Professional Documents

Culture Documents

Bis Factsheet Water Corporation Nov2020

Uploaded by

Zaita FregaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bis Factsheet Water Corporation Nov2020

Uploaded by

Zaita FregaCopyright:

Available Formats

PROJECT FACT SHEET

Water Corporation, Perth

CUSTOMER: THE CONTRACT: HAULAGE

Water Corporation Bis provides Water Corporation with critical and specialised haulage

services.

Specifically, Bis is responsible for loading and hauling processed biosolids

LOCATION: from Water Corporation’s metropolitan wastewater treatment plants to

various locations within 250 km of Perth for processing and recycling.

In so doing, it supplies Water Corporation with a series of innovative new

road train combinations engineered specifically to carry biosolids.

The new equipment solution was designed by Bis’ in-house innovation and

engineering team.

CUSTOMER OPERATIONS:

Water Corporation is the principal supplier of water, wastewater and

drainage services throughout Western Australia.

Water Corporation transports

biosolids from its three main Biosolids products are transported directly from wastewater treatment

metropolitan wastewater treatment plant collection points and delivered to agricultural land and forestry

plants to various locations and plantations for direct land application, or to compost facilities for

application sites within a 250km incorporation into fertilisers.

radius of Perth.

Road transportation of biosolids is the responsibility of specialist haulage

contractors appointed by Water Corporation and management of these

STATUS: third party contractors is an important element of the organisation’s

biosolids program.

Current

Start date: 2019

MAY, 2020 PROJECT FACT SHEET | Water Corporation, Perth // 1

» KEY ACHIEVEMENTS:

A fleet of new road train combinations pulled by Volvo

ASSETS FH16 8x4s, were developed by Bis specifically for this

contract, introducing a new level of flexibility and reliability

PEOPLE to the handling and movement of biosolids.

» There are approximately 18 Bis employees working on In addition to designing these new road train

the Water Corporation contract. combinations, Bis’ reputation for safety and reliability were

key factors in the company being awarded the contract.

EQUIPMENT

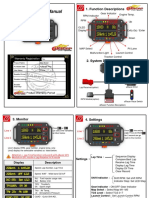

» lime-amended biosolids (LAB) trucks (with enclosed INTELLIGENT IN-CAB MONITORING

metal silo containers)

Coupled with the physical bespoke equipment solution,

» tipping trucks (fitted with air tight hydraulic tarping this contract also benefits from Bis’ unique safety and

systems) productivity management systems, including the use of

» Volvo FH16 8x4 prime movers with Eu5 16L engines best-in-class, proprietary cloud-based artificial intelligence

» proprietary cloud-based safety monitoring systems monitoring systems.

installed in each vehicle.

Bis has embarked on a digital journey to improve how we

manage and deliver safely throughout our operations, and

all of our new on-road haulage assets are fully-equipped

with technology features that drive safety improvements

with the use of both artificial intelligence and human data

analytics techniques.

Our software consolidates these data sources to create

and develop insights that alert managers and vehicle

operators to operational risks and potential issues.

In addition, our bespoke monitoring technology captures

daily operational data to help identify areas for

improvement and to drive cost efficiencies for our

customers.

NOV, 2020 PROJECT FACT SHEET | Water Corporation, Perth // 2

You might also like

- Sparks: Innovation in Action February 2021Document12 pagesSparks: Innovation in Action February 2021manishk_47No ratings yet

- U DrainDocument60 pagesU DrainsathishNo ratings yet

- Auto CAD Civil 3DDocument2 pagesAuto CAD Civil 3DCadd CentreNo ratings yet

- Automotive EngineeringDocument57 pagesAutomotive EngineeringAndreNo ratings yet

- ACO StormBrixx BrochureDocument32 pagesACO StormBrixx BrochureJose MariaNo ratings yet

- Otis FACTSHEET FinalDocument2 pagesOtis FACTSHEET FinalJuan CarlosNo ratings yet

- Productive, Safe & Reliable Complete Conveyor Solutions: Core CompetenceDocument5 pagesProductive, Safe & Reliable Complete Conveyor Solutions: Core CompetenceyatinthoratscrbNo ratings yet

- ABTG AquacultureRAS Jan 18-final-ENDocument2 pagesABTG AquacultureRAS Jan 18-final-ENFrengky RmNo ratings yet

- Fortissimo SuccessStory 605 Wavec VicusdtDocument2 pagesFortissimo SuccessStory 605 Wavec Vicusdtcarlos ivan carvajal ortizNo ratings yet

- ChemicalEngineering - Chemical Engineering April 2023Document68 pagesChemicalEngineering - Chemical Engineering April 2023Lisa FosterNo ratings yet

- Seko - 2022 Pompes & Accessoires - EngDocument128 pagesSeko - 2022 Pompes & Accessoires - EngDocu CenterNo ratings yet

- CAFE FlyerDocument2 pagesCAFE FlyerdiminicaNo ratings yet

- Model-Based Truck R&D - September 2023Document17 pagesModel-Based Truck R&D - September 2023xlnc1No ratings yet

- CSS Subsea Distribution Portfolio 1612986713Document12 pagesCSS Subsea Distribution Portfolio 1612986713maximusala83No ratings yet

- Salalah Muscat International Airports - MC 12Document4 pagesSalalah Muscat International Airports - MC 12Rwitika TarafderNo ratings yet

- Deploying PostgresDocument15 pagesDeploying Postgrespab20No ratings yet

- PM 12629Document68 pagesPM 12629Krešimir MikočNo ratings yet

- ChemicalEngineering Chemical Engineering June 2023Document56 pagesChemicalEngineering Chemical Engineering June 2023Mauricio Huerta jaraNo ratings yet

- Inge Watertechnologies Wins Another Major Contract in China: ContactDocument1 pageInge Watertechnologies Wins Another Major Contract in China: ContactKhaoula ChnitirNo ratings yet

- Definitive Guide To Enterprise Container Platforms: OCTOBER 2020Document16 pagesDefinitive Guide To Enterprise Container Platforms: OCTOBER 2020Anirban SurNo ratings yet

- IT Solutions & Services: Expert Solution On-HandDocument6 pagesIT Solutions & Services: Expert Solution On-HandPiluni MehakNo ratings yet

- Casestudy Creedence Cloud APIDocument4 pagesCasestudy Creedence Cloud APIJonathan Martinez ReyesNo ratings yet

- Design and Manufacture Water Treatment SystemsDocument20 pagesDesign and Manufacture Water Treatment SystemsVishal NakraniNo ratings yet

- Ports & Cranes CapabilityDocument23 pagesPorts & Cranes CapabilityGogyNo ratings yet

- AC-DC Power Supplies: Product UpdateDocument32 pagesAC-DC Power Supplies: Product UpdateAlim SumonNo ratings yet

- AC-DC Power Supplies: Product UpdateDocument32 pagesAC-DC Power Supplies: Product UpdateGus Khoir SrNo ratings yet

- Capability Statement Bcsas International 120111Document13 pagesCapability Statement Bcsas International 120111FranciscoOrtizPalaciosNo ratings yet

- Logistics Load Equipment for New Energy BatteryDocument52 pagesLogistics Load Equipment for New Energy BatteryCarlos WongNo ratings yet

- Cvs Dss FTP Project DescriptionDocument21 pagesCvs Dss FTP Project Descriptionmetudgn100% (1)

- Advanced Energy Management SoftwareDocument6 pagesAdvanced Energy Management Softwarecnrk777No ratings yet

- Subsea Production Systems: Capability and ExperienceDocument7 pagesSubsea Production Systems: Capability and ExperienceElendu Emmanuel ChigozieNo ratings yet

- Vishwa Brochure All FINALDocument11 pagesVishwa Brochure All FINALpooh1992No ratings yet

- Bristol PortDocument2 pagesBristol PortNasifNo ratings yet

- ACO MonoDrain BrochureDocument36 pagesACO MonoDrain BrochuremaanurayaNo ratings yet

- A Vision For Change at BP RefineryDocument2 pagesA Vision For Change at BP RefineryHazel LokeNo ratings yet

- Guidelines For Choosing, Installing, Maintaining Offshore Metering - OffshoreDocument19 pagesGuidelines For Choosing, Installing, Maintaining Offshore Metering - OffshoreShakeel AhmedNo ratings yet

- SsppsDocument8 pagesSsppsАртур ШабашNo ratings yet

- 110 CT 0209Document1 page110 CT 0209keath71No ratings yet

- WP ArcelorMittal Optimize Supply Chain PDFDocument6 pagesWP ArcelorMittal Optimize Supply Chain PDFriyadh al kamalNo ratings yet

- Milbros Answers All The QuestionsDocument1 pageMilbros Answers All The Questions00polvo00No ratings yet

- Bodas Connect - All-In-One Connectivity: End-To-End Iot Solution For Off-Highway MachineryDocument2 pagesBodas Connect - All-In-One Connectivity: End-To-End Iot Solution For Off-Highway MachineryOHW SERNo ratings yet

- PM 12695Document110 pagesPM 12695Krešimir MikočNo ratings yet

- Idc Private Cloud Solutions PcaDocument12 pagesIdc Private Cloud Solutions PcaSinh DangNo ratings yet

- With Aeris, BBOXX Provides Clean Energy Solutions To Off-Grid CommunitiesDocument3 pagesWith Aeris, BBOXX Provides Clean Energy Solutions To Off-Grid CommunitiesAndrea LivottoNo ratings yet

- Layout PlanningpresentationDocument125 pagesLayout PlanningpresentationRutwik ThesisNo ratings yet

- Guangzhou Wenchong Shipyard Flyer English Low ResDocument2 pagesGuangzhou Wenchong Shipyard Flyer English Low ResshadowshatererNo ratings yet

- YearinInfrastructure2017 DL PDFDocument316 pagesYearinInfrastructure2017 DL PDFUlisesChile GomezNo ratings yet

- The Race For More OilDocument10 pagesThe Race For More Oilk1m1mak1No ratings yet

- Mobile Offshore Drilling Units: The Preferred Choice For ClassDocument8 pagesMobile Offshore Drilling Units: The Preferred Choice For ClassDivine MelodyNo ratings yet

- ACO-Buildine-BrochureDocument28 pagesACO-Buildine-Brochures11174444No ratings yet

- Chemical Engineering 2016-02Document68 pagesChemical Engineering 2016-02iancu_jianu_6No ratings yet

- de Original 1.0Document5 pagesde Original 1.0Deepak SinghNo ratings yet

- Case Study - Centrifugal Compressor Failure Analysis - BIC MagazineDocument1 pageCase Study - Centrifugal Compressor Failure Analysis - BIC MagazineZain KhanNo ratings yet

- Whitepaper Definitive Guide To Enterprise Container PlatformsDocument15 pagesWhitepaper Definitive Guide To Enterprise Container PlatformsRazvan ManoleNo ratings yet

- Flow Assurance Programme v15Document9 pagesFlow Assurance Programme v15Raj Ranjan SinghNo ratings yet

- Ryan Thorburn - ResumeDocument12 pagesRyan Thorburn - ResumeAlien 9No ratings yet

- Transport & Installation: The Dockwise DifferenceDocument2 pagesTransport & Installation: The Dockwise DifferencejiokoijikoNo ratings yet

- Carbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersNo ratings yet

- Docker Unveiled: The Comprehensive Handbook to Streamlined DevelopmentFrom EverandDocker Unveiled: The Comprehensive Handbook to Streamlined DevelopmentNo ratings yet

- Cursor SVC - ManualDocument981 pagesCursor SVC - ManualBroCactus100% (2)

- Lapview2 User ManualDocument20 pagesLapview2 User ManualZaita FregaNo ratings yet

- Power Spark MAX User ManualDocument3 pagesPower Spark MAX User ManualZaita FregaNo ratings yet

- Race Function 2 Manual Setup GuideDocument8 pagesRace Function 2 Manual Setup GuideZaita FregaNo ratings yet

- Iveco - Euro Trakker-Star-Tech - Electrical Repair ManualDocument376 pagesIveco - Euro Trakker-Star-Tech - Electrical Repair Manualjuan94% (16)

- leaflet_concrete-transport_gb-webDocument2 pagesleaflet_concrete-transport_gb-webZaita FregaNo ratings yet

- Knock Module Manual: 1. ContentsDocument7 pagesKnock Module Manual: 1. ContentsZaita FregaNo ratings yet

- AF2 Module User Manual: Product Limited WarrantyDocument5 pagesAF2 Module User Manual: Product Limited WarrantyZaita FregaNo ratings yet

- RC Super 2 4cylinderDocument27 pagesRC Super 2 4cylinderZaita FregaNo ratings yet

- Present Joy For The Family: SpecificationDocument4 pagesPresent Joy For The Family: Specificationrizal regolNo ratings yet

- Quick Shifter User ManualDocument3 pagesQuick Shifter User ManualZaita FregaNo ratings yet

- Scania Chassis K-Series For City Bus: Technical SpecificationDocument3 pagesScania Chassis K-Series For City Bus: Technical SpecificationZaita FregaNo ratings yet

- Race Panel Manual: 1. Function DescriptionsDocument6 pagesRace Panel Manual: 1. Function DescriptionsZaita FregaNo ratings yet

- Hydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsDocument28 pagesHydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsZaita FregaNo ratings yet

- Hydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsDocument28 pagesHydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsZaita FregaNo ratings yet

- ScaniaDocument28 pagesScaniaMurali Sambandan100% (1)

- 2-Powertrains For All Requirements & ApplicationsDocument7 pages2-Powertrains For All Requirements & ApplicationsZaita FregaNo ratings yet

- Het A1: Heavy Equipment TransporterDocument2 pagesHet A1: Heavy Equipment TransporterZaita Frega0% (2)

- R 540 A6X4HA: SpecificationDocument8 pagesR 540 A6X4HA: SpecificationZaita FregaNo ratings yet

- 3-Scania Adds A 540 HP Version To It's 13-Litre Engine RangeDocument4 pages3-Scania Adds A 540 HP Version To It's 13-Litre Engine RangeZaita FregaNo ratings yet

- 4-Introducing The New Scania V8 RangeDocument3 pages4-Introducing The New Scania V8 RangeZaita FregaNo ratings yet

- 4 Job Interviews and Career Part 2Document2 pages4 Job Interviews and Career Part 2lala inriyaniNo ratings yet

- Reimagining Retail Commerce in A New Normal World 2023Document16 pagesReimagining Retail Commerce in A New Normal World 2023Beatriz Ochoa RamirezNo ratings yet

- Final AssignmentDocument4 pagesFinal AssignmentAssignment HandleNo ratings yet

- Gigabit Ethernet Micro Switch Twisted Pair Uplink PoEDocument7 pagesGigabit Ethernet Micro Switch Twisted Pair Uplink PoEFredNo ratings yet

- Production of Coated Detergent Enzyme GranulesDocument121 pagesProduction of Coated Detergent Enzyme Granulesdadang71No ratings yet

- Justmoh Procter Test So-13Document11 pagesJustmoh Procter Test So-13Abu FalasiNo ratings yet

- Intro to Python Programming: Features, Uses & InstallationDocument27 pagesIntro to Python Programming: Features, Uses & InstallationAnkurNo ratings yet

- 3000 LR NSK Double - Row - Ball - BearingDocument40 pages3000 LR NSK Double - Row - Ball - BearingÇağlar AYKUTALPNo ratings yet

- Covid 19 ImpactDocument38 pagesCovid 19 ImpactNavneet NandaNo ratings yet

- Business Analytics 705 v1 468Document468 pagesBusiness Analytics 705 v1 468Harty Robert100% (1)

- Astm G32 - 10Document19 pagesAstm G32 - 10ABINASH BEHERANo ratings yet

- 05 38 Counts Exercise & TextDocument5 pages05 38 Counts Exercise & TextANUP MUNDENo ratings yet

- PDF Photobooth Manual 2023Document24 pagesPDF Photobooth Manual 2023api-725597460No ratings yet

- NW-BT Escalator Installation Guide Book: NoticeDocument52 pagesNW-BT Escalator Installation Guide Book: NoticeResul Şenay100% (3)

- Paytm StatementDocument3 pagesPaytm Statementayushi tripathiNo ratings yet

- @airbus: Airbus S.A.SDocument627 pages@airbus: Airbus S.A.Sjoker hotNo ratings yet

- 40-BGP Regular ExpressionDocument5 pages40-BGP Regular ExpressionprakashrjsekarNo ratings yet

- Pentode JJ Ef806sDocument2 pagesPentode JJ Ef806sCristianNo ratings yet

- CV Ankit Gupta Manager DelhiDocument2 pagesCV Ankit Gupta Manager DelhiAnkit GuptaNo ratings yet

- Apple - Clean Energy and Recycled Products.Document15 pagesApple - Clean Energy and Recycled Products.Sumanyu AgrawalNo ratings yet

- Scorpio Big Daddy - CombinedBrochureDocument32 pagesScorpio Big Daddy - CombinedBrochureanshumanbiswal2319No ratings yet

- Smartphone IndustryDocument5 pagesSmartphone IndustryChief MaxNo ratings yet

- VB Programs BCA 4th SemDocument58 pagesVB Programs BCA 4th SemadarshNo ratings yet

- Movie Project PlanDocument14 pagesMovie Project PlanEris Perfect100% (1)

- Prospectus SLIET LONGOWALDocument58 pagesProspectus SLIET LONGOWALsaurabhshineNo ratings yet

- Moxa-Imc-101-Series-Datasheet-V1.3.pdf CONVERTIDOR DE MEDIOS PDFDocument4 pagesMoxa-Imc-101-Series-Datasheet-V1.3.pdf CONVERTIDOR DE MEDIOS PDFEduardo QuintanaNo ratings yet

- Manuale Stampante 3DDocument45 pagesManuale Stampante 3DMiriamNo ratings yet

- LEAP-1A - A3 - Modular Design - Rev1.3Document1 pageLEAP-1A - A3 - Modular Design - Rev1.3zeyadNo ratings yet

- Decision Support Systems: Mcgraw-Hill/IrwinDocument67 pagesDecision Support Systems: Mcgraw-Hill/IrwinAlexNo ratings yet

- Convertisseur RS485 232 TCP ABBDocument21 pagesConvertisseur RS485 232 TCP ABBPEIGNAUNo ratings yet