Professional Documents

Culture Documents

M.S and High Tensile Nuts and Bolts

Uploaded by

jamil vora0 ratings0% found this document useful (0 votes)

12 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views5 pagesM.S and High Tensile Nuts and Bolts

Uploaded by

jamil voraCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

18

M.S. And High Tensile Nuts And Bolts

PRODUCT CODE : 343201011

QUALITY AND STANDARDS : IS 1363:1992

IS 1367:1994

IS 2389:1968

IS 4206:1987

PRODUCTION CAPACITY : Qty. : 360 M.T. (Per annum)

Value : Rs. 115.5 Lakhs

PREPARED BY : Small Industries Service Institute

Industrial Estate, Kokar,

Ranchi - 834 001 (Jharkhand)

Telephone Nos. : 2544161, 2544392

Fax: (0651) 2544419

E-mail: rch_sisirnc@sancharnet.in

INTRODUCTION material is mild steel wire coil/rod of

required diameter. The composition of

An industrial fastener comprises a materials controls the quality of the

very wide range of items like nuts and bolts and nuts. The recommended

bolts, washers, studs, nails etc. Nuts and composition for nuts and bolts raw

bolts consist a major link in the family material is given as under:

of industrial fasteners and are used by

Carbon 0.22 to 0.23%

every industry. Bolt is a piece of metal

rod, whose one end is upsettled and Phosphorus 0.40%

other end is threaded. Nut is the item Manganese 0.39 to 0.60%

which rolls on these threads. Nut and

bolts are available in various shapes, Sulphur 0.50%

designs and sizes. Nuts and bolts are classified by two

Nuts and bolts are used for fastening ways: i) Their uses, ii) Shape of head.

p u r p o s e in i n d u s t r i e s w h e r e t he In terms of use, nuts and bolts are of

replacement of pieces and the parts is several types:

necessary. There are many industries Larger dia bolts, machine bolts, stand

producing these nuts and bolts of bolts, joint bolts, foundation bolts and

various sizes, but the demand too is nuts etc. in terms of shape, bolt and

increasing as well as the raw material nuts are classified by head shape like

for t h e p r o d u c t s is e a s i l y and hexagonal head, square head, round

indigenously available. The main raw head, pan head, truss head etc.

MARKET POTENTIAL 8. Cost of machinery and equipment is

approximate to that prevailing in the

The demand of nuts and bolts is market.

influenced by the following factors:

a) Trans portatio n industries, IMPLEMENTATION SCHEDULE

Railways , aircraft, wagon,

bicycles, automobile, body Sl.No. Activity Period In Weeks

builders, etc. 1. Selection of site 2

b) Electrical industries like 2. Preparation of project report 4

manufacturing of transfor mer,

3. Provisional Registration 1

electric motors, fans etc.

4. Financial arrangement 8

c) Buildin g a c tiv ities s uc h as

cons tructio n of bridges, 5. Procurement of machinery 8

fabricatio n of various steel 6. Installation, electrification and 6

structure etc. commissioning of machinery

d) Other heavy and light industries, 7. Selection and placement of staff 2

steel and wooden fur nitures, 8. Procurement of raw materials, 2

machine tools, agricultural tools etc.

mach in es an d agricultural Total 33 weeks

implements etc.

As various type of MS and HT nuts TECHNICAL ASPECTS

and bolts are used in above sectors, the

market demand is directly proportionate Process of Manufacture

to the development of these industrial The raw material used for

segments. manufacture of bolt is M.S. Rounds.

As some of the rounds available are

B ASIS AND PRESUMPTIONS rusty and not perfectly round and

1. Capacity Utilisation : 75% on single straight, it is necessary to make them

shift basis round. The rounds are pickled in the

acid tanks, washed and drawn in a

2. Time period of 1 year : 300 days

drawing machine. The cleaned rod is

3. Labour wages : Estimated on fed into the cold heading machine.

the minimum In the machine, one end of the rod

wages

is cut into the desired length with

4. Rate of interest : 16% cutting stroke and simultaneously the

5. Margin money 25% varying head for mation takes at other end.

from state to For the HT bolts, forging is done on

state hot forging press. The pins are then

6. Operation period of : 10 Years trimmed in the trimming machine. In

project quality bolts, the lower side of the

7. Rental charges for : 8,000 head is also faced. Threading is done

land and building per month in the thread rolling machines.

While manufacturing nuts, the Quality Control and Standards

hexa g ona l rod of d es i re d size is The Bureau of Indian Standards has

procured and the nuts are cut on the laid down the following quality standards

automatic nut-cutting machine. Cutted for M.S. and High tensile fasteners such

nuts blanks are drilled and tapped on as Bolts and Nuts:

the nut-tapping machine. Finally, these

IS 1363 : 1992

are deburred in the polishing barrel.

Process Flow Chart (M.S. Bolts) IS 1367 : 1994

IS 4206 : 1987

Mild steel rod

Production Capacity

Bolt cutting Quantity Value (In Rs.)

Nuts and Bolts of various 1,15,50,000

Head making sizes- 360 MT

Motive Power 85 HP.

Head trimming

Pollution Control

Thread rolling This industry involves pollution to

some extent for which State Pollution

Polishing Control Board has to be approached.

Store/despatch Energy Conservation

The unit is equipped with electric

Process Flow Chart (H.T. Bolts) pow ere d machinery. The energy

Mild steel rod conservation efforts need in unit is the

creation of awareness among the

Wire drawing workers.

Bolt cutting FINANCIAL ASPECTS

Forging A. Fixed Capital

( i ) Land and Building (Rs.)

Trimming Covered area 1600 sq. mtr. 8,000

Threading (ii) Machinery and Equipment (per month)

Sl. Description Qty. Total

Heat treatment (800OC - 900OC) No. (In Rs.)

1. Double stroke solid die cold 1No. 7,00,000

Tempering (400OC - 500OC) head forging machine suitable

for bolt dia 6 mm to 18 mm

and length 20 mm to 150 mm

Plating/Coating with 15 HP electric motor

2. Head trimming machine upto 1No. 4,70,000

18 mm dia bolt x 150 mm

Store/despatch

(ii) Raw Material (Indigenous)

Sl. Description Qty. Total

No. (In Rs.)

Sl. Particulars Qty. Amount

length with 10 HP electric No. (In Rs.)

motor

1. M.S. Wire/rod 6mm - 19.25 MT 3,46,500

3. Thread rolling machine suitable 1 No. 4,20,000 18mm dia

for upto 18 mm dia bolt x @ Rs.18,000/ MT

length 150 mm with 15 HP

electric motor 2. Hexagonal M.S. 10.75 MT 1,98,875

rod 6mm - 18mm dia

4. Bull block wire drawing 1 No. 1,00,000

@ Rs. 18,500 per MT

machine

3. Packing/Polishing L.S. 5,000

5. Wire pointing machine 1 No. 15,000

materials and

with 1 HP motor

consumables

6. Steel polishing barrel with 1 No. 45,000

Total 5,50,375

electric motor

Say 5,50,380

Nut Making Section

7. Automatic nut forming 4 Nos.12,50,000 (iii) Utilities (In Rs.)

plant, five station capacity

18 mm dia with 25 HP motor, i) Electricity and Water 19,200

lubricant and coolant pump ii) Furnace oil, 6,000 ltrs. 81,000

8. Nut tapping machine with 4 Nos. 2,20,000 @Rs. 13.50 per ltr.

3 HP motor and stater

iii) Lubricant oil etc. 1,650

9. Semi muffle oil fired furnace 1 No. 1,55,000

Total 1,01,850

10. Tempering furnace H.T. air 1 No. 75,000

circulated type electrically

heated temp. upto 500OC (iv) Other Contingent Expenses (In Rs.)

3 KW rating 1. Rent 8,000

11. Die, tools guage and L.S. 1,50,000 2. Maintenance and repair 1,500

measuring instruments

3. Postage, stationery and phone 2,500

Electrification and 3,45,000

installation @ 10% 4. Packing and transport 3,000

Office equipment and furnitures 25,000

5. Travelling and conveyance 1,500

Total 39,70,000

6. Insurance 500

B. Working Capital (per month) 7. Miscellaneous expenses 1,000

(i) Personnel

Total 18,000

Sl. Designation No. Salary Total

No. (Rs.) (In Rs.) (v) Total Recurring Expenditure

[i + ii + iii + iv]

1. Manager 1 6,000 6,000

2. Office Assistant/clerk 1 3,200 3,200 = Rs. 45,540 + 5,50,380 + 1,01,850 + 18,000

= Rs. 7,15,770

3. Skilled worker 6 3,200 19,200

(vi) Total Working Capital for 3 months Rs. 21,47,310

4. Semi-skilled Worker 2 2,500 5,000

5. Un-skilled Worker 3 2,000 6,000 C. Total Capital Investment

6. Watchman-cum-Peon 1 2,000 2,000

(i) Fixed Capital Rs. 39,70,000

Total 41,400

(ii) Working Capital (for 3 months) Rs. 21,47,310

Perquisites @ 10% 4,140

Total 45,540 Total Rs. 61,17,310

B.E.P. = 17,64,250 × 100

FINANCIAL ANALYSIS 17,64,250 + 15,97,500

(1) Cost of Production (per annum) (In Rs.) = 52%

Total recurring cost 85,89,240 Addresses of Machinery and

Depreciation on machines and 3,79,500 Equipment Suppliers

equipments @ 10%

1. M/s. Sohal Engineering

Depreciation on office and 5,000

equipment @ 20% Corporation

61, Ganesh Chandra Avenue,

Interest on total Capital 9,78,760

Investment @ 16% Kolkata - 700013

Total 99,52,500 2. M/s. Perfect Machine Tools Co.

Pvt. Ltd.

(2) Total Sales (per annum) (In Rs.)

Bell Building,

(i) By sale of MS bolts 120 MT 36,00,000

@ Rs. 30 per kg. Sir P.M. Road,

Fort, Mumbai

(ii) By sale of MS nuts 60 MT 18,00,000

@ Rs. 30 per kg. 3. M/s. Manek Lal and Sons.

(iii) By sale of HT bolts 115 MT 36,80,000 23, Ganesh Chandra Avenue,

@ Rs. 32 per kg. Kolkata - 700 013

(iv) By sale of HT nuts 65 MT 24,70,000

@ Rs. 38 per kg. 4. M/s. Industrial Machine

Total 1,15,50,000

Corporation

F-36-C, Sainik Market,

(3) Profit (per year) Rs. 1,15,50,000 - 99,52,500

= Rs. 15,97,500 Main Road, Ranchi

(4) Net Profit Ratio on Sale 5. M/s. S.S. Sabarwal and Sons

= Net profit × 100 664, Military Road,

Turnover Anand Parbat Indl. Area,

= 15,97,500 × 100 New Delhi-110005

1,15,50,000

6. M/s. Kalihar Machine Tools

= 14%

(5) Rate of Return

Plot No. 18696/1,

= Net profit × 100 K.M. Singh St. No. 7,

Total investment Ludhiana

= 15,97,500 × 100 7. M/s. H. Mann Industries

61,17,310

Ram Tirath Road,

= 26%

Amritsar - 143 001

(6) Break-even Point

Addresses of Raw Material Suppliers

Fixed Cost (per annum) (In Rs.)

1. Rent 96,000 1. M/s. Usha Martin Industries

2. Depreciation on machinery and 3,79,500

Tatisilwai,

equipment Ranchi

3. Depreciation on office equipment 5,000 2. M/s. M. V. Wires Pvt. Ltd.

4. Interest on total investment 9,78,760 Poddar Estate,

5. 40% of salary and wages 2,18,590 Mahilong,

6. 40% of other contingent expenses 86,400 Ranchi,

Total 17,64,250 3. Local Market.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- M.S. and high tensile nuts bolts productionDocument5 pagesM.S. and high tensile nuts bolts productionscribddaduNo ratings yet

- Watch Strap Metallic ProductionDocument5 pagesWatch Strap Metallic ProductionalkaNo ratings yet

- ch22 PDFDocument5 pagesch22 PDFSumeet Singh KohliNo ratings yet

- Project Report On Galvanised Nut & BoltDocument6 pagesProject Report On Galvanised Nut & BoltEIRI Board of Consultants and PublishersNo ratings yet

- CH 21Document5 pagesCH 21Mr.vijay VaddiNo ratings yet

- Ms High Tensile Nuts and BoltsDocument11 pagesMs High Tensile Nuts and Boltsmax_ashi100% (1)

- ch23 PDFDocument4 pagesch23 PDFAnonymous NUn6MESxNo ratings yet

- Fastener ProjectDocument10 pagesFastener ProjectParam Saxena0% (1)

- Fme6 Activity2 PDFDocument7 pagesFme6 Activity2 PDFFred BorjaNo ratings yet

- Design and Fabrication of Ploughing MachineDocument6 pagesDesign and Fabrication of Ploughing MachineARUN V100% (1)

- Project ProfileDocument97 pagesProject ProfileRushang PatelNo ratings yet

- Irjet V5i1098Document5 pagesIrjet V5i1098Trieu Nguyen KhoaNo ratings yet

- High Tensile Nuts BoltsDocument10 pagesHigh Tensile Nuts BoltssagarhalappaNo ratings yet

- Project Report On MS and High Tensile Bolts and NutsDocument7 pagesProject Report On MS and High Tensile Bolts and NutsEIRI Board of Consultants and PublishersNo ratings yet

- ALUMINUM RIVET PRODUCTIONDocument9 pagesALUMINUM RIVET PRODUCTIONRiefqi AlviansyahNo ratings yet

- Wire Drawing Industry ProfileDocument10 pagesWire Drawing Industry ProfileSabhaya ChiragNo ratings yet

- Design of Gears For Drilling MachineDocument10 pagesDesign of Gears For Drilling MachineRohan Julian FrancisNo ratings yet

- Project Profile: Welding ElectrodesDocument6 pagesProject Profile: Welding ElectrodesAskan NarinNo ratings yet

- Pneumatic Sheet Metal CutterDocument6 pagesPneumatic Sheet Metal CutterRagos SegundoNo ratings yet

- Carbon Brush Performance On Slip RingsDocument6 pagesCarbon Brush Performance On Slip Ringstan.garcia.ramosNo ratings yet

- Experimental Investigation of Surface Roughness and Tool Wear of Machining Rolled AA7075 Aluminium Alloy Using Advanced Cutting ToolsDocument5 pagesExperimental Investigation of Surface Roughness and Tool Wear of Machining Rolled AA7075 Aluminium Alloy Using Advanced Cutting ToolsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cam Projectt.Document16 pagesCam Projectt.fu MozaNo ratings yet

- Self Tapping ScrewDocument12 pagesSelf Tapping Screwsanjay_lingotNo ratings yet

- Reinforced Concrete Lab AssignmentDocument10 pagesReinforced Concrete Lab AssignmentHamza JameelNo ratings yet

- Fatigue Analysis of Girth Gear of A Rotary DryerDocument16 pagesFatigue Analysis of Girth Gear of A Rotary DryertaghdirimNo ratings yet

- Workshop ManualDocument26 pagesWorkshop ManualHarender KumarNo ratings yet

- 1759 8536 1 PBDocument7 pages1759 8536 1 PBMohaiminul MimNo ratings yet

- Case StudyDocument49 pagesCase StudybachayadavNo ratings yet

- Automated Coil Trimming System For Wire Rod Mills in The Digital EraDocument10 pagesAutomated Coil Trimming System For Wire Rod Mills in The Digital EraJJNo ratings yet

- Design of Nail Making Machine For Various Industrial WorkDocument8 pagesDesign of Nail Making Machine For Various Industrial WorkHIMANI PALAKSHANo ratings yet

- Healthy BLDC Motor Simulation Using Finite Element Analysis-IJAERDV04I1073133Document12 pagesHealthy BLDC Motor Simulation Using Finite Element Analysis-IJAERDV04I1073133MiteshJadhavNo ratings yet

- Quality Tool Holders PartnerDocument81 pagesQuality Tool Holders PartnerbrineytoolingNo ratings yet

- DESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Document5 pagesDESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Tanishq ShettyNo ratings yet

- Automatic Spring Rolling Machine DesignDocument7 pagesAutomatic Spring Rolling Machine DesignNkongho JohnsonNo ratings yet

- Automobile Radiators - Cores PDFDocument8 pagesAutomobile Radiators - Cores PDFHagos AwetahegnNo ratings yet

- Design and Fabrication of 4-Stroke Solenoid Engine: International Research Journal of Engineering and Technology (IRJET)Document7 pagesDesign and Fabrication of 4-Stroke Solenoid Engine: International Research Journal of Engineering and Technology (IRJET)HRITIK VERMANo ratings yet

- AbstractDocument6 pagesAbstractVaibhav ShetiyaNo ratings yet

- Mechanical Engineering Lesson on Manufacturing TechnologyDocument143 pagesMechanical Engineering Lesson on Manufacturing TechnologySATYAJIT BEHERANo ratings yet

- On The Interference of Internal GearingDocument10 pagesOn The Interference of Internal GearingprasannaNo ratings yet

- High-Quality Wire Rod and Bar Production at YongXing Special Stainless SteelDocument12 pagesHigh-Quality Wire Rod and Bar Production at YongXing Special Stainless SteelJJNo ratings yet

- STEAM TURBINE BLADE DESIGN AND MATERIAL SELECTIONDocument14 pagesSTEAM TURBINE BLADE DESIGN AND MATERIAL SELECTIONKarun PonienNo ratings yet

- IJMTST08S0703Document8 pagesIJMTST08S0703N. P. JAGANNo ratings yet

- Literature Review On Manufacturing ProceDocument8 pagesLiterature Review On Manufacturing ProceanuragpugaliaNo ratings yet

- Key 2Document22 pagesKey 2Jury.rahulNo ratings yet

- ESMDocument10 pagesESM47 Bhushan BariNo ratings yet

- ch20Document7 pagesch20Hitesh TumsareNo ratings yet

- Bansal Institute of Engineering and Technology, LucknowDocument59 pagesBansal Institute of Engineering and Technology, LucknowSunnyVermaNo ratings yet

- Fast NerDocument10 pagesFast NerVenkatashanthi PNo ratings yet

- Experimental and Analysis of Welding Electrode Wire Straightening and Cutting MachineDocument14 pagesExperimental and Analysis of Welding Electrode Wire Straightening and Cutting MachineTarig shgool HagarNo ratings yet

- Processes Involved in Production of Aluminium Sheets: Department of Mechanical EngineeringDocument29 pagesProcesses Involved in Production of Aluminium Sheets: Department of Mechanical EngineeringSudeepHandikherkarNo ratings yet

- Technical Specification For Energy Efficient Pumpsets: Dakshin Haryana Bijli Vitran Nigam LimitedDocument8 pagesTechnical Specification For Energy Efficient Pumpsets: Dakshin Haryana Bijli Vitran Nigam LimitednatanNo ratings yet

- Cutting Speed OptimizationDocument14 pagesCutting Speed OptimizationCharles OndiekiNo ratings yet

- Design & Fabrication of 360° Flexible Drilling MachineDocument4 pagesDesign & Fabrication of 360° Flexible Drilling MachineSumit ShuklaNo ratings yet

- Nat Threadmills Pricelist RevDocument20 pagesNat Threadmills Pricelist RevBryan ComynsNo ratings yet

- Manufacturing of Turbo GeneratorsDocument19 pagesManufacturing of Turbo GeneratorsKeerthana Kola100% (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Annex Iv Eu Declaration of Conformity (No XXXX)Document1 pageAnnex Iv Eu Declaration of Conformity (No XXXX)jamil voraNo ratings yet

- Design Manufacture and Simulation of BalDocument82 pagesDesign Manufacture and Simulation of BalMEER MUSTAFA ALINo ratings yet

- Fasteners - Stainless SteelDocument10 pagesFasteners - Stainless Steeljamil voraNo ratings yet

- Astm D1894-14Document7 pagesAstm D1894-14Huỳnh Phúc NguyễnNo ratings yet

- MOdule H RequirementDocument8 pagesMOdule H Requirementjamil voraNo ratings yet

- Annex 1 Essential Safety RequirementDocument12 pagesAnnex 1 Essential Safety Requirementjamil voraNo ratings yet

- Nuts and BoltsDocument42 pagesNuts and Boltsjamil voraNo ratings yet

- Guide to competent bodies for material quality certificationDocument13 pagesGuide to competent bodies for material quality certificationJAFFERNo ratings yet

- StdoutDocument1 pageStdoutMohammed NourNo ratings yet

- New PED - tcm37-17564Document3 pagesNew PED - tcm37-17564jamil voraNo ratings yet

- Full Quality Assurance Certificate: L&T Valves LimitedDocument5 pagesFull Quality Assurance Certificate: L&T Valves Limitedjamil voraNo ratings yet

- 2014 68 Eu PDFDocument96 pages2014 68 Eu PDFAlienshow100% (1)

- Crawley Borough Council: Food ComplaintsDocument5 pagesCrawley Borough Council: Food Complaintsjamil voraNo ratings yet

- Readme 1Document1 pageReadme 1Jogn DebNo ratings yet

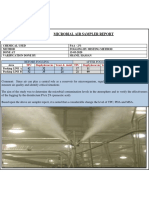

- A Study of Microbial Air Sample by PAA As DisinfectantDocument1 pageA Study of Microbial Air Sample by PAA As Disinfectantjamil voraNo ratings yet

- StdoutDocument1 pageStdoutMohammed NourNo ratings yet

- OCA - 095 Equipment Information Sheet-Handler - 181119Document1 pageOCA - 095 Equipment Information Sheet-Handler - 181119jamil voraNo ratings yet

- Data - of Best KindDocument4 pagesData - of Best Kindkt1996No ratings yet

- Food Safety Culture Module BrochureDocument8 pagesFood Safety Culture Module Brochurejamil voraNo ratings yet

- Accreditation of Certification Bodies: 4. Accreditation Criteria 4.1 Categories For AccreditationDocument39 pagesAccreditation of Certification Bodies: 4. Accreditation Criteria 4.1 Categories For AccreditationdemiNo ratings yet

- Guidelines For Certification of Grower Groups: 5.1 SCOPEDocument27 pagesGuidelines For Certification of Grower Groups: 5.1 SCOPEjamil voraNo ratings yet

- ASME VIII Div 1 Thickness FormulaDocument2 pagesASME VIII Div 1 Thickness Formulajamil voraNo ratings yet

- Food Safety Culture ExcellenceDocument5 pagesFood Safety Culture Excellencejamil voraNo ratings yet

- OCA - 115c - Initial Application (Processing & Trading) - 181119Document4 pagesOCA - 115c - Initial Application (Processing & Trading) - 181119jamil voraNo ratings yet

- OCA - 097 Product Flowinformation Sheet-Handler - 181119Document2 pagesOCA - 097 Product Flowinformation Sheet-Handler - 181119jamil voraNo ratings yet

- Thick Walled Cylinders (Corrected)Document17 pagesThick Walled Cylinders (Corrected)John Larry CorpuzNo ratings yet

- Project Plan Template: Project Conception and InitiationDocument5 pagesProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZNo ratings yet

- Project Plan Template: Project Conception and InitiationDocument5 pagesProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZNo ratings yet

- Product Launch Marketing PlanDocument17 pagesProduct Launch Marketing Planjamil voraNo ratings yet

- Specifications For Concrete Construction ACI 301-20: Field Reference ManualDocument6 pagesSpecifications For Concrete Construction ACI 301-20: Field Reference ManualIRFAN NAZIR50% (2)

- Turkstream Pipeline PrecommissioningDocument2 pagesTurkstream Pipeline PrecommissioningWayne BerreyNo ratings yet

- Hitachi - AssignmentDocument6 pagesHitachi - AssignmentPraveena IvanaNo ratings yet

- Catalog Pompe City PumpsDocument52 pagesCatalog Pompe City PumpsoanaNo ratings yet

- Digilocker VacDocument5 pagesDigilocker Vacanshikasgh3012No ratings yet

- The Design and Implementation of A Computer Based Testing System Using Component-Based Software EngineeringDocument8 pagesThe Design and Implementation of A Computer Based Testing System Using Component-Based Software EngineeringSalis KhanNo ratings yet

- How To Switch From Reactive Maintenance To Preventive Maintenance - Complete Transition GuideDocument18 pagesHow To Switch From Reactive Maintenance To Preventive Maintenance - Complete Transition GuidematshonaNo ratings yet

- 1 0 CustomerEngagement SalesContractManagement 2021Document15 pages1 0 CustomerEngagement SalesContractManagement 2021bilix76No ratings yet

- Adrián Lugo Bendezú (Senior, University of Puerto Rico Río Piedras Campus) Mentor: Tristan Goulden (AOP)Document1 pageAdrián Lugo Bendezú (Senior, University of Puerto Rico Río Piedras Campus) Mentor: Tristan Goulden (AOP)jpNo ratings yet

- Pre-Spud Checklist C-1Document2 pagesPre-Spud Checklist C-1Ericson OlaloNo ratings yet

- Oracle® Goldengate: Tutorial For Oracle To OracleDocument19 pagesOracle® Goldengate: Tutorial For Oracle To OracleNainika KedarisettiNo ratings yet

- Working With Geo Media ProfessionalDocument978 pagesWorking With Geo Media ProfessionalJacob WilliamsNo ratings yet

- Q400 Presentation - PowerplantDocument44 pagesQ400 Presentation - PowerplantTom100% (6)

- Jonathan F. Quiles Ii - Bsit - D Human Computer Interaction 2 Assignment #1Document6 pagesJonathan F. Quiles Ii - Bsit - D Human Computer Interaction 2 Assignment #1Jonathan QuilesNo ratings yet

- HR Service Delivery ReadinessDocument15 pagesHR Service Delivery ReadinessNoorNo ratings yet

- Automatic Weather StationDocument8 pagesAutomatic Weather StationMyat Tun OoNo ratings yet

- Final Report WDD3Document41 pagesFinal Report WDD3Laiba FaizNo ratings yet

- dvpns50p PDFDocument78 pagesdvpns50p PDFHanif Rathore PrinceNo ratings yet

- Cbna 13 4.2Document35 pagesCbna 13 4.2DAVID ALFONSO CARABALLO PATIÑONo ratings yet

- 4 Suspension BenchDocument5 pages4 Suspension BenchTecnicas Reunidas de AutomociónNo ratings yet

- 205-02 Rear Drive Axle and Differential - General Procedures - Ring Gear Backlash AdjustmentDocument14 pages205-02 Rear Drive Axle and Differential - General Procedures - Ring Gear Backlash AdjustmentCARLOS LIMADANo ratings yet

- Fourth Edition: Descriptive Analytics II: Business Intelligence and Data WarehousingDocument61 pagesFourth Edition: Descriptive Analytics II: Business Intelligence and Data WarehousingramhanNo ratings yet

- Autonomy IDOL Server Technical Brief 1204 Rev1Document6 pagesAutonomy IDOL Server Technical Brief 1204 Rev1Mark AldissNo ratings yet

- LabVIEW - FPGA Module User ManualDocument62 pagesLabVIEW - FPGA Module User ManualRajasekar PichaimuthuNo ratings yet

- Sonam - ResumeDocument2 pagesSonam - Resumesonam dangNo ratings yet

- Thinking ArchitecturallyDocument68 pagesThinking ArchitecturallyJose RojasNo ratings yet

- Soliman 2010Document5 pagesSoliman 2010rizkyseprinalfiNo ratings yet

- Sliit Academy: Higher National Diploma in Information Technology - Year 1, Semester 1Document23 pagesSliit Academy: Higher National Diploma in Information Technology - Year 1, Semester 1Minura AdikaramNo ratings yet

- LTE Parameter Templete Version 2 - 21072019Document402 pagesLTE Parameter Templete Version 2 - 21072019Maneesh rao0% (1)

- Ashish VermaDocument6 pagesAshish VermaAshish VermaNo ratings yet