Professional Documents

Culture Documents

Stress Concentration Factor

Uploaded by

Decor HomesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stress Concentration Factor

Uploaded by

Decor HomesCopyright:

Available Formats

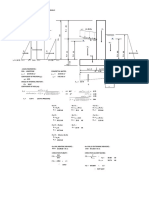

Appendix 831

APPENDIX 18 Stress Concentration Factors

3.0 Tension

smax

Kt = s

nom

F F F

2.6 snom =

Amin

d 2

r

2.2 Amin = pd

D 4

Kt

1.8

1.1 D/d = 2.0

1.4 1.2

1.01

1.0

0 0.04 0.08 0.12 0.16 0.20 0.24 0.28

r/d

Figure A18–1 Stepped round bar in tension

3.4 Tension

Thickness = t smax

Kt = s

F F nom

3.0

snom = F

h Amin

r

2.6

H Amin = th

Kt 2.2

1.8 H/h = 2.0

1.2

1.4 1.1

1.01

1.0

0 0.04 0.08 0.12 0.16 0.20 0.24 0.28

r/h

Figure A18–2 Stepped flat plate in tension

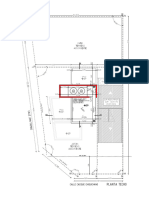

11.0

10.0 F F

d

9.0 D

F F

8.0 Basic geometry sgross = =

A pD2/4

7.0

smax = Ktg sgross

Ktg 6.0

5.0

Note: Ktg is based on the nominal stress in a

4.0 round bar without a hole (gross section).

3.0

2.0

1.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

d/D

Figure A18–3 Round bar with a transverse hole in tension

Z01_MOTT1184_06_SE_APP.indd 831 3/17/17 3:16 PM

832 Appendix

Curve A

Direct tension

5.0 on plate

Thickness = t

F F

snom = =

Anet (w – d)t

d

4.0 w

F F = total load

Basic geometry

Plate carries uniform tensile load throughout.

Kt 3.0

A B smax Curve B

Kt = s Tension-load

nom

applied through

a pin in the hole

F F

snom = =

2.0 Anet (w – d)t

1.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Plate carries uniform tensile load on one side;

d/w load is applied by a pin in the hole.

Figure A18–4 Flat plate with a central hole in tension

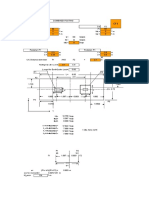

Bending in the plane

2.0 of the plate

Mc M 6Mw

snom = =

Kt Inet Snet (w3 – d3)t

1.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

M M

d/w

Note: Kt = 1.0 for d/w < 0.5 t = Thickness of the plate.

Figure A18–5 Flat plate with a central hole in bending

3.0 Bending s

Kt = smax

nom

2.6

snom = Mc = M

I S

M d M

2.2 r 3

D/d = 2.00 D S = pd

Kt 32

1.20

1.8

1.05

1.4

1.1

1.0

0 0.04 0.08 0.12 0.16 0.20 0.24 0.28

r/d

Figure A18–6 Stepped round bar in bending

Z01_MOTT1184_06_SE_APP.indd 832 3/17/17 3:16 PM

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Dresses For Every Occasion: Pattern SheetDocument19 pagesDresses For Every Occasion: Pattern SheetManuela IacobNo ratings yet

- R134 ADocument1 pageR134 AshridharbshenoyNo ratings yet

- Dynamics of Structures 4th Edition Chopra Solutions ManualDocument38 pagesDynamics of Structures 4th Edition Chopra Solutions Manualseanmosstgdkf2100% (14)

- Ebook Dynamics of Structures 4Th Edition Chopra Solutions Manual Full Chapter PDFDocument61 pagesEbook Dynamics of Structures 4Th Edition Chopra Solutions Manual Full Chapter PDFlionelhaouna9d100% (10)

- Ɣ H ƔH ƔH ƔH : KN/M KN/M KN/MDocument4 pagesƔ H ƔH ƔH ƔH : KN/M KN/M KN/MGrace LagnayoNo ratings yet

- ASEN 4013 - Exam 1: Section 3: Compressible FlowDocument2 pagesASEN 4013 - Exam 1: Section 3: Compressible FlowJacob WeinerNo ratings yet

- 4 - Arq - Casa DMDocument1 page4 - Arq - Casa DMANA TIATIRANo ratings yet

- Clase Del 12-02-2021Document3 pagesClase Del 12-02-2021EdwinNo ratings yet

- R134a - DiagramDocument1 pageR134a - DiagramDulce Rosales JardonNo ratings yet

- Elevatia Structurii Scara 1:70: I III IIDocument1 pageElevatia Structurii Scara 1:70: I III IIBratu CasianNo ratings yet

- Appendix V - ExampleDocument2 pagesAppendix V - ExamplePedro Montes MarinNo ratings yet

- F-Riviera: AlishaDocument5 pagesF-Riviera: AlishaFalisha RivienaNo ratings yet

- Input Data: Project Usan Deep Water Attachment XXXXXX To Calculation Note Ref. Yyyyyyyyy Rev. ZZDocument5 pagesInput Data: Project Usan Deep Water Attachment XXXXXX To Calculation Note Ref. Yyyyyyyyy Rev. ZZcatullusNo ratings yet

- FRICTION - From The Virginia Tech Aerodynamics and Design Software CollectionDocument9 pagesFRICTION - From The Virginia Tech Aerodynamics and Design Software CollectionIbraheem AlQadiNo ratings yet

- Combined Footing DesignDocument12 pagesCombined Footing DesignPAWANNo ratings yet

- SSE Sheet Pile Analysis Sheet v1.09Document3 pagesSSE Sheet Pile Analysis Sheet v1.09SES DESIGNNo ratings yet

- CEN TOOL Standard Padeyes V4 Rollup Padeye SheaveDocument5 pagesCEN TOOL Standard Padeyes V4 Rollup Padeye SheaveMarvan100% (1)

- Suhu Dan Teori Kinetik GasDocument8 pagesSuhu Dan Teori Kinetik GasCarrisa Ferly WidjayaNo ratings yet

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Document30 pagesHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Eng-CalculationsNo ratings yet

- 3 Dynamics 2023Document2 pages3 Dynamics 2023maryamafsar00No ratings yet

- Formula Sheet EE-434 Power Electronics: Basic Expressions CapacitorDocument3 pagesFormula Sheet EE-434 Power Electronics: Basic Expressions CapacitorMuhammad Muzammil SaleemNo ratings yet

- Deberes Y Trabajos de FísicaDocument4 pagesDeberes Y Trabajos de FísicaMauricio Javier Valladares VegaNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Document28 pagesHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNo ratings yet

- TorsiónDocument3 pagesTorsiónAlejandro Herrera LoperaNo ratings yet

- MH Stress ConcentrationsDocument6 pagesMH Stress ConcentrationstripsachinNo ratings yet

- Buckling-V4 16Document1 pageBuckling-V4 16João Mendonça SantosNo ratings yet

- 06 Practical PhysicsDocument4 pages06 Practical PhysicsHARSH SHRIVASTAVNo ratings yet

- Contact Stress of Cylinder On Flat SurfaceDocument3 pagesContact Stress of Cylinder On Flat Surfacemet-calcNo ratings yet

- Vectors - Notebook November 23, 2017Document3 pagesVectors - Notebook November 23, 2017The LegendaryCarrotMasterNo ratings yet

- Batter 1966Document3 pagesBatter 1966ait oubella marouaneNo ratings yet

- Class #6: Structural Dynamics Single Degree of Freedom Systems Forced-Damped VibrationsDocument11 pagesClass #6: Structural Dynamics Single Degree of Freedom Systems Forced-Damped VibrationsTsiNat NathaNo ratings yet

- HW5 SolDocument15 pagesHW5 Sol蒲念文No ratings yet

- Coeficientes de Arrastre de CuerposDocument3 pagesCoeficientes de Arrastre de CuerposBea NúñezNo ratings yet

- SymbolDocument3 pagesSymbolBoshra NouriNo ratings yet

- Semiconductor KDS226: Technical DataDocument2 pagesSemiconductor KDS226: Technical DataMuhajir BusraNo ratings yet

- Semiconductor KTD1351: Technical DataDocument3 pagesSemiconductor KTD1351: Technical DatarolandseNo ratings yet

- Losa D H 3 Vigas D H 6: LosasDocument1 pageLosa D H 3 Vigas D H 6: LosasYordyWilliamsCaceresQuispeNo ratings yet

- Calculating 2-D Electric FieldsDocument2 pagesCalculating 2-D Electric FieldsKittiya PunpengNo ratings yet

- Problem 1.17 PDFDocument1 pageProblem 1.17 PDFKauê BrittoNo ratings yet

- P P D P P N DT B B E1 A B E2 E2: 11701 4 MPN Idoho BP Integrity Repairs Project 11701 Bolt & End Plate Design 8 1 of 2Document2 pagesP P D P P N DT B B E1 A B E2 E2: 11701 4 MPN Idoho BP Integrity Repairs Project 11701 Bolt & End Plate Design 8 1 of 2Osas Asemota-OsagieNo ratings yet

- CAL PDF: Sse Sheet Pile Analysis, Penetration Into Sandy or Clayey Soil Sse-Excel-SectionDocument3 pagesCAL PDF: Sse Sheet Pile Analysis, Penetration Into Sandy or Clayey Soil Sse-Excel-SectionSES DESIGNNo ratings yet

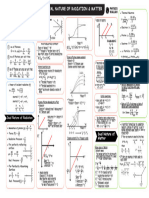

- Dual Nature of Matter & Radiation - Mind Maps - Lakshya JEE 2024Document1 pageDual Nature of Matter & Radiation - Mind Maps - Lakshya JEE 2024xoranek474No ratings yet

- Formula Rio FinalDocument3 pagesFormula Rio FinalAngel Ramirez MartinezNo ratings yet

- Concentration Factors KTDocument7 pagesConcentration Factors KTYogesh RameshNo ratings yet

- 65601a476c0a0100185f2bbc ## Dual Nature of Radiation & Matter MindDocument1 page65601a476c0a0100185f2bbc ## Dual Nature of Radiation & Matter MindprincipaltamannaNo ratings yet

- Bahas SIMAK Fisika - 260623Document16 pagesBahas SIMAK Fisika - 260623gerry_liyanaNo ratings yet

- Problem 1.18 PDFDocument1 pageProblem 1.18 PDFKauê BrittoNo ratings yet

- Exam 1 Formula Sheet: X, F X, I X 2 2 X, F 2 X, I XDocument1 pageExam 1 Formula Sheet: X, F X, I X 2 2 X, F 2 X, I Xallison0kuftaNo ratings yet

- Monopitch RoofDocument5 pagesMonopitch RoofKhalid CaliNo ratings yet

- Calculation of Beam DeflectionDocument1 pageCalculation of Beam Deflectionapi-3848892100% (2)

- Tema Contrapunct: Ep - Expozitional R.RDocument1 pageTema Contrapunct: Ep - Expozitional R.RTheodor MihaiNo ratings yet

- Ph1FCAT04 OJEAD120C08 100619 SOLUTION PDFDocument4 pagesPh1FCAT04 OJEAD120C08 100619 SOLUTION PDFmehul pantNo ratings yet

- Anexo 1Document1 pageAnexo 1Evandro PaeseNo ratings yet

- MEMOERIA DE CALCULO HoAo h5mDocument3 pagesMEMOERIA DE CALCULO HoAo h5mRamiro RapshonNo ratings yet

- Formato Zapata AisladaDocument169 pagesFormato Zapata AisladaJair SPNo ratings yet

- Grade 11 Physics Equations and Constants Name: : KinematicsDocument1 pageGrade 11 Physics Equations and Constants Name: : KinematicsJasleenNo ratings yet

- Elevator DSA OSHPDDocument2 pagesElevator DSA OSHPDjorge01No ratings yet

- Effect of Temperature On SolubilityDocument8 pagesEffect of Temperature On SolubilityMuzahid KhatryNo ratings yet

- Flight of The Red Bandit Geronimo Stilton 56 by Geronimo StiltonDocument2 pagesFlight of The Red Bandit Geronimo Stilton 56 by Geronimo StiltonhenitipNo ratings yet

- S-PCM Minutes of Meeting: Train 02Document4 pagesS-PCM Minutes of Meeting: Train 02sudeesh kumarNo ratings yet

- Lab Report Literature Review ExampleDocument5 pagesLab Report Literature Review ExampleafmzmqwdglhzexNo ratings yet

- Vacancy For Ceo-Tanzania Association of Accountants-RevisedDocument2 pagesVacancy For Ceo-Tanzania Association of Accountants-RevisedOthman MichuziNo ratings yet

- A Guide To Facts and Fiction About Climate ChangeDocument19 pagesA Guide To Facts and Fiction About Climate ChangeANDI Agencia de Noticias do Direito da Infancia100% (1)

- MLAHomeworkDocument4 pagesMLAHomeworkVANESSA SALDANANo ratings yet

- Unauthenticated Download Date - 1/31/17 4:04 AMDocument5 pagesUnauthenticated Download Date - 1/31/17 4:04 AMFahmi RaziNo ratings yet

- Kotak Mahindra Bank: Presented by Navya.CDocument29 pagesKotak Mahindra Bank: Presented by Navya.CmaheshfbNo ratings yet

- Digital Booklet - Britney Spears - Work B CH (Single)Document5 pagesDigital Booklet - Britney Spears - Work B CH (Single)Gâu EheheNo ratings yet

- FS2122-INCOMETAX-01A: BSA 1202 Atty. F. R. SorianoDocument7 pagesFS2122-INCOMETAX-01A: BSA 1202 Atty. F. R. SorianoKatring O.No ratings yet

- Estimation of Measurement Uncertainty Printout 2016-2Document94 pagesEstimation of Measurement Uncertainty Printout 2016-2GustavoCaicutoNo ratings yet

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- Ebook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFDocument41 pagesEbook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFmarvin.tappen826100% (35)

- Escrow AgreementDocument3 pagesEscrow Agreementmadelyn sarmientaNo ratings yet

- EC Ch04 Building An E-Commerce PresenceDocument72 pagesEC Ch04 Building An E-Commerce PresenceUdhaya ShatisNo ratings yet

- Biological Monitoring: Pt. Indo TrainingDocument12 pagesBiological Monitoring: Pt. Indo TrainingnursusiartiNo ratings yet

- 100 Patient NamesDocument1 page100 Patient NamesTed anadiloNo ratings yet

- Energy Valve TechDocument50 pagesEnergy Valve Techchiong cjNo ratings yet

- Small Business Management Entrepreneurship and Beyond 6th Edition Hatten Solutions ManualDocument36 pagesSmall Business Management Entrepreneurship and Beyond 6th Edition Hatten Solutions ManualketmieoilstoneqjdnwqNo ratings yet

- Sekar KSP - Hypoglicemia Ec Tipe 2 DMDocument28 pagesSekar KSP - Hypoglicemia Ec Tipe 2 DMdianarahimmNo ratings yet

- Algorithms (Complete Course) :-Btech CSE: TopicsDocument4 pagesAlgorithms (Complete Course) :-Btech CSE: TopicsRahul SinghNo ratings yet

- Stroke - Wikipedia, The Free EncyclopediaDocument31 pagesStroke - Wikipedia, The Free EncyclopediaRhonskiiNo ratings yet

- Digital Systems Design and PrototypingDocument633 pagesDigital Systems Design and PrototypingAshish Shrivastava50% (2)

- AEB Mortgage Services - Capacity Planning and ControlDocument2 pagesAEB Mortgage Services - Capacity Planning and ControlDua LeoNo ratings yet

- Commonly Asked Interview Questions Co Op Version NEWDocument2 pagesCommonly Asked Interview Questions Co Op Version NEWGail T. BorromeoNo ratings yet

- Schofield1998 - The Mohr-Coulomb Error CorrectionDocument3 pagesSchofield1998 - The Mohr-Coulomb Error CorrectionandresmelodNo ratings yet

- The Best of Bruce's Postgres Slides: Ruce OmjianDocument26 pagesThe Best of Bruce's Postgres Slides: Ruce OmjianPhotoHawkNo ratings yet

- Series: Eddy-Current DynamometersDocument11 pagesSeries: Eddy-Current DynamometersDimas AndiNo ratings yet