Professional Documents

Culture Documents

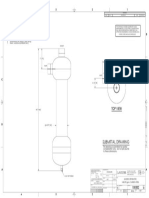

ST80 ST100 ST100A 1 Inch NPT Compression Fitting 4872c

Uploaded by

Tran Thuan TranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST80 ST100 ST100A 1 Inch NPT Compression Fitting 4872c

Uploaded by

Tran Thuan TranCopyright:

Available Formats

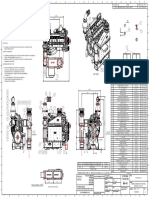

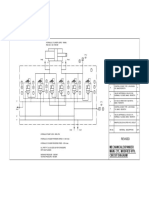

8 7 6 5 4 3 2 1

NOTICE OF PROPRIETARY RIGHTS REVISION

REV DESCRIPTION DATE

This document contains confidential technical data, including trade secrets and proprietary

information, which is the property of Fluid Components International LLC (FCI). Disclosure

of this data to you is expressly conditional upon your assent that its use is limited to

use within your company only (and does not include manufacture or processing uses).

C ECN006085 12/12/2018

Any other use is strictly prohibited without prior written consent of FCI.

PROCESS CONNECTION

OPTIONAL 3/4 INCH NPT OR 1 INCH NPT

.88

LOCAL ENCLOSURE MEETS EXPLOSION PROOF, "FP" STYLE HEAD 22

WATER AND DUST TIGHT APPROVALS. 6. COMPRESSION FITTING

(SEE MANUAL FOR SPECIFIC APPROVIAL TYPES) OPTIONAL TEFLON OR METAL FERRULE VERTICAL

D FLOW ORIENTATION D

MOUNTING ORIENTATION OF FLATS SHOWN

TO BE PARALLEL TO FLOW

FLOW ELEMENT ASSEMBLY 8.

"S" STYLE HEAD .80

2X 1/2 INCH NPT 20

OR M20X1.5

3.90 MAX

99 HORIZONTAL

FLOW ORIENTATION

.88 SHOWN

"FPC" STYLE HEAD 22

3.27 3.54

83 90

GROUND SCREW 8.00 MAX 7.

"U" LENGTH

C 203 C

Y

7.75

SPECIFICATIONS

REMOTE ENCLOSURE MEETS 5.00 4X 1/2 INCH NPT

REMOTE ELECTRONICS ASSEMBLY

197

EXPLOSION PROOF, WATER 127 OR M20X1.5

AND DUST TIGHT APPROVALS.

(SEE MANUAL FOR SPECIFIC

APPROVIAL TYPES) Customer:

Purchase Order No:

5.00

Customer Order No:

127 Wetted Surface Material:

Max Operating Temp:

M4 GROUND SCREW Max Operating Pressure:

Process Connection:

OPTIONAL DISPLAY X

Ferrule Type:

B U Length: B

4X .31 Serial No:

8 Tag No:

2X M4 SCREWS 2X 2.88 2X 4.25

4X .40

10 73 108

MOUNTING BRACKET

8. QUANTITY OF TWO (2) FLOW ELEMENT ASSEMBLIES PROVIDED FOR ST102A AND ST102AA MODELS. .25 2X 1.44 2X 1.75 2X .75

6 37 44 19

7. MAXIMUM DIMENSION WHEN FLOW ELEMENT IS INSTALLED TO CUSTOMER REQUIRED

"U" LENGTH 2X 2.25

Z

57

6. COMPRESSION FITTING SPECIFICATIONS:

- TEFLON FERRULE: 150 PSIG [10 BAR(G)] MAX; 200 F [93 C] MAX. 2.22 2.80

- METAL FERRULE: 1000 PSIG [69 BAR(G)] MAX; 500 F [260 C] MAX. 57 71

5. SEE IO&M MANUAL FOR ADDITIONAL INFORMATION AND INSTRUCTION.

OUTLINE/INSTALLATION DRAWING

UNLESS OTHERWISE SPECIFIED APPROVALS APPROVALS ® FLUIDCOMPONENTS

A 4. ALL ORIENTATIONS AND/OR MOUTING REFERENCES ARE INDICATED FROM TERMINAL ALUMINUM SST DIMENSIONS ARE IN INCHES PRODUCT CERT APVL DRAWN 4/9/2019

INTERNATIONAL LLC A

ENCLOSURE END OF SENSING ELEMENT. TOLERANCES

N/A Fouad Chirar

X 11.00 13.00 DECIMALS ANGULAR CONTRACT CHECK

SAN MARCOS, CA 92078

4/9/2019

TITLE

3. FOR ELECTRICAL OPTIONS, CONNECTIONS AND TESTS, SEE APPLICABLE WIRING Y 7.00 9.25 .X .1 1/2

N/A Matt Hall

DIAGRAM. NEXT ASSY USED ON

.XX

.XXX

.03

.010 MFG ENGR ENGR 4/9/2019 TRANSMITTER, ST100, ST80 & ST100A SERIES

Z 4.50 6.75 MATERIAL N/A Fouad Chirar COMPRESSION FITTING

2. THIS DRAWING IS REFERENCE DOCUMENT ONLY. APPLICATION MATL MGMT ENGR

N/A N/A HAZARDOUS LOCATION, REMOTE

1. DIMENSIONS IN BRACKET [ ] ARE IN MILLIMETERS. THIRD ANGLE PROJECTION MACH SURFACE MACH RAD SIZE CAGE CODE DWG NO. REV

FINISH: 125 RMS MAX .030

MFG AERO QUAL

N/A N/A D 64818 004872 C

NOTES: UNLESS OTHERWISE SPECIFIED DO NOT SCALE DRAWING

QA 4/9/2019 NUC QUAL

PARTS TO BE FREE OF BURRS & SHARP EDGES

Burt Tanaka N/A

SCALE NONE SHEET 1 OF 1

8 7 6 5 4 3 2 1

You might also like

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- DWGDocument13 pagesDWGgz.wss100% (1)

- Especificaciones Compresor Centac C700Document2 pagesEspecificaciones Compresor Centac C700Ascencio RubenNo ratings yet

- HT 300 Perfil BajoDocument7 pagesHT 300 Perfil BajoJuan SanchezNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Ilb 0300Document1 pageIlb 0300Gary Tarqui MagneNo ratings yet

- Time Delay Sensitivity Housing Cable Entry: Production 712906Document2 pagesTime Delay Sensitivity Housing Cable Entry: Production 712906Arjun BharambeNo ratings yet

- Foam System Line Proportioners: ApplicationDocument4 pagesFoam System Line Proportioners: ApplicationHarry NovaniNo ratings yet

- Sketch 4Document1 pageSketch 4Mujahid AyyubNo ratings yet

- Sy Tail ID ReportDocument4 pagesSy Tail ID ReportEr Ankush HipparkarNo ratings yet

- P27-1040 Switch - Eaton PNsDocument3 pagesP27-1040 Switch - Eaton PNsDiego LiraNo ratings yet

- Cd12-24 RPF Hardware List FullDocument1 pageCd12-24 RPF Hardware List FullinayahNo ratings yet

- NAS1351Document4 pagesNAS1351mxNo ratings yet

- Released: Iso View Back SCALE 1:30Document6 pagesReleased: Iso View Back SCALE 1:30Mohammed Saleem Syed KhaderNo ratings yet

- 12 Volt Hydraulic Pump Mte 4850 PDFDocument1 page12 Volt Hydraulic Pump Mte 4850 PDFpurnomo100% (1)

- Revisions C: D REVISED PER ECO-14-005095 AP RP E REVISED PER ECO-16-008845 AP RPDocument1 pageRevisions C: D REVISED PER ECO-14-005095 AP RP E REVISED PER ECO-16-008845 AP RPreza_azadNo ratings yet

- DSH in 621 3Document13 pagesDSH in 621 3Procurement PardisanNo ratings yet

- C139GAE40EDocument1 pageC139GAE40EdwikuNo ratings yet

- DMR 25 NIL3N-5 6 Feb 2017 PDFDocument4 pagesDMR 25 NIL3N-5 6 Feb 2017 PDFFrambia Rachmat0% (1)

- Rim Seal Pourer Data SheetDocument3 pagesRim Seal Pourer Data Sheetadilmomin45No ratings yet

- Customer's Installation: Table of Components Mark Description GridDocument1 pageCustomer's Installation: Table of Components Mark Description GridcristianNo ratings yet

- D92-1026.tarea 11-3.HARN - ENG PX9 2013 BCDocument5 pagesD92-1026.tarea 11-3.HARN - ENG PX9 2013 BCmarioNo ratings yet

- Attachment No. 01 - Tank Design SummaryDocument1 pageAttachment No. 01 - Tank Design SummarySANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Revisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFDocument1 pageRevisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFMarcos MoraisNo ratings yet

- 0420 - 118T3440 - Cooling WaterDocument2 pages0420 - 118T3440 - Cooling WaterfaisalnadimNo ratings yet

- JB5000 Drawing-SK3015-1067 RoundDocument1 pageJB5000 Drawing-SK3015-1067 Roundcarloncho1980No ratings yet

- Led110 112 114 D101 RevaDocument3 pagesLed110 112 114 D101 Revasaifasqalani39No ratings yet

- VenturiDocument4 pagesVenturilipetrol007100% (1)

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- Notes:: Trans Serv DRY WETDocument2 pagesNotes:: Trans Serv DRY WETErissonNo ratings yet

- Tampak Dan PotonganDocument1 pageTampak Dan Potonganmorning loverNo ratings yet

- Rosemount 3308 Wireless Level Radar and Liquid Level Transmitter Process Connection TypesDocument3 pagesRosemount 3308 Wireless Level Radar and Liquid Level Transmitter Process Connection TypesUsman AliNo ratings yet

- Foam System Line Proportioners: ApplicationDocument4 pagesFoam System Line Proportioners: ApplicationMohammed SayedNo ratings yet

- XOS-05.250-047-10001 Rev 0Document1 pageXOS-05.250-047-10001 Rev 0Dinesh YkatilNo ratings yet

- 8 - 6F Ah-5vcrDocument1 page8 - 6F Ah-5vcrMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Proprietary & Confidential: This Is A Static Sensitive Device. Handle & Store Appropriately To Prevent Esd DamageDocument2 pagesProprietary & Confidential: This Is A Static Sensitive Device. Handle & Store Appropriately To Prevent Esd DamagePawan PalNo ratings yet

- P825031 PyrobanDocument4 pagesP825031 PyrobanLAryo YogisworoNo ratings yet

- 5R55W Automatic Transmission (2002) : Forward ClutchDocument1 page5R55W Automatic Transmission (2002) : Forward Clutchyomi cabreraNo ratings yet

- e C7328 - 1F PDFDocument6 pagese C7328 - 1F PDFmina fawzyNo ratings yet

- 1595 GadDocument1 page1595 GadAnonymous X3PnFL6No ratings yet

- LP008Document20 pagesLP008Rojas RudyNo ratings yet

- 6inch + 2inch Gooseneck + ConnectorDocument2 pages6inch + 2inch Gooseneck + ConnectorJohnsonNo ratings yet

- Plano de Blindaje 24MDocument2 pagesPlano de Blindaje 24MAndree Ayma NuñezNo ratings yet

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumar100% (1)

- Certified: 3/23/2021 Garrett BinnsDocument1 pageCertified: 3/23/2021 Garrett Binnsjose luis rios guerraNo ratings yet

- No. Description Oper Date: Production Routing ChartDocument2 pagesNo. Description Oper Date: Production Routing Chartpubg loversNo ratings yet

- R81596, Air SchematicDocument4 pagesR81596, Air SchematicDXvikoNo ratings yet

- Atlantic Version: Applicator Data ODocument4 pagesAtlantic Version: Applicator Data OChung LeNo ratings yet

- Manual de Instalación y Operación Compas Autohelm ST 30 CompDocument39 pagesManual de Instalación y Operación Compas Autohelm ST 30 ComppevalpevalNo ratings yet

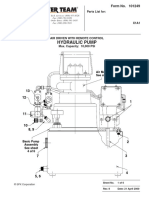

- Hydraulic Pump: Parts List ForDocument12 pagesHydraulic Pump: Parts List Forleonardo leaoNo ratings yet

- 12-10G GH-3VCMDocument1 page12-10G GH-3VCMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 02 - SIDE CONN BOTTOM OP-ModelDocument1 page02 - SIDE CONN BOTTOM OP-ModelAshfaqNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- Mechanical SealDocument1 pageMechanical SealVaibhav KaleNo ratings yet

- Rev 1 10-4-2019 PDFDocument1 pageRev 1 10-4-2019 PDFOrlando GamboaNo ratings yet

- Plantilla HT24 Ansi-2013Document4 pagesPlantilla HT24 Ansi-2013servicio5No ratings yet

- LSAW-2 Expander Main Cylinder Revised Hyd. Circuit Diagram-ModelDocument1 pageLSAW-2 Expander Main Cylinder Revised Hyd. Circuit Diagram-ModelshubhamNo ratings yet

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Document3 pagesType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatNo ratings yet

- Typical Joint Box With U-Ditch: Weephole DetailDocument1 pageTypical Joint Box With U-Ditch: Weephole DetailAbid AyubNo ratings yet

- SAP Environment, Health, and Safety (EHS)Document13 pagesSAP Environment, Health, and Safety (EHS)SAFETY VOFPLNo ratings yet

- What Is Public RelationsDocument52 pagesWhat Is Public RelationsMarwa MoussaNo ratings yet

- 1 Lesson Plan Self Assessment 1Document1 page1 Lesson Plan Self Assessment 1Neha SharmaNo ratings yet

- DLL - English 5 - Q3 - W8Document8 pagesDLL - English 5 - Q3 - W8Merlyn S. Al-osNo ratings yet

- Distribution of Continuous R.V.: Normal Distribution (CH 1.4) TopicsDocument7 pagesDistribution of Continuous R.V.: Normal Distribution (CH 1.4) TopicsPhạm Ngọc HòaNo ratings yet

- Dashrath Nandan JAVA (Unit2) NotesDocument18 pagesDashrath Nandan JAVA (Unit2) NotesAbhinandan Singh RanaNo ratings yet

- Shot Blasting Machine ApplicationsDocument7 pagesShot Blasting Machine ApplicationsBhavin DesaiNo ratings yet

- 27 Points of Difference Between Personnel Management & HRDDocument2 pages27 Points of Difference Between Personnel Management & HRDMurtaza Ejaz33% (3)

- CNNPX310R-6P: General SpecificationsDocument5 pagesCNNPX310R-6P: General SpecificationsZoheir KacimiNo ratings yet

- Debate Lesson PlanDocument3 pagesDebate Lesson Planapi-280689729No ratings yet

- Medha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Document2 pagesMedha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Varaprasad KanugulaNo ratings yet

- Birth Trauma and Post Traumatic Stress Disorder The Importance of Risk and ResilienceDocument5 pagesBirth Trauma and Post Traumatic Stress Disorder The Importance of Risk and ResilienceMsRockPhantomNo ratings yet

- Operation ManagementDocument4 pagesOperation ManagementHananiya GizawNo ratings yet

- Eea2a - HOLIDAY HOMEWORK XIIDocument12 pagesEea2a - HOLIDAY HOMEWORK XIIDaksh YadavNo ratings yet

- Slem Descriptive EssayDocument2 pagesSlem Descriptive EssayMary Jane DingalNo ratings yet

- Starex Is BTSDocument24 pagesStarex Is BTSKLNo ratings yet

- Solutions Jet FuelDocument4 pagesSolutions Jet FuelkevinNo ratings yet

- OMM807100043 - 3 (PID Controller Manual)Document98 pagesOMM807100043 - 3 (PID Controller Manual)cengiz kutukcu100% (3)

- Inqlusive Newsrooms LGBTQIA Media Reference Guide English 2023 E1Document98 pagesInqlusive Newsrooms LGBTQIA Media Reference Guide English 2023 E1Disability Rights AllianceNo ratings yet

- Milestone BillingDocument3 pagesMilestone BillingJagadeesh Kumar RayuduNo ratings yet

- Lecture No. 11Document15 pagesLecture No. 11Sayeda JabbinNo ratings yet

- Chapter 4 Seepage TheoriesDocument60 pagesChapter 4 Seepage Theoriesmimahmoud100% (1)

- CYPE 2021 + CYPE ArchitectureDocument15 pagesCYPE 2021 + CYPE ArchitectureHajar CypeMarocNo ratings yet

- Yaskawa V7 ManualsDocument155 pagesYaskawa V7 ManualsAnonymous GbfoQcCNo ratings yet

- RRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestDocument46 pagesRRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestBharat KumarNo ratings yet

- Busbusilak - ResearchPlan 3Document4 pagesBusbusilak - ResearchPlan 3zkcsswddh6No ratings yet

- Consequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentDocument11 pagesConsequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentAlliah Kate SalvadorNo ratings yet

- Program Need Analysis Questionnaire For DKA ProgramDocument6 pagesProgram Need Analysis Questionnaire For DKA ProgramAzman Bin TalibNo ratings yet

- Calculus of Finite Differences: Andreas KlappeneckerDocument30 pagesCalculus of Finite Differences: Andreas KlappeneckerSouvik RoyNo ratings yet

- Study On The Form Factor and Full-Scale Ship Resistance Prediction MethodDocument2 pagesStudy On The Form Factor and Full-Scale Ship Resistance Prediction MethodRaka AdityaNo ratings yet