Professional Documents

Culture Documents

SOP For Lane Cutting.

Uploaded by

suvojitroy20000 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

SOP for lane cutting.

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesSOP For Lane Cutting.

Uploaded by

suvojitroy2000Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

SOP for Lance cutting:

1. Before starting the job, safety talk is a must / PPE to be ensured.

2. Safety Requirement / Precautions:

a. Before starting the job at site, all the safety requirements like safety helmet, safety goggle,

face shield, overhaul, hand gloves, safety shoes, anklets, fire/ flame proof jacket, neck

guard, heat resistant visor, suitable fire extinguishers shall be decided as per the need of the

area/ site by the executing agency in association with safety officer and contractor. These

shall be documented.

3. POTENTIAL MAJOR HAZARDS:

a. Chance of fire / explosion

b. Metal burn

c. Fumes of un-burnt gases.

4. Pre-Requisites for Carrying Out Lance Cutting Work

a. Before carrying out lancing, make thorough inspection of the work place and ensure that it

is safe for lancing operations. Area where lance cutting work is to be carried out shall be

cordoned off with rope and flag

b. The executing officer, safety officer and in-charge of the shop, where the lancing work is to

be carried out, shall inspect the site, identifying the potential hazards [heat, chemical, fire,

gases, etc.]

c. No person shall be allowed to stand, walk or do any work or go for any other purpose near

cordoned off area.

d. During lance cutting operations safe distance shall be maintained by lance cutter so that

spark coming out from the cutting does not reach the cutter.

e. As lance cutting operation produces sparks which can travel long distances, inflammable

material shall not be stored in the vicinity of lance cutting operation..

f. Examine whether the job of lance cutting can be done outside. If not, remove all the

combustible material to a safe distance of at least 6 Meters.

g. If combustible material cannot be removed, cover it with non combustible coverings..

h. A valve along with pressure gauge on the Oxygen pipe line from where tapping for lance

cutting is taken shall be provided.

i. Identification mark shall be provided for the oxygen tap-off pipe line.

j. Standard Operating Practices (SOPs) related to lance cutting shall be displayed near the

work place.

k. Initially the lance pipe shall be ignited with the help of a burn bamboo or fire wood.

l. During lance cutting lance pipe is to be kept on stand and proper angle for cutting to be

maintained, so that sparks/liquid metal shall not fall towards lancer/cutter.

m. Lance pipe shall not be used for cleaning human body parts.

n. For lancing pipes involving the use of higher diameter, the pipeline shall be provided with a

regulation valve for maintaining pressure.

o. Lance pipe must be changed after 70 to 75% consumption of its length.

p. Provision of Flash Back Arrestor ( IS: 11006) to be ensured at both ends in the lance cutting

system.

5. Selection of Pipes & Hoses

a. Lance pipe [6mm to 52mm] shall have thread arrangement at both ends and shall be

connected to Oxygen gas supply properly [by tightening the socket]. Lance pipe shall

conform to IS : 10577-1982

b. Minimum length of the lance pipe inside the hose shall be 200 to 300 mm and clamped by

tightening thread & socket. Hose shall conform to IS: 447- 1988.

c. Lancing pipe length should be as per suitability of job.

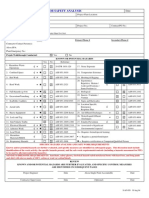

S.No. Area of Use Lance Pipe Length (In Metre)

1 Heavy Jam Cutting at Open Area 3.5 m

2 Normal Jam Lancing at Open Area 3m

3 Lance jam lancing 1.5 m

4 Normal lancing at any point or area 2.0 m

5 Ladle slide gate lancing 1.2 m

6 Ladle Lancing ( Straight position) 1.5 m

7 Slab Cutting by lancing 2.5 m

8 Refractory lance jam cutting (De- 2.0 m

Sulphurisation (DS), Laddle Furnace

(LF), Online Purging station (OLP))

d. Lancing in confined space (Preferably to be avoidable).

e. Lancing activities in RH vessel, LD vessel, Mixer or any enclosed chamber to be considered as

Category ‘A’ confined space & accordingly confined space standard to be followed. (IPSS

No.1-11-006-14).

f. Manual / motorised rescue system to be suitably installed. Provision of water line to be

made.

g. Ensure adequate ventilation . When sufficient ventilation can not be obtained without

blocking the means of access , employee in the confined space shall be protected by air line

respirators.

6. All officers and workers should follow the SOP. In case of violation the concerned person will

be responsible for his injury arising out of accident due to such violation. This is in accordance

with the compliances required in factories act cases.

You might also like

- Method Statement For Prestressing I-Girder CastingDocument6 pagesMethod Statement For Prestressing I-Girder CastingArifur Rahman Apu90% (10)

- Power and Control Cable Method of StatementDocument7 pagesPower and Control Cable Method of StatementAhmad Dagamseh100% (1)

- Method Statement For Cable Containment For CablesDocument15 pagesMethod Statement For Cable Containment For CablesshareyhouNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- Method of Statement Grounding System & Lightning ProtectionDocument7 pagesMethod of Statement Grounding System & Lightning Protectionafm0% (1)

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsFrom EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Chrony Beta and GammaDocument36 pagesChrony Beta and GammaÁdám MajorNo ratings yet

- Factors That Affect The Quality of CommunicationDocument9 pagesFactors That Affect The Quality of CommunicationWilliam Paras Inte100% (3)

- Corrosion Coupon Installation Procedure PDFDocument31 pagesCorrosion Coupon Installation Procedure PDFtrichysayeeNo ratings yet

- Access FittingDocument7 pagesAccess Fittingchakrapani vagish chandra pandeyNo ratings yet

- METHOD of STATEMENT For Grounding SystemDocument12 pagesMETHOD of STATEMENT For Grounding SystemHamada Khamis100% (1)

- Adam Junid - Assignment Sheet DCS 1205 Rev1 23mar16Document29 pagesAdam Junid - Assignment Sheet DCS 1205 Rev1 23mar16yogapostNo ratings yet

- Back Off String ShotDocument16 pagesBack Off String ShotChoayb Seller100% (1)

- Method of Statement Natural Gas Pipeline InstallationDocument7 pagesMethod of Statement Natural Gas Pipeline InstallationFrancis DhanarajNo ratings yet

- Replacement of Bad Pipe and Gate Valve Methd StatmDocument10 pagesReplacement of Bad Pipe and Gate Valve Methd StatmOdejobi OloladeNo ratings yet

- Pipeline Maintenance Section: IndexDocument55 pagesPipeline Maintenance Section: Indextenneti CHALAPATHY RAONo ratings yet

- Methodology of Grounding Installation For San MarcelinoDocument2 pagesMethodology of Grounding Installation For San MarcelinoMaryel MarianoNo ratings yet

- RAMS Generic StatementsDocument25 pagesRAMS Generic Statementsdbrocklehurst13No ratings yet

- Method Statement For Installation of Epoxy Grout SleeveDocument5 pagesMethod Statement For Installation of Epoxy Grout SleeveNithin MathaiNo ratings yet

- Hip - Qatif Aramco - FinalDocument10 pagesHip - Qatif Aramco - FinalDarius DsouzaNo ratings yet

- Hot Work Safety GuideDocument7 pagesHot Work Safety Guideafifmahfud09No ratings yet

- Final SOW-HVOF Coating On Boiler ChannelDocument29 pagesFinal SOW-HVOF Coating On Boiler ChannelCorrosion FactoryNo ratings yet

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsDocument30 pagesTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- SurveyDocument10 pagesSurveyprateek559No ratings yet

- Backoff ProcedureDocument18 pagesBackoff Procedurebilalpearltec100% (1)

- Unit2 ConsDocument22 pagesUnit2 ConsAmay HarshitNo ratings yet

- Corrosion Coupon Installation ProcedureDocument31 pagesCorrosion Coupon Installation ProcedureIqbal Mohammad100% (2)

- KHVT 3c Install Rev1Document5 pagesKHVT 3c Install Rev1Mark Anthony MatampacNo ratings yet

- Socketing Procedures For Wire Ropes Resin Socketing: Technical Report Iso/Tr 7596-1982 (E)Document6 pagesSocketing Procedures For Wire Ropes Resin Socketing: Technical Report Iso/Tr 7596-1982 (E)Jason RobertsNo ratings yet

- Method Statment Cable Tray & TrunkingDocument4 pagesMethod Statment Cable Tray & Trunkingmahroof mkuttyNo ratings yet

- Method Statement For Piling Work (Edited)Document18 pagesMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- 01 Method Statment G I Conduit Access Rev 02Document5 pages01 Method Statment G I Conduit Access Rev 02mahroof mkuttyNo ratings yet

- JCI-Nxtra-SWMS-piping & Cylinder ErectionDocument10 pagesJCI-Nxtra-SWMS-piping & Cylinder ErectionbalajiNo ratings yet

- Bruc 1 081 001Document6 pagesBruc 1 081 001Adel AhmedNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint Coatingkrishna3794No ratings yet

- 6602 Issue 2 Thermit WeldingDocument4 pages6602 Issue 2 Thermit WeldingFethi BELOUISNo ratings yet

- IACS Wear of Chains - Guide For Anchoring Equipment in ServiceDocument10 pagesIACS Wear of Chains - Guide For Anchoring Equipment in ServicegabelendaNo ratings yet

- MS For Sonic Logging - C487Document8 pagesMS For Sonic Logging - C487Anonymous S7Cq7ZDgPNo ratings yet

- Method Statement LuderitzDocument11 pagesMethod Statement LuderitzYoung R-j MafaraNo ratings yet

- Splice SteelDocument28 pagesSplice SteelNacho Tomé100% (1)

- Code of Practice SMW FDocument10 pagesCode of Practice SMW FardaneNo ratings yet

- Ms - Raking DrainsDocument5 pagesMs - Raking DrainsdeanicoNo ratings yet

- Safety Measures To Be Adopted in Work SitesDocument18 pagesSafety Measures To Be Adopted in Work SitesswethaNo ratings yet

- 28 HotworkDocument5 pages28 HotworkMohammed MinhajNo ratings yet

- BookDocument24 pagesBookdipakNo ratings yet

- Multiple-Ply Conveyor Belt Splicing Manual - EngDocument24 pagesMultiple-Ply Conveyor Belt Splicing Manual - EngShiena CaparrosNo ratings yet

- MOS For Hot Tapping Work PDFDocument20 pagesMOS For Hot Tapping Work PDFAho Chi- ShuenNo ratings yet

- Product Safety Rules: Following Product Safety Rules Are To Be Accounted During Manufacturing As Well As During UtilityDocument2 pagesProduct Safety Rules: Following Product Safety Rules Are To Be Accounted During Manufacturing As Well As During Utilitykannagi198No ratings yet

- JSA ExcavationDocument6 pagesJSA Excavationkermech21607100% (1)

- 03-Procedure For WeldingDocument8 pages03-Procedure For WeldingAyush AgarwalNo ratings yet

- Hot Works ProcedureDocument7 pagesHot Works Proceduresafetyassistant23No ratings yet

- Inspection - Spark-Testing PDFDocument3 pagesInspection - Spark-Testing PDFanandtpe1No ratings yet

- Mos - Relocating of Fire Fighting - KAYANDocument19 pagesMos - Relocating of Fire Fighting - KAYANjagp_24No ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- IndexindexDocument3 pagesIndexindexSURJIT SINGHNo ratings yet

- Pipelines and City Gate Natural Gas Ram Station - Nigeria: Cable ScheduleDocument7 pagesPipelines and City Gate Natural Gas Ram Station - Nigeria: Cable ScheduleDanilo QuevedoNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- ES - 1NZ-FXE Engine Control SystemDocument480 pagesES - 1NZ-FXE Engine Control SystemHari Prasad Ambaripeta84% (19)

- Debug 1214Document3 pagesDebug 1214Pandji AsmaraNo ratings yet

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- Functions of An EngineerDocument5 pagesFunctions of An EngineerDEUS PHILIP DURANNo ratings yet

- ME Harmonization Curricilum FinalDocument307 pagesME Harmonization Curricilum Finalratchagaraja33% (3)

- TK-C Transmitter PDFDocument4 pagesTK-C Transmitter PDFGopal HegdeNo ratings yet

- 211 A3 211 Summary ResultsDocument14 pages211 A3 211 Summary ResultsElmer Gonzalo Sullca ZapataNo ratings yet

- Bloor Research On Data MigrationDocument13 pagesBloor Research On Data MigrationivahdamNo ratings yet

- Water Technology 2015 2016 1Document86 pagesWater Technology 2015 2016 1Srinivas AkHilNo ratings yet

- GAMS TutorialDocument28 pagesGAMS TutorialWendy Tie Kai SingNo ratings yet

- Azimuthal Instabilities in Annular Combustion ChambersDocument11 pagesAzimuthal Instabilities in Annular Combustion ChambersLarry SmithNo ratings yet

- ARSTRUCTS Chapter1Document15 pagesARSTRUCTS Chapter1Aila MaeNo ratings yet

- Millikan Oil Drop ExperimentDocument6 pagesMillikan Oil Drop ExperimentruleevanNo ratings yet

- Chapter 2 Review of Related LiteratureDocument16 pagesChapter 2 Review of Related LiteratureRodel D Dosano50% (6)

- VNX Unified Storage ManagementDocument3 pagesVNX Unified Storage ManagementNicoleNo ratings yet

- Java SampleExamQuestionsDocument18 pagesJava SampleExamQuestionshmasryNo ratings yet

- Using A GMR Effect Sensor To Measure The Current in A Wire by Means of Its Magnetic FieldDocument6 pagesUsing A GMR Effect Sensor To Measure The Current in A Wire by Means of Its Magnetic FieldManeesha WijesingheNo ratings yet

- Key Features Boilermaker Proven, Legendary ReliabilityDocument2 pagesKey Features Boilermaker Proven, Legendary ReliabilityManuel Cantoral CortazarNo ratings yet

- B747F 400Document2 pagesB747F 400Nadeem100% (1)

- Smart Obj. Kiss and SwotDocument5 pagesSmart Obj. Kiss and SwotjtopuNo ratings yet

- Facts SeriesandshuntcompensationDocument56 pagesFacts SeriesandshuntcompensationIfranul HaqueNo ratings yet

- Motherboard Specifications, K8N8X-LA (Diablo) HP Pavilion T650.be Desktop PC - HP Customer Care (United States - English)Document5 pagesMotherboard Specifications, K8N8X-LA (Diablo) HP Pavilion T650.be Desktop PC - HP Customer Care (United States - English)jpntjpntNo ratings yet

- Graco Pumps Catalog 300435EN MDocument76 pagesGraco Pumps Catalog 300435EN MAlbu MihaiNo ratings yet

- Design Standards For Sanitary Sewer SysytemDocument5 pagesDesign Standards For Sanitary Sewer SysytemJoselle RuizNo ratings yet

- Subsea AccumulatorsDocument4 pagesSubsea AccumulatorsAbdul Hameed OmarNo ratings yet

- British Columbia Institut of TechnologyDocument2 pagesBritish Columbia Institut of Technologyrobertofca2266No ratings yet

- M S 1 1 - M S E 1 1: Hydraulic MotorsDocument36 pagesM S 1 1 - M S E 1 1: Hydraulic MotorsmehmetNo ratings yet

- E-Line DLDocument21 pagesE-Line DLiulian17dNo ratings yet