Professional Documents

Culture Documents

Rekomendasi Vibrasi BC-02 072023

Uploaded by

putel_ajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rekomendasi Vibrasi BC-02 072023

Uploaded by

putel_ajaCopyright:

Available Formats

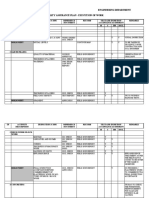

MACHINERY VIBRATION ANALYSIS REPORT

PLTU KALBAR 1 KARIMUNTING

UNIT : Coal & Ash Handling INSPECTED APPROVED

DATE

24/7/2023

EQUIPMENT : [E] BC-2 BELT CONVEYOR (KK00EAC01AF003-001)

SPEED : 1491 rpm SIGN

POWER - VOLTAGE : 450 KW- 6000 V

FREKUENSI-Pf : 50 Hz - 0.86 NAME Arif Efendi VICKY H

0 - 2.3 2.3 - 4.5 4.5 - 7.1 >7.1 MACHINE CLASS: ISO 10816-3 Group 3

ALARM LIMIT (RMS)

A B C D CURRENT STATUS B

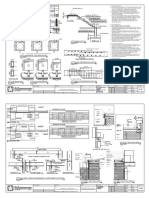

SPECTRUM PICTURE ILLUSTRATION MEASUREMENT POINT

`

TRENDING VIBRATION

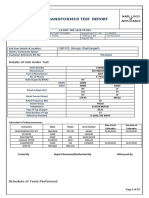

POSSIBLE CAUSE ( √ ) CHARACTERISTICS OF THE FINDINGS

ROTATING LOOSENESS P BEARING DAMAGE From the vibration measurement data using the VIBXPERT II Vibration Meter, there

STRUCTURAL LOOSENESS SLEEVE BEARING is an increase in the vibration value and a change in the spectrum pattern. Spectrum

MISALIGNMENT P SOFT FOOT and waveforms analysis show symptoms of Misalignment and Rotating Looseness.

BENT SHAFT LACK OF LUBRICATION

AERODYNAMIC SENSOR ERROR

ANALYSIS

with the results of the spectrum analysis of possible defects:

1. Misalignment

2. Rotating Looseness

RECOMMENDATION ISSUED ON DAILY PRODUCTION MEETING

1. Realignment

2. Inspection rubber coupling, replace if rubber coupling get damaged.

PT INDONESIA POWER

PLTU KALBAR 1

BIDANG ENGINEERING

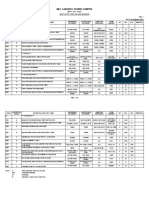

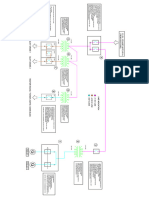

COST BENEFIT ANALYSIS ( CBA )

NO ITEM UNIT AMOUNT (Rp) INFORMATION

a b c d

I recommendation/ invesment

1. Realignment

I.I Rp 5.000.000 Value of Procurement / Project

2. Inspection rubber coupling, replace if rubber coupling get damage.

I.II - Rp - Value of Procurement / Project

I.IV Total invesment cost (I.I + I.II) Rp 5.000.000

II Lost of Opportunity Calculation

Lost of opportunity unit outage due to disruption of one of EH Pump Unit 2

Duration / Time of derate caused by disruption of one of EH Pump Unit 2

II.I Hours - Assumption of Derating Time / Outage

II.II A row caused by disruption of one of EH Pump Unit 2 kW - Assumption of Derating / Outage

II.III Potential Energy that is lost with the occurrence of a unit disturbance kWh -

II.IV Estimated HPP PLTU Kalbar 1 until 2023 Rp/kWh 885,000

II.V Estimated BPP PLTU Kalbar 1 until 2023 Rp/kWh 650,000 Basic production assumptions

II.VI Margin (Estimated HPP-Estimated BPP) Rp/kWh 235,00

II.VII Catastrophic equipment failure Rp 1.000.000.000 Assumption of Repair

Potential income lost from lost production opportunities and catastrophic failure (Potential Energy that is

II.VIII Rp -

lost with the occurrence of a unit disturbance*Margin)

III Cost Benefit Calculation

III.I Total Lost of Opportunity = Potential Lost Income Rp 1.000.000.000

III.II Get benefit (total lost of opportunity- total invesment cost) 995.000.000

III.III Cost Benefit Analysis (Σ lost of opportunity)/(Σ Biaya Pengadaan) % 19900%

III.IV Cost Benefit Analysis (CBA) > 1 = acceptable Time 199,00

You might also like

- Balara - Mechanical Drawings - IFC PDFDocument6 pagesBalara - Mechanical Drawings - IFC PDFjomer john estoneloNo ratings yet

- Codes and StandardsDocument28 pagesCodes and StandardsKagira Drawing SoltuionNo ratings yet

- Main Switchboard Drawing (Praxis PMS)Document94 pagesMain Switchboard Drawing (Praxis PMS)minpyitNo ratings yet

- UN5000 Excitation SystemDocument36 pagesUN5000 Excitation SystemDinesh Prasad Senapati100% (1)

- Interpreting Turbomachinery Vibration DataDocument60 pagesInterpreting Turbomachinery Vibration Datatungluong0% (1)

- Vibration SeverityDocument19 pagesVibration Severityanon_900141394No ratings yet

- UT ASME Report FormatDocument2 pagesUT ASME Report Formatrifa100% (1)

- Qatargas Leads Major Environmental Project to Recover Flared GasDocument4 pagesQatargas Leads Major Environmental Project to Recover Flared Gasrvkumar61No ratings yet

- 145Kv Sf6 Circuit Breaker Type Ltb145D1/B List of DrawingsDocument13 pages145Kv Sf6 Circuit Breaker Type Ltb145D1/B List of Drawingschandras20No ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- 0 Preview ISO55001Document61 pages0 Preview ISO55001putel_ajaNo ratings yet

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- Manual de Operación Mantenimiento y Partes Compresora Doosan 9235 HADocument121 pagesManual de Operación Mantenimiento y Partes Compresora Doosan 9235 HAPercy CárdenasNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Technical Specification N3 Wind Conditions: Design NotesDocument1 pageTechnical Specification N3 Wind Conditions: Design NotesMinh HoNo ratings yet

- EQUIPMENT SCHEDULE FOR MAIN LV ISOLATION TRANSFORMER AND GENERATORDocument1 pageEQUIPMENT SCHEDULE FOR MAIN LV ISOLATION TRANSFORMER AND GENERATORjendrikoNo ratings yet

- Chiller Motor Control Center Panel Specification TOWER 3 and 4 Cebu Cyberzone Mixed-UseDocument1 pageChiller Motor Control Center Panel Specification TOWER 3 and 4 Cebu Cyberzone Mixed-Usehmmm mmmhNo ratings yet

- 30600-G-G0002 4 Instr ListDocument58 pages30600-G-G0002 4 Instr Listmohamed abourayaNo ratings yet

- Wo Add PK - LHM Di BTHDocument3 pagesWo Add PK - LHM Di BTHrockmansatuNo ratings yet

- Electrical Layout - L2Document1 pageElectrical Layout - L2sushant moreyNo ratings yet

- Mansilingan Structural PDFDocument6 pagesMansilingan Structural PDFSyre Yan Moscoso Tubale100% (1)

- Schedule of Test Results For DBDocument6 pagesSchedule of Test Results For DBAtish KissoonNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Welding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable CodeDocument5 pagesWelding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable Codeanon_499770No ratings yet

- CCDocument9 pagesCCvomicih221No ratings yet

- 25571-DRG-2020Jan Fusion T2 StandardDocument5 pages25571-DRG-2020Jan Fusion T2 StandardKevin KuanNo ratings yet

- Supplier FMEA for ERW tube processDocument1 pageSupplier FMEA for ERW tube processrohitNo ratings yet

- Barroja Sfdu FinalDocument43 pagesBarroja Sfdu FinalAquimel BarrojaNo ratings yet

- 02.secondary Wiring Diagram - PJB Ub Jom Pacitan - Asbuilt (20191210)Document51 pages02.secondary Wiring Diagram - PJB Ub Jom Pacitan - Asbuilt (20191210)anugerahdwi92No ratings yet

- Not For Production: MetricDocument11 pagesNot For Production: MetricAndré MariaNo ratings yet

- M/S. Larsen & Toubro Limited Qap & Itp For Piling WorksDocument2 pagesM/S. Larsen & Toubro Limited Qap & Itp For Piling WorksAkash GiriNo ratings yet

- ERECTION SCHEME 505 - V-1711-ModelDocument1 pageERECTION SCHEME 505 - V-1711-ModelSumanNo ratings yet

- Feeder Protection M1 - BESS Side - Test ReportDocument2 pagesFeeder Protection M1 - BESS Side - Test Reportjohncarloignacio45No ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Curve Drawing 104kwDocument2 pagesCurve Drawing 104kwSaswita SaktiNo ratings yet

- 2840011922386Document1 page2840011922386amehmoodNo ratings yet

- Feeder Protection M1 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M1 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- Feeder Protection M2 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M2 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- Transformer Test Report: LA DOC. NO: LA-R-TR-003Document27 pagesTransformer Test Report: LA DOC. NO: LA-R-TR-003mayur dhandeNo ratings yet

- 'I' Check Procedure: Model 1900D Structural Inspection ManualDocument12 pages'I' Check Procedure: Model 1900D Structural Inspection ManualAdel KhelifiNo ratings yet

- Maintenance Prescription: Analysis Integrated With Accuracy and MeaningDocument1 pageMaintenance Prescription: Analysis Integrated With Accuracy and MeaningVic AnaboNo ratings yet

- Vertical Submerged Pump Data SheetDocument4 pagesVertical Submerged Pump Data SheetRijwan MohammadNo ratings yet

- QAP ExecutionDocument17 pagesQAP ExecutionSavani BhavikNo ratings yet

- " Power Details ": Project NameDocument22 pages" Power Details ": Project NameEdmar BataqueNo ratings yet

- Test Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞDocument3 pagesTest Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞBeytullah KurnalıNo ratings yet

- Ratings and Specifications: Allison TransmissionDocument2 pagesRatings and Specifications: Allison TransmissionSarra ChoucheneNo ratings yet

- Electrical Condition Monitoring AnalysisDocument3 pagesElectrical Condition Monitoring AnalysisAbdullahNo ratings yet

- Chip Detector Task CardDocument13 pagesChip Detector Task CardPablo BalderramaNo ratings yet

- B000-Em-701 (Cable Sched Shts 1-13) Rev 2Document13 pagesB000-Em-701 (Cable Sched Shts 1-13) Rev 2sardar sasNo ratings yet

- Notes:-: BAR Mark Diameter Spacing BAR NO. SR. of Bars Shape Bar DescriptionDocument1 pageNotes:-: BAR Mark Diameter Spacing BAR NO. SR. of Bars Shape Bar DescriptionEr Mukesh KumarNo ratings yet

- Issue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamDocument1 pageIssue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamGanesh YadavNo ratings yet

- Field Quality Assurance Plan for ACC PackageDocument2 pagesField Quality Assurance Plan for ACC PackageHema NandhNo ratings yet

- S2111-600-005JS Ele - Load Analysis A0Document10 pagesS2111-600-005JS Ele - Load Analysis A0Cornea IonutNo ratings yet

- Electrical One Line Diag PDFDocument5 pagesElectrical One Line Diag PDFahs beinNo ratings yet

- Cable sizing and voltage drop calculations for 440V 3-phase systemDocument2 pagesCable sizing and voltage drop calculations for 440V 3-phase systemMark DomalaonNo ratings yet

- BOQ UGC Semanggi Barat - Mampang Dan Rekonduktoring Semanggi Barat - Karet 1 X 1000Document12 pagesBOQ UGC Semanggi Barat - Mampang Dan Rekonduktoring Semanggi Barat - Karet 1 X 1000Reinhard Jesaya SimbolonNo ratings yet

- Report UT CS From 21Document112 pagesReport UT CS From 21daemsalNo ratings yet

- SYNCHRONIZERDocument1 pageSYNCHRONIZERDan PelayoNo ratings yet

- R.27.CL.P.60153.03.105.00 Configuration of The PV ParkDocument57 pagesR.27.CL.P.60153.03.105.00 Configuration of The PV ParkOperaciones YJJNo ratings yet

- QAP - Rev - 0Document4 pagesQAP - Rev - 0Ravindra YogiNo ratings yet

- Soil Investigation HIRADCDocument4 pagesSoil Investigation HIRADCZhafri Syazwi100% (1)

- Merging Result-MergedDocument4 pagesMerging Result-MergedDan PelayoNo ratings yet

- Reference List of Drawings: SwitchboardsDocument96 pagesReference List of Drawings: SwitchboardsDINESH CHATAPNo ratings yet

- Notes:-: BAR Mark Diameter Spacing BAR NO. SR. of Bars Shape Bar DescriptionDocument1 pageNotes:-: BAR Mark Diameter Spacing BAR NO. SR. of Bars Shape Bar DescriptionEr Mukesh KumarNo ratings yet

- GL XX Mobil Glygoyle SeriesDocument5 pagesGL XX Mobil Glygoyle SeriesignaciovidalNo ratings yet

- Gear Oil CLP 220-11-En - GBDocument1 pageGear Oil CLP 220-11-En - GBputel_ajaNo ratings yet

- Masri RG Series: Performance Levels Tingkatan MutuDocument1 pageMasri RG Series: Performance Levels Tingkatan Mutuputel_aja100% (1)

- Tube BendingDocument4 pagesTube BendingmainoNo ratings yet

- Tube BendingDocument4 pagesTube BendingmainoNo ratings yet

- Shell Gadus S2 - OGHDocument2 pagesShell Gadus S2 - OGHputel_ajaNo ratings yet

- Tube BendingDocument4 pagesTube BendingmainoNo ratings yet

- Peta Keandalan W-11 PDFDocument11 pagesPeta Keandalan W-11 PDFputel_ajaNo ratings yet

- Thermal Stress IdDocument13 pagesThermal Stress Idputel_ajaNo ratings yet

- ArpanDocument1 pageArpanputel_ajaNo ratings yet

- T7 - Fluid Mechanics - CH4Document15 pagesT7 - Fluid Mechanics - CH4roi constantineNo ratings yet

- Overall Process For Bagasse Pulp MillDocument12 pagesOverall Process For Bagasse Pulp MillKarthik RaghavanNo ratings yet

- Course Syllabus: Science 7Document7 pagesCourse Syllabus: Science 7Lhaine F.No ratings yet

- HYLOMAR UNIVERSAL BLUE Non-Setting Gasket CompoundDocument2 pagesHYLOMAR UNIVERSAL BLUE Non-Setting Gasket CompoundPradyumnaMaluNo ratings yet

- Qip JP 04 Engine CharacteristicsDocument36 pagesQip JP 04 Engine CharacteristicspepeNo ratings yet

- Radiation Protection Guidance Report Provides Updated Derived GuidesDocument234 pagesRadiation Protection Guidance Report Provides Updated Derived GuidesLeons Rixson SiahaanNo ratings yet

- Chapter 15 - HydrocarbonsDocument16 pagesChapter 15 - HydrocarbonsNabindra RuwaliNo ratings yet

- H21SEM: Group A13Document28 pagesH21SEM: Group A13TsukomaruNo ratings yet

- CHP 2... Safety in Pressure System (Controllable Units)Document56 pagesCHP 2... Safety in Pressure System (Controllable Units)kira ENTERTAINMENT100% (2)

- Chem Principles 7e ISM Focus 04 Even FINALDocument62 pagesChem Principles 7e ISM Focus 04 Even FINALSelma MeloNo ratings yet

- New stepless capacity control for CX screw compressorsDocument2 pagesNew stepless capacity control for CX screw compressorsMasoud KarimiNo ratings yet

- Compressor Technical Data: NJ9232GK 220-240 V 50 HZ 943NA01 A - Application / Limit Working ConditionsDocument3 pagesCompressor Technical Data: NJ9232GK 220-240 V 50 HZ 943NA01 A - Application / Limit Working ConditionsGeri SulanjakuNo ratings yet

- DF457D CORDLESS DRIVER DRILL PARTS DIAGRAM AND LIST FOR INDIADocument3 pagesDF457D CORDLESS DRIVER DRILL PARTS DIAGRAM AND LIST FOR INDIAMihai MogaNo ratings yet

- Probset3. MaterialbalancesDocument8 pagesProbset3. MaterialbalancesAbi MukundNo ratings yet

- Controladores Dixell Xm678d GBDocument14 pagesControladores Dixell Xm678d GBReinaldo MarquesNo ratings yet

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Common ConstantsDocument3 pagesCommon Constantskristan7No ratings yet

- Ujian Sem2 Physics STPM 2017Document9 pagesUjian Sem2 Physics STPM 2017Bestah Joewellster TeoNo ratings yet

- Saej 1004 V 002Document6 pagesSaej 1004 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- Isa RP16.4 1960Document10 pagesIsa RP16.4 1960OliverghNo ratings yet

- Encoder Omron PDFDocument6 pagesEncoder Omron PDFJose Paulo MarcianoNo ratings yet

- Programmable Temperature ControllerDocument2 pagesProgrammable Temperature ControllerNaveenkumar RNo ratings yet

- CH - CH - BR 1° Halide 2° Halide 3° Halide: H H C CH CL CHDocument8 pagesCH - CH - BR 1° Halide 2° Halide 3° Halide: H H C CH CL CHShahbaz NazirNo ratings yet

- DVC Mejia Thermal Power Station Vocational Training ReportDocument20 pagesDVC Mejia Thermal Power Station Vocational Training ReportFlying ColoursNo ratings yet

- Tpo50 3Document2 pagesTpo50 3Whiz YTNo ratings yet