Professional Documents

Culture Documents

UTE532

Uploaded by

Proc. RembangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UTE532

Uploaded by

Proc. RembangCopyright:

Available Formats

HALF-CUT TECHNOLOGY N TYPE I-TOPCON TECHNOLOGY

In this technology, the full cell is cut into two parts, Trina Solar has integrated half-cut technology into In 2015, the State Key Laboratory of The i-TOPCon cell has a front boron emitter and a rear full-area

which results in a reduction of electrical ribbon resis- its new generation module product series, which Photovoltaic Science and Technology (SKL passivating contact. In 2019, Trina Solar achieved a front side

tance and nally improves the overall module signi cantly improves the actual power generation, PVST) of Trina Solar began the research median e ciency over 23% on i-TOPCon cells. Empowered

e ciency by more than 2%. Also, half-cut design especially when combined with other outstanding on a large-area bifacial TOPCon cell that is with i-TOPCon technology, Trina Solar Duomax N modules

allows the module to work at low operating tempera- technologies like multi-busbar and bifacial cell aimed for industrial mass production, achieve an industry-leading output power of up to 430W.

tures, which can improve energy generation per design. naming it i-TOP- Con cell.

watt.

24.58% world-record lab cell e ciency

Better power generation with reduced High reliability with strong resistance for monocrystalline n-type (c-Si) i-TOPCon solar cell

Unique i-TOPCon cell design

internal resistance losses against hotspots 23.22% world-record lab cell e ciency

Front Ag contacts

for cast-monocrystalline n-type (c-Si) i-TOPCon solar cell

Passivation stacks

P + emitter

n-type Cz Si wafer

Tunnel SiO x

n + poly-Si

SiNx : H

Full cell Half cell Rear Ag contacts

High power output with better shading Lower operating temperature

tolerance

LID

Less than 1% Low temperature Lower micro-crack risk

36.1 38.2 LID degradation coe cient without internal stress

from the symmetrical N-Bifacial cell scheme

10

You might also like

- White Paper To Mok - FINAL-1Document26 pagesWhite Paper To Mok - FINAL-1William Mook67% (3)

- IVPS-IVPM ManualDocument16 pagesIVPS-IVPM Manualpeter100% (3)

- 30 Minutes Lesson Plan For CEFR Year 5Document3 pages30 Minutes Lesson Plan For CEFR Year 5Cyril RyanNo ratings yet

- Beta Gama Zracenje DetektorDocument1 pageBeta Gama Zracenje Detektorgesaugen50% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Laghu Parashari Siddhanta Jyotish Vedic AstrologyDocument3 pagesLaghu Parashari Siddhanta Jyotish Vedic AstrologyEeranki Subrahmanya sarma(E.S.Rao)No ratings yet

- Statement of Work (Sow) Examples Pernyataan Kerja (Sow) ContohDocument5 pagesStatement of Work (Sow) Examples Pernyataan Kerja (Sow) ContohAndi Didik Wira PutraNo ratings yet

- An Introduction To IGBT Operation: Application NoteDocument5 pagesAn Introduction To IGBT Operation: Application Noterodruren01No ratings yet

- Sixth-Generation V-Series IGBT Module Application Note - Basic Concept and FeaturesDocument11 pagesSixth-Generation V-Series IGBT Module Application Note - Basic Concept and FeaturesNA MENo ratings yet

- 3.4.3.7 Non-Volatile Memory: P+ Diode N+ Well Contact Collector Base EmitterDocument1 page3.4.3.7 Non-Volatile Memory: P+ Diode N+ Well Contact Collector Base EmitterCarlos SaavedraNo ratings yet

- Lecture-3-MOSFET BOOK XXXXXX (Compatibility Mode)Document15 pagesLecture-3-MOSFET BOOK XXXXXX (Compatibility Mode)Chaitanya KumarNo ratings yet

- 48 PT / PT Din - Connection and Junction Boxes Also For Domotics - Ip40Document4 pages48 PT / PT Din - Connection and Junction Boxes Also For Domotics - Ip40Lucian BarboiNo ratings yet

- ZXMR-UOLD144 182.2×199 - 2279×1134 (30×32NH) - 570-605W - 1200mm - 20240305 - EDocument2 pagesZXMR-UOLD144 182.2×199 - 2279×1134 (30×32NH) - 570-605W - 1200mm - 20240305 - EJs FriasNo ratings yet

- Dokumen - Tips - Mitsubishi Super Line K SeriesDocument8 pagesDokumen - Tips - Mitsubishi Super Line K SeriesJimmy MirandaNo ratings yet

- L15: Custom and ASIC VLSI IntegrationDocument24 pagesL15: Custom and ASIC VLSI IntegrationpinoytsikboyNo ratings yet

- 6 - L-7 (DK) (Pe) ( (Ee) Nptel)Document1 page6 - L-7 (DK) (Pe) ( (Ee) Nptel)GagneNo ratings yet

- Diran I 2013Document5 pagesDiran I 2013zionees01No ratings yet

- Two-Dimensional Bandgap Engineering in A Novel Si/Sige Pmosfet With Enhanced Device Performance and ScalabilityDocument4 pagesTwo-Dimensional Bandgap Engineering in A Novel Si/Sige Pmosfet With Enhanced Device Performance and ScalabilityKasshaf AhmadNo ratings yet

- SE 1.3 Slides PDFDocument16 pagesSE 1.3 Slides PDFwiles_andrewNo ratings yet

- ET3034TUx-1.3 - PVslides PDFDocument16 pagesET3034TUx-1.3 - PVslides PDFspacefrogNo ratings yet

- Fairchild IGBT BasicsDocument29 pagesFairchild IGBT BasicswhcallegariNo ratings yet

- Zero Sequence CT CatalogueDocument14 pagesZero Sequence CT CatalogueRanjitKumarNo ratings yet

- An Introduction To Integrated An Introduction To Integrated Circuits and CMOS TechnologyDocument34 pagesAn Introduction To Integrated An Introduction To Integrated Circuits and CMOS Technologymm16467No ratings yet

- N Type: Product BrochureDocument9 pagesN Type: Product BrochureEka Yuniansah WidiastutyNo ratings yet

- PICASSO SNOLAB 12a 0Document44 pagesPICASSO SNOLAB 12a 0Ivan FelisNo ratings yet

- 1.2.4 New Developments in MOSFET and IGBT TechnologyDocument6 pages1.2.4 New Developments in MOSFET and IGBT Technologyjorge armando vega prietoNo ratings yet

- Triac: SCR Can Be Used To Control Lamps, Motors, or Heaters Etc. However, One of TheDocument9 pagesTriac: SCR Can Be Used To Control Lamps, Motors, or Heaters Etc. However, One of TheMohsin Iqbal Department of Electrical EngineeringNo ratings yet

- EYS SeriesDocument2 pagesEYS Seriesjuwinthir putra bengawanNo ratings yet

- Working Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceDocument1 pageWorking Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceMeghavahinaNo ratings yet

- 8 Diodes and RectifiersDocument23 pages8 Diodes and Rectifiersaaroncete14No ratings yet

- Battery Pack Modeling PDFDocument24 pagesBattery Pack Modeling PDFamitavjhaNo ratings yet

- SolarADEPT Workshop NxtGenPwr Singh PDFDocument19 pagesSolarADEPT Workshop NxtGenPwr Singh PDFPaola MantillaNo ratings yet

- INTERCONTEC - Connectors Series B - Standard INTERCONTEC - Connectors Series B - SpeedtecDocument1 pageINTERCONTEC - Connectors Series B - Standard INTERCONTEC - Connectors Series B - SpeedtecLuis Pinto RojasNo ratings yet

- New Trench MOSFET Technology For DC-DC Converter ApplicationsDocument4 pagesNew Trench MOSFET Technology For DC-DC Converter ApplicationsLuis Enrique Morales MendezNo ratings yet

- Avx FilmDocument20 pagesAvx FilmVilnis PetersonsNo ratings yet

- Macdowel Group: Basic Electronics LABDocument13 pagesMacdowel Group: Basic Electronics LABMayank SinghNo ratings yet

- MTO™ Thyristor Power SwitchesDocument12 pagesMTO™ Thyristor Power Switchesmujtaba21No ratings yet

- Figure 3.1: Circular Diaphragm Wall Internal Bottom Excavation ElevationDocument11 pagesFigure 3.1: Circular Diaphragm Wall Internal Bottom Excavation ElevationvisvisvisvisNo ratings yet

- Lesson 7 Insulated Gate Bipolar Transistor (IGBT)Document23 pagesLesson 7 Insulated Gate Bipolar Transistor (IGBT)Chacko MathewNo ratings yet

- Techfill Nickel Cadmium Battery Catalog155 PDFDocument15 pagesTechfill Nickel Cadmium Battery Catalog155 PDFOemar JieNo ratings yet

- Study Material On IgbtDocument13 pagesStudy Material On IgbtSandipan DebNo ratings yet

- Trina Solar 210 Vertex N Product Whitepaper - FinalDocument10 pagesTrina Solar 210 Vertex N Product Whitepaper - Finaloperation.nreNo ratings yet

- Linear Integrated Circuit: 5W Audio AmplifierDocument5 pagesLinear Integrated Circuit: 5W Audio AmplifierVictor AsterdamNo ratings yet

- GaN Based HEMT High Voltage PDFDocument16 pagesGaN Based HEMT High Voltage PDFATman VaghamshiNo ratings yet

- ch2 (20231004)Document57 pagesch2 (20231004)jane8773No ratings yet

- ASWC WirelessPowerTransfer-finalDocument38 pagesASWC WirelessPowerTransfer-finalvishalNo ratings yet

- Manual Instruciton NGRDocument4 pagesManual Instruciton NGRAhmad Ikhsan KurniantoNo ratings yet

- Common Mode Current Mitigation For Medium Voltage Half Bridge SiC ModulesDocument8 pagesCommon Mode Current Mitigation For Medium Voltage Half Bridge SiC ModulesgeniuspsunNo ratings yet

- 2203 - EN - Foundations and Underpinning - 4811001251Document20 pages2203 - EN - Foundations and Underpinning - 4811001251Thomas GlasbyNo ratings yet

- Our Labs BriefDocument7 pagesOur Labs BriefnemokoNo ratings yet

- 8230e DELL Vostro 3350 Wistron Nirvana 13 PDFDocument104 pages8230e DELL Vostro 3350 Wistron Nirvana 13 PDFanh_sao_dem_92No ratings yet

- Noise Barrier: Over 40 Years of Experience ..Document1 pageNoise Barrier: Over 40 Years of Experience ..Metin AyrancıNo ratings yet

- MS and MIS PresentationDocument15 pagesMS and MIS PresentationHajerNo ratings yet

- TITAN Anchorages For Retaining StructuresDocument20 pagesTITAN Anchorages For Retaining StructuresC BNo ratings yet

- Poster - PSE 2020 (Optimized)Document1 pagePoster - PSE 2020 (Optimized)Jose David CastroNo ratings yet

- FDN340P 103694Document8 pagesFDN340P 103694freudsteakNo ratings yet

- Surface Mounted TriacsDocument15 pagesSurface Mounted TriacsElinton PassiniNo ratings yet

- Chapter 1 Introduction: Fabrication ProcessDocument1 pageChapter 1 Introduction: Fabrication ProcessCarlos SaavedraNo ratings yet

- Detector 700 Amplifier For Parabolic Mic AmplifierDocument20 pagesDetector 700 Amplifier For Parabolic Mic AmplifierjimdigrizNo ratings yet

- P-N Junction Diode Baising and Its VI CharacteristicsDocument12 pagesP-N Junction Diode Baising and Its VI Characteristicsvihan shahNo ratings yet

- UTE54Document1 pageUTE54Proc. RembangNo ratings yet

- UTE52Document1 pageUTE52Proc. RembangNo ratings yet

- Limit Switch Micro Switch Foot Switch CWLDocument3 pagesLimit Switch Micro Switch Foot Switch CWLProc. RembangNo ratings yet

- Ndustry View - Balanced GrowthDocument1 pageNdustry View - Balanced GrowthProc. RembangNo ratings yet

- Covid19 OverviewDocument1 pageCovid19 OverviewProc. RembangNo ratings yet

- Vca VCN VCG - Usa - 01 12 PDFDocument16 pagesVca VCN VCG - Usa - 01 12 PDFProc. RembangNo ratings yet

- Panel PC - VL PPC 2000Document9 pagesPanel PC - VL PPC 2000Proc. RembangNo ratings yet

- P4 Out 1Document74 pagesP4 Out 1josepheritu3No ratings yet

- PV Elite 2019 LicenseeDocument4 pagesPV Elite 2019 LicenseeHajaMideenNo ratings yet

- Proposal For Master DegreeDocument5 pagesProposal For Master DegreemyxtaNo ratings yet

- Misc-Mock Thermodyamics TestDocument2 pagesMisc-Mock Thermodyamics TestGhenwa DimachkiNo ratings yet

- HSC 2008 Mathematics Extension 2 Solutions - Jan HansenDocument14 pagesHSC 2008 Mathematics Extension 2 Solutions - Jan HansenGao WeiquanNo ratings yet

- Totalgas Module 8060 Totalgas Module 8060 Totalgas Module 8060 Totalgas Module 8060Document56 pagesTotalgas Module 8060 Totalgas Module 8060 Totalgas Module 8060 Totalgas Module 8060dieguini1No ratings yet

- Life Processes - Daily Home Assignment 01 - (Udaan 2024)Document3 pagesLife Processes - Daily Home Assignment 01 - (Udaan 2024)NadiaNo ratings yet

- Quarter3 Week8 ConstellationDocument10 pagesQuarter3 Week8 ConstellationLaika Monick Pablico TacardonNo ratings yet

- Adc 10158Document26 pagesAdc 10158Felipe LorenziNo ratings yet

- Space Robotics: PreviewDocument21 pagesSpace Robotics: PreviewAnvit TiwariNo ratings yet

- Tic, Toc: Pendulum Motion: Activity Teacher InformationDocument2 pagesTic, Toc: Pendulum Motion: Activity Teacher InformationSergioNo ratings yet

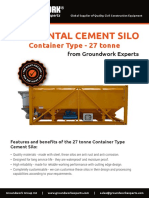

- Horizontal Cement Silo: Container Type - 27 TonneDocument4 pagesHorizontal Cement Silo: Container Type - 27 TonneAnand PuntambekarNo ratings yet

- FGD PresentationDocument32 pagesFGD PresentationSaravanan RagupathyNo ratings yet

- Matthew Weise, "Understanding Meaningfulness in Video Games"Document80 pagesMatthew Weise, "Understanding Meaningfulness in Video Games"MIT Comparative Media Studies/WritingNo ratings yet

- AccuSine PCS+ in Marine Brochure (Print)Document5 pagesAccuSine PCS+ in Marine Brochure (Print)dhanasekhar27No ratings yet

- Kinetics Body Work&Energy Impulse&MomentumDocument26 pagesKinetics Body Work&Energy Impulse&MomentumKano MolapisiNo ratings yet

- Cryptool Lab f05Document6 pagesCryptool Lab f05Vanesa Daza50% (2)

- Aadhaar FormDocument1 pageAadhaar Formbharatbhil95100% (1)

- DBMS Overview PPT FinalDocument40 pagesDBMS Overview PPT FinalCheikh SalmiNo ratings yet

- UKM AutismDocument5 pagesUKM Autisminayahyaakub1306No ratings yet

- Football Scores The Poisson Distribution and 30 YeDocument7 pagesFootball Scores The Poisson Distribution and 30 YeNsihilNo ratings yet

- Cochin University of Science & Technology: KOCHI-682022Document5 pagesCochin University of Science & Technology: KOCHI-682022navinNo ratings yet

- A Practical Approach To Business Impact AnalysisDocument20 pagesA Practical Approach To Business Impact Analysisqadir147No ratings yet

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- Monica Moya: 3126 Kernan Lake Circle #203, Jacksonville, FL - (954) 736-7681Document1 pageMonica Moya: 3126 Kernan Lake Circle #203, Jacksonville, FL - (954) 736-7681Monica MoyaNo ratings yet

- Setting Up MRI - SpecificationsDocument59 pagesSetting Up MRI - SpecificationssuneedhNo ratings yet

- خواص صخور المكمن رقم 1Document30 pagesخواص صخور المكمن رقم 1maamoun ramyNo ratings yet