Professional Documents

Culture Documents

Memory For Document Preparation

Uploaded by

ScribdTranslations0 ratings0% found this document useful (0 votes)

16 views5 pagesThis document outlines the plans and schedules for the "Creation of the South Pacific Park D1 of the Municipal Housing Program South Zone, District of Punta Negra, Province of Lima - Department of Lima" project. It includes a budget summary, timeline of 90 days to completion, and contracting details. Critical path method (CPM) was used to create a work execution program in Gantt chart format showing tasks, durations, dependencies and progress tracking. Accompanying schedules include a work progress schedule in Excel to track costs and physical completion over months, a materials procurement schedule, and an equipment utilization schedule, all derived from the work execution program.

Original Description:

FOR SIGNING OF CONTRACT - STANDARD BASES

Original Title

Memory for Document Preparation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the plans and schedules for the "Creation of the South Pacific Park D1 of the Municipal Housing Program South Zone, District of Punta Negra, Province of Lima - Department of Lima" project. It includes a budget summary, timeline of 90 days to completion, and contracting details. Critical path method (CPM) was used to create a work execution program in Gantt chart format showing tasks, durations, dependencies and progress tracking. Accompanying schedules include a work progress schedule in Excel to track costs and physical completion over months, a materials procurement schedule, and an equipment utilization schedule, all derived from the work execution program.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views5 pagesMemory For Document Preparation

Uploaded by

ScribdTranslationsThis document outlines the plans and schedules for the "Creation of the South Pacific Park D1 of the Municipal Housing Program South Zone, District of Punta Negra, Province of Lima - Department of Lima" project. It includes a budget summary, timeline of 90 days to completion, and contracting details. Critical path method (CPM) was used to create a work execution program in Gantt chart format showing tasks, durations, dependencies and progress tracking. Accompanying schedules include a work progress schedule in Excel to track costs and physical completion over months, a materials procurement schedule, and an equipment utilization schedule, all derived from the work execution program.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

MEMORY

I. NAME OF THE WORK:

"CREATION OF THE SOUTH PACIFIC PARK D1 OF THE MUNICIPAL HOUSING PROGRAM

SOUTH ZONE, DISTRICT OF PUNTA NEGRA, PROVINCE OF LIMA - DEPARTMENT OF LIMA".

II. OBJECTIVE

It is to identify the considerations that have been taken into account for the elaboration of

the Work Execution Program (CPM) with its critical path, the Schedule of Work Progress

and the Schedule of Materials Acquisition of the Work to be executed.

III. CHARACTERISTICS OF THE WORK

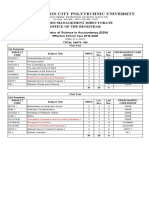

a. Summary of the Budget Offered:

Description Cost (S/.)

Direct Cost (A) S/. 294,306.57

General Expenses (B) S/. 20,601.46

Utility (C) S/. 15,290.11

SUB TOTAL (A+B+C) S/. 330,198.14

IGV S/. 59,435,66

TOTAL AMOUNT OF THE OFFER S/. 389,633.80

b. Execution period:

The work is scheduled to be completed within 90 (ninety) calendar days.

c. Contracting System:

This procedure is governed by the Lump Sum system, in accordance with the

provisions of the respective contracting file.

IV. DESCRIPTION OF THE DOCUMENTS CONSIDERED IN PARAGRAPH (l) FOR THE

COMPLETION OF THE CONTRACT

For the perfection of the contract for the execution of the work, according to the integrated

simplified awarding bases for the contracting of the execution of works, in the SPECIAL

CONDITIONS OF THE SELECTION PROCEDURE of the SPECIFIC SECTION, according to

CHAPTER II: OF THE SELECTION PROCEDURE, item 2.3 REQUIREMENTS TO PERFORM THE

CONTRACT, indicates the preparation of this report where the considerations that have

been taken into account for the preparation of the documents indicated in items i), j) and k)

are indicated. of the same item.

The documents are described below:

Work Execution Program (CPM), which presents the critical route

The schedule of work progress valued at

Schedule for procurement of materials or supplies

Equipment utilization schedule

V. WORK EXECUTION PROGRAM

The work execution program was carried out using the Gantt chart, which is a tool for

planning and scheduling tasks over a given period of time. Thanks to an easy and

comfortable visualization of the planned actions, it allows the monitoring and control of the

progress of each of the stages of the work and, in addition, it graphically reproduces the

tasks, their duration and sequence, as well as the general project schedule.

The items to be executed are linked to each other by their position in the schedule. The

start of a task that depends on the completion of a previous action will be represented by

an end-start link. It also reflects those whose development runs in parallel and can be

assigned to each activity the resources it needs in order to control the costs and personnel

required.

The Gantt chart used in the work execution program is made in a coordinate system with

two essential axes: the vertical axis shows the tasks (items) to be performed from the

beginning to the end of the project, while the horizontal axis shows the time.

Depending on the type of activities that make up the work, the values located on the

horizontal axis are defined in days at the lower level and in months at the upper level.

At a later stage, each task is assigned a light blue rectangular block indicating its degree of

progress and the time remaining for its full execution. For critical or structural tasks in the

process, we use red rectangular blocks.

Among the advantages of using the Gantt chart in the work execution program are the

following:

The Gantt chart simplifies the visualization of tasks and represents all stages and

activities of the work in one place.

This type of chart helps to manage all stages of the work and allows us to reduce

scheduling problems.

Thanks to the Gantt chart, it will be easier to identify the critical points during the

execution of the work.

The Gantt chart can be updated on any of its axes at any time (deadline extensions,

work stoppages, etc.).

It is not necessary to make the Gantt chart manually, so in this case the MSProjet

program has been used for its elaboration.

The following steps have been followed to prepare our work execution schedule using the

Gantt Chart as a project management tool:

1) The first step in developing our Gantt chart was to make a list of all the activities (line

items) which are included in the budget of the technical dossier. From this we define the

time for the completion of each task which is calculated based on the performance and

crews to be used in the execution of each item, which is also indicated in the unit cost

analysis of the technical file, then the priority items and order of achievement are

detailed.

2) The design of the Gantt chart has been made as schematic as possible, which conveys

what is most important, as it will be consulted frequently during the execution of the

work. The professionals involved in the execution process will have a clear idea of what

is happening at a specific moment in the execution process.

3) Thanks to the Gantt chart, it will be possible to clearly monitor the progress of work

execution, to easily discover critical points, idle periods and to calculate delays in

execution. In this way, it will help us to foresee possible future costs and allow us to

reschedule tasks according to new conditions that may arise (deadline extensions,

stoppages, etc.).

VI. WORK PROGRESS SCHEDULE:

It is a physical-financial schedule that allows to control the progress of the work, verifying

and comparing the programmed and executed with respect to the acquisition and valuation

of the various and necessary elements of the work, which in our case was formulated in

Excel sheet format for its practicality of use. In strictly technical terms, the work progress

schedule is derived from the CPM Work Execution Program.

In order to draw up the schedule of work progress, it is necessary to have all the activities

(work budget items) in order to have a general economic overview. Then the units, metrics

and partial cost for each item are described, which are indicated in the construction budget.

The calendar itself is divided by months, in our case in 3 columns that make a total of 3

months (90 calendar days). In each box we note the amounts for each month for each item

considered, which is in agreement with the work execution program.

At the end of this schedule we see the direct cost of the work for each month of execution,

but to this we must add the following:

Overhead, which represents 7% of the direct cost of the work.

Profit representing 5.20% of the direct cost of the work.

The sum of all amounts will result in a Sub Total. To this we add the IGV that represents

18% (Sub Total) and at the end we get a BUDGET for each month of execution.

Finally, we consider the percentages of monthly programmed and accumulated progress,

which will help us to control the monthly execution of the work.

VII. PROCUREMENT SCHEDULE FOR MATERIALS OR SUPPLIES

It is also a physical-financial schedule, but in this case it allows controlling the acquisition

and use of the resources involved in each item during the entire execution stage of the

work, which in our case was formulated in Excel sheet format for its practicality of use. In

strictly technical terms, the schedule for the procurement of materials or supplies is also

derived from the CPM Work Execution Program.

In order to draw up the schedule for the acquisition of materials or supplies, it is necessary

to have all the resources to be used during the entire execution stage of the work (labor,

materials, equipment and subcontracts). Then the units, quantities and partial cost for each

resource are described, which are indicated in the list of inputs in the technical file. The

calendar itself is divided by months, in our case in 3 columns that make a total of 3 months

(90 calendar days). In each box we write down the amounts for each month of each input

considered, which is in accordance with the work execution program.

At the end of this schedule we see the direct cost of the work for each month of execution.

VIII. EQUIPMENT UTILIZATION SCHEDULE

It is also a physical-financial schedule, but in this case it allows to control the use of

equipment involved in each item during the entire execution stage of the work, which in

our case was formulated in Excel sheet format for its practicality of use. In strictly technical

terms, the equipment utilization schedule is derived in its entirety from the materials or

supplies procurement schedule, which is in accordance with the CPM Work Execution

Program.

In order to draw up the schedule for the use of equipment, it is necessary to have only the

equipment to be used during the entire execution stage of the work. Then the units,

quantities (hm or he) and partial cost for each piece of equipment are described, which are

indicated in the list of inputs in the technical file. The calendar itself is divided by months, in

our case in 3 columns that make a total of 3 months (90 calendar days). In each box we

write down the amounts for each month for each equipment considered, which is in

accordance with the work execution program.

At the end of this schedule we see the direct cost of the work for each month of execution.

You might also like

- Internal Financial Controls-IfCORDocument47 pagesInternal Financial Controls-IfCORGovind PaliwalNo ratings yet

- Internal Quality Auditing ProcedureDocument7 pagesInternal Quality Auditing ProcedurePrime CapNo ratings yet

- Project SchedulingDocument22 pagesProject SchedulingRAHUL16398100% (1)

- Construction Schedule RequirementsDocument4 pagesConstruction Schedule Requirementsedla3710No ratings yet

- Schedule Hierarchy - An OverviewDocument3 pagesSchedule Hierarchy - An OverviewBTconcordNo ratings yet

- Two Construction Supervision & Quality ControlDocument52 pagesTwo Construction Supervision & Quality ControlbolinagNo ratings yet

- CISA Exam-Testing Concept-PERT/CPM/Gantt Chart/FPA/EVA/Timebox (Chapter-3)From EverandCISA Exam-Testing Concept-PERT/CPM/Gantt Chart/FPA/EVA/Timebox (Chapter-3)Rating: 1.5 out of 5 stars1.5/5 (3)

- CM-PE-902 Procedure For Progress and Performance Measurement PDFDocument9 pagesCM-PE-902 Procedure For Progress and Performance Measurement PDFDavid PrastyanNo ratings yet

- University of GondarDocument101 pagesUniversity of GondarAmirNo ratings yet

- Estimate at Completion (EAC)Document8 pagesEstimate at Completion (EAC)Omnia Hassan100% (1)

- CPM, Pert, Bar ChartsDocument32 pagesCPM, Pert, Bar ChartsAr Manish SrivastavNo ratings yet

- Furuno FMD ECDIS PDFDocument14 pagesFuruno FMD ECDIS PDFScribdTranslations100% (1)

- Event Data 2020Document10 pagesEvent Data 2020Wilson Menezes100% (1)

- Task Involved in Project Planning AreDocument22 pagesTask Involved in Project Planning AreLijish Balan100% (1)

- SAP Project Management PsDocument109 pagesSAP Project Management Psfather100% (1)

- Typical Reports To Aid The Progress Review: Cost ControlDocument35 pagesTypical Reports To Aid The Progress Review: Cost ControlAshish KumarNo ratings yet

- Estimation and Costing PDFDocument20 pagesEstimation and Costing PDFNidhya Sudesh SinghNo ratings yet

- Bill of Quantities - Ass.danieDocument4 pagesBill of Quantities - Ass.danieLawrence AsabaNo ratings yet

- Schedule MGMT PlanDocument32 pagesSchedule MGMT PlanDrMohamed MustaqNo ratings yet

- Project Control ToolsDocument24 pagesProject Control ToolssrsureshrajanNo ratings yet

- Estimation and CostingDocument20 pagesEstimation and CostingSubhajit Maitra100% (2)

- Integrated Cost and Schedule Control in Project ManagementFrom EverandIntegrated Cost and Schedule Control in Project ManagementRating: 2 out of 5 stars2/5 (1)

- Strategic ManagementDocument172 pagesStrategic ManagementAnil Reddy100% (1)

- Introduction to Project Management: The Quick Reference HandbookFrom EverandIntroduction to Project Management: The Quick Reference HandbookNo ratings yet

- 01311-Construction Schedule BDocument7 pages01311-Construction Schedule BNitekNo ratings yet

- Project Controls ProcedureDocument12 pagesProject Controls ProcedureNashrul KarimNo ratings yet

- Baseling Schedule/Bar Charts/Gantt Charts/ Network Diagrams From Time PlanningDocument19 pagesBaseling Schedule/Bar Charts/Gantt Charts/ Network Diagrams From Time PlanningKendra TerryNo ratings yet

- PM 015 Summer 2013Document8 pagesPM 015 Summer 2013Mohammed ThoufeeqNo ratings yet

- CEC Notes LO5-6. Done by RyanDocument16 pagesCEC Notes LO5-6. Done by RyanFrancis ZhuwaoNo ratings yet

- Wjarr 2023 0231 PDFDocument10 pagesWjarr 2023 0231 PDFBeau NorNo ratings yet

- Is.15883.2.2013 - Copy (2) oDocument3 pagesIs.15883.2.2013 - Copy (2) oKendra TerryNo ratings yet

- National Institute of Construction Management and Research GOADocument13 pagesNational Institute of Construction Management and Research GOASeyed IbrahimNo ratings yet

- Simillar TermsDocument3 pagesSimillar TermsjerinNo ratings yet

- Presented By: Group 1 Presented To: Engr. Joshua OrtizDocument26 pagesPresented By: Group 1 Presented To: Engr. Joshua OrtizYang RhiaNo ratings yet

- Unit-4 (SPM) Part - 1Document22 pagesUnit-4 (SPM) Part - 1rihanaparveen027No ratings yet

- 02 Handout 110Document5 pages02 Handout 110Eliza ColomaNo ratings yet

- Grant ChartDocument4 pagesGrant ChartNatasha SikandarNo ratings yet

- Management Assignment 1Document4 pagesManagement Assignment 1Alex BeppleNo ratings yet

- Unit 2 BM319 OKDocument6 pagesUnit 2 BM319 OKMohd AqdasNo ratings yet

- Anugraha Vasan 1812560, 5bcomp ADocument2 pagesAnugraha Vasan 1812560, 5bcomp Aanugraha vasanNo ratings yet

- Project ControlDocument12 pagesProject ControlShridhar H MujumdarNo ratings yet

- Sample Tech Paper - Performance MeasurementDocument18 pagesSample Tech Paper - Performance Measurementringlove97No ratings yet

- BM319 Unit2 Part ADocument7 pagesBM319 Unit2 Part Aitsgsb13No ratings yet

- SPM Lecture Notes (Module-3)Document14 pagesSPM Lecture Notes (Module-3)Deepak TiwariNo ratings yet

- Sen Unit 5 5 2Document11 pagesSen Unit 5 5 2Sarthak kadamNo ratings yet

- Assigment 02docxDocument3 pagesAssigment 02docxAndy Claud MassaliNo ratings yet

- ChapterDocument60 pagesChapterMa ThiNo ratings yet

- CPM and PertDocument30 pagesCPM and Pertvennu anushaNo ratings yet

- Lec#03Document23 pagesLec#03Muhammad MoizNo ratings yet

- Monitoring and Cost ControlDocument10 pagesMonitoring and Cost ControlAyyaz Tajammal MirzaNo ratings yet

- 003 Converting Linear Schedules To CPM 27.10.12Document5 pages003 Converting Linear Schedules To CPM 27.10.12Sunil Varma DanthuluriNo ratings yet

- PM NotesDocument23 pagesPM Noteschandar70No ratings yet

- Exhibit X - Rev2012!06!19Document15 pagesExhibit X - Rev2012!06!19Kamel MkaddemNo ratings yet

- Network TichniquesDocument15 pagesNetwork Tichniquesadan awaleNo ratings yet

- TMP3413 Software Engineering Lab: The Development PlanDocument41 pagesTMP3413 Software Engineering Lab: The Development PlanNurfauza JaliNo ratings yet

- CH 9 Monitoring and ControlDocument12 pagesCH 9 Monitoring and Controlkarunya vNo ratings yet

- Lectures - 13,14 & 16 March 2024Document34 pagesLectures - 13,14 & 16 March 2024RiyaNo ratings yet

- Process Routing SheetDocument4 pagesProcess Routing SheetRaj RajendranNo ratings yet

- Project Management Pop Quiz (Alicia)Document3 pagesProject Management Pop Quiz (Alicia)Chin AliciaNo ratings yet

- How To Make As Built ProgramDocument15 pagesHow To Make As Built ProgramMem Nabil RamadanNo ratings yet

- Module 3 Project Scheduling, Monitoring & Risk ManagementDocument13 pagesModule 3 Project Scheduling, Monitoring & Risk Managementhanif malgundkarNo ratings yet

- Konsep Earned Value Dalam Aplikasi Pengelolaan Proyek KonstruksiDocument9 pagesKonsep Earned Value Dalam Aplikasi Pengelolaan Proyek KonstruksiCaesar Lovely HasdynaNo ratings yet

- Interpret The Network Figures Use in Civil Engineering.: Tools For Project SchedulingDocument13 pagesInterpret The Network Figures Use in Civil Engineering.: Tools For Project SchedulingAyush SalveNo ratings yet

- Network ModelDocument69 pagesNetwork ModelAbdi NegassaNo ratings yet

- Aa Preventive Maintenance Report - ItpDocument32 pagesAa Preventive Maintenance Report - ItpScribdTranslationsNo ratings yet

- Network Layers ExplanationDocument3 pagesNetwork Layers ExplanationScribdTranslationsNo ratings yet

- Case Study - Solution - Alternative FinancingDocument6 pagesCase Study - Solution - Alternative FinancingScribdTranslationsNo ratings yet

- DD124 Exam 2Document7 pagesDD124 Exam 2ScribdTranslationsNo ratings yet

- Case 4 ASICS QuestionsDocument1 pageCase 4 ASICS QuestionsScribdTranslationsNo ratings yet

- Concept Map T8.2Document2 pagesConcept Map T8.2ScribdTranslationsNo ratings yet

- PC3 Simulation Tools For Decision MakingDocument9 pagesPC3 Simulation Tools For Decision MakingScribdTranslationsNo ratings yet

- EXCEL PracticeDocument10 pagesEXCEL PracticeScribdTranslationsNo ratings yet

- Rpas Exam Syllabus SOLVED - WordDocument9 pagesRpas Exam Syllabus SOLVED - WordScribdTranslationsNo ratings yet

- Final Exam - Financial Administration - Group N°11Document9 pagesFinal Exam - Financial Administration - Group N°11ScribdTranslationsNo ratings yet

- M2 - TI - Skills For Oral and Written Communication PDFDocument5 pagesM2 - TI - Skills For Oral and Written Communication PDFScribdTranslationsNo ratings yet

- Coca Cola Performance EvaluationDocument1 pageCoca Cola Performance EvaluationScribdTranslationsNo ratings yet

- Session My Name Is Special and UniqueDocument2 pagesSession My Name Is Special and UniqueScribdTranslationsNo ratings yet

- Final Work - Applied Statistics For Business.Document28 pagesFinal Work - Applied Statistics For Business.ScribdTranslationsNo ratings yet

- Bank Questions PC Virtual Unit 2Document13 pagesBank Questions PC Virtual Unit 2ScribdTranslationsNo ratings yet

- Risk Matrix Going On African Photo SafariDocument15 pagesRisk Matrix Going On African Photo SafariScribdTranslationsNo ratings yet

- Final Work Caixabank CaseDocument7 pagesFinal Work Caixabank CaseScribdTranslationsNo ratings yet

- Exercises and ProblemsDocument65 pagesExercises and ProblemsScribdTranslationsNo ratings yet

- Solved T-Student Distribution ExercisesDocument4 pagesSolved T-Student Distribution ExercisesScribdTranslationsNo ratings yet

- Response To Demand Rendering of Accounts.Document9 pagesResponse To Demand Rendering of Accounts.ScribdTranslationsNo ratings yet

- Administration Financière t2 UPNDocument10 pagesAdministration Financière t2 UPNScribdTranslationsNo ratings yet

- Final Questionnaire Module 2 CNDH Prevention of TortureDocument7 pagesFinal Questionnaire Module 2 CNDH Prevention of TortureScribdTranslationsNo ratings yet

- Life Center - Worthy Are You - Forever PDFDocument1 pageLife Center - Worthy Are You - Forever PDFScribdTranslationsNo ratings yet

- Legal Analysis of George OrwellsDocument10 pagesLegal Analysis of George OrwellsScribdTranslationsNo ratings yet

- SEQUENCE The Process of Construction of The Argentine National State (1853-1880) - 6th MODIFIEDDocument13 pagesSEQUENCE The Process of Construction of The Argentine National State (1853-1880) - 6th MODIFIEDScribdTranslationsNo ratings yet

- TaskDocument2 pagesTaskScribdTranslationsNo ratings yet

- Final Questionnaire Module 1 CNDH Prevention of TortureDocument5 pagesFinal Questionnaire Module 1 CNDH Prevention of TortureScribdTranslationsNo ratings yet

- Lease Agreement With Express Eviction and Future Search Clauses.Document4 pagesLease Agreement With Express Eviction and Future Search Clauses.ScribdTranslationsNo ratings yet

- Activity Module 4 CNDH What Mechanisms Appropriate in Mexico According To Cases of Violation of Human RightsDocument6 pagesActivity Module 4 CNDH What Mechanisms Appropriate in Mexico According To Cases of Violation of Human RightsScribdTranslationsNo ratings yet

- Enterprise Resource Planning - Erp: Muhammad AliDocument16 pagesEnterprise Resource Planning - Erp: Muhammad AliBenjamin adeelNo ratings yet

- MS-P01-F01 Responsibility MatrixDocument3 pagesMS-P01-F01 Responsibility MatrixMuhammad ZafarNo ratings yet

- Revenue Management SimplifiedDocument8 pagesRevenue Management SimplifiedSharwari ShahNo ratings yet

- Barilla and The JITD SystemDocument7 pagesBarilla and The JITD Systemdave6288% (16)

- Organizational Structure - SV - 1Document8 pagesOrganizational Structure - SV - 1Quyên HạnhNo ratings yet

- Ajai K Benjamin - Executive Quality Professional - Lead Auditor - July 2023 PDFDocument2 pagesAjai K Benjamin - Executive Quality Professional - Lead Auditor - July 2023 PDFNowsathAliNo ratings yet

- MG 431-Engineering Economics and Financial AccountingDocument2 pagesMG 431-Engineering Economics and Financial AccountingsubhazNo ratings yet

- EFU General and Meezan Bank Sign MOU For Takaful CoverageDocument34 pagesEFU General and Meezan Bank Sign MOU For Takaful CoverageAbass GblaNo ratings yet

- Exercises On Financial StatementDocument10 pagesExercises On Financial Statementzuraidiroslan game100% (1)

- 2019 2020 BSA CURRICULUM Jun 03 2019Document6 pages2019 2020 BSA CURRICULUM Jun 03 2019Sunshine PaglinawanNo ratings yet

- Economics in LCMDocument36 pagesEconomics in LCMSn Carbonel100% (1)

- Case Study A Profile of Toyota's Production SystemDocument1 pageCase Study A Profile of Toyota's Production SystemZhen WuNo ratings yet

- Fish ExportDocument7 pagesFish ExportIfteha Hammad ZaheerNo ratings yet

- Social Audit vs. Commercial AuditDocument1 pageSocial Audit vs. Commercial AuditSakshi JadhavNo ratings yet

- UntitledDocument4 pagesUntitledDjunah ArellanoNo ratings yet

- Ch.7 Designing Organizational Structure (Chapter Review Slides)Document27 pagesCh.7 Designing Organizational Structure (Chapter Review Slides)Tirsolito SalvadorNo ratings yet

- Activating Strategies, Behavioral ImplementationDocument16 pagesActivating Strategies, Behavioral Implementationgovindvarun9450No ratings yet

- SCM Module 5 NotesDocument14 pagesSCM Module 5 NotesNaik SamNo ratings yet

- Branch Stock Report-18Document7 pagesBranch Stock Report-18IqbalNo ratings yet

- Raichur Power Corporation Limited: Tender DocumentDocument14 pagesRaichur Power Corporation Limited: Tender DocumentRAMAN SHARMANo ratings yet

- Case Study MCOBDocument11 pagesCase Study MCOB209 105 Suriya N BNo ratings yet

- NIVELCO - Product - Catalog - 2017 Price PDFDocument230 pagesNIVELCO - Product - Catalog - 2017 Price PDFKareem RMGNo ratings yet

- Diseño Sin TítuloDocument15 pagesDiseño Sin TítuloKatya CosavalenteNo ratings yet

- CASE STUDY ANALYSIS - BioconDocument6 pagesCASE STUDY ANALYSIS - BioconAmlan JenaNo ratings yet

- Scenario - Based - Que - DbmsDocument8 pagesScenario - Based - Que - DbmsPrachi P100% (1)