Professional Documents

Culture Documents

Steam Trap Datasheet

Uploaded by

Akram VhoraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Trap Datasheet

Uploaded by

Akram VhoraCopyright:

Available Formats

Corporate Technical- Vadodara

Process Datasheets

DOCUMENT NAME : Steam Trap PREPARED BY : Akram Vhora

DOCUMENT NO.: REVIEWED BY : Dhruv Bajpai

DATE : 24/01/2022 APPROVED BY : Harindra Kaushik

REV: 0

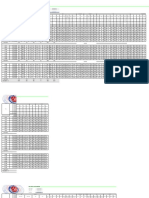

SR.NO. PARTICULARS UOM DNL SPECIFICATION

TRAP-01 TRAP-02 TRAP-03 TRAP-04 TRAP-06 TRAP-08 TRAP-10 TRAP-12 TRAP-14

A GENERAL

1 Type Float type Float type Float type Float type Float type Float type Float type Float type Float type

2 Tag no.

3 Qty 1 1 1 2 2 2 2 2 1

4 Mode of Operation Continuous Continuous Continuous Continuous Continuous Continuous Continuous Continuous Continuous

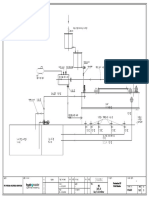

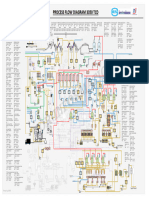

5 P&ID No

6 Location steam outlet line of ST-1802 steam outlet line of ST-1805 steam outlet line of ST-1807 jacket outlet line of P-1802 jacket outlet line of P-1803 jacket outlet line of P-1804 jacket outlet line of P-1806 jacket outlet line of P-1810 jacket outlet line of ATFD

7 Line Size mm 25 15 15 15 15 15 15 15 25

B OPERATING CONDITIONS

1 Fluid Steam Steam Steam Steam Steam Steam Steam Steam Steam

2 Steam Flowrate Kg/ hr 68 25 25 25 25 25 25 25 139

3 Operating temperature °C 139 139 139 139 139 139 139 139 168

4 Operating pressure Kg/cm2(g) 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 7.5

5 Condensate outlet Kg/ hr 68 25 25 25 25 25 25 25 139

6 Installation (horizontal/vertical) horizontal horizontal horizontal horizontal horizontal horizontal horizontal horizontal horizontal

C DESIGN DATA

1 Design code - ASME PTC 39 ASME PTC 39 ASME PTC 39 ASME PTC 39 ASME PTC 39 ASME PTC 39 ASME PTC 39 ASME PTC 39 ASME PTC 39

2 Type of trap selected - # # # # # # # # #

3 Max. Designed flow rate Kg/ hr # # # # # # # # #

4 load safey factor - # # # # # # # # #

5 Test pressure (hydraulic) Kg/cm2(g) # # # # # # # # #

6 Design Temprature °C # # # # # # # # #

7 Connection type - ASA Flnage End ASA Flnage End ASA Flnage End ASA Flnage End ASA Flnage End ASA Flnage End ASA Flnage End ASA Flnage End ASA Flnage End

8 Valve Type - # # # # # # # # #

9 IBR Rating - # # # # # # # # #

G MATERIAL OF CONSTRUCTION

1 Body - CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105

2 Cover Gasket - Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application

3 Cover Bolts & nuts - ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H ASTM -A-193 Gr B7 & ASTM -A-194 Gr 2H

4 Cover - CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105 CS-ASTM A-105

5 Valve Sheet - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

6 Valve Sheet Gasket - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

7 Pivot frame Assembly set Screw - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

8 Ball float & lever - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

9 Air vent - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

10 Air vent seal Gasket - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

11 Steam lock Release (SLR) unit - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

12 SLR unit Gasket - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

13 SLR seat - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

14 SLR seat Gasket - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

15 Support frame - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

16 Pivot fram - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

17 Isolation valve - CS CS CS CS CS CS CS CS CS

18 Bypass Valve - CS CS CS CS CS CS CS CS CS

19 NRV - SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420 SS AISI 420

20 View Glass - Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application Suitable for Steam Application

J ACCESSORIES

1 Steam Trap to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

2 Isolation valve to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

3 View Glass to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

4 Baypss valve to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

5 assmebly internal piping to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

6 Gaskets to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

7 Nut bolts to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor to be provided by the vendor

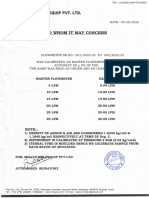

General Notes:-

Vendor to Send All the drawings for Approval before starting fabrication

Manufacturers Test certificate is required for Materials.

Stages of Inspection Will be decided By M/s Deepak Nitrite Limited & Vendor Mutually.

After Hydrotesting of Equipment at Vendors Site, it must be dried throughly.

Stages of Inspection Will be decided By M/s Deepak Nitrite Limited & Vendor Mutually.

You might also like

- Fuel TankerDocument2 pagesFuel TankerWahidanNo ratings yet

- HTTP WWW - Documentation.emer... Bulletins 0029en VSFL BulDocument8 pagesHTTP WWW - Documentation.emer... Bulletins 0029en VSFL BulRktBatamNo ratings yet

- Drawing Daf-70Document5 pagesDrawing Daf-70wahyu hidayatNo ratings yet

- Water SprinklerDocument2 pagesWater Sprinklervictor hugoNo ratings yet

- Vent Line Pressure Drop CalculationDocument4 pagesVent Line Pressure Drop CalculationRubensBoerngenNo ratings yet

- C Series Screw CompressorDocument2 pagesC Series Screw CompressorMohamedNo ratings yet

- Turquia Argentina: Included Included Included Included Included IncludedDocument1 pageTurquia Argentina: Included Included Included Included Included Includeddaniel2rialNo ratings yet

- QEV2 Series Specifications・How to Order・Dimensions (0.2MB)Document4 pagesQEV2 Series Specifications・How to Order・Dimensions (0.2MB)renanta_adiyasNo ratings yet

- Pribor Za Transformatore: Accessories For TransformersDocument4 pagesPribor Za Transformatore: Accessories For TransformersTRANqNo ratings yet

- PrintDocument2 pagesPrintvictor hugoNo ratings yet

- Auto DrainDocument11 pagesAuto DrainAji NurjamanNo ratings yet

- 42018-Emtedad El Senayaa B - SLDDocument1 page42018-Emtedad El Senayaa B - SLDMuhamed Elsayed - ZalatNo ratings yet

- P7 Journal 20190723Document20 pagesP7 Journal 20190723aditya haryantoNo ratings yet

- PDS of Flow MeterDocument1 pagePDS of Flow Meterdebu1985No ratings yet

- Chiaravalli V Belt Pulleys 2016 MAKDocument40 pagesChiaravalli V Belt Pulleys 2016 MAKShariq KhanNo ratings yet

- Grouting Operation Check SheetDocument1 pageGrouting Operation Check SheetPhoe KhwaNo ratings yet

- 42074-Omranya C SLDDocument1 page42074-Omranya C SLDMuhamed Elsayed - ZalatNo ratings yet

- Duct HydraulicsDocument2 pagesDuct HydraulicspavanNo ratings yet

- 14 CoolingDocument39 pages14 Coolingalexandremartins.getNo ratings yet

- NeumaticaDocument39 pagesNeumaticaJulian DiazNo ratings yet

- FD ISA Form S20.50 Rev 1 - OriginalDocument1 pageFD ISA Form S20.50 Rev 1 - OriginalRaphael AndradeNo ratings yet

- Comparación Técnica de Oferta COPES v2Document1 pageComparación Técnica de Oferta COPES v2Eduardo GarridoNo ratings yet

- Sanitary Clamp Data SheetDocument23 pagesSanitary Clamp Data SheetDebulus PRNo ratings yet

- Alrtac: Solenoid Valve (S/2 Way, 5/3 Way)Document2 pagesAlrtac: Solenoid Valve (S/2 Way, 5/3 Way)Nguyễn TríNo ratings yet

- SONNAX 45rfeDocument2 pagesSONNAX 45rfefulltransmissionNo ratings yet

- Atos - AdrDocument2 pagesAtos - AdrBillouNo ratings yet

- Visio-PFD Asembagus Plan B Rev1Document1 pageVisio-PFD Asembagus Plan B Rev1safitri kurniasariNo ratings yet

- PC - VRF - Systems - PART IIDocument17 pagesPC - VRF - Systems - PART IIcarlos vasquezNo ratings yet

- Daikin Screw CompressorsDocument4 pagesDaikin Screw CompressorsJevgenijs KoževnikovsNo ratings yet

- Yanmar Diesel Engine Performance Test Record: 0.9729 12 3.4 15 34 30 Athanassios G.O. DG # 1 Serial NoDocument3 pagesYanmar Diesel Engine Performance Test Record: 0.9729 12 3.4 15 34 30 Athanassios G.O. DG # 1 Serial NoAbigail EscribaNo ratings yet

- Trident Flow Controls - CatloughDocument2 pagesTrident Flow Controls - Catloughrupeshp1989No ratings yet

- FOPHDocument42 pagesFOPHHariharasudhan AnnaduraiNo ratings yet

- LogbookDocument1 pageLogbooksmrahman17323No ratings yet

- 077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuDocument1 page077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuChakravarthy BharathNo ratings yet

- RG2MC Low Pressure DN15to100 PDFDocument42 pagesRG2MC Low Pressure DN15to100 PDFAdministratorNo ratings yet

- Fulii Curele TrapezoidaleDocument42 pagesFulii Curele TrapezoidaleMichael DavenportNo ratings yet

- Reguladora Primera Etapa 2BAR PDFDocument14 pagesReguladora Primera Etapa 2BAR PDFEdwin QuicenoNo ratings yet

- 20101217134934250Document11 pages20101217134934250words2zhigang_612545100% (1)

- AAR 010 1) Flow Meter TCDocument1 pageAAR 010 1) Flow Meter TCnavneetNo ratings yet

- 42 01Document6 pages42 01Juan UrdanetaNo ratings yet

- Page 1272Document1 pagePage 1272EmilyTheDwarfNo ratings yet

- Microsoft PowerPoint - ECM660 III ADocument48 pagesMicrosoft PowerPoint - ECM660 III AJannie van Staden100% (1)

- QTN 2336 - 3 Way L PortDocument2 pagesQTN 2336 - 3 Way L Portshahkunal11No ratings yet

- PFD Asembagus Plan ADocument2 pagesPFD Asembagus Plan AsafitriNo ratings yet

- ATRA 09-2013 BulletinDocument14 pagesATRA 09-2013 BulletinossoskiNo ratings yet

- Dif-Oo15-Int-Ed-0003 PCV Rev 0Document3 pagesDif-Oo15-Int-Ed-0003 PCV Rev 0wado11No ratings yet

- WNMG 080408 (Sprocket) TitanDocument1 pageWNMG 080408 (Sprocket) TitanLiliana YuniantoNo ratings yet

- Daikin Mr02.Relief Stackvalve CatDocument3 pagesDaikin Mr02.Relief Stackvalve CatMismail EgypacNo ratings yet

- Daftar Alat - Alat Kerja PT - Cipta Sejahtera Lestari 02-Nov-18Document1 pageDaftar Alat - Alat Kerja PT - Cipta Sejahtera Lestari 02-Nov-18Widi AstutiNo ratings yet

- Bon Alkes Kamar Operasi Bon Alkes Kamar OperasiDocument5 pagesBon Alkes Kamar Operasi Bon Alkes Kamar OperasimbambixNo ratings yet

- Specifications: 2015 G 1.2 MPI KAPPA Automatic Transaxle System SpecificationsDocument49 pagesSpecifications: 2015 G 1.2 MPI KAPPA Automatic Transaxle System SpecificationsHikmah Jevie YusriNo ratings yet

- 2016 Pocket Guide (4772) - 1Document112 pages2016 Pocket Guide (4772) - 1André GomesNo ratings yet

- Deutz 234 Operating Data Record mr234-90-01Document1 pageDeutz 234 Operating Data Record mr234-90-01D.Poljachihin100% (1)

- CB-8391 CBND Technical Data - Specifications PDFDocument43 pagesCB-8391 CBND Technical Data - Specifications PDFcoyuncoNo ratings yet

- Delivery Inspection Sheet: Checked Inspec-Tion NO Item Gambar KerjaDocument2 pagesDelivery Inspection Sheet: Checked Inspec-Tion NO Item Gambar KerjaMay FattahNo ratings yet

- OBL-Alum CatalogDocument10 pagesOBL-Alum CatalogAmmar KhaleelNo ratings yet

- KSB EtanormDocument164 pagesKSB EtanormJesús DeveraNo ratings yet

- FRLM With Internal AutodrainDocument3 pagesFRLM With Internal AutodrainBiswanath LenkaNo ratings yet

- Válvula Piloto: Série 4A100Document2 pagesVálvula Piloto: Série 4A100Jovany Moisés Aguirre OrnelasNo ratings yet

- Additional Heat LoadDocument2 pagesAdditional Heat LoadAkram VhoraNo ratings yet

- 1710F01 - Side Stream Filter - PDSDocument4 pages1710F01 - Side Stream Filter - PDSAkram VhoraNo ratings yet

- Asme SB-241 6063Document1 pageAsme SB-241 6063Akram VhoraNo ratings yet

- Impeller Design DataDocument6 pagesImpeller Design DataAkram VhoraNo ratings yet

- IPDS PG - H2N Phase-1Document1 pageIPDS PG - H2N Phase-1Akram VhoraNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationAkram VhoraNo ratings yet

- 0212 - BTC Sheet NYCDocument6 pages0212 - BTC Sheet NYCAkram VhoraNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationAkram VhoraNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationAkram VhoraNo ratings yet

- Sigma-Aldrich: Safety Data SheetDocument9 pagesSigma-Aldrich: Safety Data SheetAkram VhoraNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationAkram VhoraNo ratings yet

- Sigma-Aldrich: Safety Data SheetDocument10 pagesSigma-Aldrich: Safety Data SheetAkram VhoraNo ratings yet

- Matrix Scientific: Safety Data SheetDocument4 pagesMatrix Scientific: Safety Data SheetAkram VhoraNo ratings yet

- SDS D MannitolDocument7 pagesSDS D MannitolKarla De JesusNo ratings yet

- "Extraction and Characterization of Oil From Date Seed": Bachelor of Engineering (8 Sem) IN Chemical EngineeringDocument23 pages"Extraction and Characterization of Oil From Date Seed": Bachelor of Engineering (8 Sem) IN Chemical EngineeringAkram VhoraNo ratings yet

- SDS D MannitolDocument7 pagesSDS D MannitolKarla De JesusNo ratings yet

- Reliance Paper On 29th March at New Delhi - 01Document8 pagesReliance Paper On 29th March at New Delhi - 01keyurp_60No ratings yet

- Factors For Unit ConversionsDocument2 pagesFactors For Unit ConversionsChemistNo ratings yet

- DHA SeriesDocument68 pagesDHA SeriescathylorrainegalusNo ratings yet

- Question Bank - EV - 2023 - 2024Document3 pagesQuestion Bank - EV - 2023 - 2024GarenaNo ratings yet

- 19ebkcs048 - Hitesh Kumar - Case StudyDocument4 pages19ebkcs048 - Hitesh Kumar - Case StudydsidsiNo ratings yet

- Marks Sheet - Zone-111Document17 pagesMarks Sheet - Zone-111Jyothi SwaroopreddyNo ratings yet

- Rental Book - SEADocument70 pagesRental Book - SEAmarxmaxicNo ratings yet

- Valvula de Control de 2 Vias dn15 100 en pv25 - 0Document6 pagesValvula de Control de 2 Vias dn15 100 en pv25 - 0Layton DfcNo ratings yet

- Proline Matador: Electrical Submersible Drainage Pump 50 HZDocument1 pageProline Matador: Electrical Submersible Drainage Pump 50 HZRobert ArticaNo ratings yet

- Cambridge IGCSE: Environmental Management 0680/23Document20 pagesCambridge IGCSE: Environmental Management 0680/23Asmaa Barakat AhmadNo ratings yet

- Experience With Naphthenic Acid Corrosion in Low Tan Crudes (51300-98577-SG)Document8 pagesExperience With Naphthenic Acid Corrosion in Low Tan Crudes (51300-98577-SG)Wahyu HidayatNo ratings yet

- BJ Master Glossary 062306Document64 pagesBJ Master Glossary 062306Ali AliievNo ratings yet

- Wave and SoundDocument41 pagesWave and Soundsaif begNo ratings yet

- Data Sheet - Thermostat Type MBC 8000 and MBC 8100Document9 pagesData Sheet - Thermostat Type MBC 8000 and MBC 8100Fabiola barriosNo ratings yet

- Ee00 PPPDocument203 pagesEe00 PPPlunalight253No ratings yet

- Catalogue ProductsDocument344 pagesCatalogue Productsshahar swissaNo ratings yet

- Study of Design Parameters of Solar Dryer For Drying Agriculture ProductDocument13 pagesStudy of Design Parameters of Solar Dryer For Drying Agriculture Productankit antalaNo ratings yet

- Manual Doosan P126TI DP126 PU126TIDocument238 pagesManual Doosan P126TI DP126 PU126TIFederico FigueroaNo ratings yet

- Gas Effect in Electrical-Submersible-Pump-System Stage-by-Stage AnalysisDocument12 pagesGas Effect in Electrical-Submersible-Pump-System Stage-by-Stage AnalysisAlexander Aristizábal PeñalozaNo ratings yet

- GenChem Lec 1 IntroductionDocument9 pagesGenChem Lec 1 IntroductionKian Ceasar DeolazoNo ratings yet

- DOW Investor - Day - 2022 - PresentationDocument102 pagesDOW Investor - Day - 2022 - PresentationALNo ratings yet

- Fogmaster Tri-Jet 6208: A Durable General Purpose FoggerDocument5 pagesFogmaster Tri-Jet 6208: A Durable General Purpose FoggerDANIEL MORERANo ratings yet

- Difference Between Clamp Meters and Multimeters Instrumentation ToolsDocument3 pagesDifference Between Clamp Meters and Multimeters Instrumentation ToolsTEUKUNo ratings yet

- Vehicle Photo With Registration Plate 60 MM X 30 MM: Pollution Under Control CertificateDocument1 pageVehicle Photo With Registration Plate 60 MM X 30 MM: Pollution Under Control CertificateGyasuddin MalekNo ratings yet

- Cement DPR For Expansion From 2.5 To 4.5 MtpaDocument49 pagesCement DPR For Expansion From 2.5 To 4.5 MtpaTULSIDAS DARINo ratings yet

- SumukDocument61 pagesSumukAnkush GuptaNo ratings yet

- Engine and Peripherals: Diesel Injection Petrol InjectionDocument500 pagesEngine and Peripherals: Diesel Injection Petrol InjectionAli ALiNo ratings yet

- 2022 GCSE Physics MSDocument39 pages2022 GCSE Physics MSEmma StevensNo ratings yet

- RIU-2500 - Data SheetDocument2 pagesRIU-2500 - Data SheetmelihguneriNo ratings yet

- CS-E Amendment 5Document225 pagesCS-E Amendment 5Serdar AksoyNo ratings yet

- ULTIBALLAST NAVAL BrochureDocument2 pagesULTIBALLAST NAVAL Brochurecarlos ivan carvajal ortizNo ratings yet

- Ducted Concealed Technical DataDocument2 pagesDucted Concealed Technical Datatabish.tacNo ratings yet