Professional Documents

Culture Documents

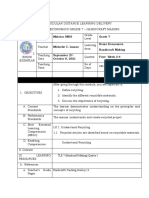

Fire Fitting Time Plan

Uploaded by

عبدالرحمن الصرميOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Fitting Time Plan

Uploaded by

عبدالرحمن الصرميCopyright:

Available Formats

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

D. Mechanical – Fire Fighting BoQs.

Ref. Description. Unit QTY

D FIREFIGHTING WORKS.

PREAMBLE

- This section shall be read in conjunction with parts of (The Fire-Fighting Technical Specifications General

and Particular) and the mech-Fire Fighting drawings, except where otherwise indicated.

- The unit price for all items in this section shall inclusive of supply, installation, selection, operation

(commissioning) works and all other luxurious, accessories, appended and required. Therefore, the item

will be fully inclusive, ready for use, with all its requirements, materials, civil works, forming or cutting holes,

chases, channels... etc in concrete structures and block/stone walls, and execution methods which the Note

supervising engineer will demand, so as the item will become finally completed.

- In the event any item/work is not mentioned in this section and it is necessary or complementary of the

work of another item already mentioned in the table of quantities, it is the contractor’s responsibility to

provide all items without any additional cost. Accordingly, the contractor must visit the site to verify the

amount of the work and taken into account all other required works, modifications or materials to finish the

work properly.

D1 PORTABLE FIRE EXTINGUISHER.

Supply, install, test, and commission Portable Fire extinguishers complete including all necessary components and

accessories, and all necessary accessories, with initial filling in a brand new cylinder with a powder-coated finish,

fitted with Gun metal union, high-pressure gas cartridge, discharge hose, wall mounting bracket, etc., manufactured

in accordance with BS EN3 / NFPA-10 standard or equivalent and certified by one or more of the well-known

certifying companies such as SASO, CE, and BSI Kitemark Quality Certificate, or equivalent, All items shall have been,

as detailed and specified in the drawings, technical specification, and the approval of the supervisor engineer.

- The Work should include Labels and identification tags, signages, and markings for all portable extinguishers. Note

a Carbon Dioxide Extinguishers (CO2) 6 Kg. No 30.0

b ABC Dry Powder Extinguisher 10 Kg. No 22.0

c Automatic Foam Fire Extinguisher 10 Liter. No 1.0

d Automatic ABC Dry Powder Fire Extinguisher 10 Kg. No 2.0

f Wheeled ABC Dry Powder Fire Extinguisher 50 Kg. No 10.0

Wheeled Foam Fire Extinguisher 50 Liter, High Quality 3% Foam, Long throw foam nozzle with grip control, one-

g person operation and movement with Refillable stored pressure unit. Working Pressure to be not less than 12 Bar, No 10.0

Test Pressure not less than 22 Bar.

D2 FIRE FIGHTING PUMPS & ACCESSORIES.

Supply, install, test, and commissioning a complete set of Fire Fighting Pumps according to NFPA 20, 14, (“UL listed &

FM approved”), 380/3/50Hz, consisting of One End Suction electric pump, One End Suction Diesel pump, and one

Vertical Multistage Jockey Pump. The pump unit price shall include 3 Nos of pump controllers, complete with

electrical wiring, pressure transmitter, site vibration isolators and vibration R.C base, and dry run protection, circuit

breakers, overload relays, Pressure gauge (Glycerine filled) with isolation valve, air vent, automatic relief valve rated

for 200 psi, Carbon steel diesel tank (240 liter), pipes, Anti-vortex assembly, Black steel pipe with thermal insulation

for diesel engine exhaust, black steel pipe and valves for fuel line, Flexible connector for Suction pipe, stainless steel

pipes or equivelent for pressure sensing line as per NFPA 20, Water level indicator, Water level switches, Non-return

valve, OS&Y gate valve rated for PN-16, relief valve, Special tools & Tackles required for Fire Pumps, Power Electrical

Cables for Main Electric & Jockey pumps motors including termination and earthing to be connected to the Fire

Fighting Main Distribution Board (FF-DB), Power & Control cabling for diesel engine and instruments panel, and all

other necessary accessories and requirements according to NFPA 20, and all civil works to finish this item according Note

to the drawings, specifications, and instruction of the employer representative. As Per Drawing 06-01 to 06-09.

- Only eccentric reducer accepted if needed in the suction line.

- Pumps Efficiency should not be less than 65%.

- The flow unit of pumps is (US GALLON PER MINUTE).

End Suction Electric Fire Pump Type FP-1 (Minimum Flow 500 GPM @124PSI).

a End Suction Diesel Stand By Fire Pump Type FP-2 (Minimum Flow 500 GPM @124 PSI). Set 1.0

Vertical multistage Jockey pump type JP (Minimum Flow 10 GPM @ 137 PSI).

D3 VALVES & ACCESSORIES.

Supply, install, test, operate, and commissioning Valves & Accessories with a minimum rated for PN-16 (“UL listed &

FM approved”), Flange type, all of which shall be in accordance with trade codes of practice and highest prevailing

engineering standards, the price includes all required works and all other necessary accessories and requirement

D3.1 works to finish this item according to the drawings, specifications, instruction, and approval of employer Note

representative. As Per Drawing 06-01 to 06-09.

a OS&Y Gate Valve, 6 Inch. No 3.0

Bill of Quantities Summary. PAGE 1 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Ref. Description. Unit QTY

b Gate Valve, 2 Inch. No 2.0

c Pressure relief valve, minimum 1 Inch. No 1.0

d Pressure gauge with isolating valve 1 Inch. No 1.0

e Automatic air release valve 1 Inch. No 1.0

f Butterfly valves, for test line 6 inch. No 1.0

g Pilot Pressure relief valve 6 Inch. No 1.0

h Flow meter, for test line 6 Inch. No 1.0

i Drain Valve, 2 Inch. No 1.0

D3.2 Float Valve. No 1.0

D3.3 Fire Resistance Stanless Steel Flexible Joint/Connector, 6 inch. No 1.0

D3.4 Anti Vortex, 12 Inch. No 1.0

D4 FIRE HOSE CABINETS.

Supply, install, test, and commissioning UL listed Mild Steel Recessed Fire hose cabinets with a minimum thickness

1.2 mm, with 40 mm diameter × 30 m long Textile hose with minimum 4.5 bar working pressure complete with

fittings, brass control valve, and all necessary, pressure reducing valve, lockshield Gate valve, hose connection valve,

swinging type, and adjustable spray nozzle, Painted with high quality electrostatic powder coating, red color, with 6

Kg powder extinguisher, All Fire hose cabinets accessories should be (“UL listed/FM approved”). The Item Include all

civil work such as chasing/chipping walls and making them good with filler material and finished in cement mortar, Note

and all accessories to complete the work as per specifications, drawings, instruction, and approval of the employer

representative. As Per Drawing 06-01 to 06-09.

a FHC. No 8.0

D5 BLACK STEEL SEAMLESS PIPES.

D5.1 Above Ground Piping.

Supply, install, test, and commissioning of Above Ground Piping Standard-weight black steel pipes ASTM A 53 Gr.B,

Type S (seamless) schedule 40 steel with bevel end, with anti-corrosion painting (Two coats of red oxide primer and

two coats of oil paint, Pipes shall include all fittings, hangers, valves, expansion joint, strainers, flanges, Gasket, and

accessories, with the suitable type of supports, anchor fasteners, bolts nuts (Galvanized), clamps, "U" bolts,

Reducers, Tees, elbows, Flanges, Including cutting, welding, fixing in / on walls, ceiling by using suitable supports,

etc., all pipes and accessories shall be new and from standard manufacturers and from a well-known brand and meet

the highest international standards and codes of practice. The Item Include all civil work such as chasing/chipping Note

walls, making boreholes in walls/floor and making them good with filler material and finished in cement mortar, and

all accessories to complete the work as per specifications, drawings, instruction, and approval of employer

representative. As Per Drawing 06-01 to 06-09.

a 1.5 inch. L.m 155.0

b 2 inch. L.m 24.0

c 3 inch. L.m 33.0

d 4 inch. L.m 26.0

e 6 inch. L.m 78.0

D5.2 Under Ground Piping with Trenches.

Supply, install, test, and commissioning Under Ground Piping with Trenches Standard-weight steel pipes ASTM A 53

Gr.B, Type S (seamless) schedule 40 steel with bevel end, for underground pipes with an anti-corrosion Tape coating

and isolation coating valves, Pipes shall include all fittings, valves, expansion joint, strainers, flanges, Gasket, Paint,

and accessories, with the suitable type of supports including bolts nuts (Galvanized), ""U"" bolts, Reducers, Tees,

elbows, Flanges, etc, all pipes and accessories shall be new and from standard manufacturers and from a well-known

brand and meet the highest international standards and codes of practice. Item Include all civil work such as

chasing/chipping walls/floor, making boreholes in walls/floor and making them good with filler material, excavation,

and backfilling of trenches in any kind of soil including rocks with a total depth of 120 cm, concrete thrust blocks, and

all accessories to complete the work as per specifications, drawings, instruction, and approval of employer

representative t. As Per Drawing 06-01 to 06-09.

a 4 inch. L.m 134.0

b 6 inch. L.m 149.0

D6 SIAMESE CONNECTION.

Bill of Quantities Summary. PAGE 2 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Ref. Description. Unit QTY

Supply, install, test, and commissioning Siamese connection with 2x65mm, Dia 100 mm, with a minimum pressure

rating PN-16 (Certified to BS5041-3 or equivelent), with Mild Steel cabinet with Reinforcement Wire Meshed Glass,

including UL listed & FM approved check valve with a minimum pressure rating PN-16, Including drain valves,

a Fittings, and all needed accessories and required works to finish the item according to the drawings, specification, Set 1.0

instruction, and approval of employer representative. As Per Drawing 06-01 to 06-09.

D7 FIRE HYDRANT.

Supply, installation, testing, and commissioning of Fire hydrant Ductile iron body with two Hose Nozzle 2.5" in

accordance with international, minimum PN16, (“UL listed/FM approved”) with Mild steel Fire Hydrant Cabinet with

minimum thickness no less than 1.2 mm, Weatherproof type for outdoor installation, Equippied with 2 pcs fire hose

Size 2.5”x 30 m synthetic rubber lined (UL listed) with end connection comply with fire hydrant outlets with Coupling,

Pin Lug Spanner Wrench, and adjustable hydrant wrench, the price should also include Underground Get Valve with

roadway box, minimum PN16 (“UL listed/FM approved”), with extension stem and castiron valve box. The item

includes all required civil works including but not limited to concrete PAD 1000 x 1000 x 200 mm foundation and

a thrust block and thrust block for elbows as requested and instructed by the site engineer, and all other necessary set 4.0

accessories and requirement works to finish this item according to the drawings, specifications, instruction, and

approval of employer representative. As Per Drawing 06-01 to 06-09.

D8 SUBMERSIBLE PUMPS.

Supply, installation, testing, and commissioning of Complete set of 2 electrical Submersible pumps set one as primary

and the other as stand by, complete with all hook up, motor starter, sensor, control panels, dry run protection,

Power cable, valve system, pipes, clamps, and all necessary accessories; capacity = 55 GPM, Total head=15 m, and all

a requirement works to finish this item according to the drawings, specifications, instruction, and approval of employer set 1.0

representative. As Per Drawing 06-01 to 06-09.

D9 SYSTEM SPARE PARTS.

Supply of original spare parts for the Fire pump as per NFPA 20, 25, and deliver these spare parts to the warehouse

stores prior to commission, these spare parts shall not be used by contractor during the 1st year of maintenance

guarantee, the spare parts to be provided shall including but not limited to set of air filters, oil filters, Fuel Filter,

Mechanical Seal for Pump, set of drive belts, set of bearings, etc. Note

Diesel Fire Pumps.

D9.1

a Set of fuel filter elements. Set 8.0

b Set of oil filter elements. Set 12.0

c Set of air filter elements. Set 6.0

d Set of all types of gasket. Set 1.0

e Set of all types of driving belts. Set 1.0

End Suction Fire Pumps.

D9.2

a Impeller. No 2.0

b Set of all types of Bearing. Set 2.0

c Set of all types of Gaskets. Set 2.0

d Set of all types of Rings & Glands. Set 2.0

e Water Slinger. No 2.0

f Shaft Sleeve. No 2.0

g Set of all Types of Bolt and Nuts. Set 2.0

D9.3

Jockey Pump.

a Set of all Types of Packing including but not limited to Packing gland washer, etc. Set 1.0

b Set of all Types of Gaskets. Set 2.0

Bill of Quantities Summary. PAGE 3 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Ref. Description. Unit QTY

c Set of all Types of Rings & Glands. Set 2.0

d Water Slinger No 1.0

e Set of all Types of Bolt and Nuts. Set 1.0

D10 MAINTENANCE & TRAINING.

Comprehensive Maintenance and Fire Scenario Training Drills for the warehouse staff members with full

responsibility of carrying out all types of Fire Scenario Drills, and maintain the system with best operational

conditions along a period of guarantee, contractor to provide preventive maintenance plan and Fire

Scenario Training Drills with his offer according to manufacturer recommendations and as per relevant

a standers, the contractor shall provide spare parts, and consumables required to carry-out preventive or L.S 1.0

breakdown maintenance of the system during the maintenance period with no additional charges, the

contractor shall carry out at least 4 visits/year to train, check, adjust, replace or balance the system to keep

it working with the best conditions, assessment report and Fire Drill Evaluation shall be prepared with every

visit shall be raised to UNOPS employer representative.

Sub-Total

Bill of Quantities Summary. PAGE 4 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Amount

Time USD

Two weeks but

after pipe line

works

Two and half

months for

complet the work

(Supply from

abroad)

Two and half

months for

complet the work

(Supply from

abroad)

Bill of Quantities Summary. PAGE 5 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Amount

Time USD

Two and half

months for

complet the work

(Supply from

abroad)

Three months for

complet the work

(Supply from

abroad)

Three months for

complet the work

(Supply from

abroad)

Bill of Quantities Summary. PAGE 6 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Amount

Time USD

Two months for

complet the work

(Supply from

abroad)

Two and half

months for

complet the work

(Supply from

abroad)

One month

Two months

(Supply from

abroad)

Two months

(Supply from

abroad)

Two months

(Supply from

abroad)

Two months

(Supply from

abroad)

Bill of Quantities Summary. PAGE 7 OF 8.

Rehabilitation Works for Sana’a Central Vaccines Warehouse.

Amount

Time USD

--

Bill of Quantities Summary. PAGE 8 OF 8.

You might also like

- SECTION 15120 Piping Specialties 1.1Document18 pagesSECTION 15120 Piping Specialties 1.1Munir RasheedNo ratings yet

- Gas Shutoff Valves: FeaturesDocument136 pagesGas Shutoff Valves: FeaturesJuan BejaranoNo ratings yet

- General Ducty Valves SpecDocument12 pagesGeneral Ducty Valves SpecpursuitofhappynessinNo ratings yet

- Ghazipur VRV VoltasDocument8 pagesGhazipur VRV VoltasFluidus EngineeringNo ratings yet

- Project Standard Specification: Plumbing Specialties 15430 - Page 1 of 19Document19 pagesProject Standard Specification: Plumbing Specialties 15430 - Page 1 of 19adel rihanaNo ratings yet

- I Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeDocument11 pagesI Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeSajeshKumarNo ratings yet

- 7-BOQ & Estimate Fire ProtectionDocument26 pages7-BOQ & Estimate Fire ProtectionTransitpoint Holiday BungalowNo ratings yet

- Inside Sales For Valves Part 3Document6 pagesInside Sales For Valves Part 3niket honnalliNo ratings yet

- Boiler Equipment (1&2)Document7 pagesBoiler Equipment (1&2)mohamedmizoNo ratings yet

- Boq STP - 1Document8 pagesBoq STP - 1jnmanivannanNo ratings yet

- Division No.4 Boq For Medical Gases Works For Ibn Khaldoun Hospital, Lahj GovernorateDocument2 pagesDivision No.4 Boq For Medical Gases Works For Ibn Khaldoun Hospital, Lahj GovernorateWael Fuad AL-MaktariNo ratings yet

- Asco Series 210 Gas Shutoff No CatalogDocument2 pagesAsco Series 210 Gas Shutoff No CatalogManuel ParraNo ratings yet

- Fire Boq Global NoidaDocument9 pagesFire Boq Global NoidaPrasanth KumarNo ratings yet

- Section 21 12 00Document3 pagesSection 21 12 00Ismail MohammadNo ratings yet

- Mechanical and Plumbing Works General Notes For All Mechanical and Plumbing WorksDocument3 pagesMechanical and Plumbing Works General Notes For All Mechanical and Plumbing WorksMOHAMED ATTIANo ratings yet

- Operating Manual: High-Pressure CleanersDocument44 pagesOperating Manual: High-Pressure CleanersPierre LangevinNo ratings yet

- Aziz Avenue InvoiceDocument3 pagesAziz Avenue Invoicebhatti.arslan1947No ratings yet

- 2" To 4" E-Type Series StrainersDocument4 pages2" To 4" E-Type Series Strainershyarub9No ratings yet

- El Balyana Medical Gas Boq Rev01Document17 pagesEl Balyana Medical Gas Boq Rev01Abdallah ElabassyNo ratings yet

- Sour ServiceDocument24 pagesSour ServicesundachaosNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- El Balyana Water Tank & Pump Room BoqDocument3 pagesEl Balyana Water Tank & Pump Room BoqAbdallah ElabassyNo ratings yet

- ÉSECÈ Group - Steam Boiler - Mar12 ENGDocument4 pagesÉSECÈ Group - Steam Boiler - Mar12 ENGDiego Otero RodríguezNo ratings yet

- Steam, Domestic Storage Water HeaterDocument7 pagesSteam, Domestic Storage Water Heaterbandithaguru6338No ratings yet

- Fire OfferDocument14 pagesFire OfferaneeshNo ratings yet

- Etp - 30 KLDDocument18 pagesEtp - 30 KLDsubramanyam kumarNo ratings yet

- Mr. Bilal REVISED BILLDocument3 pagesMr. Bilal REVISED BILLbhatti.arslan1947No ratings yet

- Hyd. Calc of 43p17 Ab - As Per P&idDocument7 pagesHyd. Calc of 43p17 Ab - As Per P&idAnindyaNo ratings yet

- ITAP AccessoriesDocument119 pagesITAP AccessoriesPremjith SudhakaranNo ratings yet

- 221005, Plumbing SpecialtiesDocument16 pages221005, Plumbing Specialtiessrp. mohammedNo ratings yet

- TS Fire Hydrant Wet SystemDocument9 pagesTS Fire Hydrant Wet System123agattarNo ratings yet

- Skyvilla Building - Sanitary BOQ - R3 - 19.11.2020Document8 pagesSkyvilla Building - Sanitary BOQ - R3 - 19.11.2020MekdesNo ratings yet

- Kumbakonam HospitalDocument12 pagesKumbakonam HospitalHari HaranNo ratings yet

- Sample Boq of FF WorkDocument115 pagesSample Boq of FF WorkZAHID IQBALNo ratings yet

- BOQDocument4 pagesBOQMahi PSNo ratings yet

- 686 BQ Plumbing Hydrant-TW.a-b (Rev.2) IbotDocument49 pages686 BQ Plumbing Hydrant-TW.a-b (Rev.2) IbotDwi Mego PrasetyoNo ratings yet

- Gas Shutoff Valves: FeaturesDocument2 pagesGas Shutoff Valves: FeaturesDidik RiswantoNo ratings yet

- SEC 226200 Laboratory Vacuum SystemDocument8 pagesSEC 226200 Laboratory Vacuum SystemAkilaJosephNo ratings yet

- B.Q Ac Work PDFDocument4 pagesB.Q Ac Work PDFtarde4hNo ratings yet

- Project: Goa Air Conditioning Works For Bottiling Hall 0.00 Description Unit QTYDocument13 pagesProject: Goa Air Conditioning Works For Bottiling Hall 0.00 Description Unit QTYRAMANA RAO UNo ratings yet

- KS Series Salt Spray Test ChamberDocument6 pagesKS Series Salt Spray Test ChamberArman FarjanNo ratings yet

- Plumbing FixturesDocument30 pagesPlumbing Fixturesadel rihanaNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Price List For The equipments-STPDocument8 pagesPrice List For The equipments-STPEcologics IndiaNo ratings yet

- 8040 NC PilotDocument4 pages8040 NC PilotMaximilianoAlvarezNo ratings yet

- Engineering: GREAT SolutionsDocument10 pagesEngineering: GREAT SolutionsDanielNo ratings yet

- ValvesDocument11 pagesValvesAdamNo ratings yet

- PoolDocument2 pagesPoolskgreenduneNo ratings yet

- Mir 01Document2 pagesMir 01Alkama ShaikhNo ratings yet

- ZhongtaiDocument4 pagesZhongtaivietsdsNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- Fire Fighting Bill ValueDocument341 pagesFire Fighting Bill ValueMuhammad Afzal100% (1)

- Válvulas Solenoides ASCO ECIDocument35 pagesVálvulas Solenoides ASCO ECIFernando MendezNo ratings yet

- Gcem4011 Co Analyser DocsDocument11 pagesGcem4011 Co Analyser DocsmukurshahNo ratings yet

- Total Cost 18,904,333: Summary of Cost (Public Health)Document19 pagesTotal Cost 18,904,333: Summary of Cost (Public Health)muzammalNo ratings yet

- Fire Protection System (Hydrant System)Document6 pagesFire Protection System (Hydrant System)adilmomin45No ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- LE Handicraft WEEK 3-4 GRADE 7 - 8Document6 pagesLE Handicraft WEEK 3-4 GRADE 7 - 8Michelle Llanes100% (1)

- Wireless Home Automated SystemDocument13 pagesWireless Home Automated SystemKassandra CanaNo ratings yet

- 1741 - Long Span Structures ReportDocument5 pages1741 - Long Span Structures ReportHuzefa SayyedNo ratings yet

- Module 3 TD 8 WEEK3Document8 pagesModule 3 TD 8 WEEK3meraaguilanNo ratings yet

- 5 Why AnalysisDocument55 pages5 Why AnalysisHarshit Sharma100% (1)

- Themes & Scriptures 2009 (Thumbnail)Document1 pageThemes & Scriptures 2009 (Thumbnail)Jenn100% (5)

- Bit Bank (KSM)Document96 pagesBit Bank (KSM)nagendra.jodhaNo ratings yet

- Surge Impedance LoadingDocument2 pagesSurge Impedance LoadingAnbu AyyappanNo ratings yet

- FORM 5 VariationDocument35 pagesFORM 5 VariationAMOS YAP WEI KANG MoeNo ratings yet

- Wallace State Community College NURSING DATABASE: Nursing HomeDocument9 pagesWallace State Community College NURSING DATABASE: Nursing HomeEnger NushunNo ratings yet

- Drahmedsoil Mechanicsnoteschapter 2Document22 pagesDrahmedsoil Mechanicsnoteschapter 2kerby munarNo ratings yet

- Unit Homework Momentum Its Conservation Ans KeyDocument6 pagesUnit Homework Momentum Its Conservation Ans KeyKristyne Olicia100% (1)

- Module 4Document5 pagesModule 4Ivan PaulinoNo ratings yet

- Escherichia Coli O157:H7 Issues and Ramifications: Executive SummaryDocument12 pagesEscherichia Coli O157:H7 Issues and Ramifications: Executive SummaryTinnysumardiNo ratings yet

- Dissertation Abstracts International Section B Sciences and EngineeringDocument5 pagesDissertation Abstracts International Section B Sciences and EngineeringCustomPapersWritingSingaporeNo ratings yet

- Pertcpm 4Document70 pagesPertcpm 4John BanielNo ratings yet

- Naples Capital Improvement Plan 2022-2026Document215 pagesNaples Capital Improvement Plan 2022-2026Omar Rodriguez OrtizNo ratings yet

- Summa S One Series Product PresentationDocument32 pagesSumma S One Series Product PresentationPU PUNo ratings yet

- Chapter 1 Revised Edition HeheheDocument75 pagesChapter 1 Revised Edition HeheheWendell MagdaluyoNo ratings yet

- Electrical Systems Instructions Manual Sames DRT6364 UkDocument26 pagesElectrical Systems Instructions Manual Sames DRT6364 UkGermando NUNESNo ratings yet

- Hanson PDFDocument10 pagesHanson PDFAlberto Caceres ValenciaNo ratings yet

- Isolated Roller Guide Shoes WRG200, WRG300Document15 pagesIsolated Roller Guide Shoes WRG200, WRG300Johan GuíaNo ratings yet

- Isotermas de Sorcion ManzanaDocument12 pagesIsotermas de Sorcion ManzanaFELIPEGORE ArbeláezNo ratings yet

- STRATAGEN STIMPRO Software Product Information Sheet 1001 1Document2 pagesSTRATAGEN STIMPRO Software Product Information Sheet 1001 1Oussama AissaouaNo ratings yet

- Test 5-11-2019 Excretory System - Pharmacist Zaheer AbbasDocument3 pagesTest 5-11-2019 Excretory System - Pharmacist Zaheer AbbasabbaszaheerNo ratings yet

- Spring 2019 PDFDocument56 pagesSpring 2019 PDFMayyage LokayaNo ratings yet

- SCM Apo 4.0 Training Course in Supply Network Planning: DeeperDocument44 pagesSCM Apo 4.0 Training Course in Supply Network Planning: DeeperArjun KNo ratings yet

- SRT Ts Trainingbooklet 2016 PDFDocument44 pagesSRT Ts Trainingbooklet 2016 PDFAde YahyaNo ratings yet

- ASC - General - Purpose - Capacitor For HallsensorDocument19 pagesASC - General - Purpose - Capacitor For HallsensorLusiNo ratings yet

- Integral AKDocument22 pagesIntegral AKkatherine anne ortiz100% (1)