Professional Documents

Culture Documents

BET 31 Lesson 1 - Introduction To Industrial AC Motor Control

Uploaded by

Juanito BartulumeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BET 31 Lesson 1 - Introduction To Industrial AC Motor Control

Uploaded by

Juanito BartulumeCopyright:

Available Formats

Lesson 1: Introduction to Industrial Motor Control |1

University of Makati

College of Technology Management

Electrical Technology

Learning Material

BET 31 : Industrial Motor Control

Introduction to

Lesson 1 : Industrial AC Motor Control

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |2

Lesson 1: Introduction to Industrial Motor Control

Objectives:

At the end of the lesson, you are expected to:

1. Define the terminologies relating to industrial AC motor control,

2. Determine the purpose of industrial AC motor control, and

3. Discuss the AC motor control parts.

Introduction:

The lesson will introduce you to AC motor control pertaining to the

various terminologies used. It will also present you the definition and

purpose of industrial motor control and the essential parts of industrial

motor control.

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |3

Definition:

Motor Control Motor control is that part of the electrical system which

starts, stops, and reverses motors that drives various

pieces of equipment. In addition, motor control

equipment is designed to limit starting current and

control starting torque.

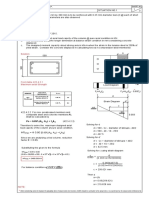

PARTS OF MOTOR CONTROL

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |4

PURPOSE OF MOTOR CONTROL

1. To start and stop the motor

2. To reverse the rotation of the motor

3. To regulate the speed of the motor

4. For jogging or inching

5. For dynamic braking

6. For plugging

7. To protect the motor and its operator

✓ Several terms must be first compared and understood before

proceeding as these terms have different meaning as used in motor

controls.

1. OVERCURRENT PROTECTION versus OVERLOAD PROTECTION

✓ Over current protection is installed in the power circuit to protect

the conductors and may exist in the form of fuses or circuit breakers.

✓ Overload protection is installed in the circuit to protect the motor’s

winding and may exist in the form of overload relays, heaters or

elements.

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |5

2. WIRING DIAGRAM versus SCHEMATIC DIAGRAM

✓ A wiring diagram attempts to illustrate the physical location of all

components, motors and the like are shown in the actual position

that would be found on the installation.

✓ A schematic diagram should be used when designing or

troubleshooting an installation. Control components are re-

arranged to simplify the tracing of the circuit. Line, ladder, or

elementary diagrams are other terms used in lieu of the schematic

diagram.

3. POWER CIRCUIT versus CONTROL CIRCUIT

✓ Power circuit conductors are sized according to the current drawn

by the motor and form the power circuit.

✓ Control circuit contains the control devices that will initiate the

starting or stopping of the motor.

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |6

PARTS OF MOTOR CONTROL CIRCUIT IN AN ENCLOSURE

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |7

SCOPE OF MOTOR CONTROL

Disconnect:

Type and Rating

Motor Control Circuit:

Full Voltage Starter

Reduced Voltage Supply Conductors:

Starter Number, Size and Type

Reversing or Non-

Reversing

Jogging Control

Cycle Control

Size, Type, Rating of Motor Conductors:

Magnetic Contactor Number, Size and Type

and Overload Relay

Motor:

Type, Rating, Phase,

Voltage and Starter

Type

BET 31: INDUSTRIAL AC MOTOR CONTROL

Lesson 1: Introduction to Industrial Motor Control |8

ARTICLE 4.30 MOTORS, MOTOR CIRCUITS, AND CONTROLLERS

4.30.1.1 Scope. This article covers motors, motor branch-circuit and

feeder conductors and their protection, motor overload protection,

BET 31: INDUSTRIAL AC MOTOR CONTROL

You might also like

- Power Electronics: Lecture Notes of Power Electronics CourseFrom EverandPower Electronics: Lecture Notes of Power Electronics CourseNo ratings yet

- Activity 5 Motor Control Components Familiarization and TestingDocument9 pagesActivity 5 Motor Control Components Familiarization and TestingCarlos Angelito MoralesNo ratings yet

- Information Sheet # 1: Ilocos Sur Polytechnic State CollegeDocument10 pagesInformation Sheet # 1: Ilocos Sur Polytechnic State CollegeJopetNo ratings yet

- Basic of Motor Control CentersDocument76 pagesBasic of Motor Control CentersParasPatel80No ratings yet

- Mech - DrivesDocument89 pagesMech - DrivesankurNo ratings yet

- PPT1-Inroduction To PLC and Relay SystemDocument51 pagesPPT1-Inroduction To PLC and Relay SystemKAILA FUNTANILLANo ratings yet

- Technical Guidebook 1 10 en RevfDocument446 pagesTechnical Guidebook 1 10 en RevfTfelx CflexNo ratings yet

- ABB Technical Guide No 1 REVCDocument36 pagesABB Technical Guide No 1 REVCVijay KumarNo ratings yet

- ELC 311 (2022 - 2023) Motor ControllerDocument13 pagesELC 311 (2022 - 2023) Motor ControllerChristian CanabeNo ratings yet

- Waijung Blockset-STM32F4 Environment For Real Time Induction Motor Speed ControlDocument7 pagesWaijung Blockset-STM32F4 Environment For Real Time Induction Motor Speed ControlHưng NguyễnNo ratings yet

- AVR PrivateDocument2 pagesAVR PrivateChung NguyenNo ratings yet

- MCC 1Document14 pagesMCC 1Arif SugestyanNo ratings yet

- ABB Drives Technical Guide BookDocument446 pagesABB Drives Technical Guide Bookمحمد زينايNo ratings yet

- Electric Motor 6Document20 pagesElectric Motor 6abdulkadhir100% (1)

- Motor Control CenterDocument81 pagesMotor Control CenterMohamed Mohamed100% (2)

- Project Reprt333Document49 pagesProject Reprt333dhirajsingh_avit83% (6)

- Siemens Motor - Control - CentersDocument80 pagesSiemens Motor - Control - Centersmarf123No ratings yet

- Speed Control of A 2HP DC MotorDocument25 pagesSpeed Control of A 2HP DC MotorEdul BrianNo ratings yet

- Electric Motors Reference GuideDocument166 pagesElectric Motors Reference GuideYashveer100% (2)

- Electric Motors Reference GuideDocument166 pagesElectric Motors Reference GuideHemendra Jani100% (1)

- Basics of Motor Control CentersDocument72 pagesBasics of Motor Control CentersRaihanKhan100% (1)

- Digital Motor Control 1-Day Workshop Student GuideDocument188 pagesDigital Motor Control 1-Day Workshop Student GuideAndualemNo ratings yet

- ABC Relay Coordination GuideDocument96 pagesABC Relay Coordination GuiderubenvasquesNo ratings yet

- Unit 61 Features and Applications of Electrical MachinesDocument11 pagesUnit 61 Features and Applications of Electrical MachinesHaris BaigNo ratings yet

- Activity 1 SafetyDocument6 pagesActivity 1 SafetyCarlos Angelito MoralesNo ratings yet

- Technical Guide ABB EMERSON EDUARDO RODRIGUESDocument222 pagesTechnical Guide ABB EMERSON EDUARDO RODRIGUESEmerson Eduardo RodriguesNo ratings yet

- ABBDrives TechnicalGuideBook PDFDocument446 pagesABBDrives TechnicalGuideBook PDFDoDuyBacNo ratings yet

- ABB Technical Guide 1 - Direct Torque ControlDocument32 pagesABB Technical Guide 1 - Direct Torque ControlASM_213No ratings yet

- MCC 1Document13 pagesMCC 1www.otomasyonegitimi.comNo ratings yet

- TechnicalGuideBook DRIVES ABBDocument442 pagesTechnicalGuideBook DRIVES ABBAngel Dimaria100% (1)

- Principles of Electric Motor Control in 40 CharactersDocument19 pagesPrinciples of Electric Motor Control in 40 Charactersolanvillegas2003No ratings yet

- Electrical Industry Guide to AC and DC Motor ControlDocument1 pageElectrical Industry Guide to AC and DC Motor ControlJohn Christian EstrelladoNo ratings yet

- Direct Torque Control: Technical Guide No. 1Document32 pagesDirect Torque Control: Technical Guide No. 1vthiyagain100% (1)

- Application Guidelines For Instantaneous-Trip Circuit Breakers in Combination Motor Starters PDFDocument8 pagesApplication Guidelines For Instantaneous-Trip Circuit Breakers in Combination Motor Starters PDFRajuNo ratings yet

- MeasurementBestPractices WillwerthHammond 0612Document18 pagesMeasurementBestPractices WillwerthHammond 0612andres monederoNo ratings yet

- Colegio de San Juan de Letran - Calamba: Motor Control Center (MCC)Document20 pagesColegio de San Juan de Letran - Calamba: Motor Control Center (MCC)ELLAINE DE CLARONo ratings yet

- University Institute of Engineering Department of Academic UnitDocument41 pagesUniversity Institute of Engineering Department of Academic UnitAkhil SainiNo ratings yet

- Nema-Application-guidefor AC Adjustable Speed Drive SystemsDocument10 pagesNema-Application-guidefor AC Adjustable Speed Drive Systemsshadi22No ratings yet

- Aman_powertrainev_electricalDocument12 pagesAman_powertrainev_electricalsebecay203No ratings yet

- Electrical Drives and Controls - 0Document172 pagesElectrical Drives and Controls - 0samuel yegzawNo ratings yet

- Final PDF EditedDocument6 pagesFinal PDF EditedFirdous NaazNo ratings yet

- Actuators and Drive SystemDocument58 pagesActuators and Drive Systemdanilopangatungan8No ratings yet

- Basic Principles of Motor Controls: Unit 1-IntroductionDocument8 pagesBasic Principles of Motor Controls: Unit 1-IntroductionMoustafa MahmoudNo ratings yet

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Electrical Motor Products: International Energy-Efficiency Standards and Testing MethodsFrom EverandElectrical Motor Products: International Energy-Efficiency Standards and Testing MethodsNo ratings yet

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Namma Kalvi 12th Maths Book Back and Creative Questions em 219383Document185 pagesNamma Kalvi 12th Maths Book Back and Creative Questions em 219383TharaneshNo ratings yet

- Al KynesDocument12 pagesAl KynesjolanpascualNo ratings yet

- Easytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFDocument10 pagesEasytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFСергей Заика100% (1)

- Development of Female Genital Tract and Its AnomaliesDocument44 pagesDevelopment of Female Genital Tract and Its AnomaliesSuresh KatakamNo ratings yet

- Panasonic Conduit CatalogDocument8 pagesPanasonic Conduit CatalogAhmed Said100% (2)

- Max Out On Squats Every Day PDFDocument7 pagesMax Out On Squats Every Day PDFsamsung684No ratings yet

- Ball Pen Canvas Painting Exhibition MumbaiDocument19 pagesBall Pen Canvas Painting Exhibition Mumbaiapi-25885725No ratings yet

- Plant Associated Biofilms: Causes and ConsequencesDocument32 pagesPlant Associated Biofilms: Causes and ConsequencesGarima DhirNo ratings yet

- Industrial Training IntroductionDocument1 pageIndustrial Training Introductionsgurjar07No ratings yet

- Aryatech Brochure IndiaDocument12 pagesAryatech Brochure IndiaHari RamNo ratings yet

- Tesla Inc. Analysis: Industry, Strategy, Governance, Financials & 5-Year ForecastDocument29 pagesTesla Inc. Analysis: Industry, Strategy, Governance, Financials & 5-Year ForecastAditya JandialNo ratings yet

- March 31-Drugs PDFDocument10 pagesMarch 31-Drugs PDFfan-a-tykNo ratings yet

- Deltopectoral Approach to the ShoulderDocument28 pagesDeltopectoral Approach to the ShoulderChrysi TsiouriNo ratings yet

- Datasheet GenDocument2 pagesDatasheet GenEdgar Bonilla MuñozNo ratings yet

- Table Napkin Folding TechniquesDocument6 pagesTable Napkin Folding TechniquesMiguel BaricuatroNo ratings yet

- English 8-Quiz On Context CluesDocument2 pagesEnglish 8-Quiz On Context CluesMELINDA FERRERNo ratings yet

- Chapter2 AligningSelectionProjectsDocument36 pagesChapter2 AligningSelectionProjectsZeynep SenerNo ratings yet

- Minimizing Penalty in Industrialpower Factor Correction by Engaging Apfc UnitDocument15 pagesMinimizing Penalty in Industrialpower Factor Correction by Engaging Apfc UnitabellNo ratings yet

- NCERT Solutions For Class 8 Science Chapter 6Document4 pagesNCERT Solutions For Class 8 Science Chapter 6D Rong saNo ratings yet

- Electrical Estimating Forms and DiagramsDocument48 pagesElectrical Estimating Forms and Diagramsjanmczeal100% (3)

- Operations ManualDocument534 pagesOperations ManualAlthea Joy Castor SobretodoNo ratings yet

- Dynamic Simulation of Insulin-Glucose Interaction in Type 1 Diabetes With MATLAB Simulink®Document11 pagesDynamic Simulation of Insulin-Glucose Interaction in Type 1 Diabetes With MATLAB Simulink®Jonas KristantoNo ratings yet

- Upper Gastro Intestinal BleedingDocument13 pagesUpper Gastro Intestinal BleedingmuniningmicanNo ratings yet

- Electronic Control Module (ECM) : Shutdown SIS Previous ScreenDocument5 pagesElectronic Control Module (ECM) : Shutdown SIS Previous ScreenWladimir AmaguañaNo ratings yet

- Dolphin Facts For Kids Ilovepdf CompressedDocument1 pageDolphin Facts For Kids Ilovepdf CompressedtechboostmrktgNo ratings yet

- DR Vatsal Patel AhmedabadDocument30 pagesDR Vatsal Patel AhmedabadSayali PhansekarNo ratings yet

- HeavyMetalLimits For Leachability PROP 65 PB and CDDocument3 pagesHeavyMetalLimits For Leachability PROP 65 PB and CDspades24kNo ratings yet

- Building Schedule 050721Document6 pagesBuilding Schedule 050721Parth DaxiniNo ratings yet

- Amplifiers and OscillatorsDocument109 pagesAmplifiers and OscillatorsAdilNo ratings yet

- Sample Final OutputDocument3 pagesSample Final OutputRey Dominique VillarNo ratings yet