Professional Documents

Culture Documents

Pipe 03

Pipe 03

Uploaded by

jb.dqaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe 03

Pipe 03

Uploaded by

jb.dqaCopyright:

Available Formats

Installation Method Lafarge can produce

concrete pipe in a variety

The usual construction sequence for tunneling and jacking concrete pipe is:

Installation Method Lafarge can produce

of sizes for trenchless

Installation

The•Installation

Excavate

usual

Method

Method

jacking

construction pits or shafts,

sequence construct

for tunneling andjacking

jackingabutments or thrust

concrete pipe is: blocks, and

Lafarge

Lafarge cancan

concrete pipeproduce

installation in awith

produce variety

the jacking

install jacks, jacking frame and guide rails. concrete

of sizes

concrete pipe

for in

orpipe in a variety

trenchless

tunnelinga variety

methods. The

The The

usual

usualconstruction

construction sequence

sequence forfortunneling

tunnelingand andjacking

jacking concrete

concrete pipepipe is: is:

• Begin jacking

• Excavate tunnel excavation

pits or shafts, by machine,

construct or hand,abutments

jacking dependingoron conditions.

thrust blocks, and of sizes

of installation

sizes for for trenchless

trenchless

with the

pipe sections are jacking

designed

• Lower firstjacking

section of pipe,andposition jacks and abutments

jacking frame, and jack pipe

• •install

Excavate jacks,

Excavate jackingjacking frame

pitspits

or or shafts,

shafts, guide rails.

construct

construct jackingabutments

jacking or thrust

thrustblocks,

blocks,and and installation

installation

or tunnelingwith the

with jacking

the

methods. jacking

for the additional axialThe

forward.

• install

Begin tunnel

install jacks,excavation

jacking by and

frame machine,

and guide or hand, depending on conditions.

rails.

jacks, jacking frame guide rails. or pipe

tunneling

or tunneling

sectionsmethods. TheThe

methods.

are designed

• ••Lower

Continue

Beginfirsttunnel excavation,

section of pipe,

excavation remove

position

by soiljacks

machine, through

and pipe,

jacking insert

frame, succeeding

and jack pipe sections of pipe force encountered in these

Begin tunnel excavation by machine, ororhand,

hand, depending

depending on

on conditions.

conditions. pipe

pipesections

sections are are

designed

designed

between the lead pipe and jacks and jack forward. for the additional axial

operations and can be

• •forward.

Lower

Lower firstfirst section

section of pipe,

of pipe, positionjacks

position jacksandandjacking

jacking frame,

frame, andand jack

jackpipepipe forfor

thethe

additional axial

• •forward.

Repeat

forward.

Continue sequence,remove

excavation, excavation, soil removal,

soil through pipe insertion

pipe, insert succeeding andsections

jacking,ofuntilpipethe force additional

encountered

produced axial

withinports

thesefor

• operation

Continue is complete.

excavation, remove soil through pipe, insert succeeding sections of pipe force encountered in these

• between

Continuethe lead piperemove

excavation, and jacks soil and

throughjack pipe,

forward. insert succeeding sections of pipe force encountered

operations

grout and can inbethese

between

• •between

Consistency

Repeat the lead

the leadofpipe

sequence, pipe andfacilitates

material

excavation,

and jacks

jacks

soilandand easier

jack forward.

removal, grading

pipe

jack forward. and even

insertion compaction.

and jacking, until the operations andorcan

lubrication.

be

•operation

Repeatissequence, excavation, soil removal, pipe insertion and jacking, until the operationswith

produced and ports

can be for

complete.

• Repeat sequence, excavation, soil removal, pipe insertion and jacking, until the produced with ports for

operation is complete. produced

grout with ports for

or lubrication.

• operation

Consistency of material facilitates easier grading and even compaction.

is complete. grout or lubrication.

• Consistency of materialsuch facilitates easier grading and even compaction. grout or lubrication.

• Consistency oflubricant,

Occasionally a material facilitates as bentonite

easier grading slurry,and is pumped into the space between

even compaction.

the tunnel bore and the outside of the pipe to reduce frictional resistance. After the

jacked

Occasionally pipe

Occasionally have

a lubricant, reached

a lubricant, suchsuchtheir

asas final

bentonite position,

bentonite slurry,grout

slurry, isispumpedis frequently

pumped into thepumped

into the spacebetween

space into this

between

thesame

tunnel space

Occasionally bore

the tunnelabore to

and insure

the

lubricant,

and thesuchcontinuous

outside of thebearing

as bentonite

outside pipe to

of the pipeslurry,with

reduce

to reducethe surrounding

frictional

is pumped

frictionalinto soil.

resistance.

the space

resistance. After the

between

After the

jacked pipe

the tunnel

jacked pipe have

bore have reached

and the their

outside

reached final

theiroffinal position,

the position, grout

pipe to reduce is frequently

grout isfrictional pumped

frequentlyresistance.

pumped into into

Afterthis

thisthe

When

same

jacked space

samepipeincreased

to insure

have

space resistance

to reached

insure their develops

continuous

continuous bearing

final due

position,

bearing with to

with soilsurrounding

the

grout

the isconditions

frequentlysoil.

surrounding orpumped

length of

soil. intorun,this

intermediate

same space to insure jacking stations may

continuous bearing be inserted at periodic intervals.

with the surrounding soil. The intermediate

When increased

jacking

When station

increased resistance

pushes

resistance develops

only due

the several

develops duetoto soil

soilconditions

lengths ahead while

conditions or

or length of run,

bearing

length of run,

on the pipe

intermediate

intermediate

behind.

When The use

increased jacking

jacking stations

stations

of intermediate

resistance may may be be

develops jacking inserted

inserted

due to soil atat periodic

periodic

stations

conditions intervals.

intervals.

reduces The

The

axial loads

or length intermediate

intermediate

of run, on the pipe and

jacking

jacking

required

intermediate station

station pushes

jacking

jacking pushes only

capacity.only

stations the the

may several

several lengths

lengths

be inserted ahead

atahead

periodic while

while bearing The

bearing

intervals. on

on thethe pipe

pipe

intermediate

behind.

behind. The The

use use

of of intermediate

intermediate jacking

jacking stations

stations

jacking station pushes only the several lengths ahead while bearing on the pipe reduces

reduces axial

axial loads

loads on

on the

the pipe

pipeandand

required

required jacking

jacking capacity.

capacity.

The number

behind. The useand capacity of the

of intermediate jacksstations

jacking primarily reducesdepends axialuponloadsthe onsize and length

the pipe and of

required

the pipejacking

to becapacity.

jacked and the type of soil encountered. Abutments for the jacks must

The

Thebe number

number andand capacity

capacity of ofthethe jacksprimarily

jacks primarilydepends

depends upon upon thethe size

size and

andlength

length of

thestrong

pipe toenough

be jacked andand largetheenough

type of soil to distribute

encountered. theAbutments

maximum capacity

for the jacks theofjacks to

of must

the pipe

Thethe to behind

number be andjacked

capacityand thethe

of typejacksof soil encountered. Abutments for the jacks must

be soil

strong enough the andbackstops.

large enough toprimarily

distribute depends

the maximum upon the size

capacity and

of thelength

jacksofto

be

thestrong

pipe to enough

be jackedand and largethe enough

type tosoil

of distribute the maximum

encountered. Abutments capacity

for of jacks

the the jacks

mustto

the soil behind the backstops.

the soil behind

be strong enough theand backstops.

large enough to distribute the maximum capacity of the jacks to

the soil behind the backstops.

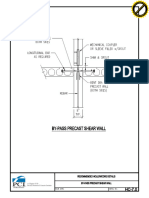

1. Steel Bell 4. Confined Groove Joint

1. Steel Bell 4. Confined Groove Joint

2.2.Reinforcing

Reinforcing 5.Lube

5. LubeororGrout

Grout Port

Port

1. Steel Bell Cushion 4. Confined Groove Joint

3.3.Jacking

Jacking Cushion

2. Reinforcing 5. Lube or Grout Port

1. Steel Bell 4. Confined Groove Joint

3. Jacking Cushion

2. Reinforcing 5. Lube or Grout Port

3. Jacking Cushion EDMONTON PIPE PLANT

PHONE: (780) 479-5232 | FAX: (780) 410-3699

17

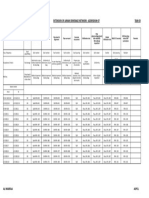

MICRO TUNNELING PIPE

MICRO TUNNELLING PIPE

MICRO TUNNELLING PIPE

> STRAIGHT-WALL PIPE

> STRAIGHT-WALL PIPE

> STRAIGHT-WALL PIPE

Price Per MetrePrice Per Metre Actual Dimensions (mm) Actual Dimensions (mm)

Price Per Metre Actual Dimensions (mm)

Diameter

Diameter (mm) Diameter Diameter

(mm) (in.) (in.) (m) Weight

Length Length (m)

(kgs/m) A Weight (kgs/m)

B A B

Diameter (mm) Diameter (in.) Length (m) Weight (kgs/m) A B

300

300 12” 12” 1.22 1.22

200 445 20070 445 70

300

375

375 12”

15” 15” 1.22

1.22 200

254

1.22 445

500 25470

98 500 98

375

450

450 15”

18” 18” 1.22

1.22 254

337

1.22 500

623 33798

83 623 83

450

525 18”

21” 1.22 337 623 83

525 21” 1.22 509

1.22 713 50990 713 90

525

600 21”

24” 1.22 509 713 90

600 24” 1.22 616

1.22 799 61695 799 95

600

750 24”

30” 1.22 616 799 95

750 30” 2.45 715

2.45 979 109

715 979 109

750

900 30”

36” 2.45 715 979 109

900 36” 2.45 943

2.45 1160 123

943 1160 123

900 36” 2.45 943 1160 123

TUNNEL

> MICRO TUNNELING PIPE WITH STEEL BANDS

TUNNEL

> > MICRO TUNNELING PIPE

MICROTUNNELING WITHWITH STEEL

STEEL BANDS

BANDS

PIPEPIPE

Contact

Contact your Lafarge

your Lafarge Representative

Representative for more

Contact

for more on

information your Lafarge

information Representative

on pipes and

Microtunneling

for more

available information

sizes.

Microtunneling pipes on

and available

Microtunneling pipes and available

Wesizes.

can also offer technical assistance on

sizes.

We can

selecting also offer

trenchless technical

method and designing

We can also offer technical

assistance on selecting trenchless

pipes.

assistance

method and ondesigning

selecting trenchless

pipes.

method and designing pipes.

EDMONTON PIPE PLANT EDMONTON PIPE PLANT

18 PHONE: (780) 479-5232EDMONTON PIPE

| FAX: (780) PLANT

410-3699

17

PHONE: (780) 479-5232 | FAX: (780) 410-3699

PHONE: (780) 479-5232 | FAX: (780) 410-3699

17

CATCH BASIN MATERIAL - 600MM

95 610 95

800

PARTIAL

PARTIAL OPENING FOR

1950

400

150mm -

CATCH BASIN

OPENING

600MM

300mm PIPE

500

250

800

Weight Price

Product

(kgs/pc) ($ each)

600mm x 1.95m catch basin c/w monolithic floor 1005 $679

0.150m x 635mm Grade Ring 120 $113

0.100m x 635mm Grade Ring 80 $100

0.075m x 635mm Grade Ring 60 $95

0.050m x 635mm Grade Ring 40 $90

Notes:

1. 600mm catch basins do not come with steps.

2. For 600mm diameter catch basins, 1.95m is the only available height. Barrels are not available for this size.

3. Catch basins come with 2 lift pins. 4-ton lifting clutches are required. Please inquire.

4. Please see page 23 for additional catch basin material.

5. Gaskets do not come with catch basins. Please inquire if required.

6. If pipe to manhole connector is needed (for smooth wall flexible pipe only) please call for additional price.

EDMONTON PIPE PLANT

PHONE: (780) 479-5232 | FAX: (780) 410-3699

19

CATCH BASIN MATERIAL - 750MM

750mm Catch Basin C/W Monolithic Floor

CATCH BASIN

750MM

LES

Weight Price

Product

(kgs/pc) ($ each)

750mm x 1.83m CB c/w Monolithic Base 1460 $863

750mm x 1.22m CB c/w Monolithic Base 1030 $658

750mm x 1.22m CB Barrel (No Steps) 820 $390

750mm x 0.61m CB Barrel (No Steps) 400 $233

750mm Slab Top with 635mm Opening 220 $265

Notes:

1. Catch basins and riser barrels do not come with steps for this diameter.

2. Catch basins come with 2 lift-pins, 4-ton lifting clutches are required. Please inquire.

3. Please see page 23 for additional Catch Basin material.

4. Gaskets do not come with monolithic catch basins. Please inquire if required.

5. If pipe to manhole connector is needed (for smooth wall flexible pipe only) please call for additional price.

EDMONTON PIPE PLANT

20 PHONE: (780) 479-5232 | FAX: (780) 410-3699

CATCH BASIN MATERIAL - 900MM

900mm Catch Basin C/W Monolithic Floor

CATCH BASIN

900MM

Weight Price

Product

(kgs/pc) ($ each)

900mm x 1.83m catch basin c/w monolithic base 1975 $1284

900mm x 1.22m catch basin c/w monolithic base 1440 $1002

900mm base 420 $413

900mm slab top c/w 910mm opening 195 $385

900mm slab top c/w 635mm opening 315 $387

0.150m x 900mm grade ring w/910mm opening 220 $198

0.100m x 900mm grade ring w/910mm opening 180 $149

Notes:

1. Monolithic catch basins in 900mm size do not come with steps.

2. For 900mm CB’s with steps, use separate base and barrels as shown above. (This method is required for Strathcona County)

3. Please see page 23 for manhole barrel riser pricing.

4. Catch basins come with 2 lift pins cast in. 4-ton lifting clutches are required. Please inquire if required.

5. Gaskets do not come supplied with monolithic catch basin material. They do come included with separate base and barrel configuration.

6. If pipe to manhole connector is needed (for smooth wall flexible pipe only) please call for additional price.

EDMONTON PIPE PLANT

PHONE: (780) 479-5232 | FAX: (780) 410-3699

21

You might also like

- 04 Concrete-Testing Range-LowDocument22 pages04 Concrete-Testing Range-LowRavinder GulairNo ratings yet

- Concrete Barriers Joints FHWADocument3 pagesConcrete Barriers Joints FHWAroberto_cordero_4No ratings yet

- Jacking Pipes 33Document18 pagesJacking Pipes 33Onat100% (1)

- Bridge Deck Construction - Insitu With Void Formers & Post-TensionedDocument1 pageBridge Deck Construction - Insitu With Void Formers & Post-TensionedengrmasgharNo ratings yet

- Construction Schedue SampleDocument5 pagesConstruction Schedue Samplepawan paudelNo ratings yet

- MatrixDocument2 pagesMatrixRecardoNo ratings yet

- Developerguides Typical Manhole Detail Drawings 2022Document7 pagesDeveloperguides Typical Manhole Detail Drawings 2022Arnold HernandezNo ratings yet

- Direct Pipe EN PDFDocument6 pagesDirect Pipe EN PDFDiego CalderonNo ratings yet

- Pavingexpert - Formwork and ShutteringDocument6 pagesPavingexpert - Formwork and Shutteringraobabar21No ratings yet

- Titan - Soft Soil StabilizationDocument6 pagesTitan - Soft Soil StabilizationCarlos MakheleNo ratings yet

- Subsoil DrainsDocument3 pagesSubsoil DrainsAbdelrahman ElshahedNo ratings yet

- Eaton Fabricated Strainer Model 90 Technical Information USDocument2 pagesEaton Fabricated Strainer Model 90 Technical Information USlucasNo ratings yet

- Amvic ICF 10 Step Construction GuideDocument2 pagesAmvic ICF 10 Step Construction GuidedanNo ratings yet

- 05 Metode KerjaDocument19 pages05 Metode Kerjaahmad maulidiNo ratings yet

- Knauf Hammer Fixing ScrewDocument2 pagesKnauf Hammer Fixing ScrewAmir SohailNo ratings yet

- Type 1 - 43sqmDocument1 pageType 1 - 43sqmRandall MayNo ratings yet

- ENG Soil Retention Elements 2022Document1 pageENG Soil Retention Elements 2022Ranete FlorinNo ratings yet

- 10-01-04-1 FTDocument2 pages10-01-04-1 FTeng.gharbiNo ratings yet

- TSE 10 07 00 1 FT - Doc AngDocument2 pagesTSE 10 07 00 1 FT - Doc AngEduardo CastilloNo ratings yet

- The Design of A Suspended Concrete Transport Pipeline SystemDocument7 pagesThe Design of A Suspended Concrete Transport Pipeline SystemJohnGS007No ratings yet

- WalkmakerDocument2 pagesWalkmakerxianzaiegNo ratings yet

- Eaton Model 85 Y StrainerDocument2 pagesEaton Model 85 Y StrainersatphoenixNo ratings yet

- Corro LogicDocument8 pagesCorro Logicrizalsatya.nugraha26No ratings yet

- Aggregates - The Difference Between Crushed Stone and GravelDocument6 pagesAggregates - The Difference Between Crushed Stone and GravelKehinde Olaoluwa100% (1)

- Adobe Scan 10 Feb 2022Document6 pagesAdobe Scan 10 Feb 2022Gopal BadyalNo ratings yet

- Roc V4 Weighbridge: Options & AccessoriesDocument2 pagesRoc V4 Weighbridge: Options & AccessoriesKhalidNo ratings yet

- 2023-00-00 Channel Bolt Fixings AnconDocument20 pages2023-00-00 Channel Bolt Fixings AnconerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Tubes 2004Document40 pagesTubes 2004António GradeNo ratings yet

- Trapped Floor GullyDocument1 pageTrapped Floor GullyBoraNo ratings yet

- Fencewall DesignDocument1 pageFencewall DesignNana BarimaNo ratings yet

- BTS3900L Quick Installation GuideDocument14 pagesBTS3900L Quick Installation Guidejaymin915No ratings yet

- 00 RPS-Bored PilingDocument4 pages00 RPS-Bored PilingchongweelinNo ratings yet

- E149-205 Engineered Class SprocketsDocument57 pagesE149-205 Engineered Class SprocketsRichard VachonNo ratings yet

- Bill No. 8000 BoxDocument5 pagesBill No. 8000 BoxYedenekachew NigussieNo ratings yet

- Design Multistory Buildings Maxi - of It of - , ConDocument1 pageDesign Multistory Buildings Maxi - of It of - , ConjosNo ratings yet

- Industrial Flooring Steel Fibre Reinforced ConcreteDocument2 pagesIndustrial Flooring Steel Fibre Reinforced ConcreteFiras ZineNo ratings yet

- Birch-King Flow DirectionDocument4 pagesBirch-King Flow DirectionBruceNo ratings yet

- TBA - Stack Bonding FactsheetDocument2 pagesTBA - Stack Bonding FactsheetAdrianNo ratings yet

- Funniculars Shell RoofDocument2 pagesFunniculars Shell RoofHIMA MiniNo ratings yet

- 3 - Plane - Wind FenceDocument1 page3 - Plane - Wind FenceRamesh GaurNo ratings yet

- Sewer Check List Task-3Document1 pageSewer Check List Task-3csacas sacscNo ratings yet

- 4N Tapping Band NewDocument2 pages4N Tapping Band NewAkshat JainNo ratings yet

- 202 Sections EE & FFDocument1 page202 Sections EE & FFD HOLNo ratings yet

- Presentation Report - Culvert - Retaining Wall - StaadProDocument30 pagesPresentation Report - Culvert - Retaining Wall - StaadProDHYEY PARMARNo ratings yet

- Deep Horizon Incident RCADocument1 pageDeep Horizon Incident RCABiju Basheer CNo ratings yet

- Dot 18750 DS1Document102 pagesDot 18750 DS1Maisie SuyatNo ratings yet

- AirlinerMagazine 1960-09Document12 pagesAirlinerMagazine 1960-09Alejandro Vigar100% (1)

- Pipe Culverts Check ListDocument2 pagesPipe Culverts Check ListSubramanian BalakrishnanNo ratings yet

- Betocrete-C17 CatalogueDocument2 pagesBetocrete-C17 CatalogueWuttipong WangNo ratings yet

- Binder ManholeDocument34 pagesBinder Manholemanjubd1No ratings yet

- Mud Hopper (K1050-20-41) User ManualDocument4 pagesMud Hopper (K1050-20-41) User ManualTony100% (1)

- Type 2 - 45sqmDocument1 pageType 2 - 45sqmRandall MayNo ratings yet

- Bill No. 8000 SlabDocument5 pagesBill No. 8000 SlabYedenekachew NigussieNo ratings yet

- Type 4 - 55sqmDocument1 pageType 4 - 55sqmRandall MayNo ratings yet

- BSC Crawler Concrete Pumps Brochure ENDocument5 pagesBSC Crawler Concrete Pumps Brochure ENanstn84No ratings yet

- Rail TrackworkDocument3 pagesRail TrackworkAbdelrahman ElshahedNo ratings yet

- Rfa Guide & ChecklistDocument1 pageRfa Guide & ChecklistCarlo CabuhatNo ratings yet

- 13 Inch Body DiameterDocument1 page13 Inch Body DiameterGeorge SobhyNo ratings yet

- SikaGrout 214-11Document3 pagesSikaGrout 214-11vu hungNo ratings yet

- EC2 Vs ACI3184Document3 pagesEC2 Vs ACI3184jb.dqaNo ratings yet

- Precast hcs0115Document3 pagesPrecast hcs0115jb.dqaNo ratings yet

- Precast hcs0114Document2 pagesPrecast hcs0114jb.dqaNo ratings yet

- HKdesign 012323Document2 pagesHKdesign 012323jb.dqaNo ratings yet

- HKdesign 012325Document2 pagesHKdesign 012325jb.dqaNo ratings yet

- Mong Coc vcn08182Document2 pagesMong Coc vcn08182jb.dqaNo ratings yet

- HKdesign 01231Document2 pagesHKdesign 01231jb.dqaNo ratings yet

- O-Cell Barrette13Document2 pagesO-Cell Barrette13jb.dqaNo ratings yet

- Soil Mechanic0015Document1 pageSoil Mechanic0015jb.dqaNo ratings yet

- Mong Coc vcn01116Document2 pagesMong Coc vcn01116jb.dqaNo ratings yet

- Etabs 16Document3 pagesEtabs 16jb.dqaNo ratings yet

- Soil 011Document2 pagesSoil 011jb.dqaNo ratings yet

- Soil 0112Document2 pagesSoil 0112jb.dqaNo ratings yet

- Etabs 19Document3 pagesEtabs 19jb.dqaNo ratings yet

- Soil 0113Document2 pagesSoil 0113jb.dqaNo ratings yet

- Etabs 15Document4 pagesEtabs 15jb.dqaNo ratings yet

- Etabs 17Document3 pagesEtabs 17jb.dqaNo ratings yet

- Alain Pecker4Document3 pagesAlain Pecker4jb.dqaNo ratings yet

- Alain Pecker5Document2 pagesAlain Pecker5jb.dqaNo ratings yet

- Alain Pecker3Document3 pagesAlain Pecker3jb.dqaNo ratings yet

- SIka Water Bar - 03Document3 pagesSIka Water Bar - 03jb.dqaNo ratings yet

- 4Document3 pages4jb.dqaNo ratings yet

- Pipe Catalogue 03Document5 pagesPipe Catalogue 03jb.dqaNo ratings yet

- Failure Load Analysis Methods Based On Instrumented Large Diameter Bored PilesDocument8 pagesFailure Load Analysis Methods Based On Instrumented Large Diameter Bored Pilesjb.dqaNo ratings yet

- Pipe Catalogue 02Document5 pagesPipe Catalogue 02jb.dqaNo ratings yet

- Pipe Catalogue 01Document5 pagesPipe Catalogue 01jb.dqaNo ratings yet

- Accuracy of Extrapolation MethodsDocument10 pagesAccuracy of Extrapolation Methodsjb.dqaNo ratings yet

- Numerical Investigation On Behavior of Compressive PilesDocument13 pagesNumerical Investigation On Behavior of Compressive Pilesjb.dqaNo ratings yet

- Conceptual Fire Design and AssessmentDocument60 pagesConceptual Fire Design and Assessmentjb.dqaNo ratings yet