Professional Documents

Culture Documents

Engineering Report (DP)

Uploaded by

ROMMEL TADENAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Report (DP)

Uploaded by

ROMMEL TADENACopyright:

Available Formats

ENGINEER’S REPORT

TWO-STOREY COMMERCIAL BUILDING PROJECT

XENTROMALL

SANTIAGO

Pan Phil. Highway Cor. Fourlanes, Villasis, Santiago City Isabela 3311

A Project of

XRC MALL DEVELOPER, INC.

353 J.P. Rizal Street corner Diamond Street, Barangay Sto. Nino, Marikina City 1800

Prepared by:

TOTAL DEIONIZATION SOLUTIONS, INC.

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna, Region 4A

Tel/Fax Nos.: +63 49 531-1505, 530-8270

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

Website: www.tds.com.ph

August 27, 2018

I. BASIC INFORMATION ON PROJECT AND PROPONENT

Basic Project Information

Project Name:

TWO-STOREY COMMERCIAL BUILDING PROJECT

Name of Establishment:

XENTROMALL SANTIAGO

Project Location:

Pan Phil Highway Cor Fourlanes Villasis Santiago City

Threshold Limits: Total floor area occupied: 16,302.00 m2

Total land area occupied: 9,341 m2

Nature of Project:

COMMERCIAL

Pollution Control Officer: MARICEL V. MAÑAGO

Contact Numbers: 09062967314

Project Schedule: 11 hrs/day from 9:00 am to 8:00pm for 7 days/week

Manpower: Staff: 17 (Security and Housekeeping)

Admin: 3

Project Proponent:

XRC MALL DEVELOPER, INC.

Office Address: 353 J.P. RIZAL STREET CORNER DIAMOND STREET, BARANGAY

STO. NINO, MARIKINA CITY

Owner: ALEXANDER M. CRUZ

Contact Numbers: (02) 948-1528

Basic Preparer Information

Preparer/Consultant: TOTAL DEIONIZATION SOLUTIONS, INC.

Business Address: Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna,

Region 4A

Landline +63 2 519-4097

Total Deionization Solutions, Inc. Page 2 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

+63 49 531-1505

Fax No: +63 49 530-8270

Website: www.tds.com.ph

bmw@tds.com.ph

e-mail address: tds@tds.com.ph

willybautista2004@yahoo.com

1.2 Project Description

The XentroMall Santiago Project shall cover an area of 16,302square meters located in Pan

Phil Highway, Cor. Fourlanes Villasis Santiago City, Isabela, Region 2.

The proposed project will cover the construction and operation of two-storey commercial

building located at Pan Phil Highway, Cor Fourlanes Villasis Santiago City, Isabela which

will cover a total floor area of 16,302 square meter situated within a total land area of

9,341 square meters embraced under Transfer Certificate of Title No. TSC-27190, 27189,

35828 and 29586 with the following components: Supermarket, Leasable Commercial Areas

and Stalls, Hotel, Food Court/Fast Food Section, Administration Room, Comfort Rooms,

Storage Rooms, Sewage Treatment Plant, Electrical/Generator Set Room, Material Recovery

Room, Terminal/Parking Area.

The project has an ECC with reference no. ECC-R02-1207-0138 issued by the Department of

Environment and Natural Resources, through the Environment Management Bureau, Region

2 last August 13, 2012. Likewise, this Engineer’s Report has been prepared in relation to the

application of Wastewater Discharge Permit for the project.

1.3 Project Schedule

This commercial establishment opens Eleven (11) hours a day, Seven (7) days a week all

throughout the year.

1.4 Manpower

Manpower requirement varies per project phase such as:

Total Deionization Solutions, Inc. Page 3 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

Table 1

Manpower Requirement

Manpower Expertise/Skills Sourcing

Project Phase Nature of Job

Requirement Needed Scheme

Priority to

Managerial,

applicants who

Supervisory, Admin

are residents

works, Sales Office and

of Santiago

Operational 20 employees Executives, crew, Maintenance

and adjacent

Security and

barangay,

Maintenance Staff

cities and

municipalities

The number of customer varies daily since the commercial building and its tenants has

dining and retail trading activities.

II. DESCRIPTION OF WASTEWATER

2.1 Nature and Character

Discharge from the project is generally domestic wastewater that comes from the

sanitation requirements of clients and employees, discharge from the tenants of

different activities, and from washing and cleaning around the area.

Domestic wastewater is mainly comprised of water together with relatively small

concentrations of suspended and dissolved organic and inorganic solids. Among the

organic substances present in sewage are carbohydrates, lignin, fats, soaps, synthetic

detergents, proteins and their decomposition products, as well as various natural and

synthetic organic chemicals.

2.2 Chemical and Physical Composition

Based on the available data, the influent wastewater has the following characteristics as

the basis of design for the Sequential Batch Reactor Treatment Process installed for the

project:

Table 3

Wastewater Characteristics

Parameters Influent Unit

BOD5 400 mg/L

COD 800 mg/L

Total Deionization Solutions, Inc. Page 4 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

TSS 300 mg/L

Oil & Grease 40 mg/L

Color 300 PCU

pH 6.7-8.0 unit

Total Coliform 20,000 MPN/100ml

2.3 Receiving Body of Water

The effluent of the commercial building discharges to Santiago City –Public Drainage, it

is the nearest receiving body of water which is a “Class C” under the official water

classification. For DENR Class C Water Standard for effluent:

Table 4

Wastewater Characteristics

Parameters Effluent Unit

BOD 50 mg/L

COD 100 mg/L

TSS 70 mg/L

Oil & Grease 5 mg/L

Color 150 PCU

pH 6.5-9.0 unit

Total Coliform 10x103 MPN/100ml

2.4 Water Consumption and Discharge

Santiago Water District provides the water requirement of the XentroMall Santiago

Project for their operation, domestic and sanitary purposes. The actual water

consumption is twenty six cubic meters per day (26 m3/d) not yet fully occupied and

operational (Please see attached Water Bills).

Wastewater from the project will generally come from the sanitation requirements of

clients, tenants, and employees, discharge from different units, and from washing and

cleaning around the area.

Total Deionization Solutions, Inc. Page 5 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

At present, the average wastewater flow rate is estimated to be twenty five cubic

meters per day (25m3/d), not yet fully occupied and operational, and is treated to

their Sequential Batch Reactor Process Sewage Treatment Plant with a maximum

design capacity of Fifty cubic meters per day (80m3/d).

Note that the total is the consumption of the entire establishment and that the

wastewater discharge varies depending on the daily activities of its tenants and the

volume of consumer per unit.

2.5 Flow Measurement Equipment

No water meter is installed at effluent point.

III. TREATMENT PROCESS DESIGN DESCRIPTION

The Wastewater Treatment Facility uses the Sequential Batch Reactor (SBR) Process. It is a

combination of physical, biological, and chemical treatment processes.

The Sewage treatment facility is designed at a capacity of 80m3/day. Influent wastewater is

mostly from the domestic, washing and sanitary sources. It is designed to have 90-98%

removal efficiency.

The Sewage Treatment Facility consists of the following unit operations:

1. SUMP PIT / SCREENING

Raw wastewater from the production lines is collected in this tank. It flows into a bar

screen where coarse materials and large debris are prevented from entering the

wastewater treatment area. These materials may damage the aerobic process and plant

equipment such as pumps, valves, nozzles, channels, sludge removal equipment, hang

over weirs, pipelines and appurtenances. Screening is performed to prevent serious plant

operation and maintenance problems.

2. EQUALIZATION TANK

After the preliminary treatment (screening), the influent water will flow to the

equalization tank. The equalization tank will be used for storing the influent temporarily

and as a preventive measure to protect the effluent quality in extreme storm conditions.

This tank also acts to equalize the flow in terms of organic loading. Mixing will be

provided by air blower through submersed diffusers to prevent occurrence of anaerobic

condition. Then influent will be pumped into the aeration tank.

Total Deionization Solutions, Inc. Page 6 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

3. SBR TANK

The pretreated wastewater will now be treated in a biological treatment process. SBR

requires smaller footprints on the site. The tanks are acting as the equivalent of several

components in a single tank such as aeration, secondary clarifier and sludge return

system.

There will be four to six cycle of SBR process per day. Each cycle shall be 4-6 hours, 2-3

hours aeration, 1-2 hour settling and 1 hour decant. The effluent from the wet well shall

be treated in a continuous flow.

The waste water will be fed continuously into the inlet pre-aeration chambers of the SBR

basin and is directed down through openings at the bottom of the baffle wall into the

main aeration chamber. The inlet pre-aeration controls the incoming flow and prevents

short-circuiting and provides the pre-treatment of the waste water before it enters the

main aeration chamber. The same main chamber used for aeration shall be used for

sludge wasting and decanting process.

In the inlet pre-aeration chamber, a high concentration of soluble BOD is available to

microorganisms in a relatively small basin volume which creates a high “Food to

Microorganisms” (F:M) ratio and encourages the maximum bio sorption of food by the

microorganisms. This also acts as a biological selector encouraging the proliferation of

the most desirable organisms and eliminates the growth of filamentous bacteria that

cause sludge bulking and poor settling.

The aeration stage involves the utilization of Biological Oxygen Demand (BOD) and

ammonia nitrogen, where applicable by microorganisms. The length of the aeration

period is two hours and the sludge mass determines the degree of the treatment. This

aeration period will depend on the strength of the raw sewage and the degree of

nitrification provided for treatment. During the settling stage, aeration is stopped and the

sludge settles leaving the clear, treated effluent above the sludge blanket. The duration of

the sludge settling is 60 minutes. During the decanting stage, the process effluent is

removed from the top of the tank through the floating decanter without disturbing the

settled sludge.

Excess sludge is wasted periodically during the SBR operation at the time with the

decanting stage. As with any activated sludge treatment process, sludge wasting is the

main control of effluent quality and microorganism population size. This is how the

operator exerts control over the effluent quality by adjusting the mixed liquor suspended

solids (MLSS) concentration and the Mean Cell Residence time (MCRT).

The SBR chambers have a complete air distribution system using fine bubble diffusers.

Air is supplied from the three-lobe type air blowers through these diffusers to be

installed equidistant at the bottom of the tank. The blower system is designed to provide

sufficient airflow to meet the system process requirements. The blower will be allowed to

Total Deionization Solutions, Inc. Page 7 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

operate during aeration phase to mix and oxygenate the wastewater to produce biomass

or sludge. The blower stops after completion of the aeration time and the biomass formed

are allowed to settle to the bottom of the basin leaving a layer of clear water on top based

on the programmed period of time.

The uppermost clear water is discharged from the top of the basin while the basin is

continuously receiving the influent using a rugged, corrosion resistant stainless steel

floating type decanter located on the basin center end opposite from the inlet reaction

chamber. The decanter is parked on the top water level (TWL) during the aeration and

settling phases of the cycle, a scum / sludge exclusion installed to eliminate any

possibility of solids/biomass carryover during these periods and also allow an easy

access and service without the need to enter the basin.

The floating decanter is always under pressure both during aeration and settling as well

as 3-5 minutes before decanting to assume that no solids will carry-over with the treated

water. After the five (5) minutes time, the decanter motorized valve open to continuously

discharge the effluent to the chlorine contact tank while the air solenoid valve from the

finish line will closed. Excess sludge will be removed using non-clog submersible pump

during decant phase to maintain the mixed liquor suspended solids (MLSS) requirement.

The amount of biomass present in the system can be checked by getting the Sludge

Volume Index (SVI). The sludge waste pump run can be adjusted to obtain the average

MLSS and MCRT by adjusting the time of run at the Human Machine Interface (HMI)

mounted on the control panel. The decanted wastewater from the SBR basin shall be

disinfected at the chlorine contact chamber provided with baffles to avoid short-

circuiting of flows with a minimum retention time of 30- 60 minutes of the peak-flow.

The chlorine shall destroy the disease-causing microorganisms. The liquid chlorine with

an appropriate dosage of 5.0mg/li shall be fed automatically and mixed with the effluent

of the SBR basins. Generally, a chlorine residual of 0.5 mg/li. after contact time indicates

effective disinfections. The chlorine dosing system shall be operated automatically by

synchronizing with the decanter operations. The effluent volume will be monitored by a

flow meter and will now proceed to the water re-use treatment plant.

The chlorinated water effluent water from the chlorine contact tank/effluent storage tank

shall be pumped to the filter. The pump shall deliver a pressure and flow sufficient to run

the automatic backwash screen filter even during the backwash mode. The Automatic

backwash filter shall reduce the total suspended solids to 5 mg/l. The screen filter can

reject the total suspended solids particulates larger than 20 microns.

4. CHLORINE CONTACT TANK

Supernatant liquid from the Sedimentation Tank enters the Chlorine Contact chamber.

Liquid is further treated with liquid chlorine to kill pathogenic bacteria still present in the

Total Deionization Solutions, Inc. Page 8 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

effluent. Treated water is finally discharge into the sewer line leading to the nearby

receiving body of water.

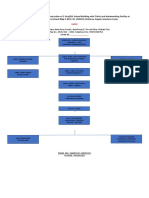

IV. TREATMENT PLANT EFFICIENCY

Chlorinator

(Influent)

Influent Screening Equaliza SBR Chlorine Treated

Septic tion Tank Contact Tank Effluent

Tank Tank

Waste

Activated

Sludge

1st Stage 2nd Stage 3rd Stage

Physical Treatment Biological Treatment Chemical Treatment

BOD in = 400mg/L BOD in = 380mg/L BOD in = 30mg/L

BOD out = 380mg/L BOD out = 30mg/L BOD out = 30mg/L

Efficiency = 5% Efficiency = 92% Efficiency = 0%

Effluent Design DENR Standard for

Parameter Influent Unit % Efficiency

Target Class “C” Water

BOD 400 30 50 mg/L 93

COD 800 60 100 mg/L 93

Color 300 70 150 PCU 77

TSS 300 40 70 mg/L 87

Total Deionization Solutions, Inc. Page 9 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

O&G 40 3 5 mg/L 93

pH 6.7-8.0 6.5-8.5 6.5-9.0 unit range

Total

20,000 3,000 10,000 MPN/100ml 85

Coliform

V. DESIGN CALCULATIONS

Please see attached detailed design computations on the succeeding pages.

Conventional Activated Sludge Process

Abbreviation:

HRT - Hydraulic Retention Time

SWD - Side Water Depth

MLSS - Mixed-Liquor Suspended Solids

MLVSS - Mixed-Liquor Volatile Suspended Solids

F/M - Food to Mass Ratio

Yobs - Observed Yield

Q - Influent Wastewater Flowrate

So - Influent substrate concentration

Si - Effluent substrate concentration

Px - Increase in the mass of MLVSS

WAS - Waste Activated Sludge

SRT - Sludge Retention Time

TOR - Transfer Oxygen Rate

STOR - Standardized Transfer Oxygen Rate

Pd - Pressure Discharge

Qd - Flowrate Discharge

Qs - Flowrate Suction

Basis:

QAve 80.00m3/day

Peak Factor 2.0

BOD5 400.00mg/L

SCREEN CHAMBER

Quantity 1 unit

Volume 0.67 m3

SWD 0.30 m

Total Deionization Solutions, Inc. Page 10 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

Area 2.22 m2

Length 2.78 m

Width 0.80 m

EQUALIZATION TANK

Quantity 1 unit

Number of Diffuser

units

(coarse bubble)

HRT 10.67 hours

Volume 35.56 m3

SWD 1.2 m

Area 29.63 m2

Length 11.85 m

Width 2.50 m

SBR TANK

Quantity 1 Unit

Cycle 3 Cycles/day

Volume of WW to be treated 28 m3/cycle/tank

Volume to be decanted 33 %/cycle/tank

Required volume of tank 84.85 m3/tank

SWD/tank 3.10 m

Area/tank 11.52 m2

Length/tank 4.80 m

Width/tank 2.40 m

BOD Loading 32.00 Kg/d/tank

Decant System

Volume of decant 28.00 m3

Decant Rate 0.47 m3/min

CHLORINATION TANK

Quantity 1 unit

HRT 30.00 mins.

Volume 12.60 m3

SWD 2.00 m

Area 1.44 m2

Length 2.40 m

Width 0.60 m

Total Deionization Solutions, Inc. Page 11 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

EQUIPMENT SPECIFICATION

AIR REQUIREMENT

SBR TANK

AOR 4.65 kg O2/hr

SOR 9.31 kg O2/hr/tank

SW of Air 1.20 units

O2 Content of Air 0.232 23% O2

OTE of diffusers 35 %

Qd 1.59 m /min

3

Qd with SF 1.59 m3/min

Pd 0.36 kgf/cm2

Qs @90% eff 2.53 m3/min/tank

Diffuser Flow Rate 5.80 CFM

0.16 m3/min

Diffuser Quantity 12 pcs/tank

Equalization Tank

Volume of Tank 35.56 m3

Air Requirement 0.02 m3/ m3 - min

Qd 0.53 m3/min

Pd 0.17 kgf/cm2

Qs 0.50 m3/min

2 units – 2.53 m3/min. vs. 0.35kgf/cm2 SBR Air blower

12 units - 2.0-3.5scfm fine bubble disc diffuser for SBR Tank

PUMP REQUIREMENTS

Transfer Pump

Vol. of WW/cycle 28.00 m3

Fill Duration 2.00 hr

Pump Capacity 0.23 m3/min.

Decanter (fix) 0.47 m3/min. vs. 1.00M TDH

1 unit - 4"Ø PVC Decanter w/ 1/2” Ø Solenoid Valve

Chemical Dosing Pump

@4mg/L 0.93 L/hr vs. 1 bar

1 unit - 9.00L/hr. vs. 1.00 Bar chemical dosing pump

Total Deionization Solutions, Inc. Page 12 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

ENGINEER’S REPORT

XENTROMALL SANTIAGO

SANTIAGO CITY, ISABELA, REGION 2

VI. COST OF INSTALLATION AND MAINTENANCE

In 2017, the STP of the establishment was installed and the cost of design and construction is One

Million Eight Hundred Thousand Pesos (PhP 1,800,000.00).

Presently, the STP is fully functional with proper maintenance by their in-house operator. The cost

incurred for the regular maintenance is approximately Twenty Four Thousand Pesos per month

(PhP 24,000.00/mo.) including chemicals.

Prepared by:

TOTAL DEIONIZATION SOLUTIONS, INC.

Jorge J. Magarzo

Operation & Maintenance Manager

Total Deionization Solutions, Inc.

Environmental Consultant for:

XRC Mall Developer, Inc.

Maricel V. Mañago

Pollution Control Officer

XentroMall Santiago Project

Total Deionization Solutions, Inc. Page 13 of 13

Building No. 11, Don Onofre Industrial Village, Cabuyao, Laguna

You might also like

- Lattel Construction Corporate ProfileDocument34 pagesLattel Construction Corporate ProfileMark Joseph EsponillaNo ratings yet

- JackyDocument7 pagesJackyJenny DiapoletNo ratings yet

- J-L Tripoint Enterprise Engineering Services DocumentDocument19 pagesJ-L Tripoint Enterprise Engineering Services DocumentMavic Escuadro LaraNo ratings yet

- Eastern Power Construction Company Profile 2020Document30 pagesEastern Power Construction Company Profile 2020Delmar FerrerNo ratings yet

- Contractual Data:: Allocation Releases Obligation DisbursementDocument2 pagesContractual Data:: Allocation Releases Obligation DisbursementtrixiaNo ratings yet

- E-PR-006 Projects Civil EngineerDocument4 pagesE-PR-006 Projects Civil EngineerMohamed ArafaNo ratings yet

- Contractual Data:: Allocation Releases Obligation DisbursementDocument2 pagesContractual Data:: Allocation Releases Obligation DisbursementtrixiaNo ratings yet

- Managing Sewerage in Bandung CityDocument25 pagesManaging Sewerage in Bandung Cityachmadrb1971No ratings yet

- PDS Abbah King Cement CorporationDocument25 pagesPDS Abbah King Cement CorporationHerwin NavarreteNo ratings yet

- IntroductionDocument10 pagesIntroductionAlbert Jun Piquero AlegadoNo ratings yet

- Coto 3 Hydro 90014004Document1 pageCoto 3 Hydro 90014004BJ AbelaNo ratings yet

- Project Description STPDocument5 pagesProject Description STPBroker GlendieNo ratings yet

- Shutter MAINDocument22 pagesShutter MAINOvais MunshiNo ratings yet

- PDS Ingrid3Document25 pagesPDS Ingrid3RLB QS LAGUNANo ratings yet

- Kibungan HydroDocument51 pagesKibungan HydroGenevieve GayosoNo ratings yet

- EminorBR_Cv (1)Document6 pagesEminorBR_Cv (1)Erickson MalicsiNo ratings yet

- Proposal To MainstreamDocument4 pagesProposal To MainstreamBart LuceñaNo ratings yet

- Ptechnologies Industries Corp Company ProfileDocument27 pagesPtechnologies Industries Corp Company Profilejhay lagmanNo ratings yet

- Proposed Collector and Admin Complex in PatnaDocument8 pagesProposed Collector and Admin Complex in PatnaAshoka MithiranNo ratings yet

- Contractual Data:: Allocation Releases Obligation DisbursementDocument2 pagesContractual Data:: Allocation Releases Obligation DisbursementtrixiaNo ratings yet

- Note:: Cagayan de Oro City 1St District Engineering OfficeDocument1 pageNote:: Cagayan de Oro City 1St District Engineering OfficeErika Faye GutierrezNo ratings yet

- Cricket BatsDocument48 pagesCricket BatsFaisal HassanNo ratings yet

- 001CSIR - SMART-Poblacion Cabadbaran Cell SiteDocument8 pages001CSIR - SMART-Poblacion Cabadbaran Cell SiteHoney GimoNo ratings yet

- Consultant's BackgroundDocument23 pagesConsultant's Backgroundalzhammer manupacNo ratings yet

- Weekly Accompishment Report Format WPR 002 (18 - 24) February 2023Document29 pagesWeekly Accompishment Report Format WPR 002 (18 - 24) February 2023rhannie garciaNo ratings yet

- Innogy Brochure and 2019 Q1Q2 TrainingsDocument2 pagesInnogy Brochure and 2019 Q1Q2 TrainingsTivorshio MacabodbodNo ratings yet

- Abstract of QuotationDocument1 pageAbstract of QuotationNhiel Patrick EvangelistaNo ratings yet

- ESP Summary for New Manila Reclamation ProjectDocument34 pagesESP Summary for New Manila Reclamation ProjectAaron Patrick Llevado RellonNo ratings yet

- Ab - Duo Construction: Contract Organizational ChartDocument1 pageAb - Duo Construction: Contract Organizational ChartVan Gioffri BalisalisaNo ratings yet

- Bamboo Shoot ProcessingDocument39 pagesBamboo Shoot ProcessingJayant HandeNo ratings yet

- CNC Application for DPWH Flood Mitigation Project in Sipocot Camarines SurDocument1 pageCNC Application for DPWH Flood Mitigation Project in Sipocot Camarines SurAngelica Joyce DyNo ratings yet

- 19F00009 - LetterDocument1 page19F00009 - LetterAngelica Joyce DyNo ratings yet

- Sundra: Portable Solar Umbrella With Built-In Power Bank HandleDocument82 pagesSundra: Portable Solar Umbrella With Built-In Power Bank HandleAisha Marie EsguerraNo ratings yet

- Abridge Company ProfileDocument28 pagesAbridge Company ProfilesaikacyberemailNo ratings yet

- DownloadDocument64 pagesDownloadRenato EvangelistaNo ratings yet

- Natan Teknik Mandiri Performance Budget Mechanical & Electrical Hm. Sampoerna Project - PandaanDocument11 pagesNatan Teknik Mandiri Performance Budget Mechanical & Electrical Hm. Sampoerna Project - PandaanMangatas MarbunNo ratings yet

- DSV Pre-Qualification Questionaire - DB&BDocument7 pagesDSV Pre-Qualification Questionaire - DB&BVinci BondocNo ratings yet

- Pre-Final Inspection_Tinalon PHFDocument2 pagesPre-Final Inspection_Tinalon PHF19vigor25No ratings yet

- Short Highlight Report: From ToDocument2 pagesShort Highlight Report: From ToNay Win MaungNo ratings yet

- Modelling Structural Performance and Risk For Enhanced Building Resilience and ReliabilityDocument20 pagesModelling Structural Performance and Risk For Enhanced Building Resilience and ReliabilityPrasanth SekarNo ratings yet

- VGHJKKKDocument7 pagesVGHJKKKArnawama LegawaNo ratings yet

- Project Feasibility Study of Waste Management in IndonesiaDocument7 pagesProject Feasibility Study of Waste Management in IndonesiaEko Tjahjantoko0% (1)

- PT Barata Indonesia: Leading Indonesian Engineering CompanyDocument15 pagesPT Barata Indonesia: Leading Indonesian Engineering CompanyDen Bagoes ReditoNo ratings yet

- BALTAZAR, Mariz EllaineDocument5 pagesBALTAZAR, Mariz EllaineClark InternationalNo ratings yet

- Review Winter Project 2020 - 21Document52 pagesReview Winter Project 2020 - 21Virbhadra BaradNo ratings yet

- Company ProfileDocument5 pagesCompany ProfileDerick MacedaNo ratings yet

- COLLECTORATE Building DetailsDocument5 pagesCOLLECTORATE Building DetailsAshoka MithiranNo ratings yet

- Queenbee Revised Project ProposalDocument24 pagesQueenbee Revised Project ProposalPSTC SDNNo ratings yet

- 2022-EASTPEN-COMPANY-PROFILE-updated 01.16. 2023 PDFDocument32 pages2022-EASTPEN-COMPANY-PROFILE-updated 01.16. 2023 PDFEllen ProfetaNo ratings yet

- Updated Initial Condition Report Pgk-12Document104 pagesUpdated Initial Condition Report Pgk-12William KundaNo ratings yet

- Report Control Room Lawe 220218-RE0Document78 pagesReport Control Room Lawe 220218-RE0ajiNo ratings yet

- 2nd Quarter Avida Centera SMR - LatestDocument16 pages2nd Quarter Avida Centera SMR - LatestBrainard ConcordiaNo ratings yet

- Who is MEC EngineeringDocument21 pagesWho is MEC EngineeringRafael Pagán CáceresNo ratings yet

- Aracanut Plates 10 LakhsDocument19 pagesAracanut Plates 10 LakhsManju MysoreNo ratings yet

- King Salman Energy ParkDocument4 pagesKing Salman Energy ParkLarry Stanford0% (1)

- Resume (Allen Robert Wagan)Document6 pagesResume (Allen Robert Wagan)Chigz LeczzNo ratings yet

- ZoningDocument9 pagesZoningCheene AbacanNo ratings yet

- Wheather Jun 17Document54 pagesWheather Jun 17Misz_10_ScorpioNo ratings yet

- Delivering Water and Power: GIS for UtilitiesFrom EverandDelivering Water and Power: GIS for UtilitiesPat HohlRating: 4 out of 5 stars4/5 (1)

- Pollution Control Technologies for Small-Scale OperationsFrom EverandPollution Control Technologies for Small-Scale OperationsNo ratings yet

- B&G Hydronics Manual - How System Components Really WorkDocument36 pagesB&G Hydronics Manual - How System Components Really WorkrjcantwellNo ratings yet

- Plumbing Calculation Report-Rev.01Document205 pagesPlumbing Calculation Report-Rev.01AslamNo ratings yet

- Water Agencies Standards PDFDocument38 pagesWater Agencies Standards PDFlimin zhangNo ratings yet

- Material Valve, Fittting, Pump Room - PT MicoDocument9 pagesMaterial Valve, Fittting, Pump Room - PT MicoPurnama HelmiNo ratings yet

- 02 - WaterCycle - CEE350 (1) UIUCDocument17 pages02 - WaterCycle - CEE350 (1) UIUCENo ratings yet

- Bep Rev.c-New 20 MLD WTP, NathavaliDocument380 pagesBep Rev.c-New 20 MLD WTP, NathavaliAnonymous 7l8AIyq2No ratings yet

- Comparative Study of Septic Tank, Anaerobic Filter, and Anaerobic Baffled Reactor For Treating Domestic WastewaterDocument1 pageComparative Study of Septic Tank, Anaerobic Filter, and Anaerobic Baffled Reactor For Treating Domestic WastewaterRathborey ChanNo ratings yet

- HKTM StokDocument406 pagesHKTM Stokfratk8093No ratings yet

- Surface Water Treatment PlantDocument17 pagesSurface Water Treatment PlantKamran RanaNo ratings yet

- Direct Heating Substation for HomesDocument2 pagesDirect Heating Substation for HomesDaniel VisaNo ratings yet

- Valve Data Sheet 01Document1 pageValve Data Sheet 01kapsarcNo ratings yet

- Piping - Design - Info (Version 2)Document245 pagesPiping - Design - Info (Version 2)mehul10941No ratings yet

- DR17 HDPE Friction Loss TableDocument1 pageDR17 HDPE Friction Loss TablefaisalseprizalNo ratings yet

- Piping DesignDocument122 pagesPiping Designfacebookshop100% (9)

- Review Module: - Hydraulics 4Document2 pagesReview Module: - Hydraulics 4YeddaMIlaganNo ratings yet

- Form - 11 - Report of Examination or Test of Pressure Vessel or PlantDocument3 pagesForm - 11 - Report of Examination or Test of Pressure Vessel or Planthdpanchal86No ratings yet

- Turbo II PDFDocument72 pagesTurbo II PDFPiterHaroldNo ratings yet

- Parker (D) Deceleration ValvesDocument17 pagesParker (D) Deceleration ValvesMohamed RashedNo ratings yet

- Flow Meters and Orifice PlatesDocument4 pagesFlow Meters and Orifice PlatesayberkNo ratings yet

- Water TestDocument2 pagesWater TestKhin Aung HtooNo ratings yet

- Easier t2 e 5116 Uks2 World Water Day Leaving No One Behind Differentiated Reading Comprehension Activity Ver 3Document6 pagesEasier t2 e 5116 Uks2 World Water Day Leaving No One Behind Differentiated Reading Comprehension Activity Ver 3cocoyipNo ratings yet

- Campus STP DesignDocument6 pagesCampus STP DesignHarish LakshminarayananNo ratings yet

- Rain Water Harvesting Methods & BenefitsDocument2 pagesRain Water Harvesting Methods & BenefitsPradeep NairNo ratings yet

- Customer Ledger As On 25 04 2019Document14 pagesCustomer Ledger As On 25 04 2019abhishek ganeshNo ratings yet

- White Paper W Edits - Luke SummerDocument10 pagesWhite Paper W Edits - Luke Summerapi-583606190No ratings yet

- W5 Tentative CDVAT Amount for DI Pipe FittingsDocument4 pagesW5 Tentative CDVAT Amount for DI Pipe FittingsSaifur RahmanNo ratings yet

- NAHRIM's Experiencein Rainwater Utilisation System Research-SlidesDocument13 pagesNAHRIM's Experiencein Rainwater Utilisation System Research-SlideskaishiNo ratings yet

- JIS H 3300 - 2006 Copper Andcopper Alloy Seamless Pipes and TubesDocument35 pagesJIS H 3300 - 2006 Copper Andcopper Alloy Seamless Pipes and TubesTRONGHAI266100% (2)

- Wastewater Treatment Methods ComparisonDocument54 pagesWastewater Treatment Methods ComparisonPamela MendozaNo ratings yet

- Esbe GB General Katalog 2013Document212 pagesEsbe GB General Katalog 2013temp1227100% (1)