engagement in mm

Ultimate tensile strength in Mpa

ield strength in Mpa (80% of UTS is Yield strength)

ess area cross section in mm^2

itch diameter = d - (0.6495*P)

You might also like

- Thread Engagement Length CalculationDocument2 pagesThread Engagement Length CalculationVenkateswaran venkateswaran100% (1)

- Design of fillet weld as per BS EN 1993 1 8 CL 4.5.3Document2 pagesDesign of fillet weld as per BS EN 1993 1 8 CL 4.5.3Giri DharanNo ratings yet

- KDS 41 17 00 2019Document75 pagesKDS 41 17 00 2019Suso IglesiasNo ratings yet

- Shell-Bottom Joint Strength CheckDocument3 pagesShell-Bottom Joint Strength CheckKP SahuNo ratings yet

- AD 2000 Flange Design Calculation DIN 2505Document2 pagesAD 2000 Flange Design Calculation DIN 2505mechengg01100% (1)

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Design of base plate for columnDocument6 pagesDesign of base plate for columnsoumyaNo ratings yet

- Api - 650 - 2007 - 40Document1 pageApi - 650 - 2007 - 40Raul GonzaloNo ratings yet

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Document11 pagesWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleNo ratings yet

- Pages From ASME PTB-4-2013 - Section VIII-Division 1 Example Problem ManualDocument4 pagesPages From ASME PTB-4-2013 - Section VIII-Division 1 Example Problem Manualzguy360No ratings yet

- Seimic Response of Liquid Storage TankDocument4 pagesSeimic Response of Liquid Storage TanklucianduNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Heavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsDocument2 pagesHeavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsSuresh BabuNo ratings yet

- Bolt Load Calculation StepsDocument2 pagesBolt Load Calculation StepsSrikanth ShankarNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNo ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDFrancisco RojasNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- Anchor Calculation - Case 2Document10 pagesAnchor Calculation - Case 2MdShahbazAhmedNo ratings yet

- Steel Column Base Plate Analysis: Blue Cells Are Input DataDocument1 pageSteel Column Base Plate Analysis: Blue Cells Are Input DataHansal Soni0% (1)

- Pipe cap thickness and coupling rating calculationsDocument2 pagesPipe cap thickness and coupling rating calculationsmasaminathanNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Roark's FormulasDocument14 pagesRoark's FormulasDavide FerrareseNo ratings yet

- PEC-EN-STN-C-13619-17-Mar-2014-Document169 pagesPEC-EN-STN-C-13619-17-Mar-2014-Raja RamNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- Recommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11Document6 pagesRecommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11perdhana2000No ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Flange Input CalcDocument12 pagesFlange Input CalcdharwinNo ratings yet

- Anchor Reinforcement AnalysisDocument10 pagesAnchor Reinforcement AnalysisTarek AbulailNo ratings yet

- Waste Water Equalising Tank Anchor Chair DetailsDocument4 pagesWaste Water Equalising Tank Anchor Chair DetailsShaheed HossainNo ratings yet

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionDocument6 pagesChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionGaurav BedseNo ratings yet

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- Wind Load Reaction Force Due To Wind Action From Stack Acting On The Fan DeckDocument3 pagesWind Load Reaction Force Due To Wind Action From Stack Acting On The Fan Deckikanyu79No ratings yet

- ASME BPVC.VIII.1 corrosion guidelinesDocument2 pagesASME BPVC.VIII.1 corrosion guidelinescanizales70No ratings yet

- Anchor Bolt Design Spreadsheet Revision 0a, April 2003Document12 pagesAnchor Bolt Design Spreadsheet Revision 0a, April 2003Vietanh PhungNo ratings yet

- Base Plate Design Metric Units PDFDocument8 pagesBase Plate Design Metric Units PDFVinayak PatilNo ratings yet

- Sample Shear ConnectionDocument1 pageSample Shear ConnectionmaheshbandhamNo ratings yet

- Cleat Angle ConnectionDocument38 pagesCleat Angle ConnectionMadhubalan AlagarNo ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Calculation For Column Base Plate (H-Shape)Document9 pagesCalculation For Column Base Plate (H-Shape)Syafiruddin CokiNo ratings yet

- Calculating Wind Load on a Dish AntennaDocument1 pageCalculating Wind Load on a Dish AntennadovermanNo ratings yet

- Davit Trolley - Validation of Davit & Support BracketDocument17 pagesDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapNo ratings yet

- Design of Chequered Plate DesignDocument2 pagesDesign of Chequered Plate DesignadihindNo ratings yet

- Nozzle neck thickness calculation UG-45Document2 pagesNozzle neck thickness calculation UG-45Lcm TnlNo ratings yet

- Saddle design calculationsDocument9 pagesSaddle design calculationsduf fuNo ratings yet

- Bolt Torq. (Moss+Farr)Document9 pagesBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Steel Silo - AaaDocument22 pagesSteel Silo - AaaABDUL AASHIKNo ratings yet

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackNo ratings yet

- Vertical Vessel Foundation Design Input Parameters: Geometrical DescriptionDocument8 pagesVertical Vessel Foundation Design Input Parameters: Geometrical DescriptionAnonymous xcFcOgMiNo ratings yet

- Comparision IS VS EURO PDFDocument7 pagesComparision IS VS EURO PDFRadhaKrishnanTNo ratings yet

- Base plate design calculations and stressesDocument29 pagesBase plate design calculations and stressessatyakamNo ratings yet

- TEMA Eighth Edition - ClarificationsDocument13 pagesTEMA Eighth Edition - ClarificationsJerome100% (1)

- Chapter 3: Tank DesignDocument4 pagesChapter 3: Tank Designevrim77No ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Armature Skew Angle Calculation Description Result: Le Tapped Hole Le ScrewDocument2 pagesArmature Skew Angle Calculation Description Result: Le Tapped Hole Le ScrewVenkateswaran venkateswaranNo ratings yet

- Thread Length Verification for 1-1/8Document2 pagesThread Length Verification for 1-1/8PravinNo ratings yet

- Armature Resistance CalculationDocument5 pagesArmature Resistance CalculationVenkateswaran venkateswaranNo ratings yet

- Die Casting Die Parameter - Calculation - GuidelineDocument8 pagesDie Casting Die Parameter - Calculation - GuidelineVenkateswaran venkateswaranNo ratings yet

- Wiper Motor Torque CalculationDocument2 pagesWiper Motor Torque CalculationVenkateswaran venkateswaranNo ratings yet

- Spot Welding Strength CalculationDocument14 pagesSpot Welding Strength CalculationVenkateswaran venkateswaranNo ratings yet

- 96.rivet Cost Estimation TemplateDocument1 page96.rivet Cost Estimation TemplateVenkateswaran venkateswaranNo ratings yet

- Class 3 Lever Effort Force CalculationDocument6 pagesClass 3 Lever Effort Force CalculationVenkateswaran venkateswaranNo ratings yet

- Worm Gear Efficiency and Motor Stall Torque Relation CalculationDocument8 pagesWorm Gear Efficiency and Motor Stall Torque Relation CalculationVenkateswaran venkateswaranNo ratings yet

- Blow Mould Component Cost EstimationDocument6 pagesBlow Mould Component Cost EstimationVenkateswaran venkateswaran100% (1)

- Calculating force using Newton's second lawDocument4 pagesCalculating force using Newton's second lawVenkateswaran venkateswaranNo ratings yet

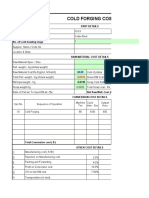

- 94.cold Forging Cost Estimation SheetDocument5 pages94.cold Forging Cost Estimation SheetVenkateswaran venkateswaranNo ratings yet

- Specific Gravity CalculationDocument3 pagesSpecific Gravity CalculationVenkateswaran venkateswaranNo ratings yet

- Gear Motor Calculation - 1Document2 pagesGear Motor Calculation - 1Venkateswaran venkateswaranNo ratings yet

- Press Tool Technical RequirementsDocument6 pagesPress Tool Technical RequirementsVenkateswaran venkateswaranNo ratings yet

- Worm Sliding Speed CalculationDocument4 pagesWorm Sliding Speed CalculationVenkateswaran venkateswaranNo ratings yet

- Injection Mould Component Cost EstimationDocument7 pagesInjection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Poly Carbonate - Injection Mould Component Cost EstimationDocument7 pagesPoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Force CalculationsDocument14 pagesForce CalculationsVenkateswaran venkateswaranNo ratings yet

- Gear Motor Calculation-2Document3 pagesGear Motor Calculation-2Venkateswaran venkateswaranNo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Rubber Grommet Cost Estimation SheetDocument1 pageRubber Grommet Cost Estimation SheetVenkateswaran venkateswaran100% (1)

- Calculations For Gear Box of Stabiliser Gear Box. ExistingDocument2 pagesCalculations For Gear Box of Stabiliser Gear Box. ExistingVenkateswaran venkateswaranNo ratings yet

- Motor CalculationDocument5 pagesMotor CalculationVenkateswaran venkateswaranNo ratings yet

- Injection Mould Component Cost EstimationDocument7 pagesInjection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Gear box calculations for stabiliser IP65Document2 pagesGear box calculations for stabiliser IP65Venkateswaran venkateswaranNo ratings yet

- Trapezodial Thread Efficiency - Co-Efficient Force - Steel To Steel Dry DynamicDocument16 pagesTrapezodial Thread Efficiency - Co-Efficient Force - Steel To Steel Dry DynamicVenkateswaran venkateswaranNo ratings yet

- Bearing Load CalculationDocument3 pagesBearing Load CalculationVenkateswaran venkateswaranNo ratings yet

- HOW FLANGE FINISH AFFECTS GASKET PERFORMANCEDocument8 pagesHOW FLANGE FINISH AFFECTS GASKET PERFORMANCEVenkateswaran venkateswaranNo ratings yet

- Trapezodial Thread Efficiency - Co-Efficient Force - Steel To Steel Grease DynamicDocument4 pagesTrapezodial Thread Efficiency - Co-Efficient Force - Steel To Steel Grease DynamicVenkateswaran venkateswaranNo ratings yet

- Blow Mould Component Cost EstimationDocument6 pagesBlow Mould Component Cost EstimationVenkateswaran venkateswaran100% (1)

- Gate Solved Paper EmechDocument22 pagesGate Solved Paper EmechatifNo ratings yet

- Mechanical Properties Quiz SolutionsDocument2 pagesMechanical Properties Quiz Solutionsaileen eustaquioNo ratings yet

- Tests for CTE Widening ProjectDocument3 pagesTests for CTE Widening ProjectalfieNo ratings yet

- Reinforced Concrete Beam DesignDocument12 pagesReinforced Concrete Beam DesignstylistikNo ratings yet

- 2017 - GFRP Laminates - Beams - Ansys - Thesis PDFDocument222 pages2017 - GFRP Laminates - Beams - Ansys - Thesis PDFNaga PhaneendraNo ratings yet

- Exp-4 Torsion TestDocument5 pagesExp-4 Torsion TestHanamant HunashikattiNo ratings yet

- Active Earth Pressure of Narrow Cohesive Backfill On Rigid Retaining Wall of Rotation About The BottomDocument18 pagesActive Earth Pressure of Narrow Cohesive Backfill On Rigid Retaining Wall of Rotation About The BottomJagan JNo ratings yet

- Crack WidthDocument21 pagesCrack WidthBalaji HariNo ratings yet

- Mechanics of CompositesDocument10 pagesMechanics of Compositesdeepakjournal100% (2)

- B. Can A Buried Natural Gas Pipeline Buckle Locally During Earthquake Ground ShakingDocument19 pagesB. Can A Buried Natural Gas Pipeline Buckle Locally During Earthquake Ground ShakingJaime SeguraNo ratings yet

- KURSUS - PENYIASATAN - KEJURUTERAAN - FORENSIK - Case - 1Document23 pagesKURSUS - PENYIASATAN - KEJURUTERAAN - FORENSIK - Case - 1Sathiswaran SelvamNo ratings yet

- PVF Principle of Virtual ForcesDocument3 pagesPVF Principle of Virtual ForcesRameez FaroukNo ratings yet

- Behavior of Gravity Load Designed Reinforced Concrete Buildings Subjected To EarthquakesDocument13 pagesBehavior of Gravity Load Designed Reinforced Concrete Buildings Subjected To EarthquakesMarimuthu KaliyamoorthyNo ratings yet

- IIW Fatigue Recommendations SummaryDocument143 pagesIIW Fatigue Recommendations SummaryClaudio RodriguesNo ratings yet

- Dharhara Pyramid STR ReportDocument48 pagesDharhara Pyramid STR ReportAmok BajracharyaNo ratings yet

- Intrinsic and Extrinsic Properties of A RockDocument1 pageIntrinsic and Extrinsic Properties of A Rockanon00No ratings yet

- Direct Shear TestDocument18 pagesDirect Shear TestJemuel FloresNo ratings yet

- Padeye PATIDocument43 pagesPadeye PATIbayu_23RNo ratings yet

- Design of Flexbile and Rigid Pavements: Solution: (D)Document16 pagesDesign of Flexbile and Rigid Pavements: Solution: (D)mtanveerkarobariNo ratings yet

- CE302 Chap1-3Document106 pagesCE302 Chap1-3anesu dhewaNo ratings yet

- Design Procedure for LTHA and NLTHA using Modified Ground MotionsDocument4 pagesDesign Procedure for LTHA and NLTHA using Modified Ground MotionsAnita KartikaNo ratings yet

- ANSYS - Fatigue Analysis - Simulation - ConfluenceDocument6 pagesANSYS - Fatigue Analysis - Simulation - ConfluenceNur Rohman ArifNo ratings yet

- Bevel Gear Load CapacityDocument11 pagesBevel Gear Load CapacityAriel Rasjido50% (2)

- Moment Curvature CurveDocument25 pagesMoment Curvature CurveWahabAshrafNo ratings yet

- Residual Stresses and Fatigue at Tubular Welded StructuresDocument12 pagesResidual Stresses and Fatigue at Tubular Welded StructuresElias KapaNo ratings yet

- Soil Test ResultDocument38 pagesSoil Test ResultMARKCHRISTMASNo ratings yet

- Short-time Cavitation Erosion of ConcreteDocument6 pagesShort-time Cavitation Erosion of Concretefiligrana2012No ratings yet

- CV2302 - Lateral Earth PressureDocument21 pagesCV2302 - Lateral Earth PressureGabriel ChenNo ratings yet

- OMAE2011-Detailed Contact Analysis of The J Tube Riser Pull in MethodDocument9 pagesOMAE2011-Detailed Contact Analysis of The J Tube Riser Pull in MethodKaushik Kumar SirvoleNo ratings yet