Professional Documents

Culture Documents

Butt Weld Strength

Uploaded by

manivel.maruthamuthu0 ratings0% found this document useful (0 votes)

13 views1 pageThis document section discusses design requirements for butt welds, including:

1) Butt welds should use matching electrodes with properties equivalent to the parent metal, so the weld strength can equal the parent metal strength.

2) For partial penetration butt welds, the throat size should equal the minimum penetration depth from one side.

3) The minimum throat size for longitudinal partial penetration welds is 2 times the thickness of the thinner part, or larger if needed to resist forces.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document section discusses design requirements for butt welds, including:

1) Butt welds should use matching electrodes with properties equivalent to the parent metal, so the weld strength can equal the parent metal strength.

2) For partial penetration butt welds, the throat size should equal the minimum penetration depth from one side.

3) The minimum throat size for longitudinal partial penetration welds is 2 times the thickness of the thinner part, or larger if needed to resist forces.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageButt Weld Strength

Uploaded by

manivel.maruthamuthuThis document section discusses design requirements for butt welds, including:

1) Butt welds should use matching electrodes with properties equivalent to the parent metal, so the weld strength can equal the parent metal strength.

2) For partial penetration butt welds, the throat size should equal the minimum penetration depth from one side.

3) The minimum throat size for longitudinal partial penetration welds is 2 times the thickness of the thinner part, or larger if needed to resist forces.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

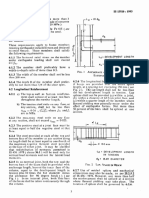

BS 5950-1:2000 Section 6

a) Welds subject to longitudinal shear b) Welds subject to transverse forces

c) Resultant transverse force on weld

Figure 31 Fillet welds Directional method

6.9 Design of butt welds

6.9.1 Design strength

All full penetration butt welds and partial penetration butt welds should be made using matching

electrodes or other welding consumables. A matching electrode should have a specified minimum tensile

strength, yield strength, elongation at failure and Charpy impact value each equivalent to, or better than,

those specified for the parent metal. Provided that a matching electrode is used, the design strength of a

butt weld should be taken as equal to that of the parent metal.

6.9.2 Throat size of partial penetration butt welds

The throat size of a single-sided partial penetration butt weld, see Figure 32a) and Figure 32c), or the size

of each throat of a double-sided partial penetration butt weld, see Figure 32b) and Figure 32d), should be

taken as equal to the minimum depth of penetration from that side of the weld.

The minimum throat size of a longitudinal partial penetration butt weld should be 2 t where t is the

thickness (in mm) of the thinner part joined, unless a larger throat size is needed to resist the applied

forces.

6.9.3 Capacity of partial penetration butt welds

Single-sided partial penetration butt welds that are asymmetric relative to the parts joined should not be

used to resist tension or compression, unless the connection is suitably restrained against rotation. In

calculating the stress in the weld, the resulting eccentricity should be taken into account.

150 © BSI 05-2001

You might also like

- Cisc Vs AiscDocument11 pagesCisc Vs Aiscanon_326950184100% (1)

- Chapter 6 ConnectionDocument30 pagesChapter 6 ConnectionIvy SeahNo ratings yet

- Welds - Static and Fatigue Strength - IiDocument27 pagesWelds - Static and Fatigue Strength - IiOuseppachan Ambooken100% (1)

- CH 7 Simple Beam End Connections-9-13Document60 pagesCH 7 Simple Beam End Connections-9-13JakesNo ratings yet

- Is 13920Document47 pagesIs 13920Ravinder KumarNo ratings yet

- Recommended Details For Reinforced Concrete ConstructionDocument3 pagesRecommended Details For Reinforced Concrete ConstructionYol AtienzaNo ratings yet

- Column Detailing and Design RecommendationsDocument3 pagesColumn Detailing and Design RecommendationsJohn STCNo ratings yet

- Design of Plate GirdersDocument30 pagesDesign of Plate GirdersTHULASI MNo ratings yet

- Objective For BeamsDocument7 pagesObjective For BeamsSuvra Sankha Chattopadhyay (sscp)No ratings yet

- R.C.C.-shear, Bond and Development LengthDocument35 pagesR.C.C.-shear, Bond and Development LengthKishan PurohitNo ratings yet

- CE Board Problems in Steel DesignDocument10 pagesCE Board Problems in Steel Designrmrv valdezNo ratings yet

- Design of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)Document16 pagesDesign of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)anirbanpwd76No ratings yet

- Detailing of Reinforced Concrete Structures in Seismic Zone-Baljeet SirDocument35 pagesDetailing of Reinforced Concrete Structures in Seismic Zone-Baljeet Siranuragcool062No ratings yet

- Quiz 6Document1 pageQuiz 6Nikki Marie G OclaritNo ratings yet

- ستيل ستركشرDocument73 pagesستيل ستركشرAws SamaNo ratings yet

- Shear Connection in Composite Bridge Beams - SteelconstructionDocument12 pagesShear Connection in Composite Bridge Beams - Steelconstructionpatricklim1982No ratings yet

- AASTHO Horizontally Curved Steel Girder Highway Bridges 2003 - Part2 PDFDocument28 pagesAASTHO Horizontally Curved Steel Girder Highway Bridges 2003 - Part2 PDFMehedi HasanNo ratings yet

- Shear StudsDocument3 pagesShear StudsrahuljoagNo ratings yet

- SRC343 Topic 3 Beams - Part 2 - Shear - Student Version PDFDocument11 pagesSRC343 Topic 3 Beams - Part 2 - Shear - Student Version PDF晓春王No ratings yet

- Ductile Detailing Considerations As Per Is 13920 2016 DERSDocument41 pagesDuctile Detailing Considerations As Per Is 13920 2016 DERSAbijithNo ratings yet

- TheoryDocument10 pagesTheoryPadamNo ratings yet

- Torsion1 PDFDocument47 pagesTorsion1 PDFalaaNo ratings yet

- Reinforced Concrete Design Module 7 Subject: CE 74A-Reinforced Concrete DesignDocument25 pagesReinforced Concrete Design Module 7 Subject: CE 74A-Reinforced Concrete DesignJemson VictorioNo ratings yet

- Composite Deck Technical Manual: 3WH-36 Hi FormDocument33 pagesComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNo ratings yet

- Design of Singly Reinforced BeamDocument7 pagesDesign of Singly Reinforced BeamfelipeNo ratings yet

- Pertemuan 2 PDFDocument21 pagesPertemuan 2 PDFClara Oktaviana SitinjakNo ratings yet

- Mat Chapter 31Document27 pagesMat Chapter 31hemant_durgawaleNo ratings yet

- Print 2Document4 pagesPrint 2COMEDY NEPALNo ratings yet

- Assignment 8Document5 pagesAssignment 8Mohammed Junaid ShaikhNo ratings yet

- ES 13 1920A Problem Set 2Document5 pagesES 13 1920A Problem Set 2Charmaine ColetaNo ratings yet

- 9347 2 1 PDFDocument6 pages9347 2 1 PDFEdu-IngenieroNo ratings yet

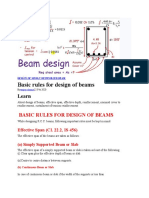

- Basic Rules For Design of BeamsDocument8 pagesBasic Rules For Design of BeamsJaswanth JNo ratings yet

- Shear StudsDocument4 pagesShear Studsaldeto71No ratings yet

- Design For ShearDocument8 pagesDesign For ShearAdil8686No ratings yet

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Pedestal Is A Compreuion Member. Effective Lenlthofwhich Does Notexceed Time. Least Lateral DimensionDocument2 pagesPedestal Is A Compreuion Member. Effective Lenlthofwhich Does Notexceed Time. Least Lateral DimensionsaratNo ratings yet

- Binder1 66 PDFDocument1 pageBinder1 66 PDFAbdul RahmanNo ratings yet

- 02 LenturDocument26 pages02 LenturRinaldi PelawiNo ratings yet

- 3Document6 pages3k2org.seoNo ratings yet

- SADSt BeamsDocument27 pagesSADSt BeamsFrank JohnNo ratings yet

- Design of Machine Members I Jan 2023Document12 pagesDesign of Machine Members I Jan 2023chinniparamesh92No ratings yet

- 7.1 Longitudinal Reinforcement: S.No Description Status Remarks 7 Columns and Inclined MembersDocument4 pages7.1 Longitudinal Reinforcement: S.No Description Status Remarks 7 Columns and Inclined MembersJagadish kumar.kNo ratings yet

- 01-Shear in BeamsDocument62 pages01-Shear in BeamsIbrahim KhadraNo ratings yet

- Module 9-Ductile Frame BuildingsDocument20 pagesModule 9-Ductile Frame BuildingsThomas John Doblas AgrabioNo ratings yet

- 6 Restrained Beams HandoutDocument2 pages6 Restrained Beams HandoutEng TrNo ratings yet

- Effect of Shear Reinforcement On Punching Shear CaDocument11 pagesEffect of Shear Reinforcement On Punching Shear CaFelipeMatiasCardosoNo ratings yet

- CISC Steel Design Series: Beam Load Tables - Rectangular HSSDocument20 pagesCISC Steel Design Series: Beam Load Tables - Rectangular HSSTony ParkNo ratings yet

- 38CDocument3 pages38CDarshit D RajNo ratings yet

- F.A.L. Conducive Engineering Review Center: 2 Floor, Cartimar Building, C.M. Recto Avenue, Quiapo, ManilaDocument3 pagesF.A.L. Conducive Engineering Review Center: 2 Floor, Cartimar Building, C.M. Recto Avenue, Quiapo, ManilaJerome AdduruNo ratings yet

- 11a - Diseño Por Fuerza CortnteDocument6 pages11a - Diseño Por Fuerza CortnteKaren Esther Acuña VelasquezNo ratings yet

- Structures Module 3 Notes FullDocument273 pagesStructures Module 3 Notes Fulljohnmunjuga50No ratings yet

- Codal Provision For BeamDocument2 pagesCodal Provision For BeamNoor Mohd100% (1)

- Clause 7.4: Transverse Reinforcement Clause 7.5: Design Shear Force in ColumnsDocument45 pagesClause 7.4: Transverse Reinforcement Clause 7.5: Design Shear Force in ColumnsMujtaba AndrabiNo ratings yet

- Test Booklet: Steel StructuresDocument16 pagesTest Booklet: Steel StructuresICE Group of Education BhopalNo ratings yet

- Shear StudsDocument4 pagesShear StudsmaricusiaNo ratings yet

- Chapter 9Document24 pagesChapter 9alcaponeNo ratings yet

- Unit - 4: Design of BeamsDocument27 pagesUnit - 4: Design of BeamsfarhanyazdaniNo ratings yet

- 107 ConcreteDocument44 pages107 Concretenoadspls2029No ratings yet

- Flexure (Comm. I3.: Fig. C-I3.2. Calculation of Shrinkage Effects (From Chien and Ritchie (1984) )Document59 pagesFlexure (Comm. I3.: Fig. C-I3.2. Calculation of Shrinkage Effects (From Chien and Ritchie (1984) )Geovana Castillo XijunNo ratings yet

- Indian Stacdard: Methods of Sampling of Steel For Prestressed and Reinforced ConcreteDocument11 pagesIndian Stacdard: Methods of Sampling of Steel For Prestressed and Reinforced Concretemanivel.maruthamuthuNo ratings yet

- Fusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardDocument12 pagesFusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian Standardmanivel.maruthamuthuNo ratings yet

- Cembrit Installation Alu and Steel 2021 ExportDocument21 pagesCembrit Installation Alu and Steel 2021 Exportmanivel.maruthamuthuNo ratings yet

- WindDocument8 pagesWindmanivel.maruthamuthuNo ratings yet

- Wind 2Document1 pageWind 2manivel.maruthamuthuNo ratings yet

- Punch HolesDocument1 pagePunch Holesmanivel.maruthamuthuNo ratings yet