Professional Documents

Culture Documents

Is.456.2000 29

Uploaded by

Shafeen0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

is.456.2000 29

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageIs.456.2000 29

Uploaded by

ShafeenCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

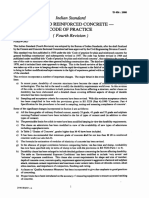

IS 456: 1000

'Dable2 Gndes of Concnte

(Clause 6.1.9.2.2.15.1.1 and 36.1)

where

Group Grade DeI.....IIOIl Spedfted Cba 1Ie Ec is the short tenn static modulus of elasticity in

eo.,...." S til

N/mm2•

ISO ami Cube at 210.,."

Nlmm2 Actual measured values may differ by ± 20 percent

(I) (2) (3) from the values obtained from the aboveexpression.

Ordinary M 10 10

Concrete M IS IS

6.2.4 Shrinlcage

M20 20 The total shrinkage of concrete depeRds upon the

Slalldllrd M2S 2S constituents of concrete, size of the member and

Concrete M30 30 environmental conditions. For a givenhumidity and

M3S 3S temperature, the total shrinkage of concrete is most

M40 40

M4S 45 influenced by the total amount of waterpresentin the

MSO SO concrete at the time of mixing and, to a lesserextent,

MSS SS by the cementcontent.

Hi,h M60 60 6.2.4.1 In the absence of test data, the approximate

Strength M6S 65

Concrete M70 70 value of the total shrinkage strain for deslan may be

M7S 75 takenas 0.000 3 (for moreinfonnation, see IS 1343).

M80 80

NOTES 6.2.S Crtepof Concrete

I Inthedesipotion of concrete mixM refersto the mixlUld the

number to the specified compnlUive Itrenath of 150 mm size

Creep of concrete depends, in addition to the factors

cube lit 28 days.expressed in N/mmJ. listed in 6.2.4, on the stress in the concrete. age at

1 Forconcrete of com~ssive strenath areaterthan M55.desip loading and the duration of leading. As long as the

parameters givenin the llalldllrd maynot be applicable and the stress in concrete does not exceed one-third of its

values may be obtained from specialized literatures and characteristic compressive strength, creep may be

experimcntalresults.

assumed to be proportional to the stress.

justifya higherstrength fora particular structure due to 6.1.5.1 Intheabsence ofexperimental data and detailed

age. information on theeffectof thevariables, the ultimate

6.2.1.1 For concrete of grade M 30 and above. the creep strain may be estimated from the following

rate of increase of compressive strength withageshall values ofcreep coefficient (that is.ultimate creep strain!

be basedon actualinvestigations. elastic strain at the age of loading); for long span

structure, it is advisable to determine actual creep

6.2.1.2 Where members are subjected to lowerdirect

strain, likelyto take place:

load duringconstruction, they should be checkedfor

stresses resulting from combination of directloadand Ageat Loading Creep Coefficient

bending duringconstruction.

7 days 2.2

6.2.2 Tensile Strength of Concrete 28 days 1.6

The flexural and splitting tensile strengths shall be I year 1.1

obtained as described in IS 516 and IS 5816

NOTE-The ultill1lle creep 1UIin. eatimlled as described above

respectively. When the designer wishes to use an does not include the elastic IItI'lIin.

estimateof the tensilestrength from the compressive

strength, the following formula may be used: 6.2.6 Thermal Expansion

Flexural strength, fer = 0.7..[l; N/mm2 The coefficient of thermal expansion depends on IllltUI'e

of cement, the aggregate,. the cement content, the

where f", is thecharacteristic cubecompressive strength relative humidity and the size of sections. The value

of concretein N/mm 2• of coefficient of thermal expansion for concrete with

6.2.3 Elastic Deformation different aggregates may be takenas below:

The modulus of elasticity is primarily influenced by Type ofAggregate Coefficient ofThermal

the elastic properties of the aggregate and to a lesser .Expansionfor Concrrte/"C

extent by the conditions of curing avet age of the

Quartzite 1.2 to 1.3 x 10'5

concrete, the mix proportions and the type of cement.

Sandstone 0.9 to 1.2 x 10"

The modulus of elasticity is normally related to the

compressive strengthof concrete. Granite . 0.7 to 0.95 x 10"

Basalt 0.8 to 0.95 x 10"

6.2.3.1 The modulus of elasticity of concrete can be

Limestone 0.6lQ,.o.9 x 10'5

assumed as follows: ..1

" '."

16

You might also like

- Solucionario Faires PDFDocument641 pagesSolucionario Faires PDFjuan13579100% (8)

- Design of MasonryDocument21 pagesDesign of MasonrySunil KumarNo ratings yet

- Retaining Wall (L-Type) 3.0mDocument22 pagesRetaining Wall (L-Type) 3.0mPrabha KaranNo ratings yet

- National Forensic Sciences University: IS 456:2000 Section 6 - ConcreteDocument16 pagesNational Forensic Sciences University: IS 456:2000 Section 6 - ConcretePriyam AndhariaNo ratings yet

- Analysis of Strength On Recycled Concrete Using PP FiberDocument5 pagesAnalysis of Strength On Recycled Concrete Using PP FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Paving Notes 20 The Importance of Factors Affecting Concrete ShrinkageDocument6 pagesPaving Notes 20 The Importance of Factors Affecting Concrete ShrinkageFrank MtetwaNo ratings yet

- Mechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. EspleyDocument6 pagesMechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. Espleyjulio1051No ratings yet

- Le Rcterized Fire: Esign by Fatigue Characteristics Sity, NnotDocument8 pagesLe Rcterized Fire: Esign by Fatigue Characteristics Sity, NnotAbhilashNo ratings yet

- IRC 112-2020-PartDocument19 pagesIRC 112-2020-Part2BA19CV059 Rakshita SarangmathNo ratings yet

- Serviceability of Beams and One Way SlabsDocument20 pagesServiceability of Beams and One Way Slabsjust meNo ratings yet

- Arma 93 0649Document4 pagesArma 93 0649Pavel IastrebovNo ratings yet

- Teorija - Experimental Determination Mechanical Properties Clay Brick MasonryDocument19 pagesTeorija - Experimental Determination Mechanical Properties Clay Brick Masonrypedja0% (1)

- @ Batch 10 - FinalDocument18 pages@ Batch 10 - FinalLohit D KariNo ratings yet

- Design of Prestressed Concrete Decks: Coventry University MSC Bridge Engineering ModuleDocument7 pagesDesign of Prestressed Concrete Decks: Coventry University MSC Bridge Engineering Moduleaggrey noahNo ratings yet

- M2 - Reinforced Concrete PropertiesDocument7 pagesM2 - Reinforced Concrete PropertiesKrushna LokareNo ratings yet

- Advisory Notes 2 2Document64 pagesAdvisory Notes 2 2Antuanet SaldañaNo ratings yet

- Time Dependent Analysis in SAP2000Document7 pagesTime Dependent Analysis in SAP2000Reynaldo Valdez HerreraNo ratings yet

- Design of Shear Reinforcement For Timber BeamsDocument16 pagesDesign of Shear Reinforcement For Timber BeamsUlrich HübnerNo ratings yet

- Designed Concrete MixDocument6 pagesDesigned Concrete MixniceseshaNo ratings yet

- Masonry Structural Behaviour at Different Scales Under Compressive LoadingDocument8 pagesMasonry Structural Behaviour at Different Scales Under Compressive LoadingOyeniyi Samuel KehindeNo ratings yet

- Fatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, GermanyDocument6 pagesFatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, GermanyRamchandraNo ratings yet

- CMD by M.Y.Sabnis & G.MDocument22 pagesCMD by M.Y.Sabnis & G.Msnehal BiradarNo ratings yet

- تصميم خرسانة مسلحة 4Document27 pagesتصميم خرسانة مسلحة 4Mohammad AlshaijiNo ratings yet

- Textile Reinforced Concrete - Overview, Experimental and Theoretical InvestigationsDocument8 pagesTextile Reinforced Concrete - Overview, Experimental and Theoretical InvestigationsHanna MarshellaNo ratings yet

- RCD Module 1 INTRO TO FUNDAMENTALS OF REINFORCED CONCRETE DESIGNDocument20 pagesRCD Module 1 INTRO TO FUNDAMENTALS OF REINFORCED CONCRETE DESIGNHannylet OcateNo ratings yet

- Kabaldin 2007Document5 pagesKabaldin 2007MoqaNo ratings yet

- Design Data: A. General. The Specific Concrete Properties Used inDocument10 pagesDesign Data: A. General. The Specific Concrete Properties Used inAnoop GuptaNo ratings yet

- 10.11.1 - Factored Axial Forces Pu, Factored Moments M1 and M2 at The Ends of TheDocument2 pages10.11.1 - Factored Axial Forces Pu, Factored Moments M1 and M2 at The Ends of TheFatima AhmedNo ratings yet

- Lecture 4 03-02-2024Document20 pagesLecture 4 03-02-2024ahmed11 engyemenNo ratings yet

- Coventry University MSC Bridge Engineering Module Differential Shrinkage and Creep of Composite SlabDocument6 pagesCoventry University MSC Bridge Engineering Module Differential Shrinkage and Creep of Composite Slabaggrey noahNo ratings yet

- Multilayer Dielectric Thickness CalculationDocument4 pagesMultilayer Dielectric Thickness Calculationabdallah meziti-proNo ratings yet

- RCD Module 1 INTRO TO FUNDAMENTALS OF REINFORCED CONCRETE DESIGN 3Document22 pagesRCD Module 1 INTRO TO FUNDAMENTALS OF REINFORCED CONCRETE DESIGN 3EMIL JOHN P. ANTONIONo ratings yet

- 1999 No 9Document13 pages1999 No 9alfakir fikriNo ratings yet

- Crack Formation and Fracture Energy of Normal andDocument12 pagesCrack Formation and Fracture Energy of Normal andIngénieurCivilNo ratings yet

- A Model For Textile Reinforced Concrete Under Imposed Uniaxial DeformationsDocument8 pagesA Model For Textile Reinforced Concrete Under Imposed Uniaxial DeformationsSutharshananNo ratings yet

- Chapter 1 Intro Edited Sept 2020 1Document14 pagesChapter 1 Intro Edited Sept 2020 1Hannylet OcateNo ratings yet

- 23 Failure Criteria For Rocks PDFDocument20 pages23 Failure Criteria For Rocks PDFVu ThuygiangNo ratings yet

- Ijciet 10 11 032Document10 pagesIjciet 10 11 032Adnane OURABAHNo ratings yet

- 23 Failure Criteria For RocksDocument21 pages23 Failure Criteria For RocksKiki Shawol Onew MvpsNo ratings yet

- Gravitydams Capitulo IIIDocument14 pagesGravitydams Capitulo IIIJemersonDanteGuerreroYreneNo ratings yet

- Mayorca & MeguroDocument4 pagesMayorca & MeguroSergio Alonso Sunley Pocasangre INGNo ratings yet

- SMiRT-23 Impact Paper-FinalDocument10 pagesSMiRT-23 Impact Paper-FinalMrigendra Nath RayNo ratings yet

- 14 Design Notes For Masonry Industrical Warehouse BuildingDocument57 pages14 Design Notes For Masonry Industrical Warehouse BuildingTH YungNo ratings yet

- Long Term CurvatureDocument21 pagesLong Term CurvatureArlandooNo ratings yet

- 1 s2.0 S0022024810010614 MainDocument4 pages1 s2.0 S0022024810010614 MainColin WangNo ratings yet

- Lec2 Materials 2Document9 pagesLec2 Materials 2Fadi Al-QasemNo ratings yet

- 3.sivananda Flyover PMC WODocument9 pages3.sivananda Flyover PMC WOShaileshRastogiNo ratings yet

- Structural Design & Drawing-I (RCC) : Sri Satya Sai University of Technology & Medical Sciences, Sehore (M.P.)Document118 pagesStructural Design & Drawing-I (RCC) : Sri Satya Sai University of Technology & Medical Sciences, Sehore (M.P.)phoneservice3.69No ratings yet

- Tensile Strength Direct Joints in Roller Compacted Concrete DamsDocument4 pagesTensile Strength Direct Joints in Roller Compacted Concrete Damsjaviermorandi100No ratings yet

- CreepDocument1 pageCreepSrinivasulu Reddy KoduruNo ratings yet

- Mechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. EspleyDocument6 pagesMechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. EspleyAlexandre GomesNo ratings yet

- University of Windsor: Material PropertiesDocument15 pagesUniversity of Windsor: Material PropertiesMohammed Mudassir MirzaNo ratings yet

- Special Concretes: Assignment ON February-2002 Question PaperDocument19 pagesSpecial Concretes: Assignment ON February-2002 Question PapersyedNo ratings yet

- PLAXIS - 3D2018 Tutorial Lesson 09 PDFDocument14 pagesPLAXIS - 3D2018 Tutorial Lesson 09 PDFMarwan HMNo ratings yet

- 2) Introduction To WSD, Rectangular BeamsDocument10 pages2) Introduction To WSD, Rectangular BeamsVanessa Rosal PalerNo ratings yet

- Reinforced Concrete - I DMU Lecture NotesDocument206 pagesReinforced Concrete - I DMU Lecture NotesAntenehNo ratings yet

- Abdullah M. Zeyad (2020)Document12 pagesAbdullah M. Zeyad (2020)maxNo ratings yet

- Model of Fracture, Friction, Andwear Phenomena of Porous IronDocument17 pagesModel of Fracture, Friction, Andwear Phenomena of Porous IronBurag HamparyanNo ratings yet

- WST High Loading RatesDocument7 pagesWST High Loading RatesPrayush RajbhandariNo ratings yet

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocument12 pagesRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARNo ratings yet

- Numerical Investigation of TheDocument11 pagesNumerical Investigation of Theqasim.asif9No ratings yet

- Is.456.2000 Page 22 23Document2 pagesIs.456.2000 Page 22 23Balaji GuntiNo ratings yet

- Is.456.2000 23Document1 pageIs.456.2000 23ShafeenNo ratings yet

- Is.456.2000 24Document1 pageIs.456.2000 24ShafeenNo ratings yet

- Is.456.2000 27Document1 pageIs.456.2000 27ShafeenNo ratings yet

- Is.456.2000 21Document1 pageIs.456.2000 21ShafeenNo ratings yet

- Is.456.2000 12Document1 pageIs.456.2000 12ShafeenNo ratings yet

- Bms OffersDocument16 pagesBms OffersShafeenNo ratings yet

- Is.456.2000 8Document1 pageIs.456.2000 8ShafeenNo ratings yet

- Bms-Offers 6Document1 pageBms-Offers 6ShafeenNo ratings yet

- Is.456.2000 14Document1 pageIs.456.2000 14ShafeenNo ratings yet

- Is.456.2000 12Document1 pageIs.456.2000 12ShafeenNo ratings yet

- Is.456.2000 4Document1 pageIs.456.2000 4ShafeenNo ratings yet

- Iso-648 Laboratory Glassware - Single-Volume PipettesDocument18 pagesIso-648 Laboratory Glassware - Single-Volume PipettesDawn HaneyNo ratings yet

- Bms-Offers 12Document1 pageBms-Offers 12ShafeenNo ratings yet

- Bms Offers 10Document1 pageBms Offers 10ShafeenNo ratings yet

- Bms-Offers 1Document1 pageBms-Offers 1ShafeenNo ratings yet

- Bms Offers 10Document1 pageBms Offers 10ShafeenNo ratings yet

- Bms-Offers 9Document1 pageBms-Offers 9ShafeenNo ratings yet

- Bms-Offers 6Document1 pageBms-Offers 6ShafeenNo ratings yet

- Bms-Offers 4Document1 pageBms-Offers 4ShafeenNo ratings yet

- Civeil TricksDocument6 pagesCiveil TricksmathanNo ratings yet

- Structural Irregularities 2Document12 pagesStructural Irregularities 2Ankit DalviNo ratings yet

- 14 01-2005Document8 pages14 01-2005Nirav AcharyaNo ratings yet

- Som BasicsDocument26 pagesSom BasicsTarun AgarwalNo ratings yet

- Ec9 Ex94 Beam Column HAZDocument5 pagesEc9 Ex94 Beam Column HAZimotalpNo ratings yet

- Deflections Due To Loading As Per ACIDocument8 pagesDeflections Due To Loading As Per ACIRishabh LalaNo ratings yet

- 7-3 (Combined Bending and Axial Load)Document10 pages7-3 (Combined Bending and Axial Load)Jhon Edinson Ramirez GarciaNo ratings yet

- Longterm Deflection Comparison With EtabsDocument6 pagesLongterm Deflection Comparison With EtabsArnel Dodong100% (1)

- Embankment SlopeDocument16 pagesEmbankment SlopeFlorentina SuduNo ratings yet

- Som 1Document1 pageSom 1Cristina Mauren PajesNo ratings yet

- Bi-Axial Test With Mohr-Coulomb ModelDocument0 pagesBi-Axial Test With Mohr-Coulomb ModelMOSHITOMOSHITANo ratings yet

- 09thick BeamsDocument5 pages09thick BeamsDeepak ChachraNo ratings yet

- Z PurlinDocument25 pagesZ Purlinharishram123456100% (1)

- SCI1307Document71 pagesSCI1307Yashika Bhathiya JayasingheNo ratings yet

- Lab 6 - Wide Flange BeamDocument4 pagesLab 6 - Wide Flange BeamJanithNo ratings yet

- Critical Review of Is 1893-1 and - 2 Draft 2023 Ver 2Document14 pagesCritical Review of Is 1893-1 and - 2 Draft 2023 Ver 2SzcNo ratings yet

- C8-Seismic Assessment of Unreinforced Masonry Buildings PDFDocument189 pagesC8-Seismic Assessment of Unreinforced Masonry Buildings PDFMaria Luisa RGNo ratings yet

- Curved BeamDocument46 pagesCurved BeambadriNo ratings yet

- Chapter One-Soil Compression and Settlement AnalysisDocument92 pagesChapter One-Soil Compression and Settlement AnalysisLencha BekeleNo ratings yet

- Eng Lab ModuleDocument58 pagesEng Lab ModuleFirzana AmiraNo ratings yet

- Piers PDFDocument3 pagesPiers PDFmahmoud elkhedrNo ratings yet

- Original PDF Reinforced Concrete Design 9th Edition PDFDocument41 pagesOriginal PDF Reinforced Concrete Design 9th Edition PDFnicholas.weist993100% (37)

- MSC NASTRAN Patran Progressive Failure and Delam 021712Document53 pagesMSC NASTRAN Patran Progressive Failure and Delam 021712alitariq90No ratings yet

- 7 - Transformation of Stress and StrainDocument22 pages7 - Transformation of Stress and StrainMehmet CiglaNo ratings yet

- PurlinDocument34 pagesPurlinnaveenaeeNo ratings yet

- Study of Siesmic Analysis of Multistorey Building With or Without Floating ColumnsDocument18 pagesStudy of Siesmic Analysis of Multistorey Building With or Without Floating ColumnsAnkita PalNo ratings yet

- Basic Structural Design ConceptsDocument21 pagesBasic Structural Design Conceptscuterose95No ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignSovich82No ratings yet